Patents

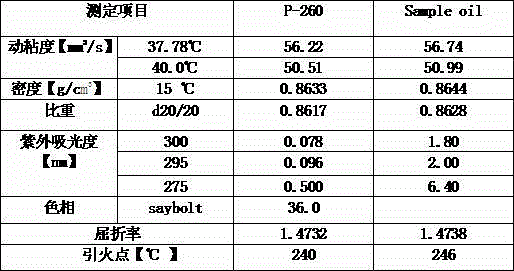

Literature

59results about How to "Uniform distribution of micropores" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Micropore hydrogenated aluminum porcelain tube and preparation thereof

ActiveCN101412619AUniform distribution of microporesLower firing temperatureGas phaseTemperature resistance

The invention relates to the field of an alumina ceramic pipe, in particular to a micropore alumina ceramic pipe and a method for preparing the same, and solves the problems that the prior art can not satisfy four good performances of high temperature resistance, corrosion resistance, high insulativity, and nontoxicity at the same time. The invention provides the micropore alumina ceramic pipe which is prepared from the following raw materials: 88 to 95 percent of alpha aluminum oxide, 2 to 4 percent of suzhou clay, 2 to 4 percent of talcum powder, 0.2 to 2 percent of calcium carbonate, 0.1 to 1.5 percent of strontium carbonate, and 0.2 to 1.5 percent of silicon dioxide. The method uses fluoride containing calcination alpha aluminum oxide powder together with five additives of the suzhou clay, the talcum powder, the calcium carbonate, the strontium carbonate, and the silicon dioxide which are mixed and ground evenly to prepare the micropore alumina ceramic pipe, so that the firing temperature of the ceramic piece is greatly reduced; and through exact formulation design, solid phase, liquid phase and gas phase are collocated reasonably, thus the prepared micropore ceramic piece not only has evenly distributed micropores and good mechanical strength, but also does not change the four good performances of the aluminum oxide.

Owner:温州市润基精密陶瓷件有限公司

Porous oxide ceramic heat insulating material for kilns and preparation method of porous oxide ceramic heat insulating material

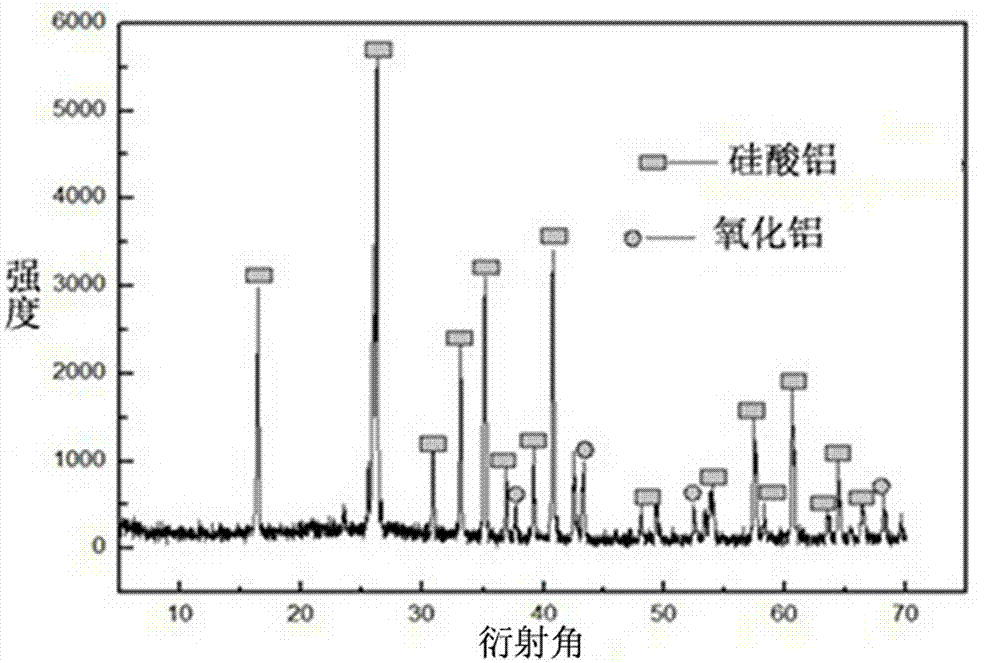

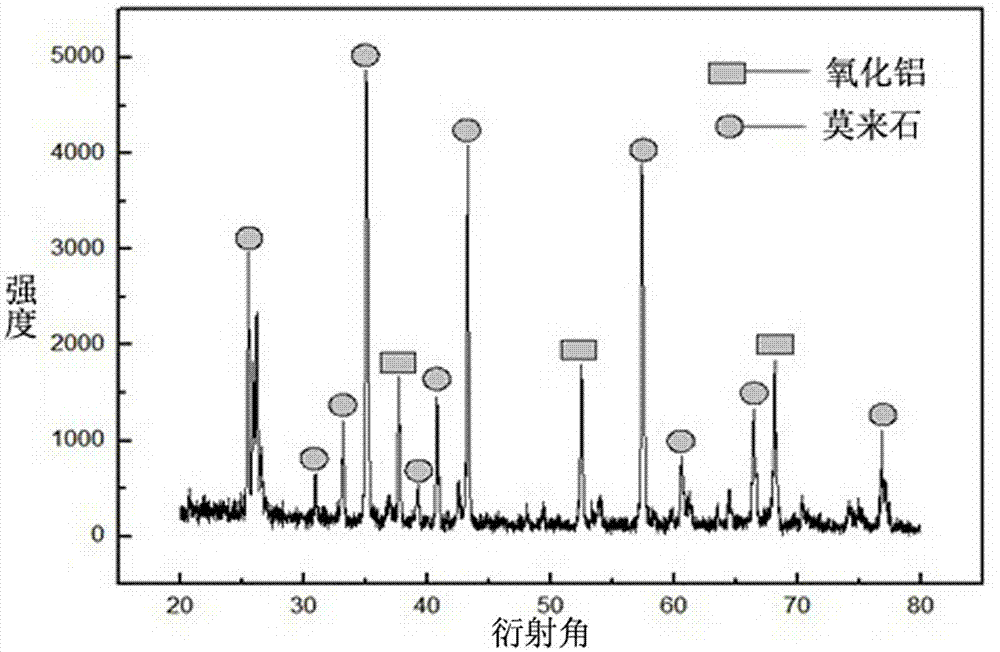

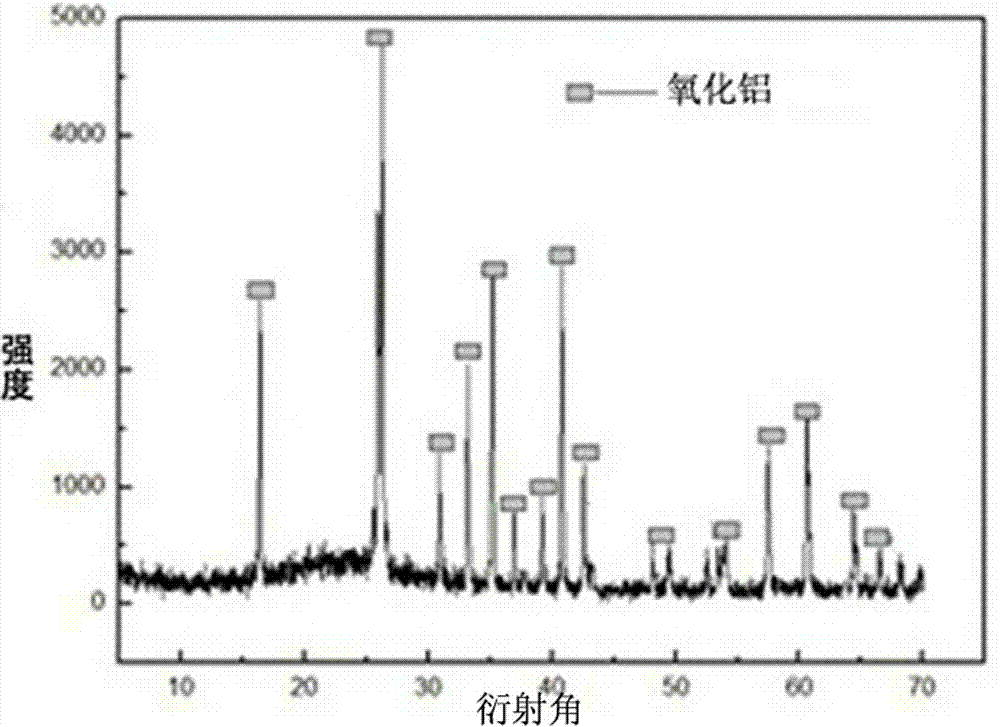

The invention discloses a porous oxide ceramic (aluminum silicate, mullite, alumina ceramics) prepared according to a foam in-situ consolidation method. Porous aluminum silicate, mullite, alumina ceramics each are made from the following raw materials: kaolin, bauxite, silicon micropowder, aluminum oxide and quartz, as well as a gas-generating agent (metal aluminum powder, rosin soap or sodium lauryl sulfate, polyvinyl alcohol or sodium carboxymethyl cellulose, agar), a foaming agent, a foam stabilizer and a forming agent. The porous oxide ceramic is prepared by the following steps: (1) preparation of ceramic slurry; (2) foaming of the slurry; (3) in-situ injection-consolidation forming of the slurry; and (4) drying and burning of formed blanks. The porous oxide ceramic heat insulating material has a uniform distribution of porosity and is good in heat-insulating effect and thermal shock resistance. According to the method, the process is simple, the cost is low, heat insulating materials for high-temperature kilns working in different temperatures (1200-1600 DEG C) can be produced, the heat insulating material product is not liable to chalking or cracking during long-term use, and the service life of the porous oxide ceramic heat insulating material is prolonged when compared with that of the existing kiln heat insulating material.

Owner:WUHAN UNIV OF TECH

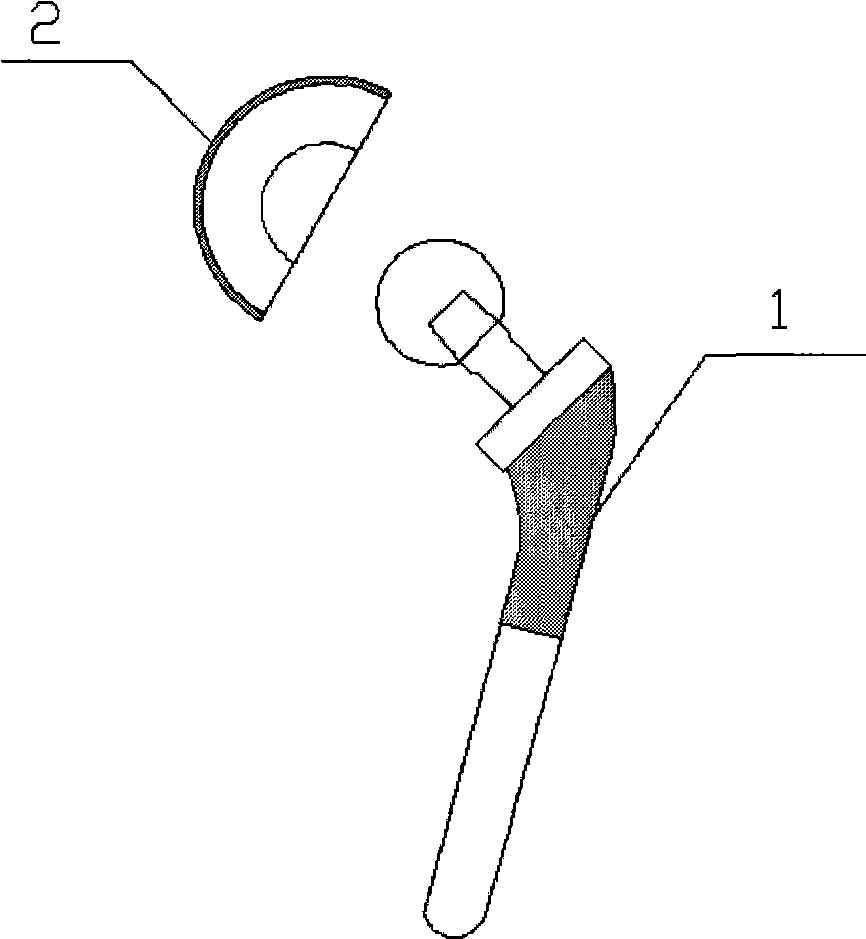

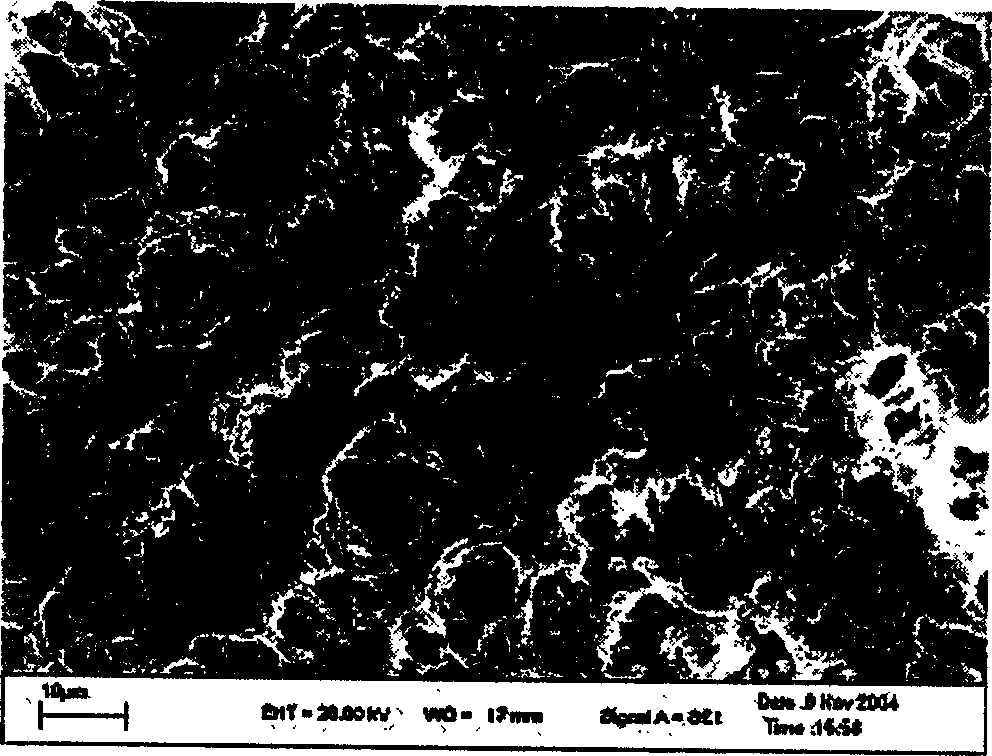

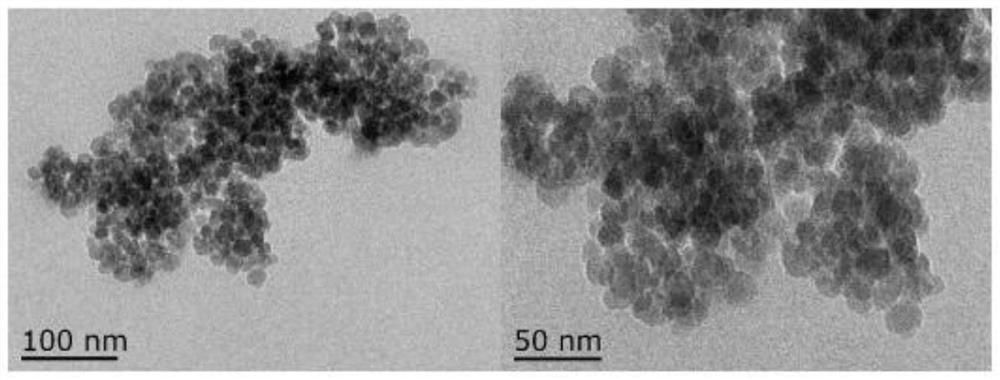

Artificial hip joint with nano and porous structure on surface and preparation method thereof

InactiveCN101496749AImproves strength and hardnessReduce stress shieldingJoint implantsFemoral headsCotyloid CavityHuman organism

The invention relates to an artificial hip joint with surface nanometer and porous structure in the technical field of medical appliance and a preparation method thereof. In the artificial hip joint, the part of a femoral head handle or / and acetabulum combined with human organism has a scale of surface layer grains of between 1 and 500nm, and has an evenly distributed porous structure; and the artificial hip joint has a gradient nanometer structure from the surface inwards, the scale of the grains gradually increase along with increase of distance with the surface, until a scale of a conventional untreated state is achieved, and the thickness of the gradient nanometer layer is between 1 and 500 mu m. The preparation method comprises the following steps that: the artificial hip joint obtains the nanometer gradient structure layer by surface high-energy treatment technology; and then, the nanometer gradient structure layer is subjected to acid treatment so as to obtain a porous structure on the surface, thereby obtaining the artificial hip joint. The artificial hip joint and the method not only can effectively reduce stress shield effect of an implant body and a bone, but also can improve interface combination of the prosthesis and the bone, effectively improve the loosened implanted prosthesis, and have excellent application in the field of biomedicine.

