Coating for performance enhancement of semiconductor apparatus

a technology for semiconductor apparatus and coating, applied in the field of coating for performance enhancement of semiconductor apparatus, can solve the problems of affecting the corrosion of the plasma to the various elements of the chamber, so as to enhance the surface roughness of the coating, improve the performance of the coating packaged showerhead, and enhance the surface density and stability of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

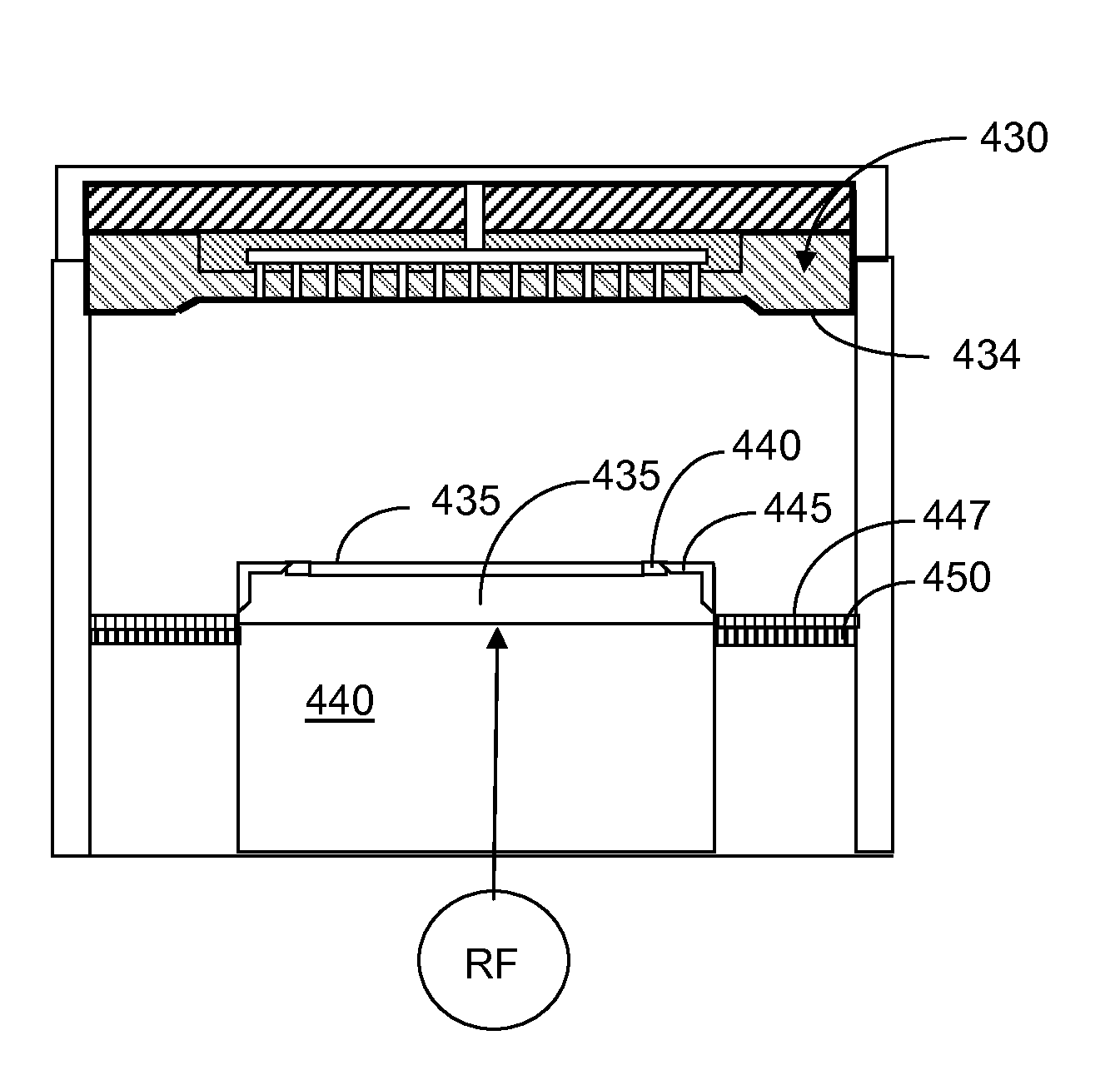

