High-performance magnesium base alloy material and method for preparing same

A magnesium-based alloy, high-performance technology, applied in the field of material science to achieve the effects of small macrostructure, excellent thermal stability, and high tensile mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

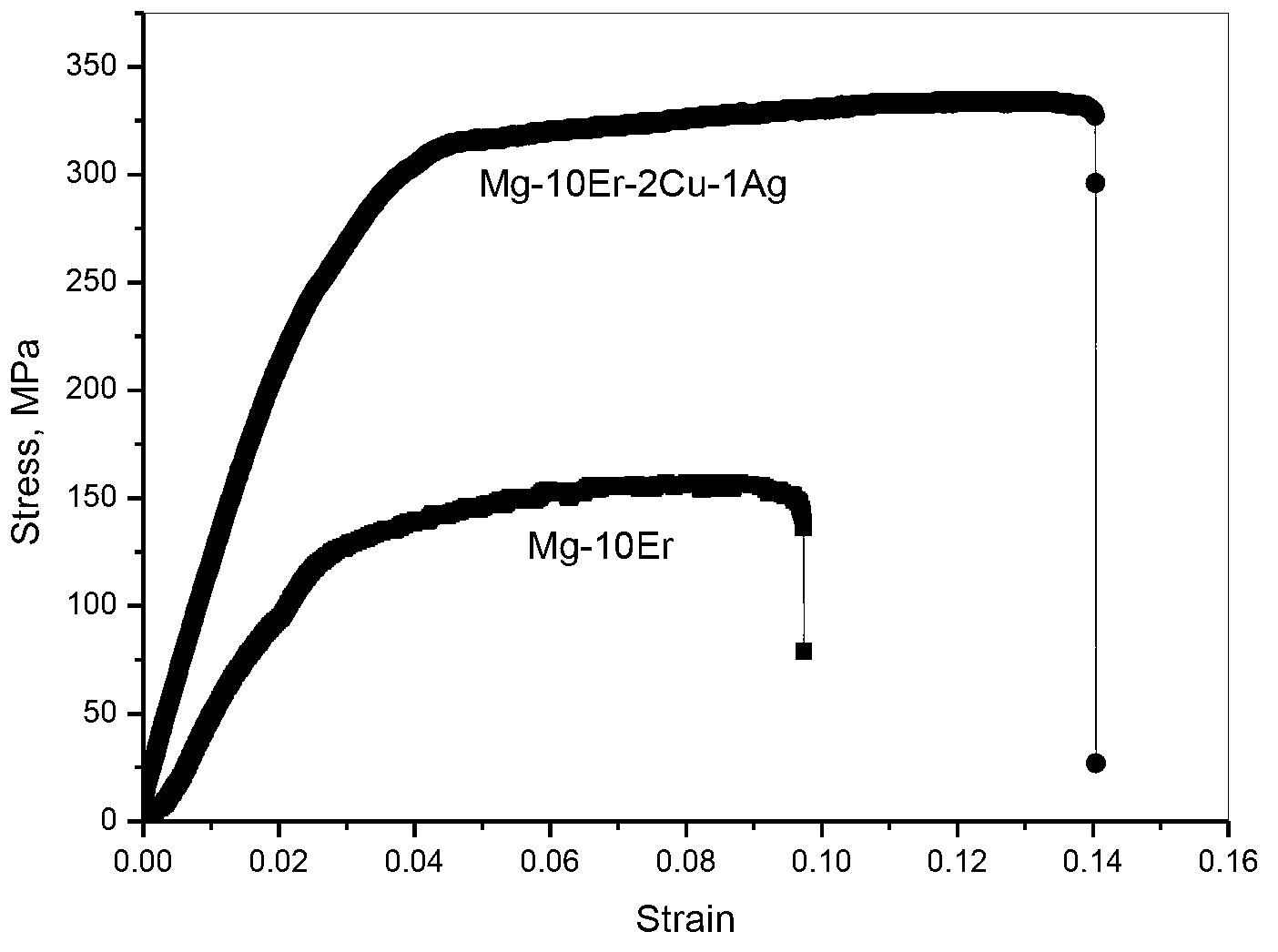

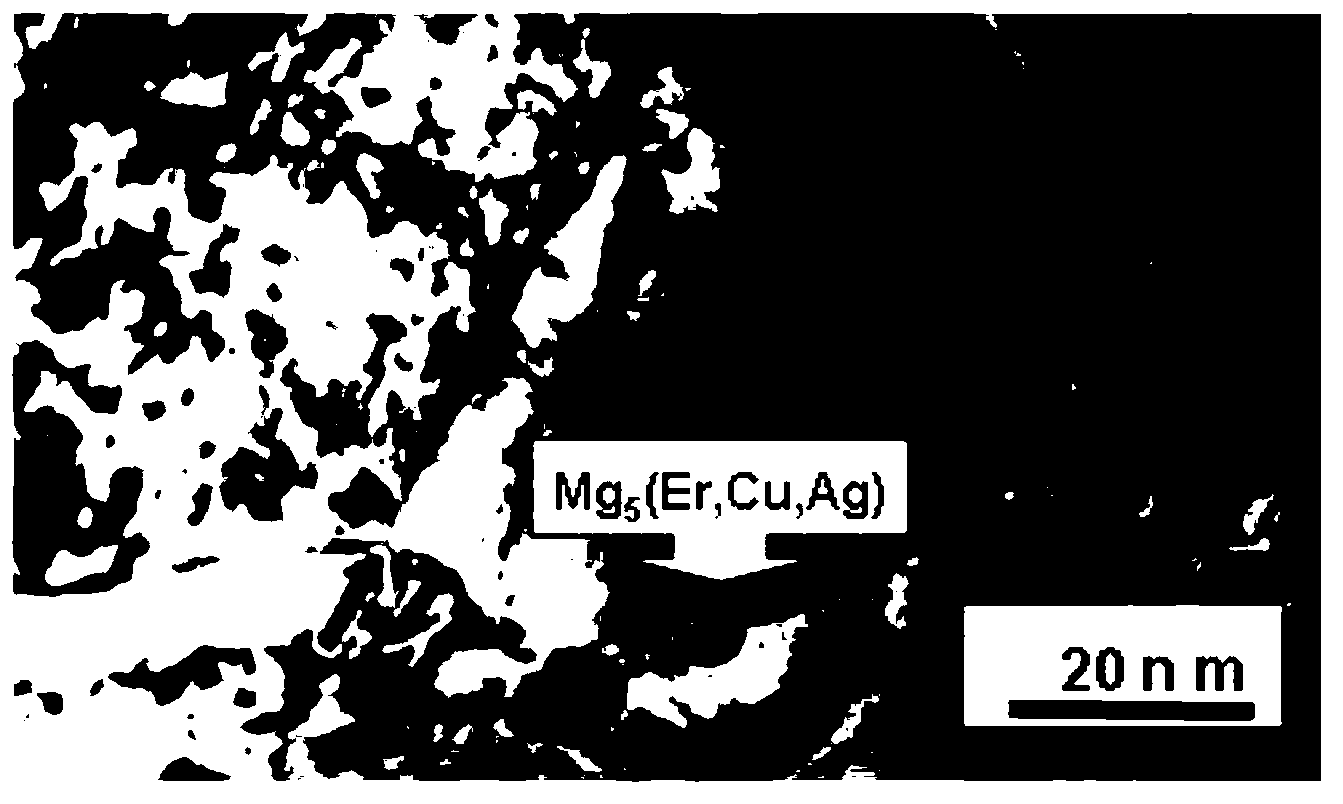

[0014] Use pure Mg-10Er master alloy and pure Cu, Ag elements to prepare alloy elements according to 87Mg-10Er-2Cu-1Ag (mass ratio). Using ordinary casting method, melting at 760 degrees, heat preservation for 20 minutes and casting into rods with a diameter of 50mm. Then carry out homogenization treatment at 450°C / 24h; then carry out hot extrusion at 430°C, the extrusion ratio is 12:1, and the extrusion speed is 5mm / min. The extruded rods are air-cooled. The hot-extruded alloy maintains high tensile mechanical properties in a wide temperature range (room temperature to 350°C). At room temperature, the tensile strength is 373MPa, the yield strength is 232MPa, and the tensile elongation is 14.5%. see figure 1 , Comparison of plasticity and strength of hot-extruded multi-component Mg-Er-Cu-Ag phase and binary Mg-Er alloy at room temperature; figure 2 It is a transmission electron micrograph of hot-extruded multi-component Mg-Er-Cu-Ag.

Embodiment 2

