Three-dimensional packaging phase change heat dissipation device

A technology of three-dimensional packaging and heat dissipation device, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of limited heat, complex system, and easy vibration, etc., to eliminate noise and vibration, enhance heat and mass transfer, and improve The effect of heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

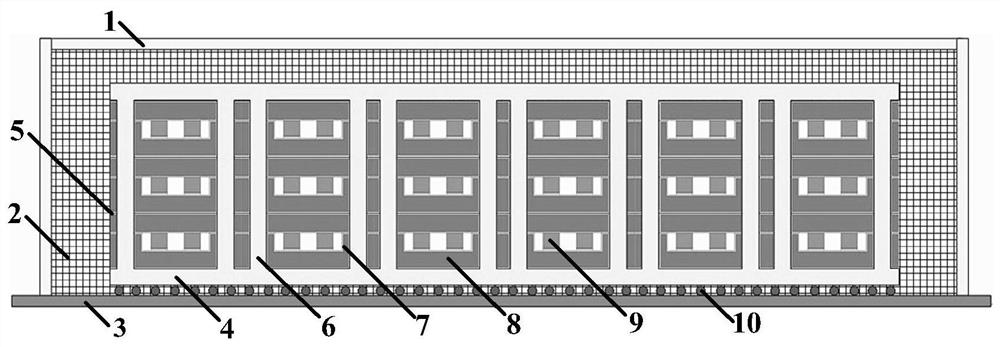

[0032] refer to figure 1 , the three-dimensional packaging phase change heat dissipation device of this example includes an upper packaging shell 1, a phase change material 2, a lower packaging substrate 3, a three-dimensional heat pipe 4 and a three-dimensional packaging stack 7, and the upper packaging shell 1 and the lower packaging substrate 3 constitute a package In the casing, the three-dimensional packaging stack 7 is embedded in the three-dimensional heat pipe 4 and placed in the packaging casing, which is covered with a phase change material 2 and fixed with the lower packaging substrate 3 through solder balls 10 .

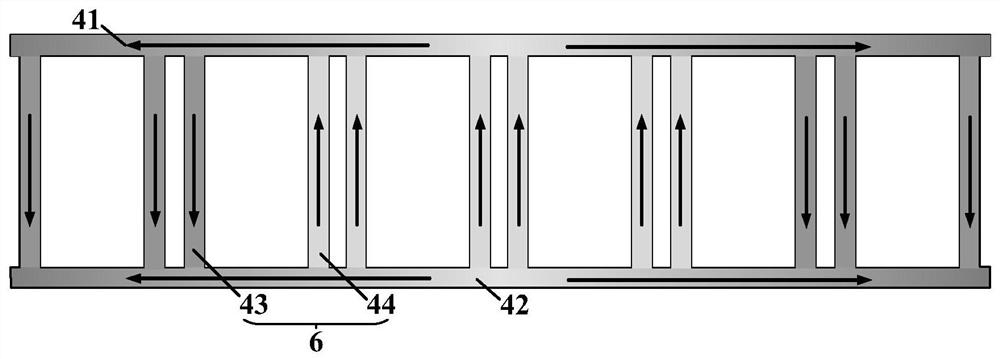

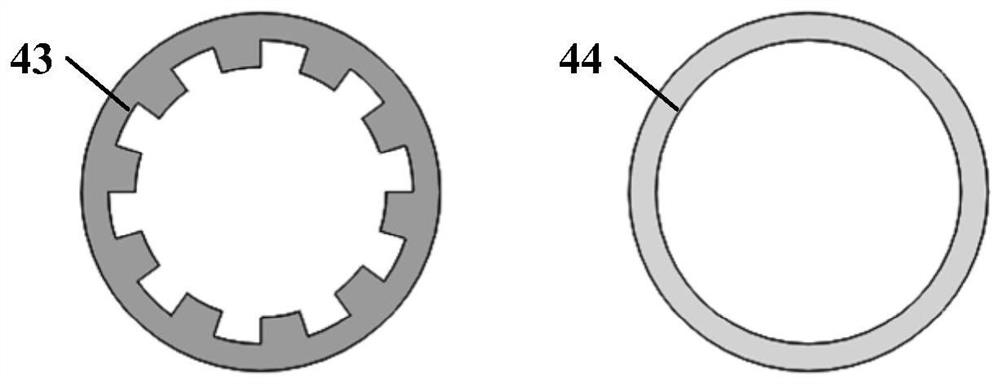

[0033] The three-dimensional packaging stack 7 includes a plurality of packaging monolayers, each packaging monolayer is composed of a device layer 5, a thermal TSV component 6, a silicon substrate 8, and a microchannel 9,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com