Owner:SHANGHAI JIAO TONG UNIV

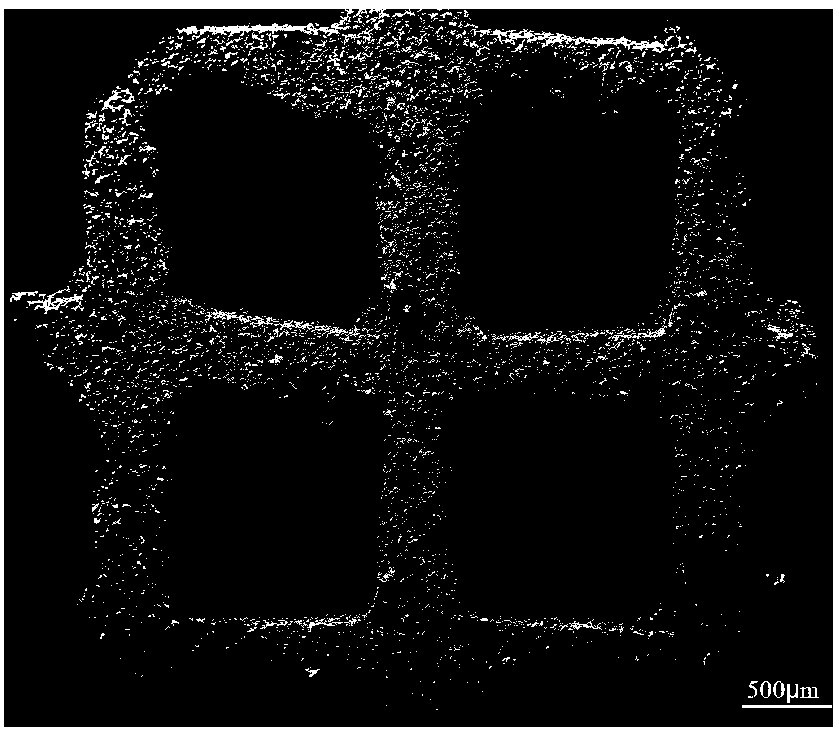

Al<4>SiC<4> and Al composite reinforced silicon carbide honeycomb ceramic and preparation method thereof

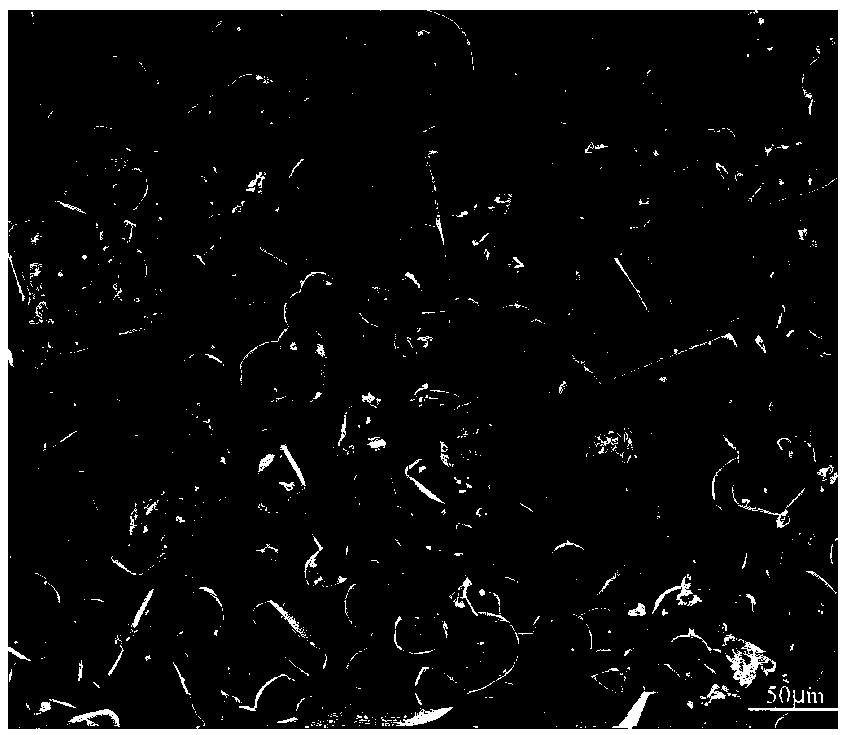

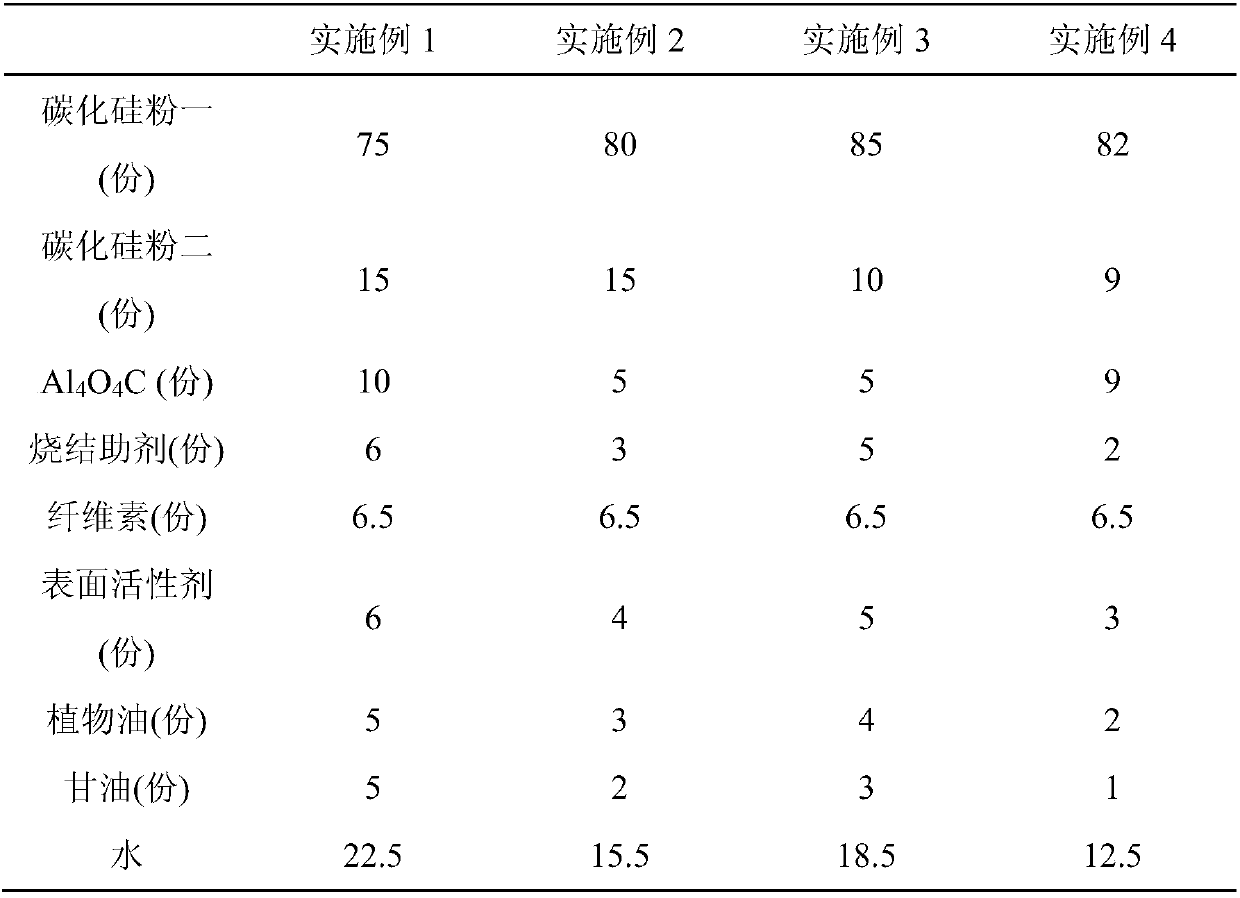

The invention discloses a preparation method of Al<4>SiC<4> and Al composite reinforced silicon carbide honeycomb ceramic. The preparation method comprises the following steps: taking silicon carbidepowder A, silicon carbide powder B, Al<4>SiC<4> and Al powder as main materials, adding a metal oxide accounting for 5-15 wt% of the main materials as a sintering aid, on the basis of the mass of themain material, dissolving 7.5wt% of cellulose, 3-5 wt% of a surfactant, 1.5-3.5 wt% of vegetable oil and 1-4 wt% of glycerol in equal mass of water to obtain a binding agent, mixing the main materials, the sintering aid and the binding agent uniformly, so as to obtain a mixture; pouring the mixture into a vacuum extruder for forming, performing drying, so as to obtain a honeycomb ceramic green body; heating the honeycomb ceramic green body to 2000-2200 DEG C under an argon atmosphere condition, preserving heat for 1-3 hours; and performing natural cooling, so as to obtain the Al<4>SiC<4> and Al composite reinforced silicon carbide honeycomb ceramic. According to the Al<4>SiC<4> and Al composite reinforced silicon carbide honeycomb ceramic prepared by the method, raw material utilization rate is high, the production efficiency is high, the structure of the product is wall-flow type, the purification capacity on the waste gas is improved, the microstructure is good, the micropore distribution is uniform, and the mechanical strength is high.

Owner:NANJING KERUI SPECIAL CERAMICS

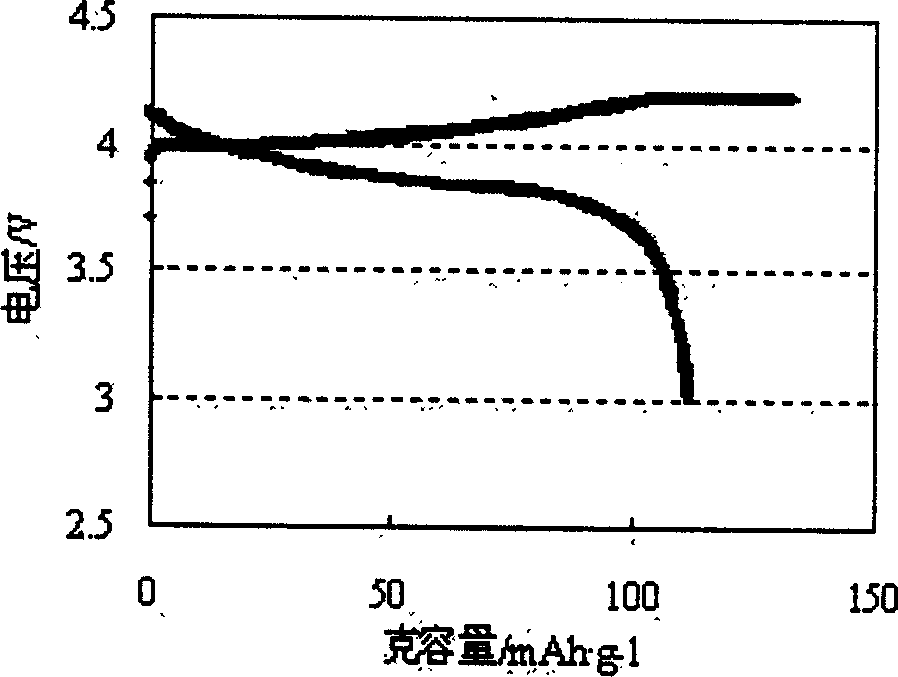

Process for preparing blended micrometer TiO2 polymer electrolyte

The present invention relates to the preparation process of electrolyte for polymer lithium ion cell. The present invention uses micron level TiO2 powder as stuffing for polymer electrolyte film, and prepares PVDF-HFP base polymer electrolyte film via phase transfer process. In the weight ratio of PVDF-HFP to TiO2 in 9-49, weight ratio of PVDF-HFP to deionized water to acetone in 1 to 0.25-1.25 to 5-15, the mixture of solvent and non-solvent is added into the mixture of polymer matrix PVDF-HFP and micron stuffing TiO2 to obtain while homogeneous porous polymer film, which is then soaked in electrolyte liquid for lithium ion cell to obtain electrolyte film with ionic conducting performance and finally heat treated. The present invention has improved and stabilized pore structure of polymer electrolyte film and raised electrochemical performance and mechanical performance of electrolyte film.