[0016] Use pure Mg-8Er master alloy and pure Cu, Ag elements to prepare alloy elements according to 89Mg-8Er-2Cu-1Ag (mass ratio). Smelting at 760 degrees, heat preservation for 20 minutes and casting into rods with a diameter of 50mm. Then carry out homogenization treatment at 450°C / 24h. Then, hot extrusion was carried out at 430° C., the extrusion ratio was 12:1, and the extrusion speed was 5 mm / min. The extruded rods are air-cooled. The hot-extruded alloy maintains high tensile mechanical properties in a wide temperature range (room temperature to 350°C). At 300°C, the tensile strength is 161MPa, the yield strength is 148.54MPa, and the tensile elongation is 47. %.

Embodiment 3

[0018] Use pure Mg-8Er master alloy and pure Cu, Ag elements to prepare alloy elements according to 90Mg-8Er-1Cu-1Ag (mass ratio). Smelting at 760 degrees, heat preservation for 20 minutes and casting into rods with a diameter of 50mm. Then carry out homogenization treatment at 450°C / 24h. Then, hot extrusion was carried out at 430° C., the extrusion ratio was 12:1, and the extrusion speed was 5 mm / min. The extruded rods are air-cooled. The hot-extruded alloy maintains high tensile mechanical properties in a wide temperature range (room temperature to 350°C). The tensile strength at 350°C is 106MPa, the yield strength is 90MPa, and the tensile elongation is 59.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com