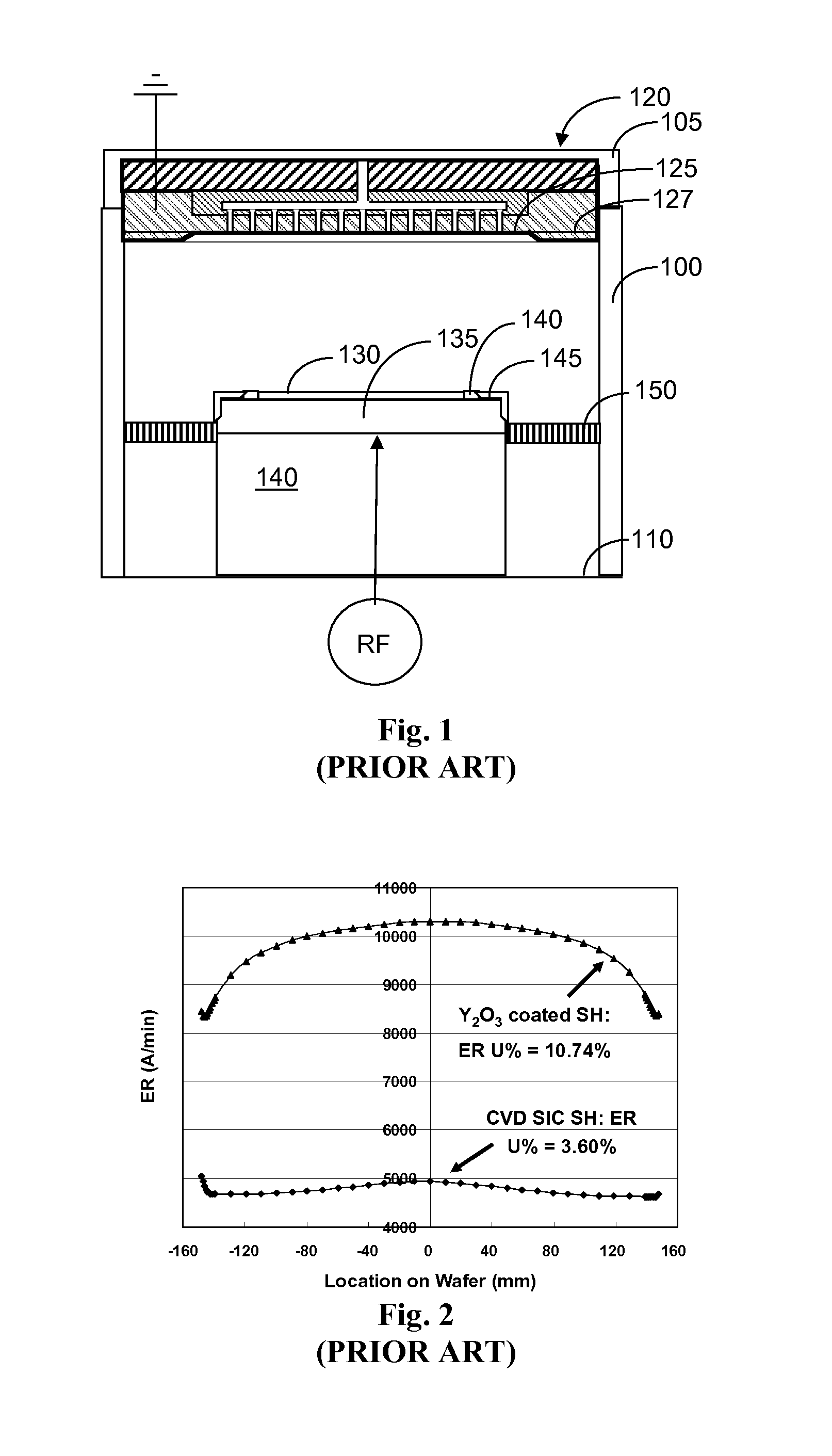

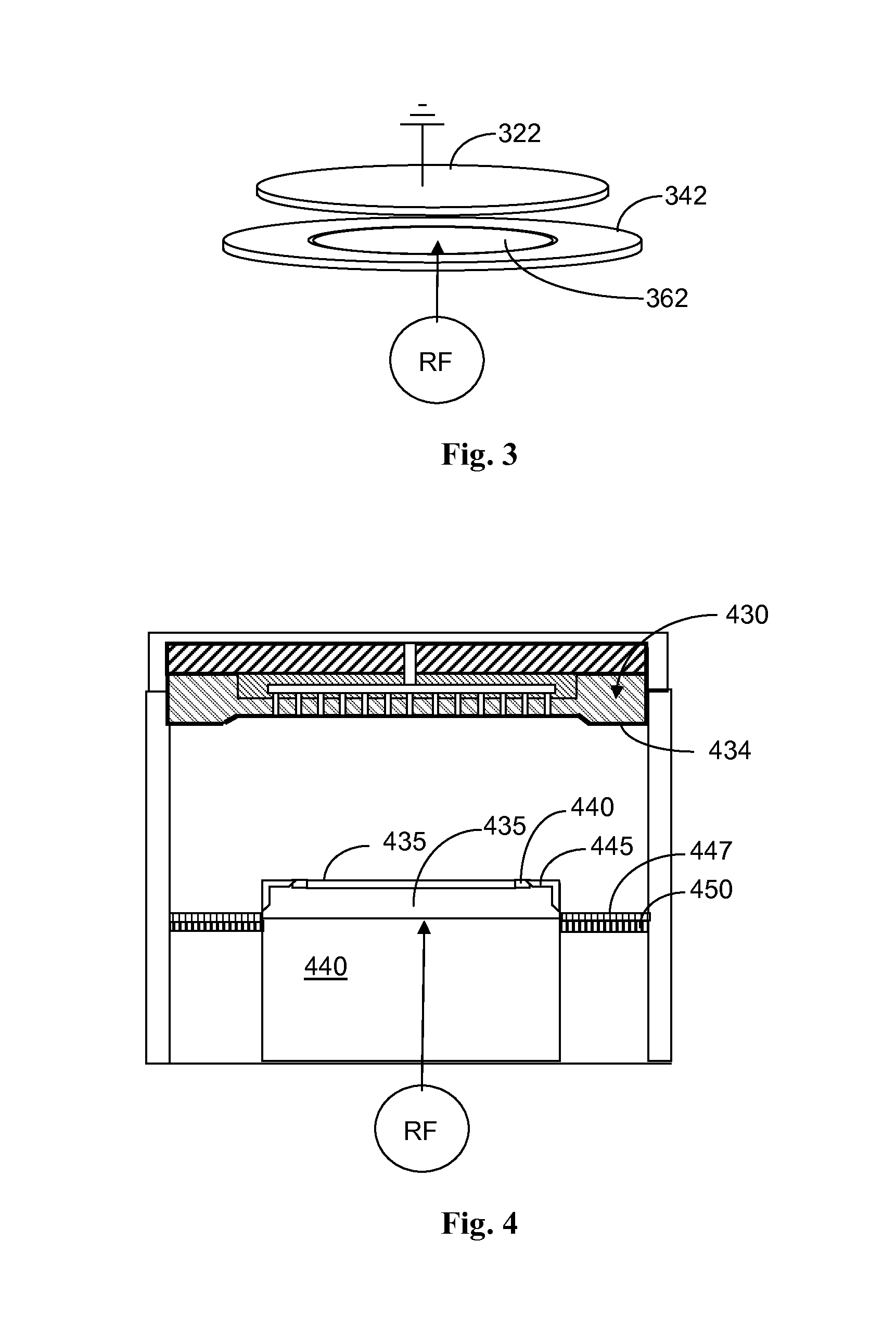

[0044]Various embodiments will now be described, providing improved coatings for showerheads, which improve erosion and particle performance of the showerhead, together with coated cathode assembly for enhancing etch rate and plasma uniformity. FIG. 3 is a schematic illustrating the arrangement for a capacitively coupled plasma chamber. In this embodiment, the top electrode 322 is grounded and the RF power is applied to the bottom electrode, which in this example is composed of electrode 362 and extension 342. The top electrode 322 may be composed of the perforated plate, or a combination of perforated plate and grounding ring. The bottom electrode 362 may be embedded in the chuck, or be part of the pedestal supporting the chuck. The extension 342 may be composed of one or a combination of focus ring, cover ring, flow equivalent ion shied, and / or plasma confinement ring. By proper selection of the elements comprising the upper and lower electrodes, and proper coating of these elemen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Porosity | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com