High power nickel-hydrogen accumulator negative electrode active substance and its preparation method and nickel-hydrogen accumulator

A negative electrode active material, a technology for nickel-metal hydride batteries, which is applied in the direction of alkaline battery electrodes, battery electrodes, electrode manufacturing, etc. and other problems, to achieve the effects of good oxidation resistance, improved high current discharge performance, good electrical contact and electrochemical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

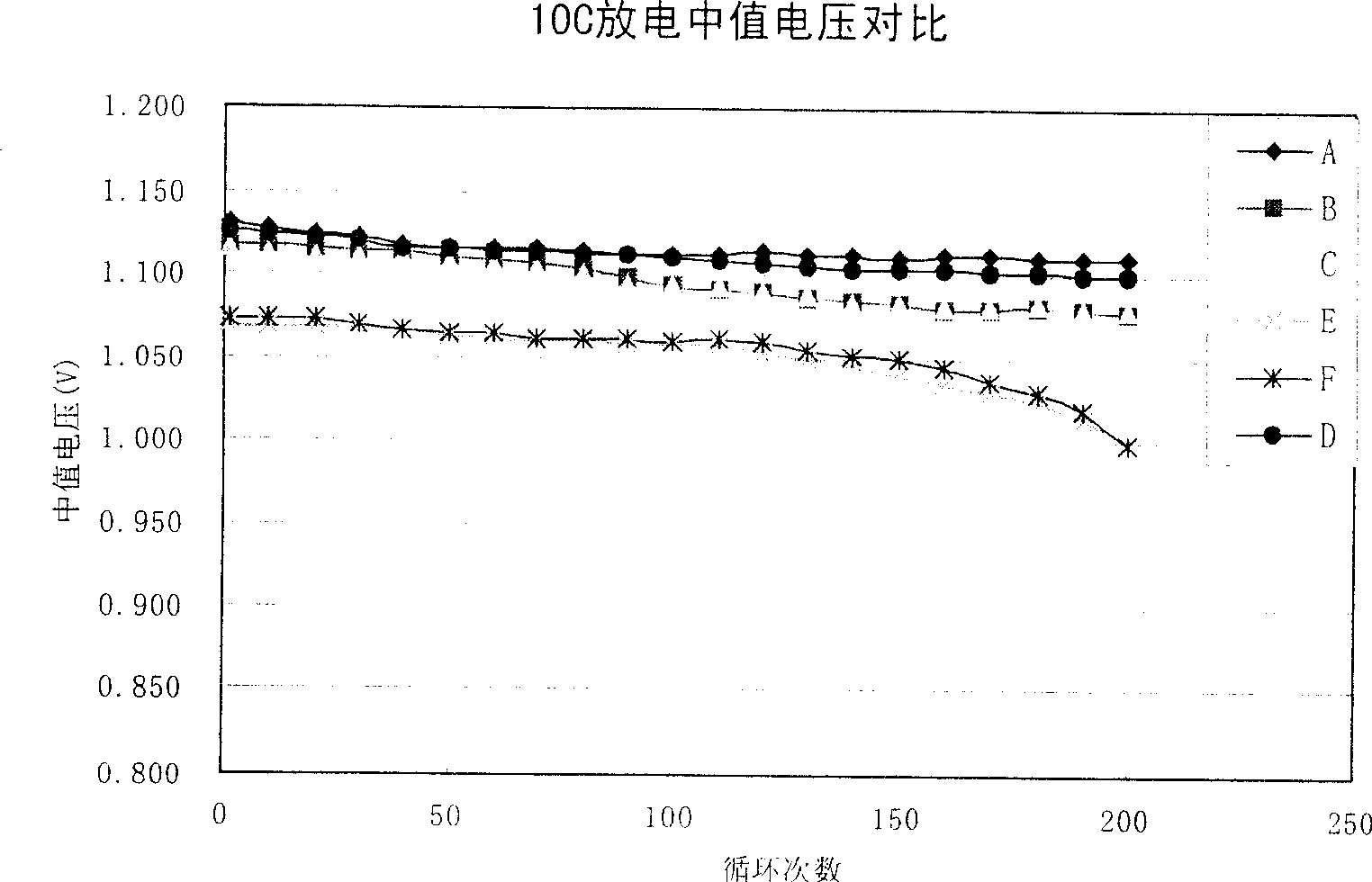

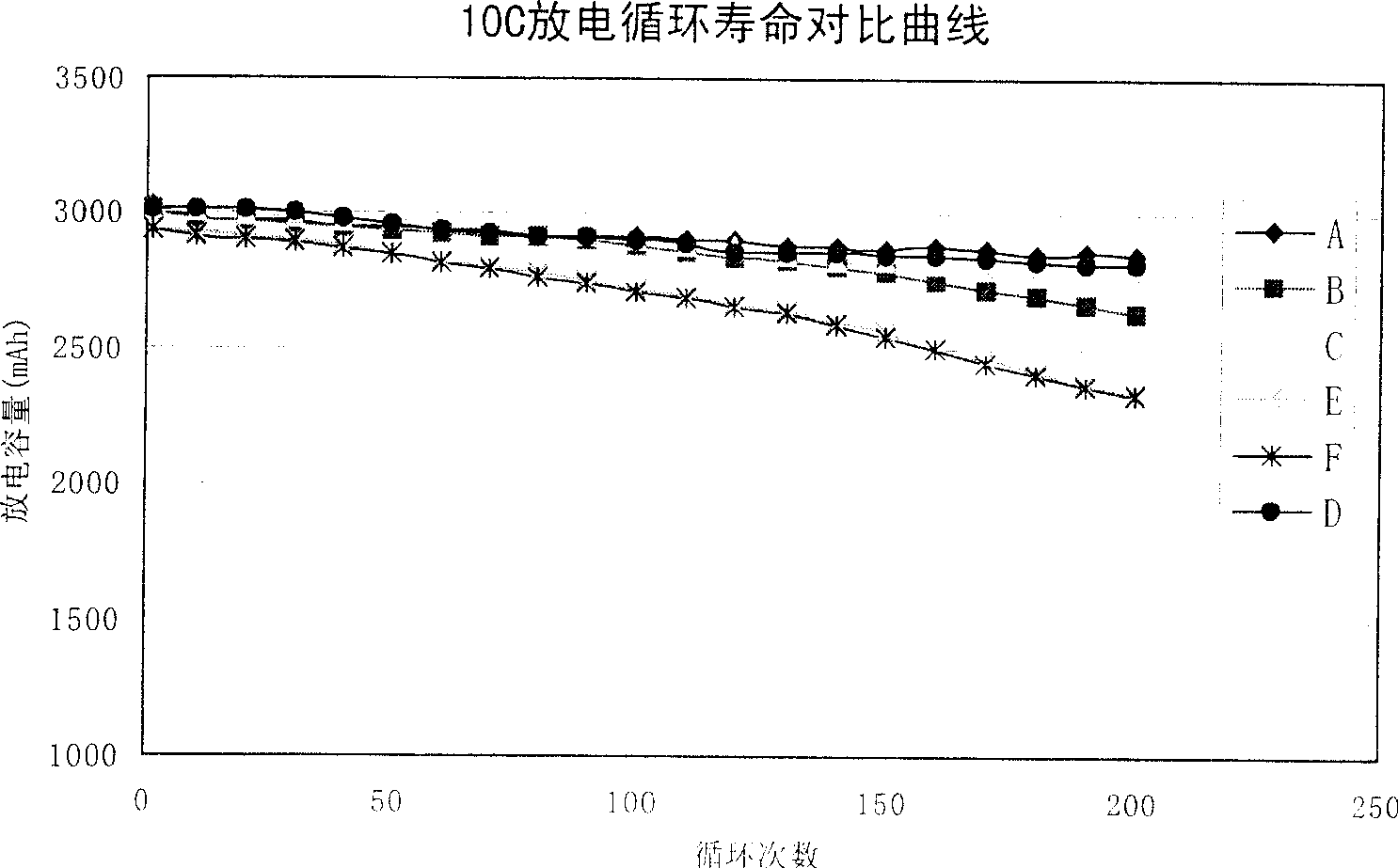

Examples

Embodiment 1

[0017] The hydrogen storage alloy master powder to be treated MmNi 3.55 co 0.75 mn 0.4 Al 0.3 (Mm represents a mixed rare earth composed of one or more of La, Ce, Pr, and Nd) is placed in a special magnetron sputtering coating machine, and the hydrogen storage alloy mother powder can be produced by known methods. The coating machine adopts planar magnetron sputtering target, and the target material is nickel, palladium, platinum, gold, rhodium and other metals that are not easy to be completely oxidized by oxygen, and is easy to dissolve in alkaline aqueous solution with aluminum and zinc. An alloy formed by a combination of one or two metals. In this example, nickel-aluminum alloy is preferred, wherein the preferred proportion of aluminum is 30% (atomic ratio), the target is set vertically and horizontally, the target height is about 3m, and the single processing capacity of the coating machine is 200kG. The powder to be treated falls freely from the top of the coating ma...

Embodiment 2

[0027] Embodiment 2: The difference from Step 1 of Embodiment 1 is that the hydrogen storage alloy powder is sputtered twice in a vacuum sputter coating machine. The thickness of the film on the surface of the alloy is measured to be about 0.05 μm, and then the second step is performed, and the specific surface after treatment is about 0.15 m 2 / g, the battery is made through Step 3, which is recorded as Class B;

Embodiment 3

[0029] The difference from Step 1 of Example 1 is that the hydrogen storage alloy powder is sputtered 15 times in a vacuum sputter coater. Measure the thickness of the film on the surface of the alloy to be about 0.5 μm, and then carry out the second step of treatment, and the specific surface after treatment is about 0.8m 2 / g, the battery is made through Step 3, which is recorded as Class C;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com