Distributed crack sensor based on coaxial cable

A coaxial cable and sensor technology, applied in the field of engineering structure safety monitoring, can solve the problems of difficult anti-corrosion treatment, easy damage, and large medium interference, and achieve the effects of eliminating poor winding contact, easy industrial production, and improving service performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

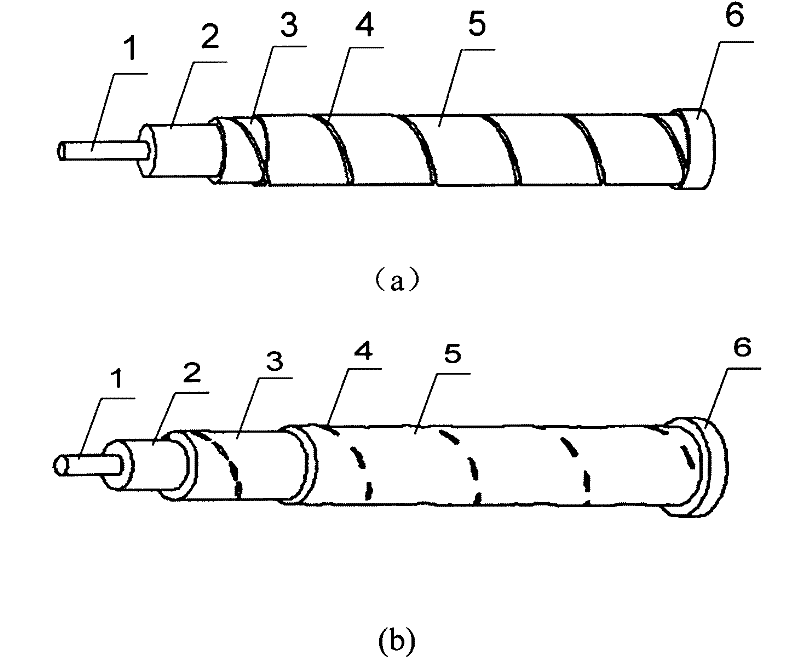

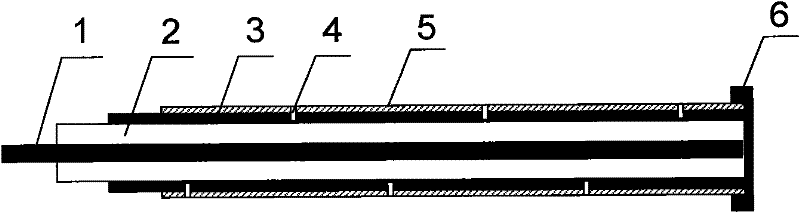

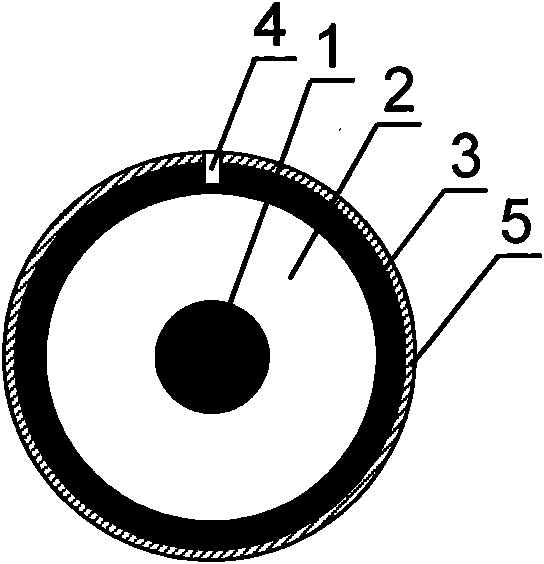

[0019] The structure of the distributed crack sensor based on the coaxial cable of the present invention is as follows: figure 1 , figure 2 with image 3 As shown, the sensor includes: 1 inner conductor; 2 insulating layer; 3 outer conductor; 4 weak thread; 5 anti-corrosion coating; 6 tail end protective sleeve. Among them, the inner conductor can be made of gold, silver, copper, aluminum and other metal materials with good electrical and thermal conductivity; the outer conductor can be made of copper, aluminum and other metal materials with good corrosion resistance and easy pressure processing; The thread is processed by applying rotary forward traction to the coaxial cable, and at the same time using a drill to carve grooves on the outer conductor layer of the coaxial cable; the point-type weak thread is processed by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com