Owner:UNIV OF SCI & TECH BEIJING

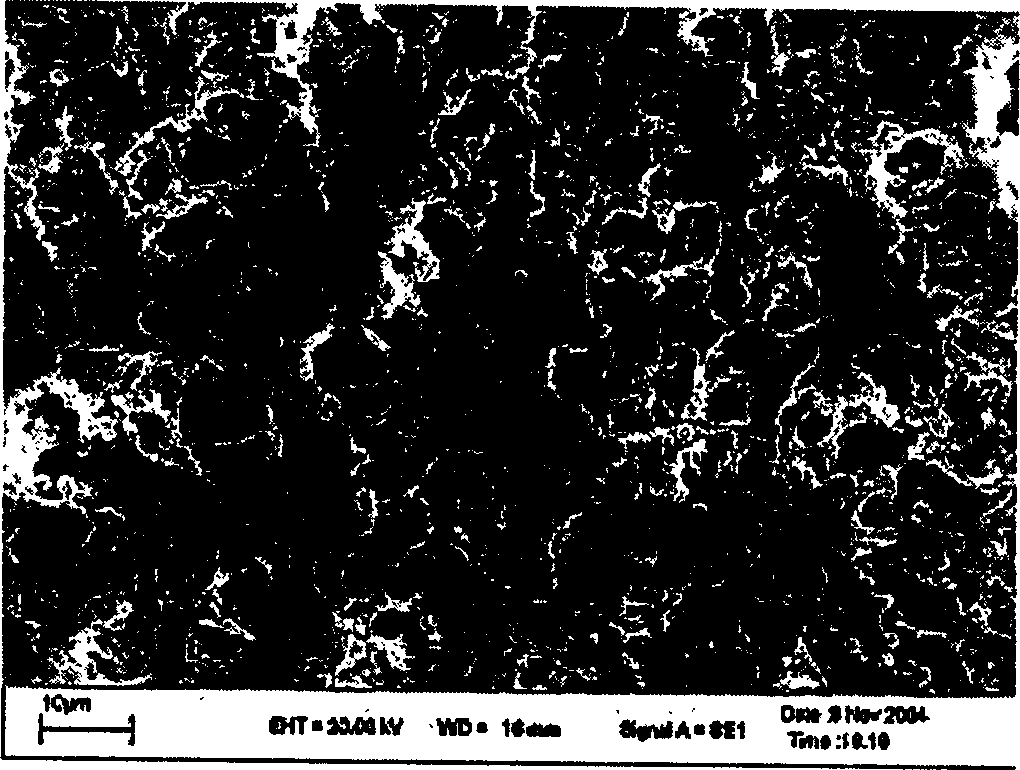

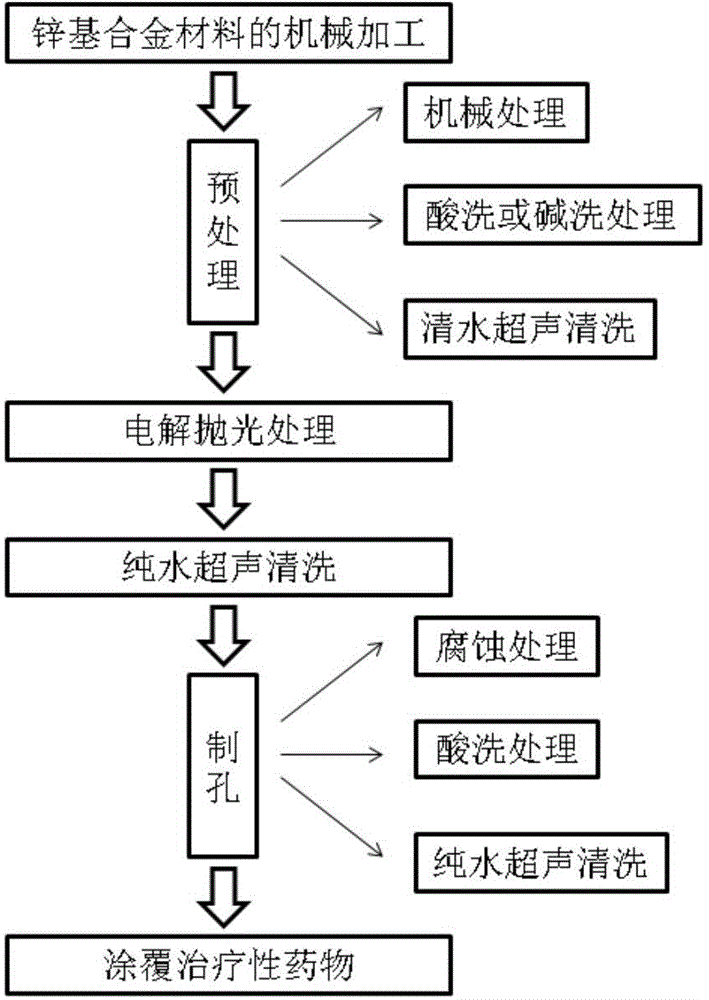

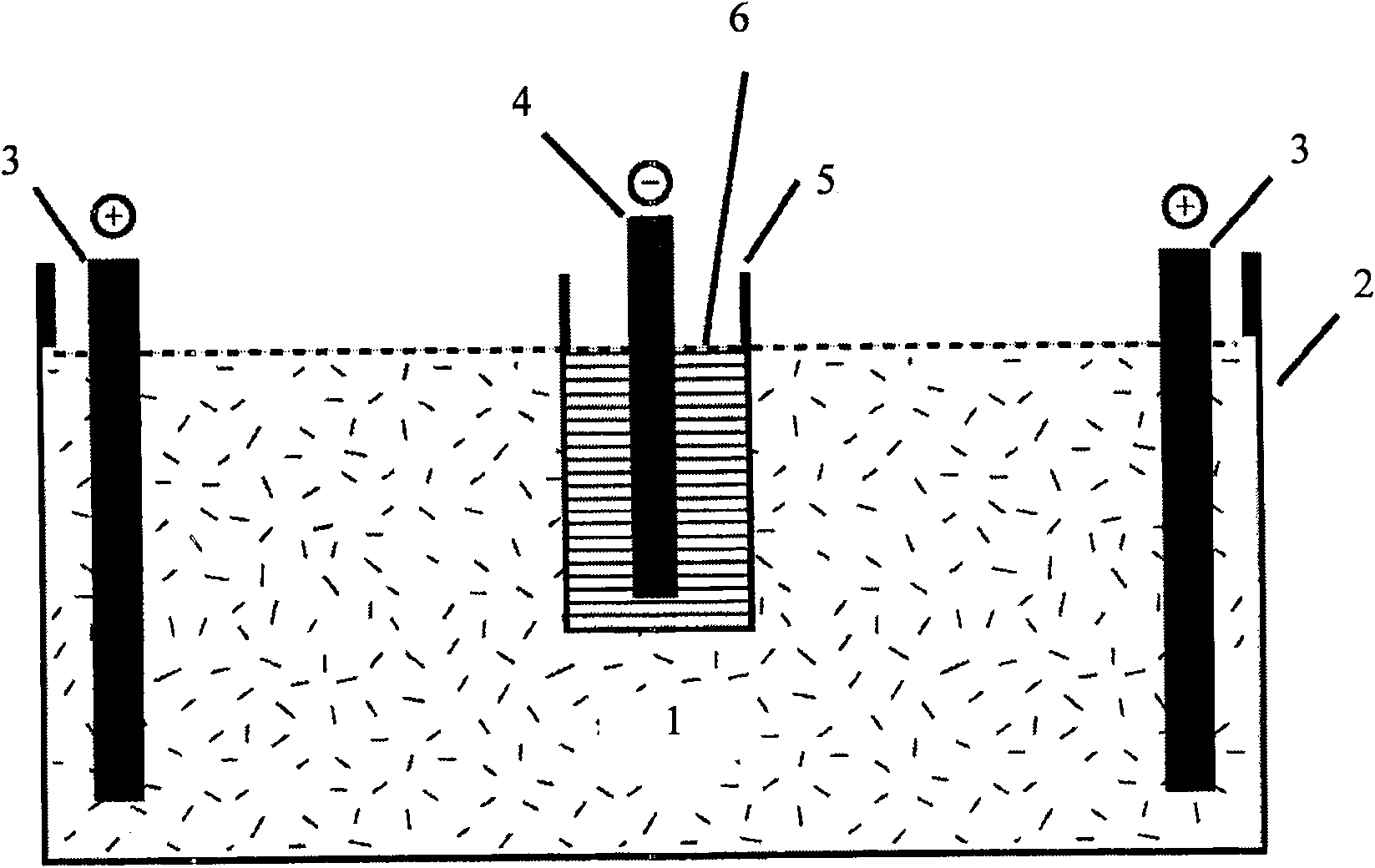

Degradable zinc-based micropore drug-loaded support and preparation method thereof

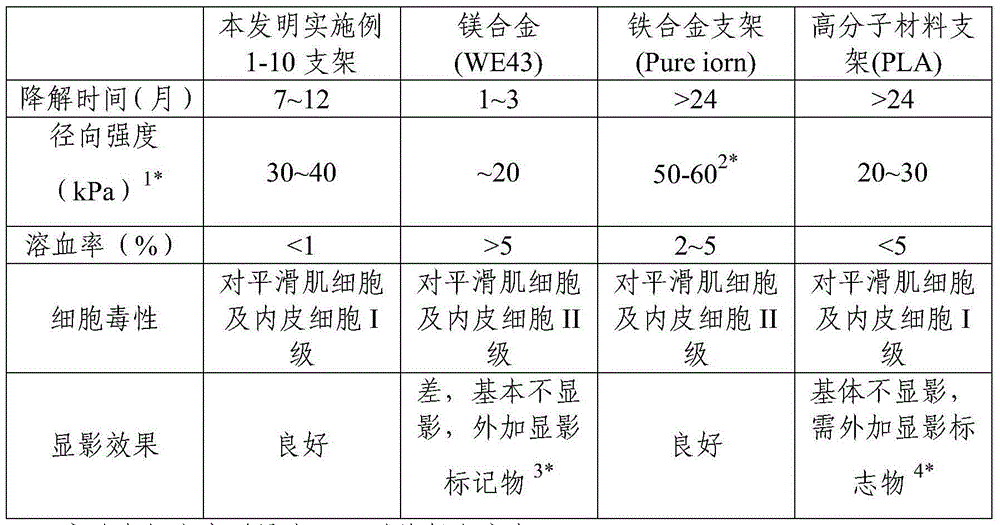

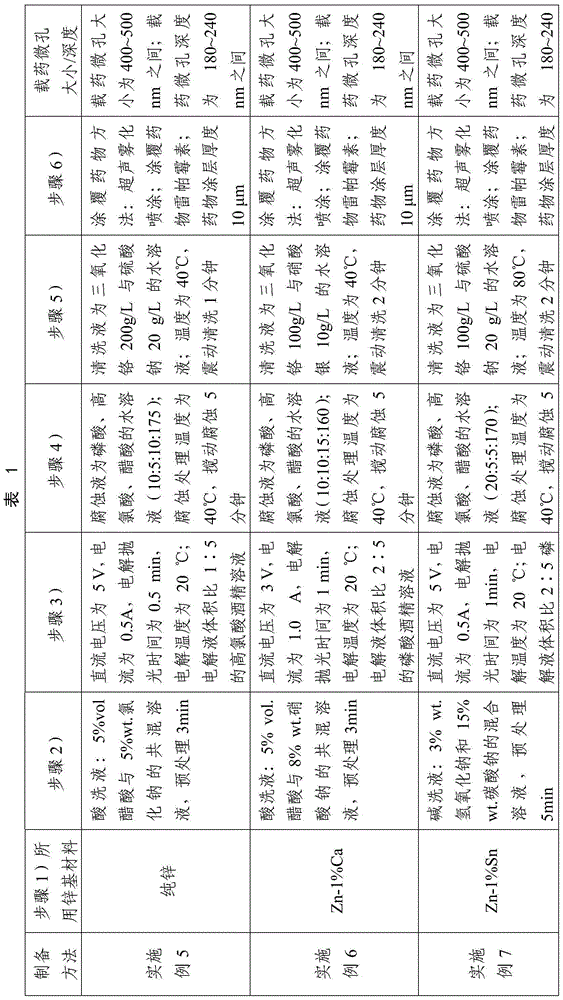

The invention relates to a degradable zinc-based micropore drug-loaded support and a preparation method thereof. The support comprises a degradable zinc-based material support matrix, uniform drug-loaded micropores are arranged on the surface of the support matrix, a therapeutic medicine coating covers the surface provided with uniform drug-loaded micropores, and the support matrix is in a cylinder net structure. The preparation method comprises the following steps: 1)processing the degradable zinc based material to the support matrix; 2)pretreating the surface of the support matrix; 3)performing electrolytic polishing processing on the support matrix; 4)performing corrosion processing on the support matrix after polishing; 5)pickling the support matrix after corrosion; and 6)coating a therapeutic medicine on the surface of the support matrix after aperture making. The support has good support performance after implantation for more than 4 months due to superior corrosion resistance of a zinc alloy matrix material, uniform micropores are distributed on the matrix surface, the therapeutic medicine layer is coated, so that medicine release can be controlled, support effect of the metal support can be fully performed, and the drug-loaded support has medical science curative effect with drug eluting support for inhibiting intimal hyperplasia to restenosis.

Owner:LEPU MEDICAL TECH (BEIJING) CO LTD

Mist side pressure-sensitive adhesive

ActiveCN103374322AUniform distribution of microporesUniform pore diameterNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesTemperature resistanceIsocyanate

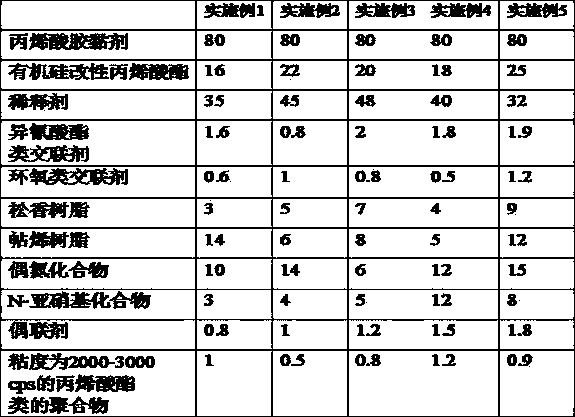

The invention discloses a mist side pressure-sensitive adhesive. The pressure-sensitive adhesive consists of the following components in parts by weight: 100 parts of an acrylic ester adhesive, 30-50 parts of a diluting agent, 0.5-2 parts of an isocyanate crosslinking agent, 0.5-2 parts of an epoxy crosslinking agent, 5-20 parts of rosin resin, 2-15 parts of an azo compound, 2-15 parts of an N-nitroso compound, 0.5-2 parts of a coupling agent and 0.3-1.5 parts of an acrylic ester polymer. The mist side pressure-sensitive adhesive realizes uniformity and a mist side of light, improves the transmittance of the light and the adhesive force between a polyester film layer and a lamp shade at the same time, has high-temperature resistance, and ensures the reliability of product performance.

Owner:太仓斯迪克新材料科技有限公司

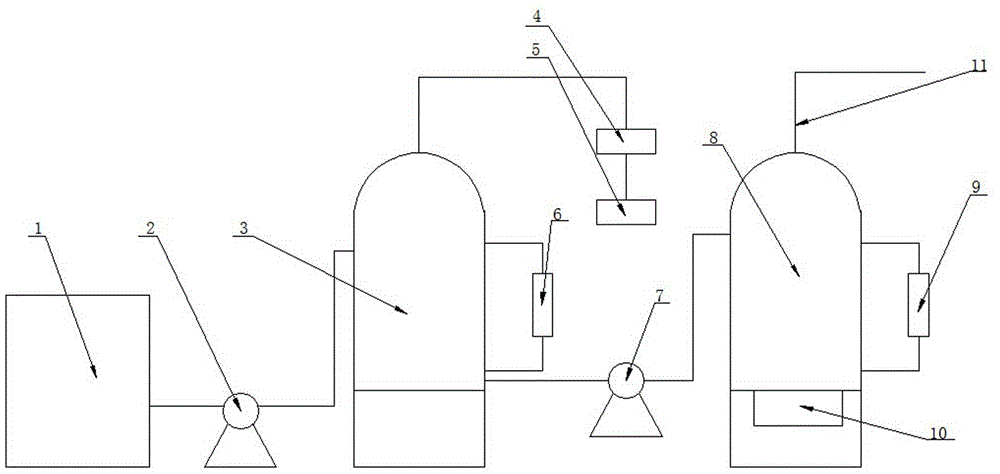

Device and process for recovering waste solvent generated in wet-process production of battery separators

ActiveCN104478150AUniform pore sizeImprove breathabilityTreatment with plural serial refining stagesMultistage water/sewage treatmentLithiumDistillation

The invention relates to a process for recovering a waste solvent generated in wet-process production of battery separators. Waste dichloromethane, wastewater and waste paraffin oil generated in extraction stage of the production process are subjected to processes including high-temperature negative-pressure distillation, a gas-phase condensation and oil-liquid separation and dichloromethane having a purity of 99.95% and paraffin oil having a purity of 99.99% are finally obtained and the wastewater meets environment-friendly emission standards. A set of recovery system disclosed by the invention has the advantages of inexpensive finished products, relatively small energy consumption and easiness in operation, has broad application prospects and brings significant cost revolution for wet-process production of domestic lithium-ion separators.

Owner:中材锂膜(常德)有限公司

Preparation method and application of desulfurization catalyst

InactiveCN108479744AIncreased Pore DistributionHigh activityDispersed particle separationCatalyst activation/preparationSteam activationActive ingredient

The invention provides a preparation method and application of a desulfurization catalyst, and belongs to the field of environmental protection. The catalyst takes coal gangue as a raw material, the coal gangue is subjected to calcining, steam activation, hole expanding and carbon skeleton structuring, and a porous C-Al2O3-SiO2 composite carrier is obtained; the active ingredients are loaded on the surface of the carrier. The catalyst is large in specific surface area and low in price, it is found through testing that the desulfurization efficiency is kept at 89.2% or above, and the time of duration exceeds 220 min; the catalyst can be widely applied to catalytic desulfurization of large flue gas emission enterprises such as steel enterprises, coal-fired power plants and the metallurgicalindustry; the catalyst preparation method provides a new way for comprehensive utilization of the coal gangue.

Owner:孙燕霞

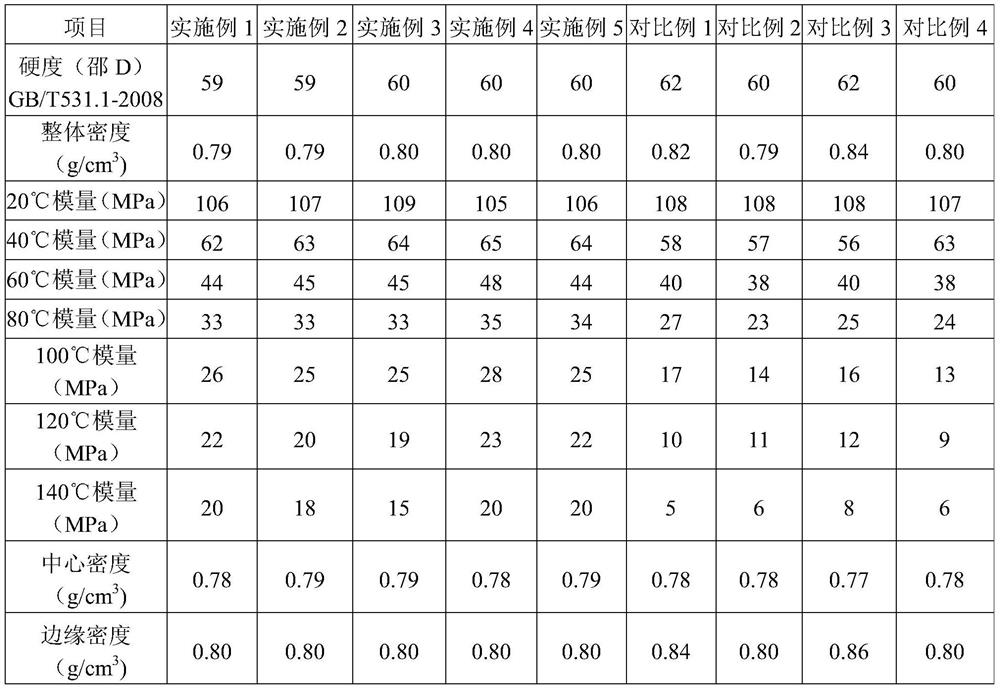

Polishing layer of chemical mechanical polishing pad and preparation method therefor

The invention discloses a polishing layer of a chemical mechanical polishing pad and a preparation method therefor. The polishing layer is prepared from raw materials containing a isocyanate prepolymer, a curing agent and a functional filler; the prepolymer is obtained by two-step reaction of diisocyanate and polytetrahydrofuran polyol; the component of the curing agent is an amine cross-linking agent; and the functional filler is an expanded polymer hollow microsphere. The polishing layer prepared thereby has the advantages that the elastic modulus changes stably along with the temperature, the porosity (the micropore volume fraction is high) is high, and the density is uniform.

