Medical high abrasion resistance titanium alloy composite and gradient in-situ nano multiphase abrasion reduction medical titanium alloy 3D printing method

A 3D printing and composite material technology, which is applied in the field of high-performance medical titanium alloy manufacturing, can solve the problems of complex smelting process, low forming precision, and limited performance, so as to improve interface wetting characteristics, wear resistance, and comprehensive performance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

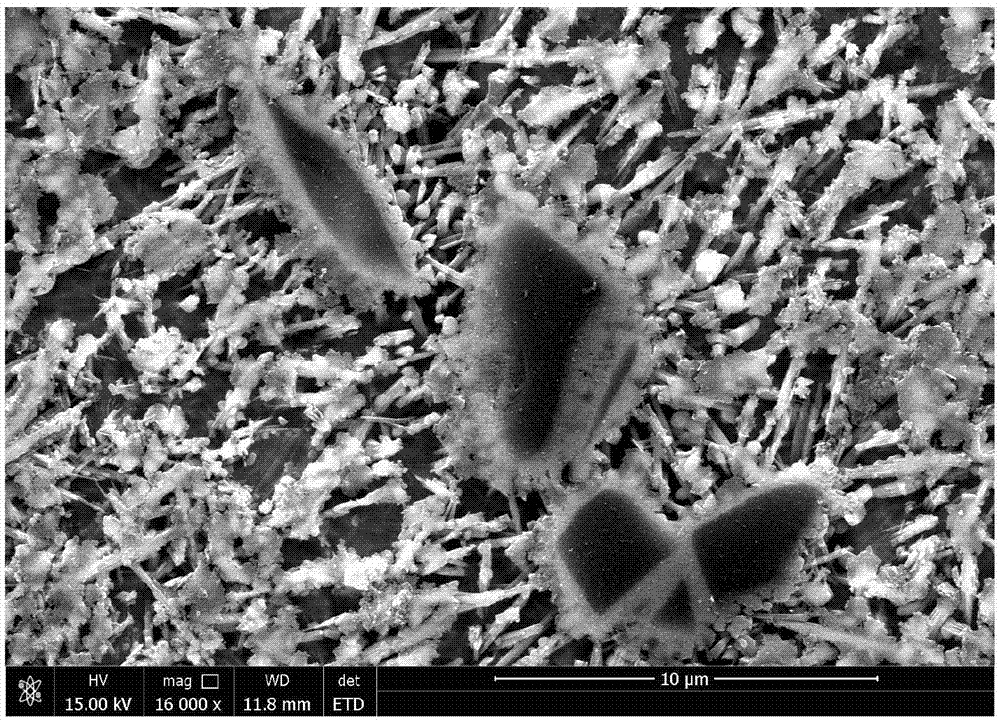

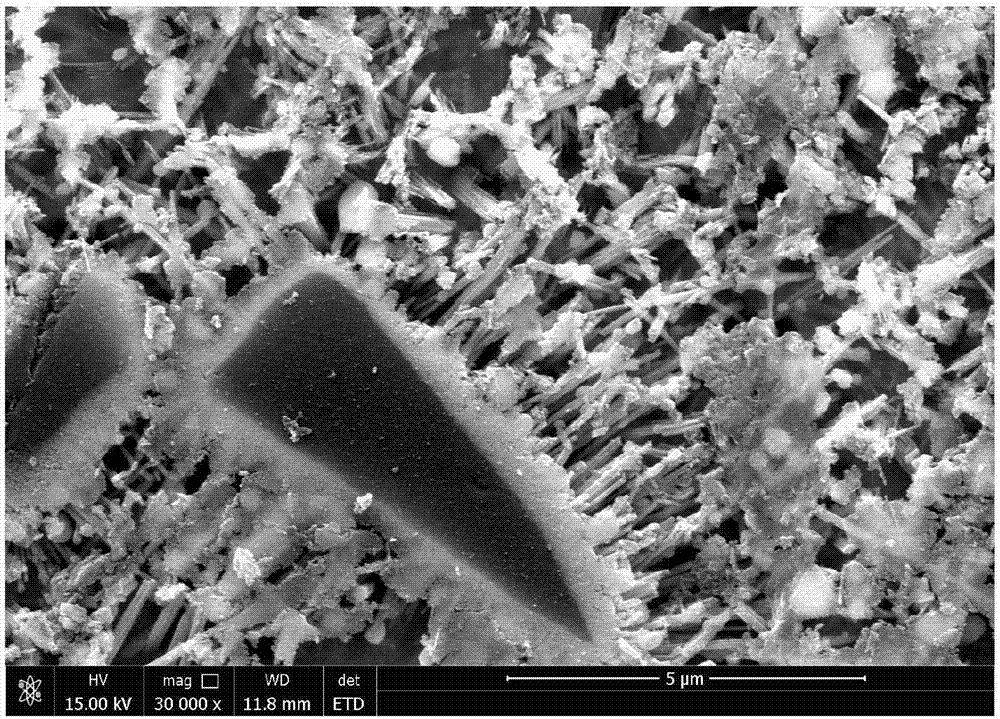

[0042] The present invention provides a method for 3D printing gradient in-situ nano-composite phase wear-reducing medical titanium alloy, using laser selective melting technology to form gradient in-situ nano-composite phase ceramic wear-reducing medical titanium alloy, including the following specific steps:

[0043] Step (1): After weighing the pure titanium powder with a purity of 99.99% and a particle size of 10-40 μm and the boron carbide ceramic powder with a particle size of 1-10 μm according to the mass ratio of 95 wt% and 5 wt%, respectively, use The high-energy ball mill mixed the mixed powder under the protective atmosphere of high-purity argon with a purity of 99.99%. The rotating speed was 200 rpm. The material ratio is 1:5, and stainless steel balls with a diameter of Φ4~Φ10 are selected to obtain uniformly mixed forming powder;

[0044] Step (2): Construct a three-dimensional model of the medical titanium alloy sample and slice it, with a layer thickness of 30 ...

Embodiment 2

[0047] The difference between this embodiment and Example 1 is that in step (1), the mass fraction of boron carbide ceramic powder is set to 15%, the mass fraction of medical Ti-Al alloy powder is set to 85%, and the others are the same as in Example 1.

Embodiment 3

[0049] The difference between this embodiment and Example 2 is that in step (3), the laser output linear energy density is set to 175 J / m, and the substrate preheating temperature is set to 175° C., and the others are the same as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com