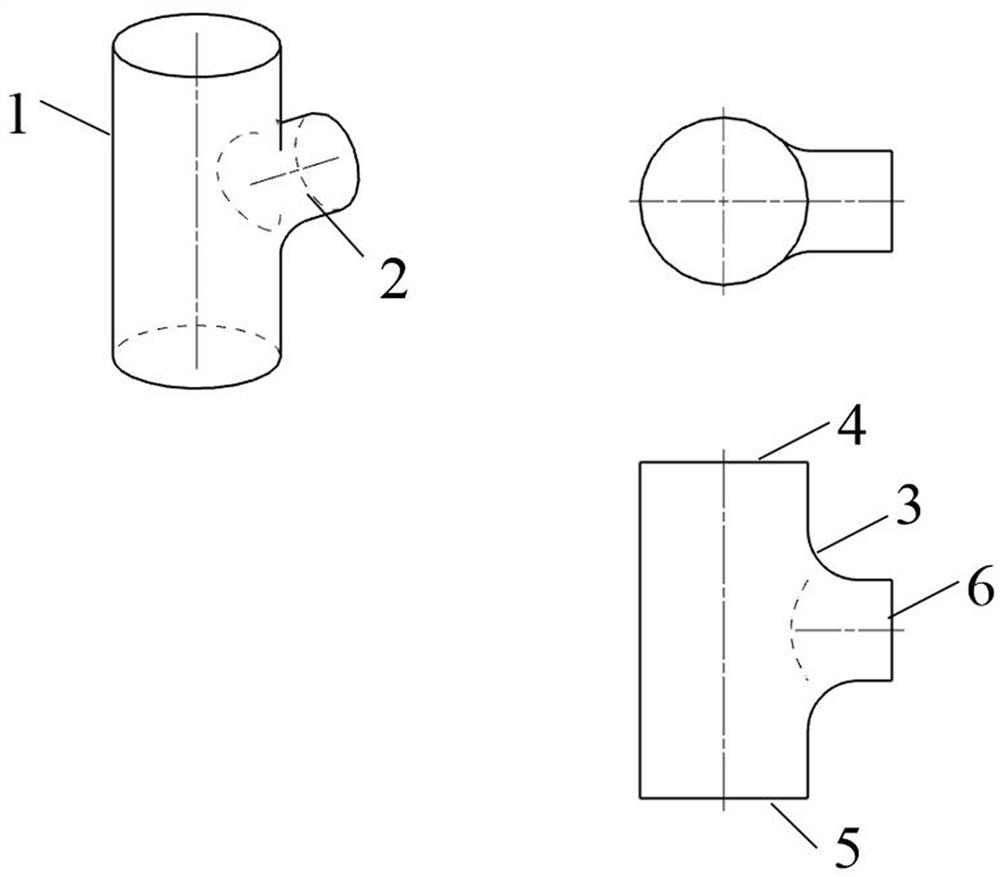

A high surface quality machining method for small T-shaped parts with weak stiffness and easy oxidation

A processing method and an easy-to-oxidize technology, applied in the direction of comprehensive factory control, metal processing equipment, manufacturing tools, etc., can solve problems such as weak stiffness vibration deformation, surface oxidation, etc., to improve manufacturing level, promote development, improve surface roughness and The effect of subsequent use performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

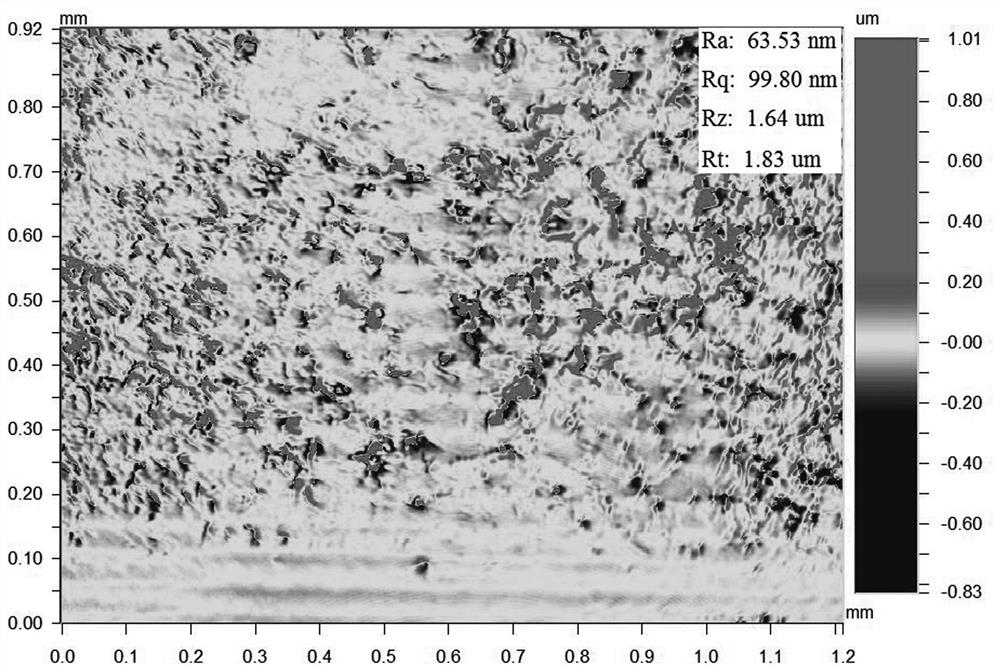

[0050] The present embodiment provides a high surface quality processing method for a small T-shaped part with weak stiffness and easy oxidation, including the following steps:

[0051] Step 1. Preparation of T-shaped parts blanks:

[0052] like Figure 4 As shown in the figure, a cylindrical material of pure aluminum or pure copper is prepared as the blank material for the processing of T-shaped parts, and the blank material is installed on the machine tool for cutting to prepare a blank part; the blank part includes the front end of the T-shaped part to be processed area 7 and The clamping end 9 at the rear end, the connecting part between the to-be-processed area 7 of the T-shaped part and the clamping end 9 is set as a conical transition 8;

[0053] The goal of the blank processing stage is to remove a large amount of material, the material is pure aluminum or pure aluminum (aluminum or copper content > 99.99%), the overall length of the blank material is 21.5 mm, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com