Owner:万华化学集团电子材料有限公司

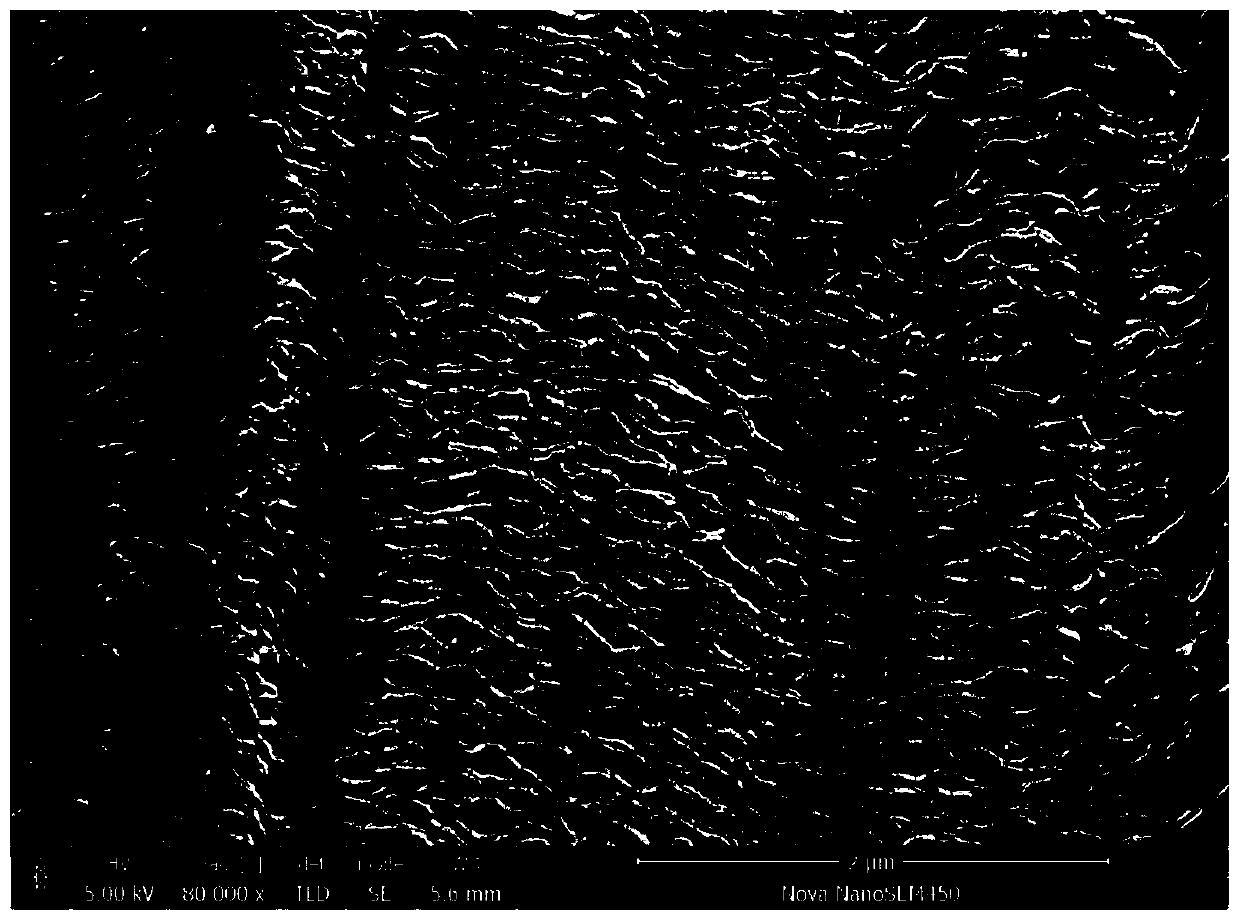

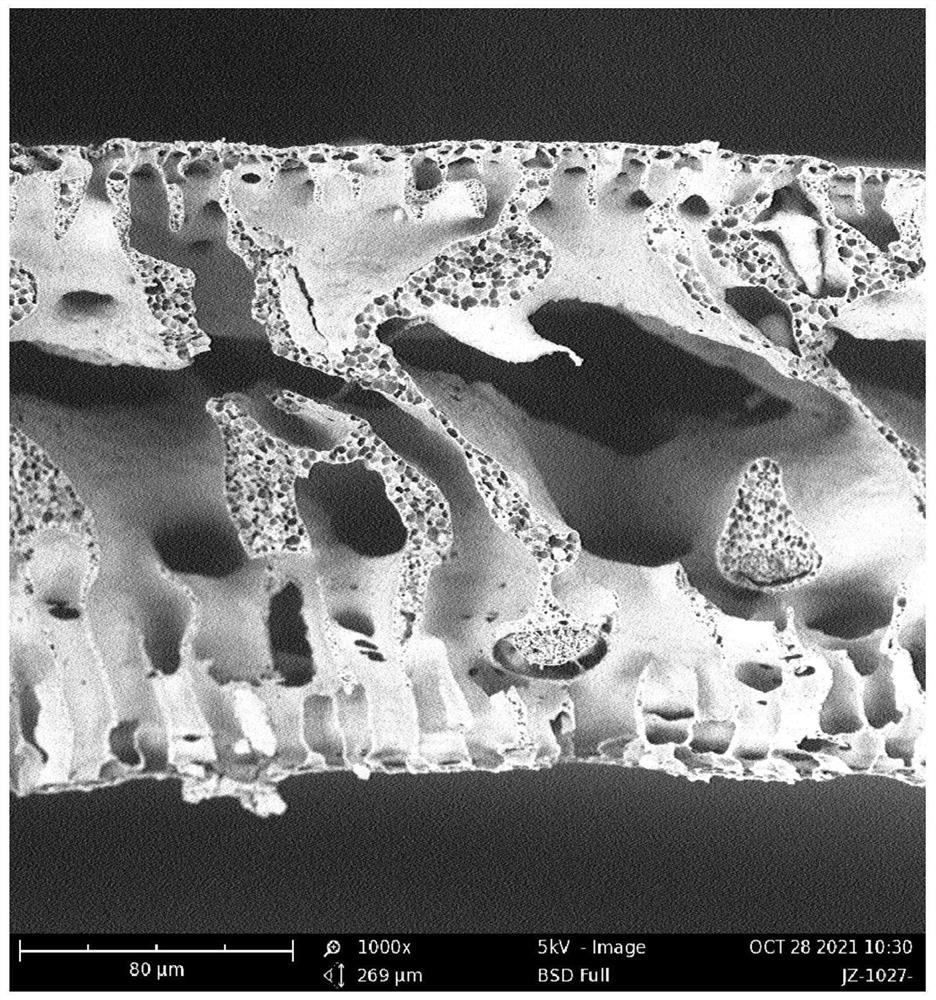

Method for preparing polyvinylidene fluoride microporous film

InactiveCN104147945ARegular structureOptimal Control StructureSemi-permeable membranesN dimethylformamideLithium chloride

The invention relates to technology for preparing a polyvinylidene fluoride microporous film. The method adopts non-water-soluble ester pore-forming additives, changes the traditional film preparation technology of immersion precipitation phase separation, and is characterized in that N,N-dimethylformamide is selected and used as a solvent, dimethyl phthalate, dibutyl phthalate and dioctyl phthalate are selected and used as pore-forming additives, and dibutyl phthalate is preferable. Compared with water-soluble inorganic salt micromolecules like lithium chloride, ammonium chloride and sodium nitrate (NaNO3), as well as low-molecular-weight water-soluble polyethylene glycol, polyvinylpyrrolidone, glycerin and the like, the film prepared by adopting the non-water-soluble ester pore-forming additives has the advantages of very regular microporous structure, even micropore distribution, narrow pore size distribution of micropores, and controllable microporous structure. In addition, the preparation method realizes low energy consumption and zero emission in a production process, the operation is simple, large-scale continuous production can be realized, the technology controllability is high, and the product is stable in quality.

Owner:BEIJING UNIV OF CHEM TECH

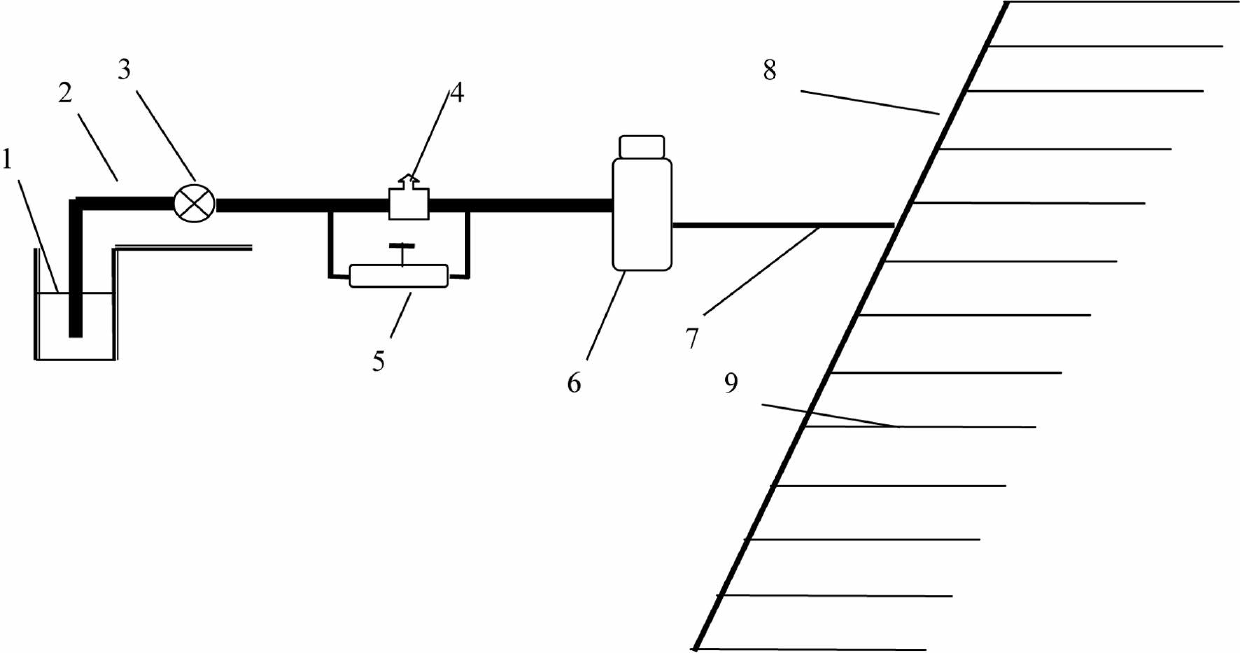

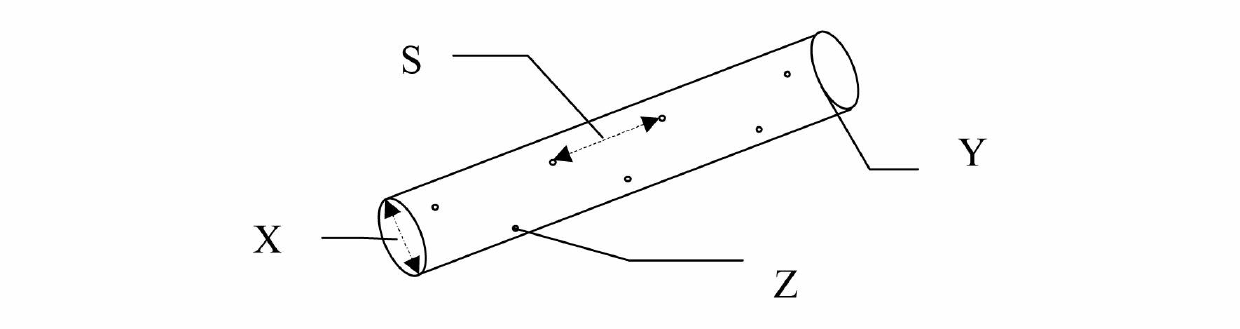

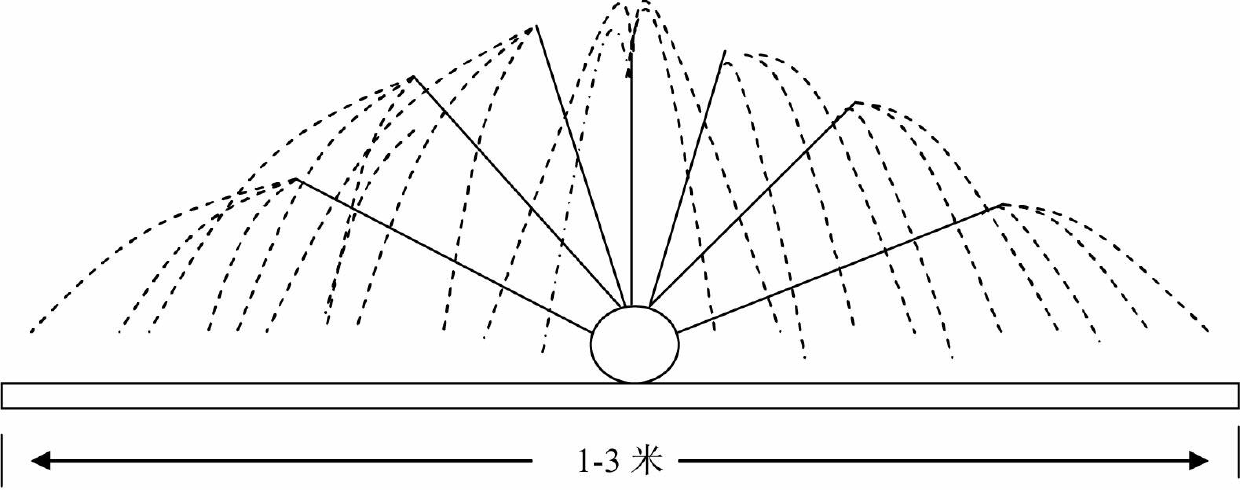

Novel micro-irrigation belt and preparation method and application thereof

InactiveCN102553740AReasonable formulaSimple production processWatering devicesSpray nozzlesAgricultural irrigationAgricultural engineering

The invention discloses a novel micro-irrigation belt and a preparation method and an application thereof. The entire novel micro-irrigation belt is a belt-shaped pipe body; the outer surface of the belt-shaped pipe body has a convex-concave structure; and the side wall of the belt-shaped pipe body is provided with a plurality of micro holes. The micro-irrigation belt comprises the following raw material components in percentage by weight: 75-90 percent of polyethylene particles, 5-10 percent of an antioxidant, 5-7 percent of EVA (Ethylene Vinylacetate) particles, 1-3 percent of a toner, 4-9 percent of an antifoaming agent and 2-6 percent of a toughening agent. In application to agricultural irrigation, the micro-irrigation belts are paved in a field at the intervals of 0.5-1 meter, are connected with a water pump through a filter, and are connected with the filter through a pipeline. The micro-irrigation belt disclosed by the invention has the advantages of reasonable formula, wide raw material source, simple production process, good anti-ageing effect and high anti-blocking performance. The surface of the micro-irrigation belt is uneven, micro holes of the micro-irrigation belt are distributed uniformly, and the micro-irrigation belt is elastic, so that high anti-ageing performance, high anti-bonding performance, uniform water dripping and high anti-blocking performance are realized, and the micro-irrigation belt is suitable for an irrigation system in which a modern cultivating way is adopted.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI +1

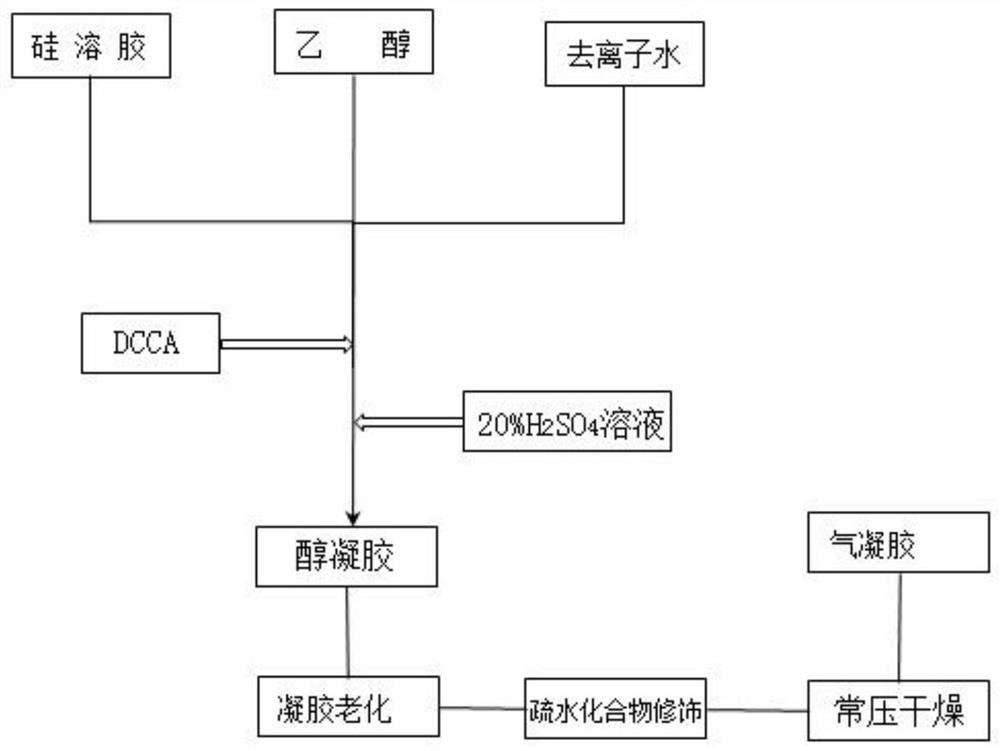

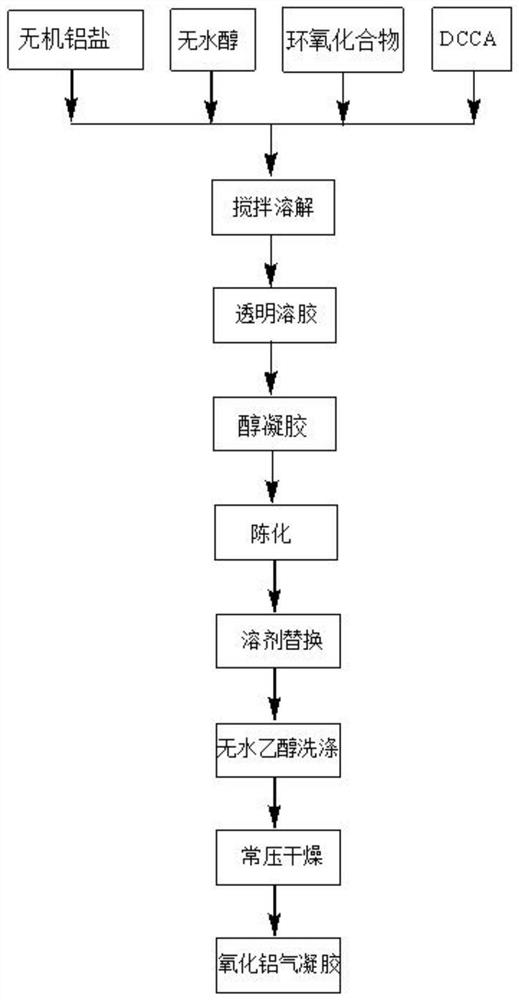

Composite aerogel thermal insulation material as well as preparation method and application thereof

