Friction stir welding-braze welding composite welding method for dissimilar metal bonding structure

A technology of friction stir welding and dissimilar metals, applied in welding equipment, metal processing equipment, welding/welding/cutting items, etc., can solve the problems of reducing the effective bearing thickness of the interface, difficult to remove, structural failure, etc., to avoid brittle metal The effect of compound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

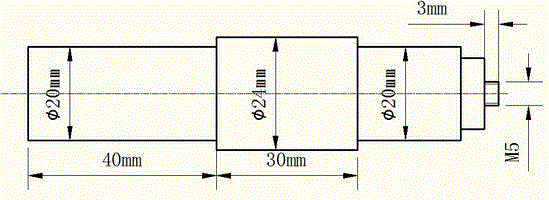

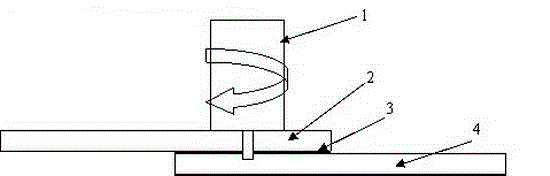

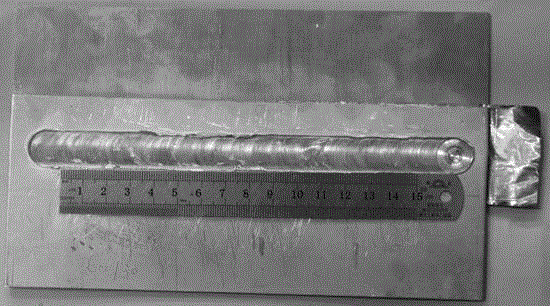

[0018] Such as figure 2 As shown, the present invention is implemented in this way, a "friction stir welding-brazing" composite welding method for dissimilar metal overlapping structures, which includes a stirring head 1, an upper metal 2, an intermediate metal 3 and a lower metal 4 , which is characterized in that: the shoulder of the stirring head 1 presses the upper metal 2 while maintaining high-speed rotation, the stirring needle penetrates the upper metal 2 and directly contacts the lower metal 4, the heat generated by the mutual friction between the shoulder and the upper metal 1 passes through The conduction of the upper layer metal 1 melts the middle layer metal 3; the molten metal 3 quickly dissolves the upper layer metal 1 and the lower layer metal 4 at the interface, and removes the work hardening layer while removing the oxide film, and cleans the contact interface so that elements occur at the interface Diffusion, forming a brazed weld. At the same time, the lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com