A micro-groove group extrusion molding device for ultrasonic rough surface

An extrusion molding, rough surface technology, applied in the field of micro-groove group extrusion molding device, can solve the problems of small capillary suction, no surface rough structure, etc., to enhance the capillary suction, broaden the application, overcome the effect of smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The purpose of the invention of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the embodiments cannot be repeated here one by one, but the implementation of the present invention is not therefore limited to the following embodiments.

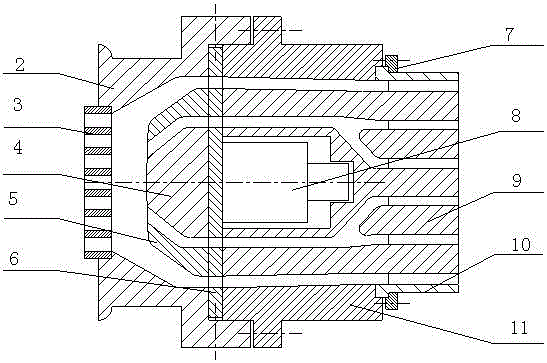

[0014] Such as figure 2 As shown, a micro-groove group extrusion molding device with an ultrasonic rough surface includes a machine head body 2, a main body 11, a fluid distribution support 6, a core mold 9 with a flow channel inside, and an outer die 10. The machine head The body 2 and the main body 11 are connected by bolts, and the fluid-distributing support 6 is fixed between the junction of the machine head body 2 and the main body 11. The left end of the machine head body 2 is provided with a filter screen 3, and the machine head body 2 The inner cavity is facing the filter screen 3 and is provided with a set of inner sub-fluid 4 and outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com