ActiveCN112456961AImprove Morphological StructureImprove network structure strengthInsulation improvementSilicon compoundsThermal insulationHigh heat

The invention relates to the technical field of thermal insulation materials for aerospace, and provides a composite aerogel thermal insulation material as well as a preparation method and applicationthereof. The preparation method comprises the following steps: mixing SiO2 aerogel and Al2O3 aerogel, grinding, mixing the mixed powder with water, and carrying out thermocuring in a mold to obtain acomposite aerogel thermal insulation material, wherein the SiO2 aerogel and the Al2O3 aerogel are prepared by adopting an improved sol-gel method. By doping the Al2O3 aerogel with the SiO2 aerogel, contact points among Al2O3 aerogel particles are reduced, and surface / body diffusion is inhibited, so that high-temperature sintering and alpha conversion of Al2O3 are inhibited, and the purpose of improving the high-temperature resistance and the heat insulation performance of Al2O3 is achieved. When the composite aerogel thermal insulation material is used for thermal insulation, the external temperature of the thermal insulation material is lower than 200 DEG C under the conditions that the internal temperature is 1200 DEG C and the thickness of the thermal insulation material is 1 cm, and the aviation thermal insulation requirement can be met.

Owner:南京龙宇光电材料科技有限公司 +1

Method for triggering production of PE/PE/PE structure high-strength diaphragm through unilateral stretching

InactiveCN105161653AImprove hydrophilicityImprove conductivityCell seperators/membranes/diaphragms/spacersLi-accumulatorsSizingMaterials science

The invention discloses a method for triggering production of a PE / PE / PE structure high-strength diaphragm through unilateral stretching. The method includes the following steps of base diaphragm production, unrolling, preheating, cold stretching, hot stretching, annealing sizing and rolling. According to the method, amphiphilic compounds are added in PE materials, the hydrophilicity on the surfaces of micropores is improved, lasting hydrophilicity is achieved, the capacity of the product for adsorbing electrolyte is greatly enhanced, and the conductivity of lithium batteries is improved.

Owner:范建国

Al4O4C enhanced silicon carbide honeycomb ceramic and preparation method thereof

ActiveCN107814583AStrong thermal shock resistanceStrong thermal fatigue resistanceCeramicwareGranularityThermal expansion

The invention discloses Al4O4C enhanced silicon carbide honeycomb ceramic and a preparation method thereof. The Al4O4C enhanced silicon carbide honeycomb ceramic is prepared from raw material ingredients in parts by mass: 75 to 85 parts of first silicon carbide powder, 5 to 15 parts of second silicon carbide powder, 5 to 10 parts of Al4O4C, 2 to 6 parts of sintering aid, 12.5 to 22.5 parts of binding agent and 12.5 to 22.5 parts of water, wherein the purity of the first silicon carbide powder is 85 to 99.9wt%, the granularity of the first silicon carbide is 5 to 50mu m, the purity of the second silicon carbide is 85 to 99.9wt%, and the granularity of the second silicon carbide is 0.05 to 0.5mu m. The Al4O4C enhanced silicon carbide honeycomb ceramic disclosed by the invention has the characteristics of high raw material utilization rate and high production efficiency; furthermore, a product structure is in a wall flow type, so that purifying capacity to waste gas is improved; the product is easy to form, and a process is easy to control; the Al4O4C enhanced silicon carbide honeycomb ceramic prepared by the method has the advantages of good microstructure, even micropore distribution, high mechanical strength and low thermal expansion coefficient.

Owner:JIANGSU GAOCHUN CERAMICS

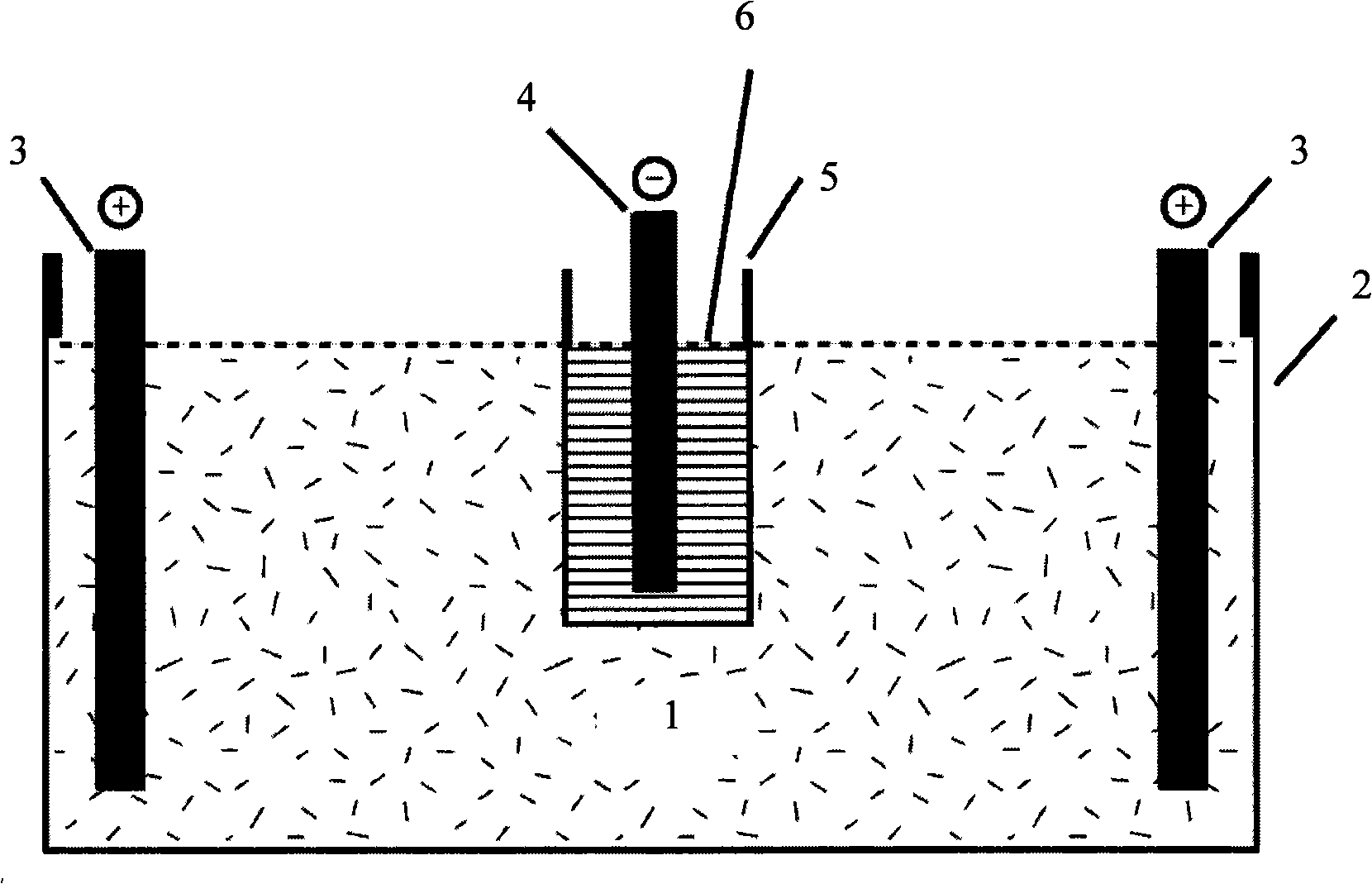

Ceramic diaphragm electrolytic cells, preparation method and application thereof

The invention discloses a ceramic diaphragm electrolytic cell, which is an open container. The materials comprise the following compositions by weight percent: 50 to 75 portions of aluminum oxides and 30 to 60 portions of silicon oxides. Moreover, the total volume of micropores of the ceramic diaphragm electrolytic cell occupies 10 to 40 percent of that of the electrolytic cell, and the aperture of the micropores is 0.3 to 1.5 micrometers. The ceramic diaphragm electrolytic cell has the advantages of low cost, uniform distribution of the micropores, singular aperture, capability of well meeting the requirement of penetration of metallic ions, simple preparation process and easy realization.

Owner:YIXING XINGGUANG CERAMICS INST

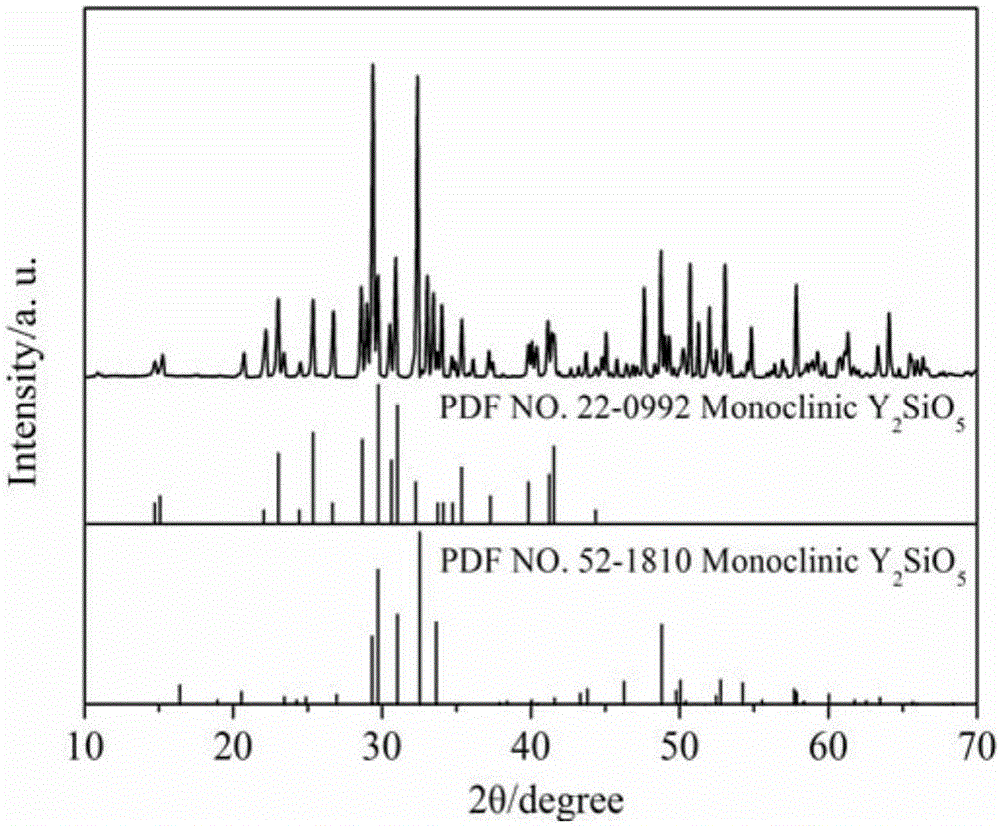

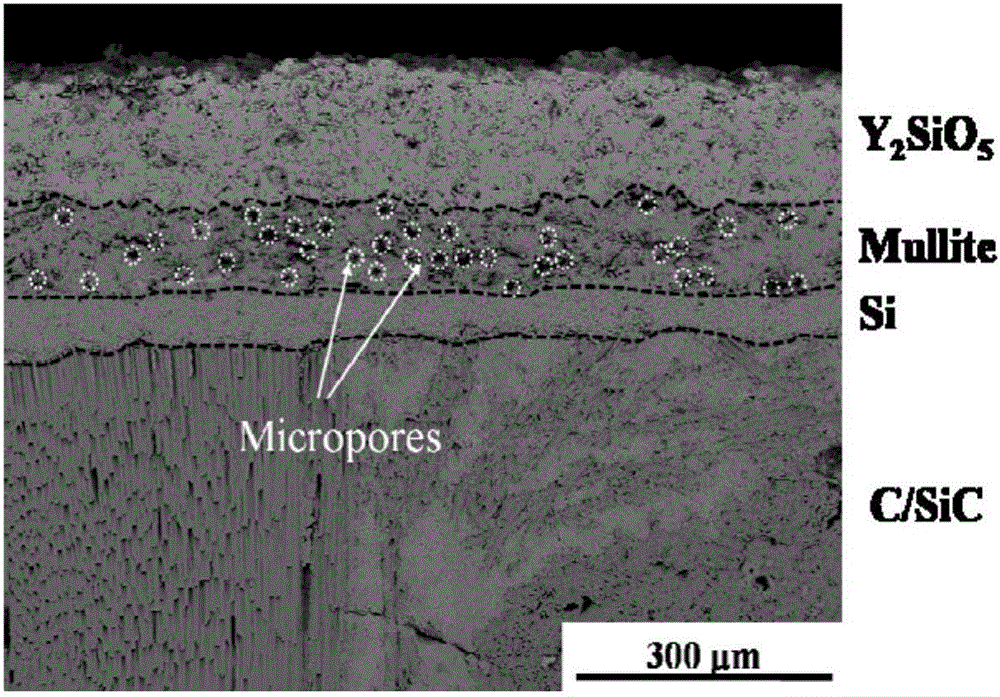

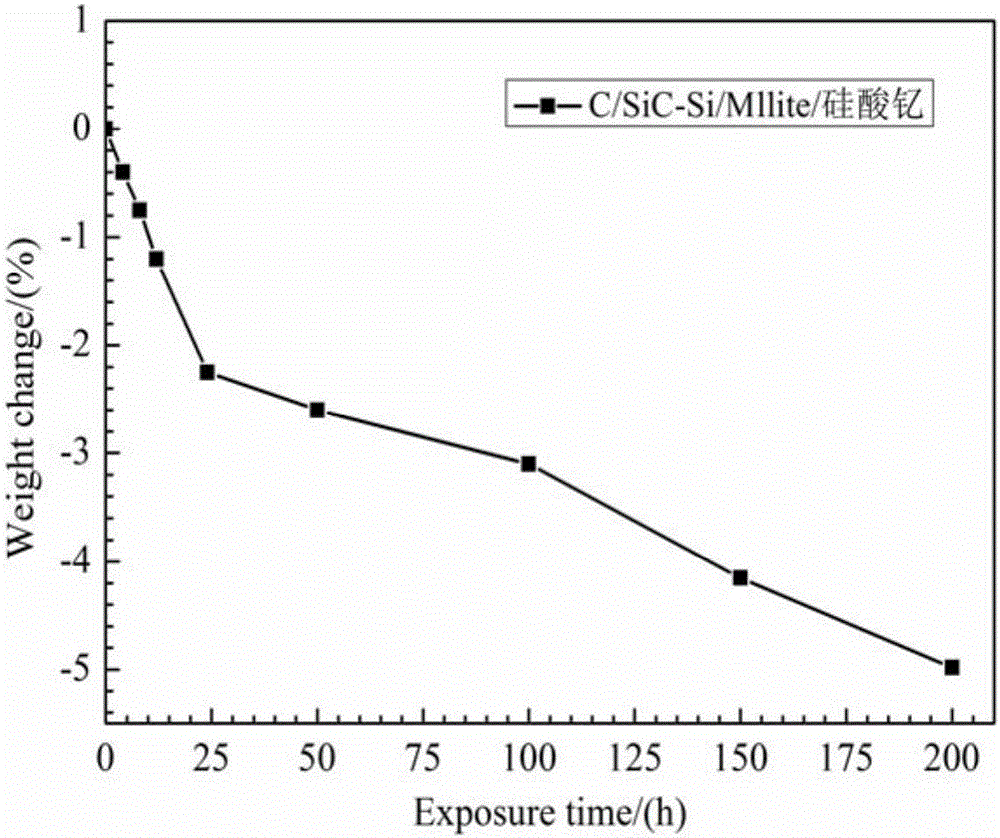

Method for preparing microstructural interlayer interface Mullite/yttrium silicate complex coating

The invention relates to a method for preparing a microstructural interlayer interface Mullite / yttrium silicate complex coating. The method comprises the steps that mullite fibers are ball-milled into powder, and the powder is dispersed into 1-methyl pyrrolidone to obtain an even suspension; a mixed adhesive is added to be mechanically stirred to be uniform, the mixture is injected to the surface of a C / SiC composite with a Si boding layer, and a mullite porous coating is obtained through sintering; yttrium nitrate hexahydrate and ethyl orthosilicate are taken to be dissolved in deionized water to obtain sol, the mullite porous coating is spin-coated with the sol after heat dipping, and repeated heat dipping-heat treatment is carried out to obtain the dense Mullite / yttrium silicate environmental barrier complex coating. Compared with the prior art, the method has the advantages that micropores are evenly distributed, interface binding is good, and crack growth is resisted.

