Quaternary hypoeutectic high-entropy alloy excellent in strength and plasticity match and preparation method thereof

A high-entropy alloy and hypoeutectic technology, which is applied in the field of quaternary hypoeutectic high-entropy alloy and its preparation, can solve the problems that cannot overcome the trade-off between strength and plasticity, and achieve a simple, reliable and safe preparation method , The effect of fine eutectic phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

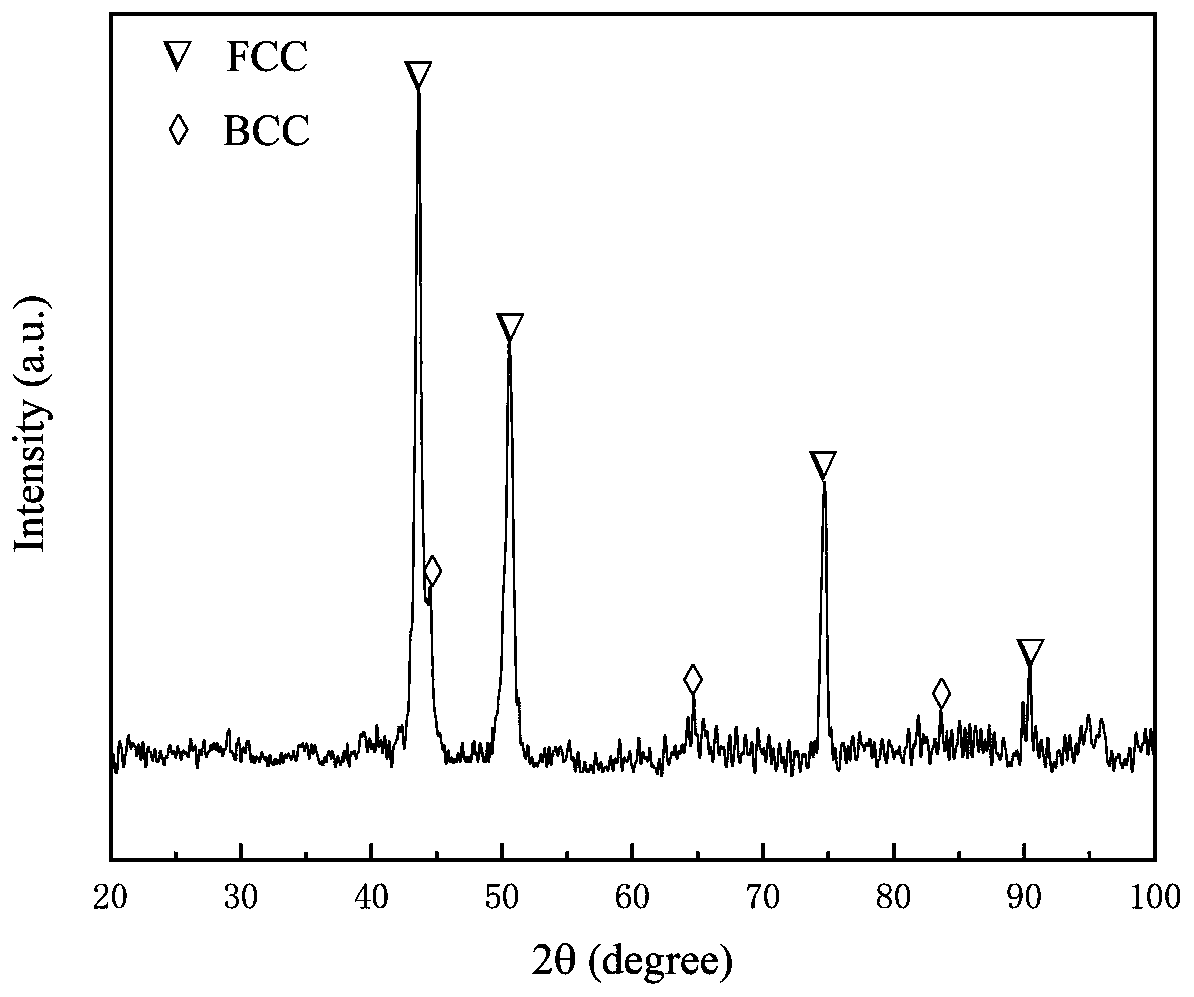

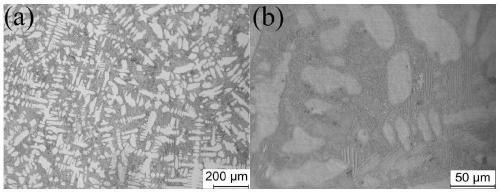

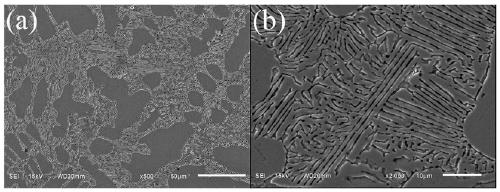

Method used

Image

Examples

Embodiment 1

[0032] A quaternary hypoeutectic high-entropy alloy Al with strong plasticity and good matching 14 Cr 28 Fe 28 Ni 30 The specific steps are as follows:

[0033] Use SiC sandpaper and a grinder to remove the surface impurities and oxides of Al, Co, Cr and Ni elemental metal raw materials, and then place them in different containers to add alcohol and ultrasonically clean twice. The purity of Al, Co, Cr and Ni elemental metal raw materials are all Not less than 99.9wt%,

[0034] Weigh the Al, Co, Cr and Ni elemental metal raw materials after ultrasonic cleaning according to the molar ratio of 14:28:28:30, mix the raw materials with a total mass of 80g and place them in a high vacuum non-consumable arc melting furnace. , Under the protection of argon, at a vacuum degree of 2.5×10 ﹣3 Electric arc smelting under MPa, smelting time 8min, obtain alloy liquid, stir and cool, obtain alloy ingot;

[0035] Repeat the arc melting, stirring and cooling process after turning the alloy ingot;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com