Atomizing device and atomizing element thereof

A technology of atomization devices and components, applied in electrical components, electrochemical generators, and other household appliances, can solve problems such as reduced power tolerance, deterioration of heater materials, product failure, etc., and achieve improved power tolerance , Solve surface oxidation and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In order to make the above and other technical content, features and advantages of the present invention more comprehensible, the following specifically cites relevant embodiments, together with the accompanying drawings, for a detailed description as follows.

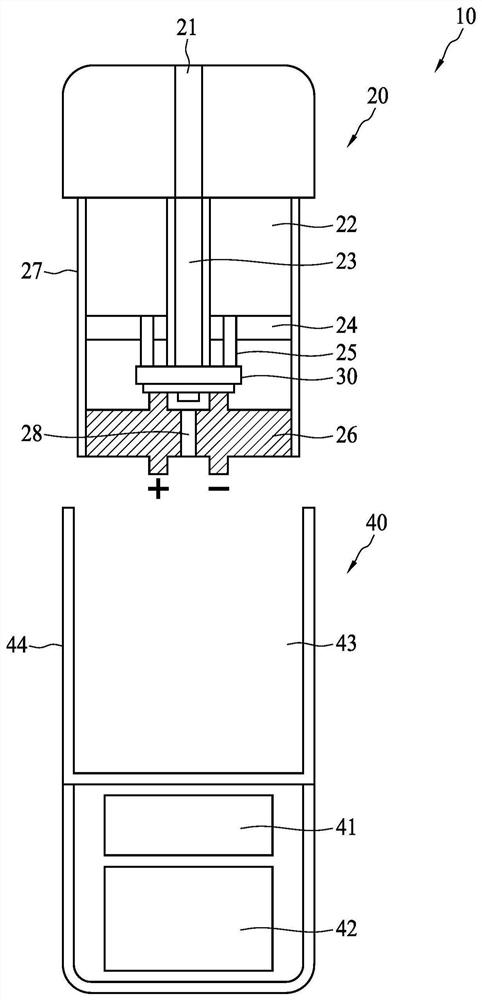

[0060] figure 1 An atomizing device 10 is shown configured for use with, for example, an electronic cigarette. The atomizing device 10 can be, for example, flat, cylindrical or other types, and includes a nozzle part 20 and a power supply part 40 . The power supply part 40 has a cavity 43 which can accommodate the main body of the suction nozzle part 20 and can be combined with the suction nozzle part 20 . Thus, the nozzle portion 20 can be used in the form of a replacement cassette.

[0061]The nozzle part 20 includes an air outlet hole 21 , a storage tank 22 , a flue 23 , a spacer 24 , a liquid channel 25 , an electrode fixing seat 26 , a housing 27 and an air inlet 28 . The storage tank 22 stores materials...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com