Owner:SHANGHAI JIAO TONG UNIV

Magnesium alloy micro-arc oxidation electrolyte and preparation method thereof and magnesium alloy surface treatment method

ActiveCN110241452AEasy to produceUniform distribution of microporesAnodisationMicroballoon preparationMicro arc oxidationAnion intercalation

The invention provides magnesium alloy micro-arc oxidation electrolyte and a preparation method thereof and a magnesium alloy surface treatment method. The magnesium alloy micro-arc oxidation electrolyte comprises the following components by mass concentration: 15-70 g / L of sodium hydroxide, 5-40 g / L of sodium silicate, 5-25 g / L of sodium carbonate, 0.5-3 g / L of anionic surfactants, and 1-10 g / L of microcapsules; and the microcapsules comprise corrosion-inhibition anionic insertion layer hydrotalcite capsule cores, and capsule walls coated on the capsule cores. The magnesium alloy micro-arc oxidation electrolyte is additionally provided with a proper amount of the microcapsules with corrosion-inhibition anionic insertion layer hydrotalcite as the capsule cores; after coating layers are broken, corrosion-inhibition anions are fed in solution to exchange with Cl-; the hydrotalcite achieves an effect of covering wound surfaces of the broken coating layers; and dual effects of corrosion inhibition and self-repair of the coating layers are achieved.

Owner:JIAXING UNIV

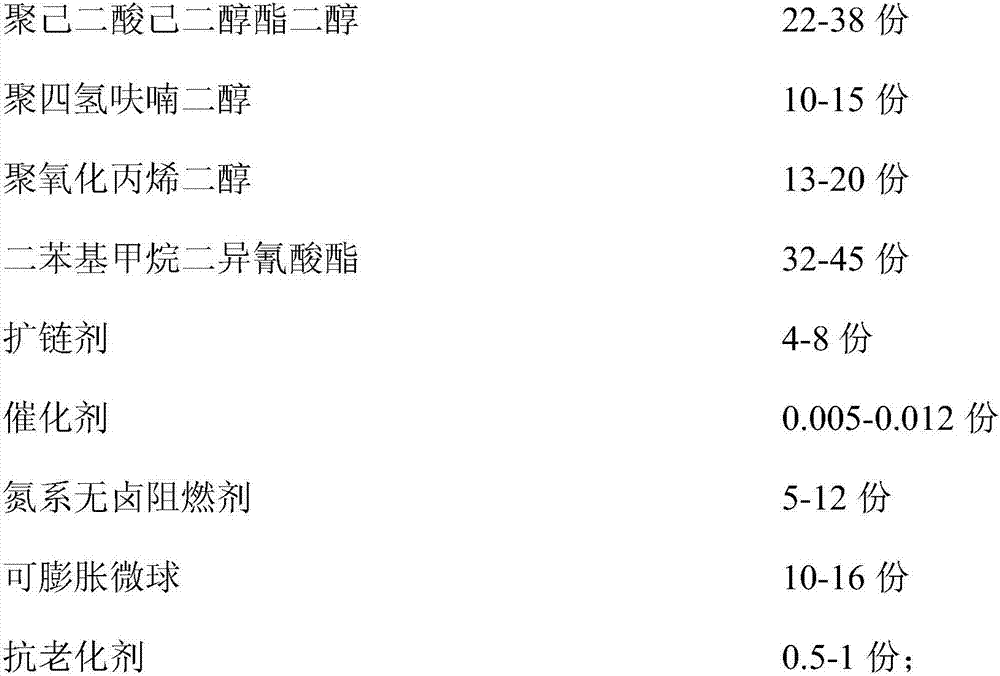

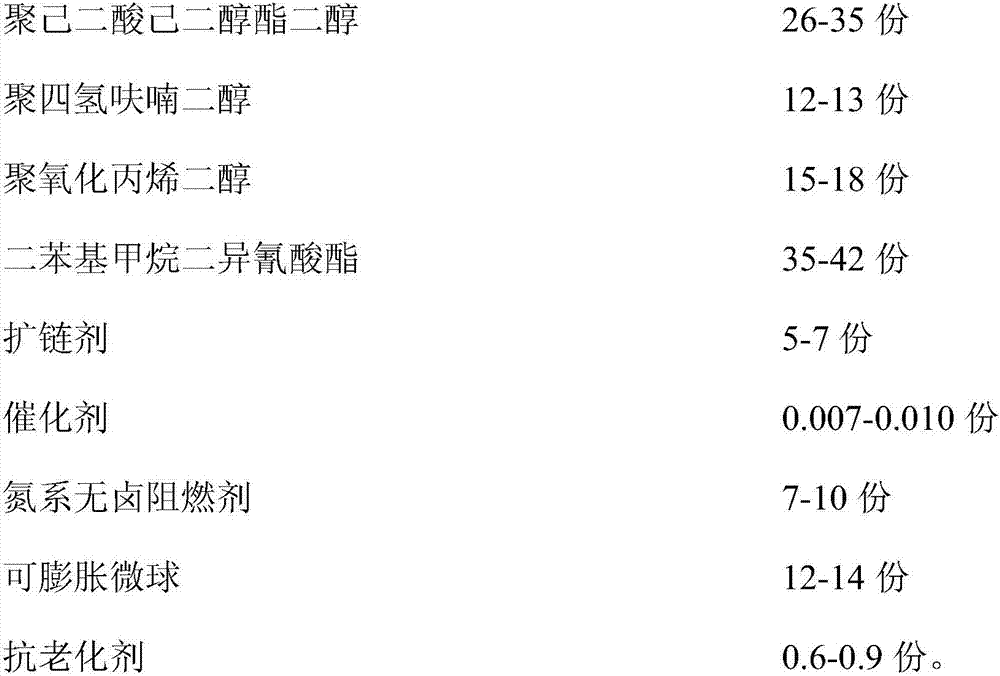

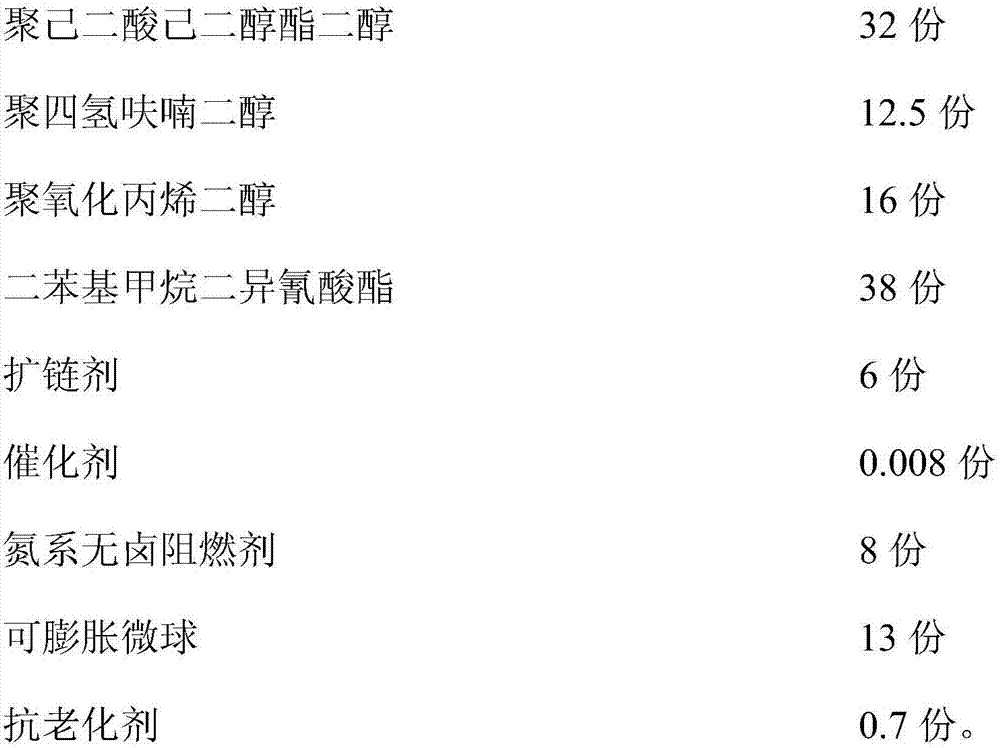

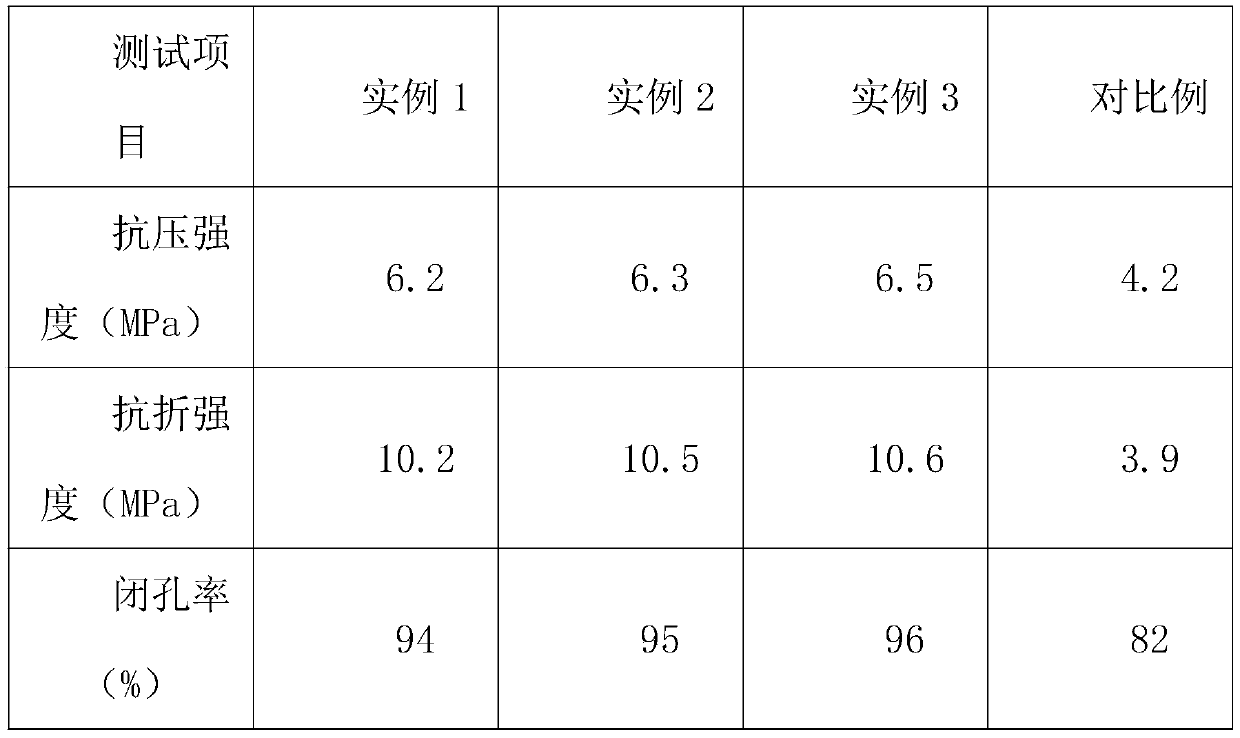

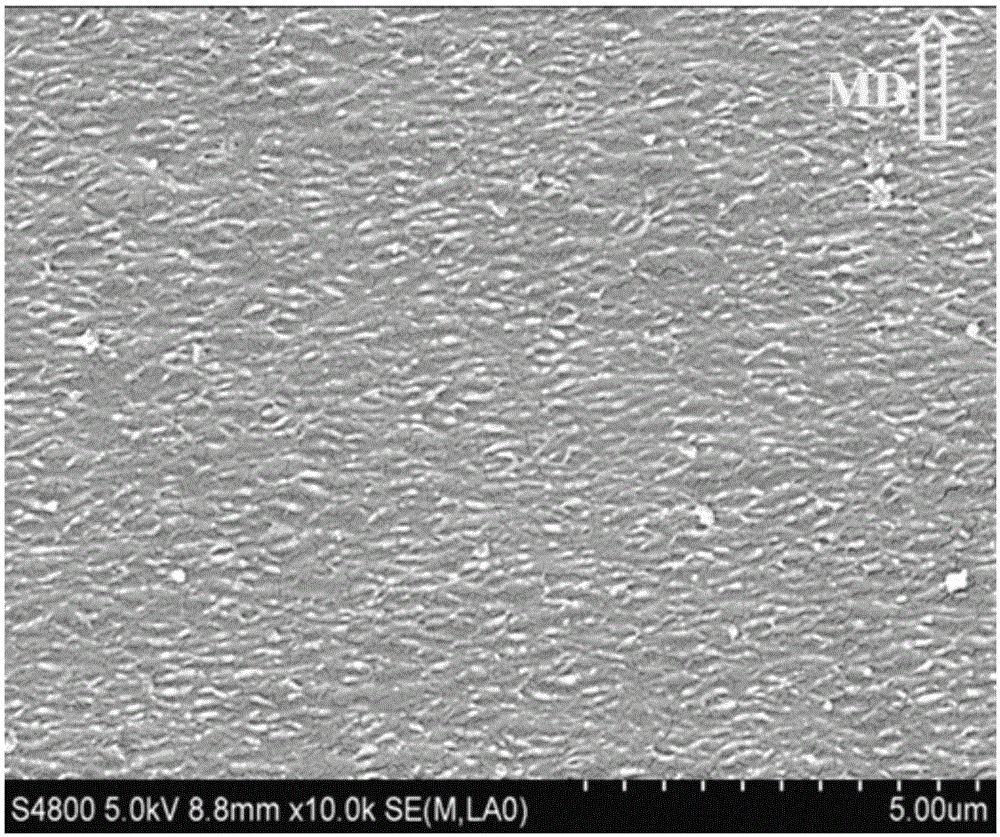

Flame retardant type thermoplastic polyurethane elastomer and preparation method thereof

The invention provides a flame retardant type thermoplastic polyurethane elastomer and a preparation method thereof. The flame retardant type thermoplastic polyurethane elastomer is prepared from the following raw materials in parts by weight: 22-38 parts of polyhexamethylene adipate glycol, 10-15 parts of polytetrahydrofuran glycol, 13-20 parts of polyoxypropylene glycol, 32-45 parts of diphenyl methane diisocyanate, 4-8 parts of a chain extender, 0.005-0.012 part of a catalyst, 5-12 parts of a nitrogen-containing halogen-free flame retardant, 10-16 parts of expandable microspheres and 0.5-1 part of an antiaging agent; and the catalyst is prepared from organic tin and organic bismuth with the mass ratio being (3-5) to 1. The thermoplastic polyurethane elastomer prepared by the invention has a micropore structure; through mutual synergistic effect of the nitrogen-containing halogen-free flame retardant and the expandable microspheres, the prepared thermoplastic polyurethane elastomer has excellent flame retardancy, good comprehensive properties and lower tension set characteristic.

Owner:俞秀英

Preparation method of aerated concrete block

InactiveCN111056811ACuring temperature loweredLow raw material costCeramic shaping apparatusCeramicwareCotton fibreBuilding material

The invention discloses a preparation method of an aerated concrete block, which belongs to the technical field of preparation of building materials. According to the invention, calcium carbide subjected to semi-dry oil surface modification is used as an air entraining agent; and a plurality of effective components are used as air inlet components. The porous rock wool fibers are coupled with themodified calcium carbide powder; the fiber strength is improved, the red mud contains aluminum oxide, calcium oxide and other metal oxides; the aluminum oxide exists in the red mud in the form of crystalline fibers; after pressing and sintering, the crystalline fibers are longitudinally oriented in the aerated concrete block and are crossed and wound with the porous rock cotton fibers in the aerated concrete block to form a woven mesh, so that the mechanical strength of the aerated concrete block is further enhanced, the heat preservation and insulation performance of the aerated concrete block is improved, and the application prospect is wide.

Owner:解正祥

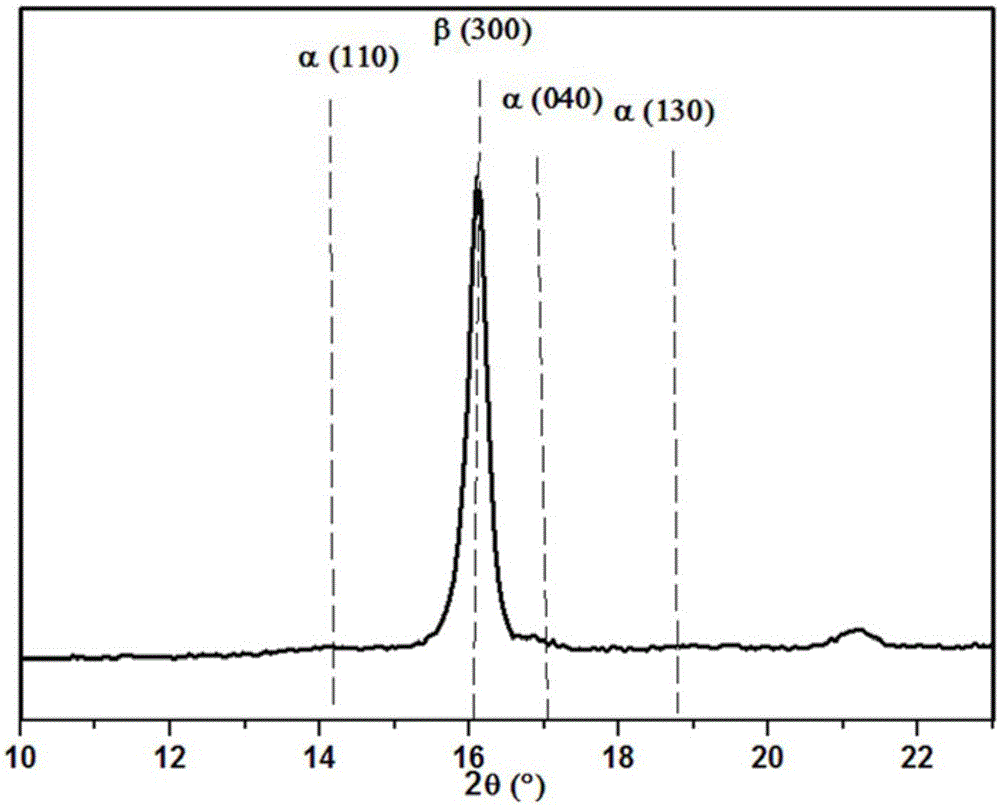

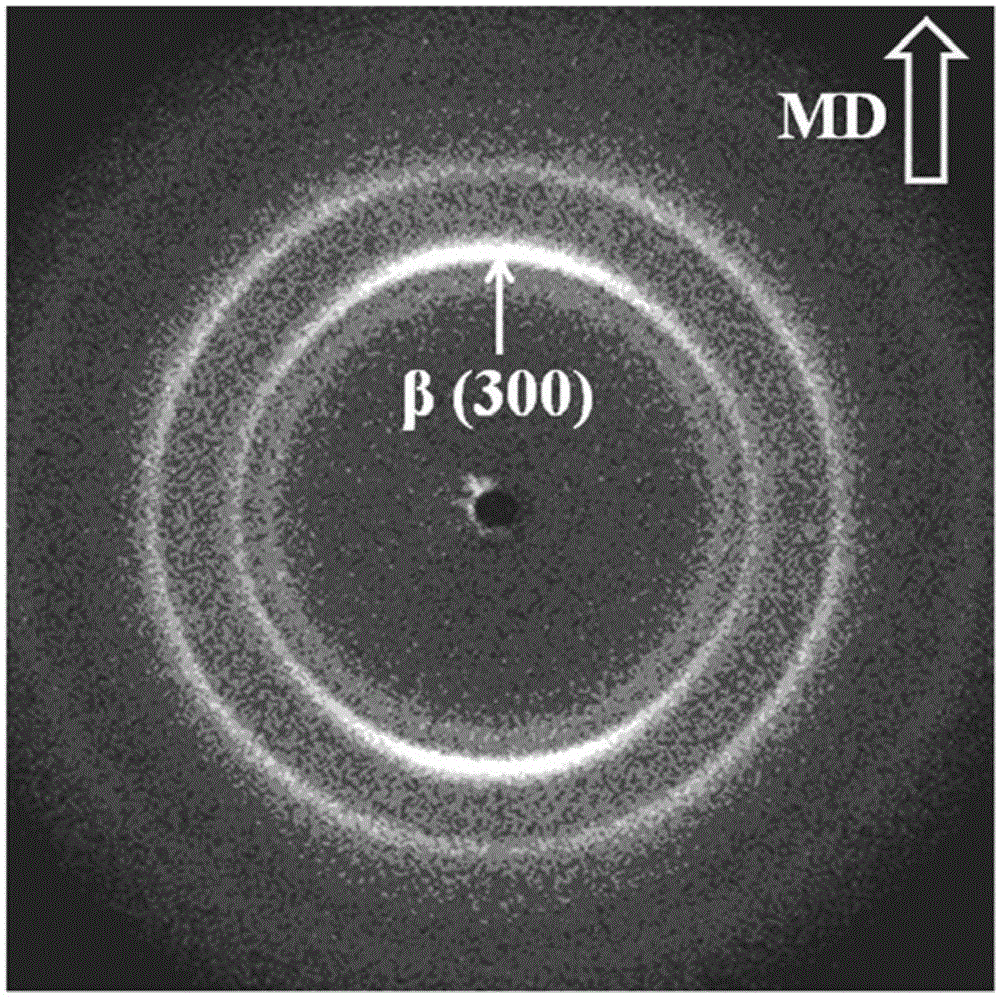

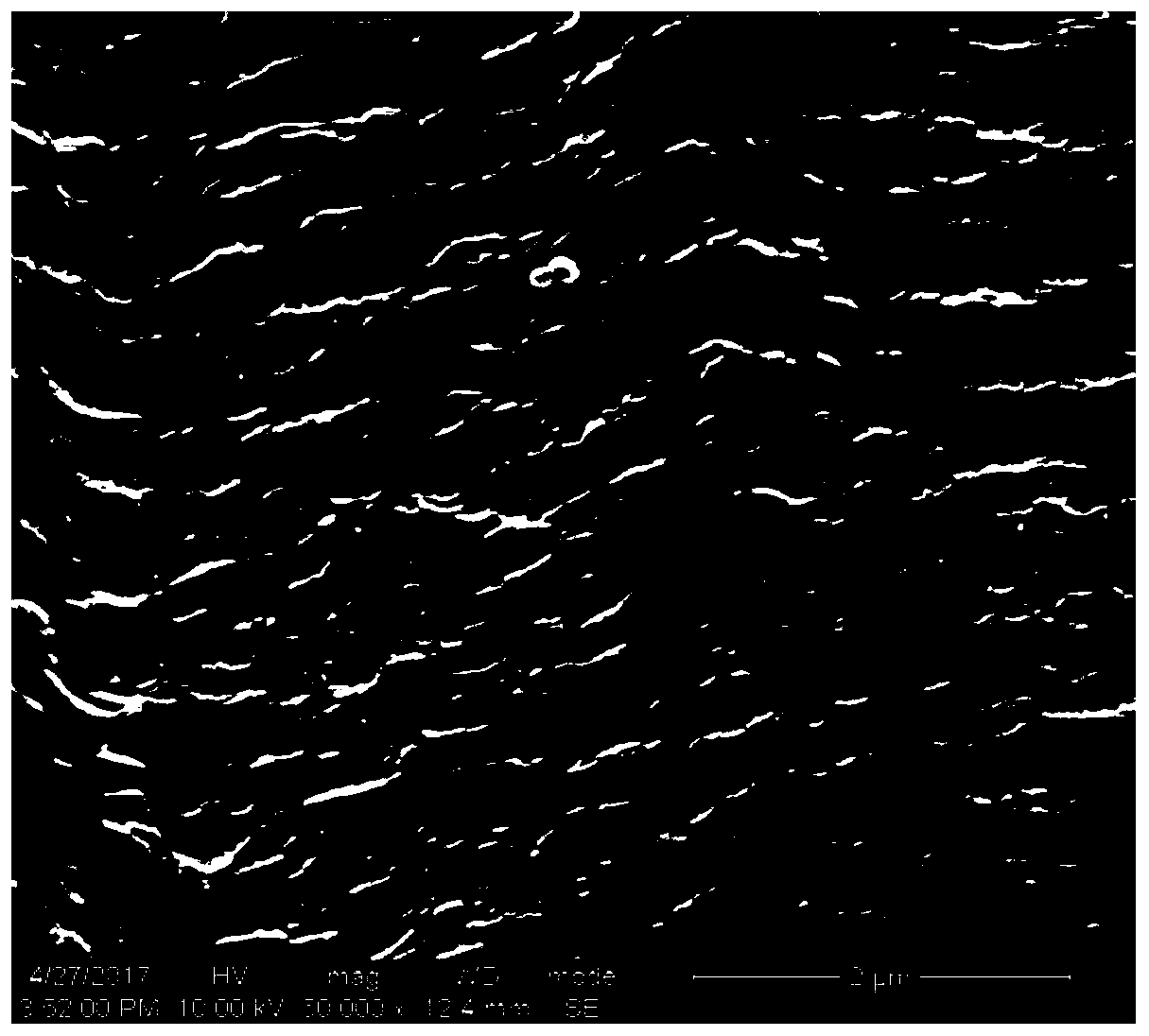

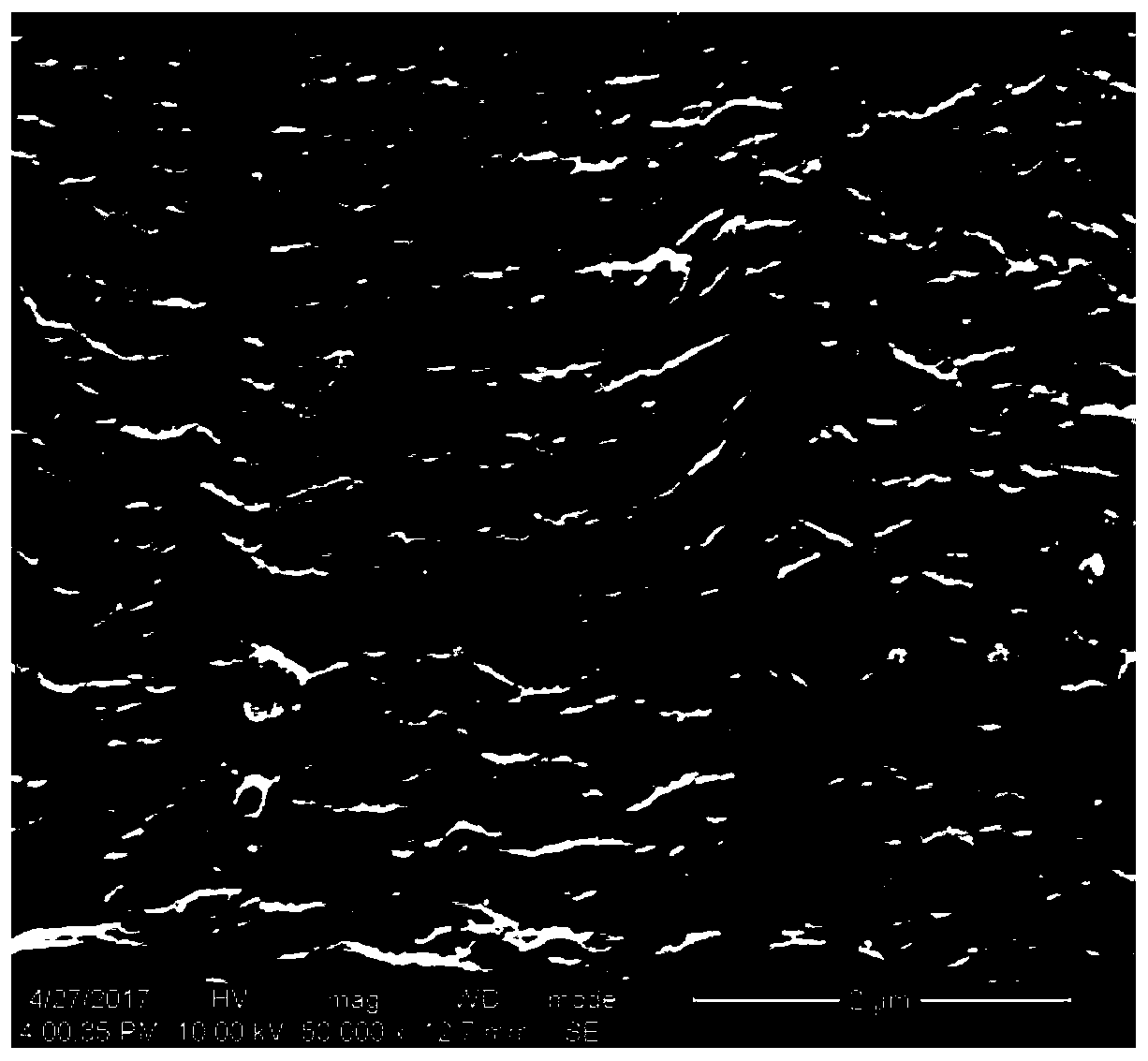

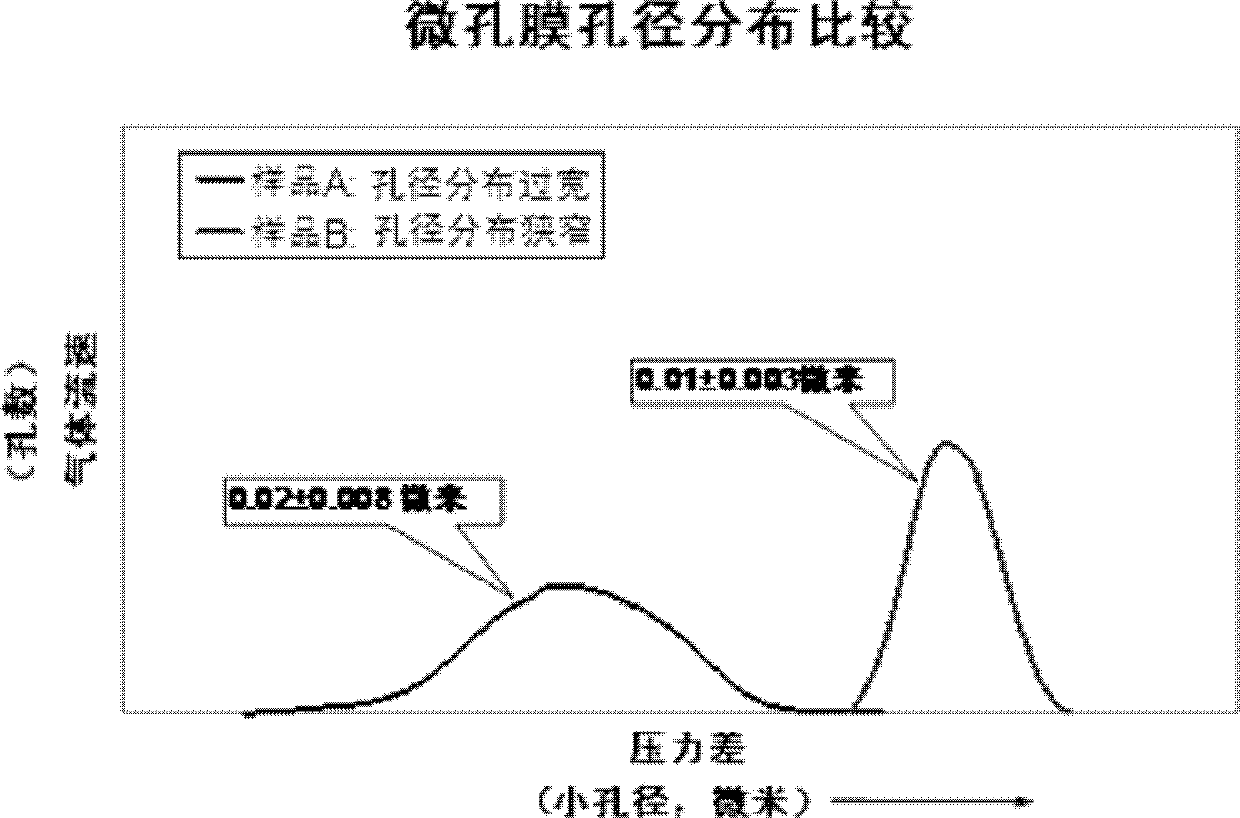

Oriented beta-polypropylene base membrane, polypropylene microporous membrane and method for manufacturing same

The invention belongs to the field of microporous membranes, and provides an oriented beta-polypropylene base membrane, a polypropylene microporous membrane and a method for manufacturing the same. The oriented beta-polypropylene base membrane comprises polypropylene and beta-crystal nucleating agents. Plate beta-crystals are distributed on membrane substrates and are oriented along directions perpendicular to an extrusion direction of the base membrane, F values of orientation degrees are 0.5-0.8, K values of relative contents of the plate beta-crystals in the base membrane are 0.7-0.95, the thickness of the base membrane is 30-50 micrometers, and the base membrane is manufactured in a blow molding membrane forming mode. The base membrane is subjected to longitudinal-transverse step-by-step bidirectional stretching and heat setting to obtain the polyethylene microporous membrane. The thickness of the microporous membrane is 8-15 micrometers, the average aperture of the microporous membrane is 20-60nm, and the porosity of the microporous membrane is 40%-50%. The oriented beta-polypropylene base membrane, the polypropylene microporous membrane and the method have the advantages that micropores are uniformly formed in the microporous membrane, the microporous membrane is narrow in aperture distribution range and is applicable to products such as lithium ion batteries and power batteries, accordingly, the uniformity of medium transmission density of battery products can be improved, and the thicknesses of the battery products can be reduced.

Owner:CHENGDU WISEDONE TECH

Ceramic diaphragm electrolytic cells, preparation method and application thereof

The invention discloses a ceramic diaphragm electrolytic cell, which is an open container. The materials comprise the following compositions by weight percent: 50 to 75 portions of aluminum oxides and 30 to 60 portions of silicon oxides. Moreover, the total volume of micropores of the ceramic diaphragm electrolytic cell occupies 10 to 40 percent of that of the electrolytic cell, and the aperture of the micropores is 0.3 to 1.5 micrometers. The ceramic diaphragm electrolytic cell has the advantages of low cost, uniform distribution of the micropores, singular aperture, capability of well meeting the requirement of penetration of metallic ions, simple preparation process and easy realization.

Owner:YIXING XINGGUANG CERAMICS INST

Preparation method of thermal insulation easy-to-cut ceramic tile

InactiveCN107586103AUniform distribution of microporesHigh porosityCeramic materials productionCeramicwareSurface energyAluminium oxide

The invention relates to the technical field of production of ceramic tiles of building materials, and particularly relates to a preparation method of a thermal insulation easy-to-cut ceramic tile. Arecycled foam sheet particle is added in the ceramic tile, and EPS in the foam sheet particle produces a foaming effect in the sintering process of the ceramic tile. Sodium lignosulphonate extracted from a corncob reduces the surface energy of the ceramic tile, the stain is prevented from invading into a micropore to cause blockage, and the purpose of thermal insulation is fulfilled. The main rawmaterial is red mud, aluminum oxide exists in the red mud in the form of a crystal fiber, the crystal fiber is longitudinally oriented in the ceramic tile after being compressed and sintered, the direction of cutting stress and the orientation direction of the crystal fiber are the same when the crystal fiber is cut by a cutting machine, the breakage of the crystal fiber is avoided in the cutting,the expansiveness of the foam sheet particle is good, the wear degree of a cutting tool is also reduced in the cutting, and the purpose that the ceramic tile is easy to cut is fulfilled.

Owner:吴亚琴

High density polyethylene lithium-ion battery separator with high porosity, and preparation method thereof

The invention belongs to the field of separators, and relates to a lithium-ion battery separator and a preparation method thereof. The invention provides a preparation method of a high density polyethylene lithium-ion battery separator with high porosity, comprising extrusion casting and stretching, wherein the stretching process adopts a uniaxial stepwise stretching method, comprising: stretchingan oriented casting base film along the casting direction at a stretching rate of 100mm / min to 300mm / min under a room temperature condition for a deformation amount of 10-60%, and performing heat setting at 120-130 DEG C; then cooling to the room temperature, and continuing to stretch the oriented casting base film along the casting direction at the same stretching rate as the first time for thesame deformation amount; stretching the oriented casting base film at a stretching rate of 30mm / min to 50mm / min for a deformation amount of 30-150%, and performing heat setting at 120-130 DEG C; and finally performing cooling to obtain the lithium-ion battery separator. The obtained separator has high porosity, uniform pore size and uniform pore distribution.

Owner:SICHUAN UNIV

Inflatable cotton bale and production method thereof

The invention discloses an inflatable cotton bale and a production method thereof, and belongs to the technical field of polyurethane foam materials. The inflatable cotton bale comprises 13-18 parts of polyether polyol, 8-10 parts of isocyanate, 0.04-0.07 part of an amine catalyst, 0.2-0.3 part of silicone oil, 1-3 parts of a foaming agent, 0.05-0.07 part of stannous octoate, 0.7-0.9 part of an opening agent, 7-9 parts of paraffin and 30-35 parts of an organic solvent, wherein the organic solvent can be used for dissolving paraffin. The method improves the tensile strength of the material, sothe cotton bale is not prone to being snapped.

Owner:泉州玺堡家居科技有限公司

Lithium ion battery diaphragm and preparation method thereof

ActiveCN102136557BUniform distribution of microporesUniform passCell component detailsPore diameterLithium-ion battery

Owner:SHANGHAI SHUANGAO ENERGY TECH

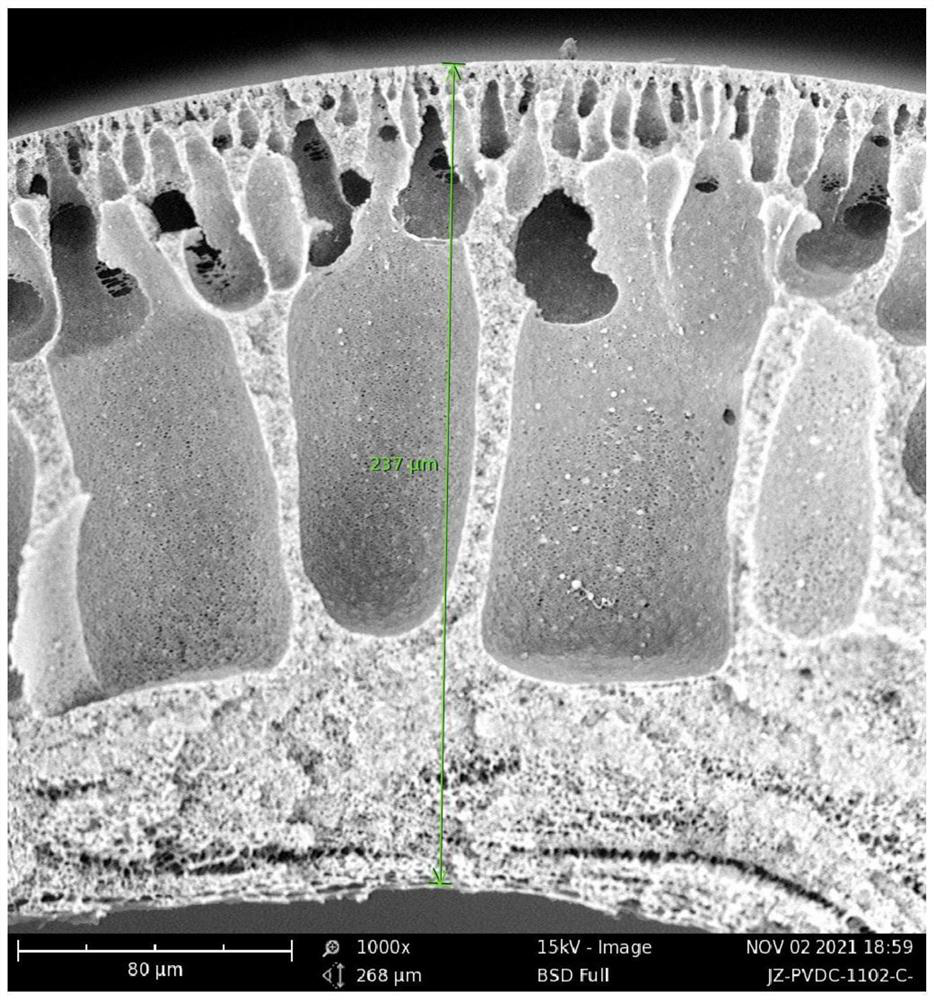

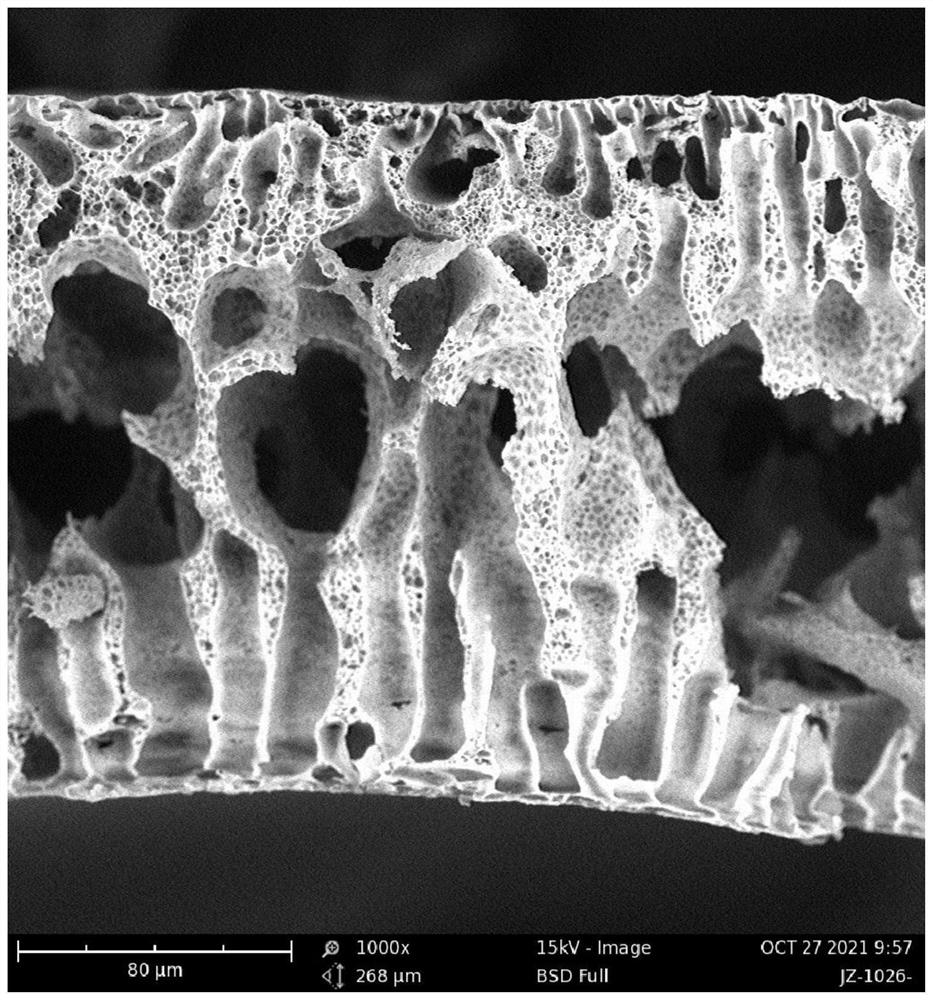

Polyvinyl butyral blending enhanced polyvinylidene chloride membrane and preparation method thereof

ActiveCN114588792AIncreased tensile elongation at breakImprove mechanical propertiesMembranesSemi-permeable membranesPolymer scienceFoaming agent

The invention relates to the field of filtering membrane materials, and discloses a polyvinyl butyral blending enhanced polyvinylidene chloride membrane and a preparation method thereof in order to solve the problem that a polyvinylidene chloride membrane in the prior art is poor in mechanical property and cannot be used as a micro-ultrafiltration membrane material. The polyvinylidene chloride / polyvinyl butyral composite material is prepared from the following components: 10 to 30 wt% of polyvinylidene chloride, 0.1 to 10 wt% of polyvinyl butyral, 0.5 to 20 wt% of a pore-foaming agent, 0.5 to 10 wt% of an additive and 50 to 80 wt% of a solvent. The polyvinyl butyral and the polyvinylidene chloride are blended, so that the tensile elongation at break of the polyvinylidene chloride film is enhanced, the mechanical property of the polyvinylidene chloride film is improved, micropores in the prepared polyvinylidene chloride film are uniformly distributed, the pore size is controllable, the preparation steps are simple, the cost is low, and industrial production can be realized.

Owner:NINGBO SHUIYI FILM TECH DEV CO LTD

Magnesium alloy micro-arc oxidation method and micro-arc oxidation electrolyte

PendingCN114540905AUniform distribution of microporesReduce roughnessAnodisationElectrolytic agentMicro arc oxidation

The invention discloses a magnesium alloy micro-arc oxidation method and a micro-arc oxidation electrolyte. The micro-arc oxidation electrolyte comprises 15-75 g / L of sodium hydroxide, 5-40 g / L of sodium metasilicate, 10-45 g / L of sodium tetraborate, 3-8 g / L of sodium tartrate, 0.5-2 g / L of a nonionic surfactant and 1-10 g / L of microcapsules. The microcapsule is a layer-by-layer self-assembled microcapsule, and the corrosion inhibitor in the microcapsule is a mixture of 2-mercaptobenzothiazole and 8-hydroxyquinoline. The magnesium alloy is pretreated and then serves as an anode to be placed in magnesium alloy micro-arc oxidation electrolyte, stainless steel serves as a cathode, constant-current micro-arc oxidation is conducted, and the micro-arc oxidation coating is formed on the surface of the magnesium alloy. The micro-arc oxidation coating contains the layer-by-layer self-assembly microcapsules, and the self-repairing problem of local damage of the micro-arc oxidation coating can be further solved.

Owner:JIAXING UNIV

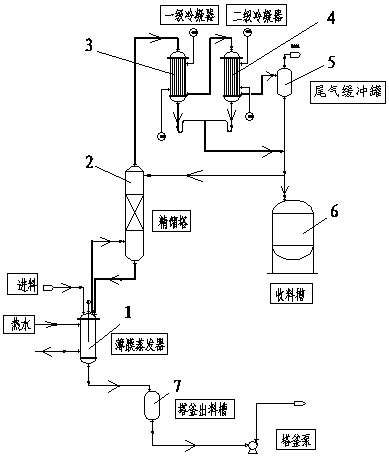

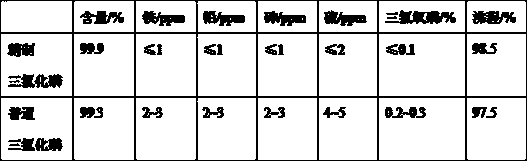

Phosphorus trichloride refining equipment and technology

PendingCN109775676AQuality improvementImprove qualityPhosphorus halides/oxyhalidesRefluxBoiling point

The invention discloses refining equipment of phosphorus trichloride, which comprises a thin film evaporator, a distillation tower, a first-stage condensing device, a second-stage condensing device and a high boiling point receiving tank. The thin film evaporator, the distillation tower, the first-stage condensing device, the second-stage condensing device and the high boiling point receiving tankare connected sequentially with pipes. A receiving line is arranged at the bottom of the first- stage condensing device and the second-stage condensing device to directly connect with the high boiling point receiving tower, and a branch of the receiving line is connected with the thin film evaporator. An air outlet is arranged on the second-stage condensing device to connect with an exhaust gas buffer tank. A reflux port is arranged at the bottom of the rectifying tower to connect with a reflux inlet of the thin film evaporator. A discharge port is arranged at the bottom of the thin film evaporator to connect with a tower discharge tank. Brine at -10 oC is used as a condensate in the secondary condensing device. According to the phosphorus trichloride refining equipment and technology, the content of yellow phosphorus purchased from abroad is higher than 99.9% after special refining treatment and the content of the special key ions arsenic is reduced to 4ppm, thus the quality of phosphorus trichloride produced is very high.

Owner:NANTONG JIANGSHAN AGROCHEM & CHEM LIMITED LIABILITY

Corrosion-inhibiting microcapsules, preparation method thereof, magnesium alloy micro-arc oxidation electrolyte containing same and application thereof

ActiveCN110241424BInhibit expansionPlay a self-healing functionAnodisationElectrolytic agentMicro arc oxidation

The invention provides corrosion-inhibiting microcapsules, a preparation method thereof, a magnesium alloy micro-arc oxidation electrolyte containing the same, and applications. The preparation method of the invention comprises the following steps: adding polyvinyl alcohol, urea, ammonium chloride, resorcinol and an emulsifier into water for mixing, adjusting pH to alkaline, and reacting; adding linseed oil and a corrosion inhibitor to the reaction solution, an emulsion is obtained; formaldehyde is added to the obtained emulsion and reacted; the pH is adjusted to acidity, and the reaction is continued; the reaction solution is cooled, separated, purified and dried to obtain corrosion-inhibited microcapsules. The magnesium alloy micro-arc oxidation electrolyte of the invention does not contain harmful elements such as Cr, P, F, etc., which provides an application basis for the industrialization direction of the magnesium alloy micro-arc oxidation of environmental protection and pollution-free; at the same time, it can be used on the surface of magnesium alloy. A coating with uniform micropore distribution, small roughness and good corrosion resistance is formed; since the micro-arc oxidation coating contains corrosion-inhibiting microcapsules, it can still provide long-term protection for magnesium alloys after the coating is damaged.

Owner:JIAXING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com