Oriented beta-polypropylene base membrane, polypropylene microporous membrane and method for manufacturing same

A technology of polypropylene microporous film and polypropylene base film, which is applied in the field of microporous film, can solve the problems of poor micropore distribution uniformity, difficult industrial production, and insufficient relative content of β crystals, etc., and achieve uniform deformation mode and high orientation degree , the effect of narrow pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

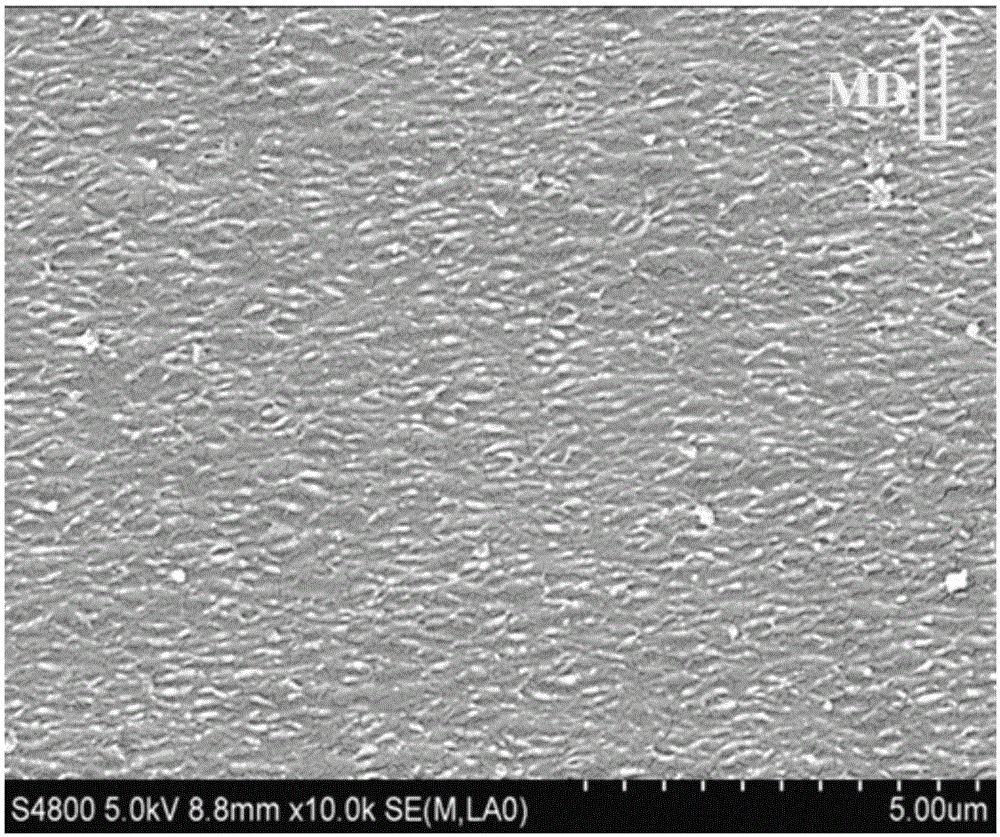

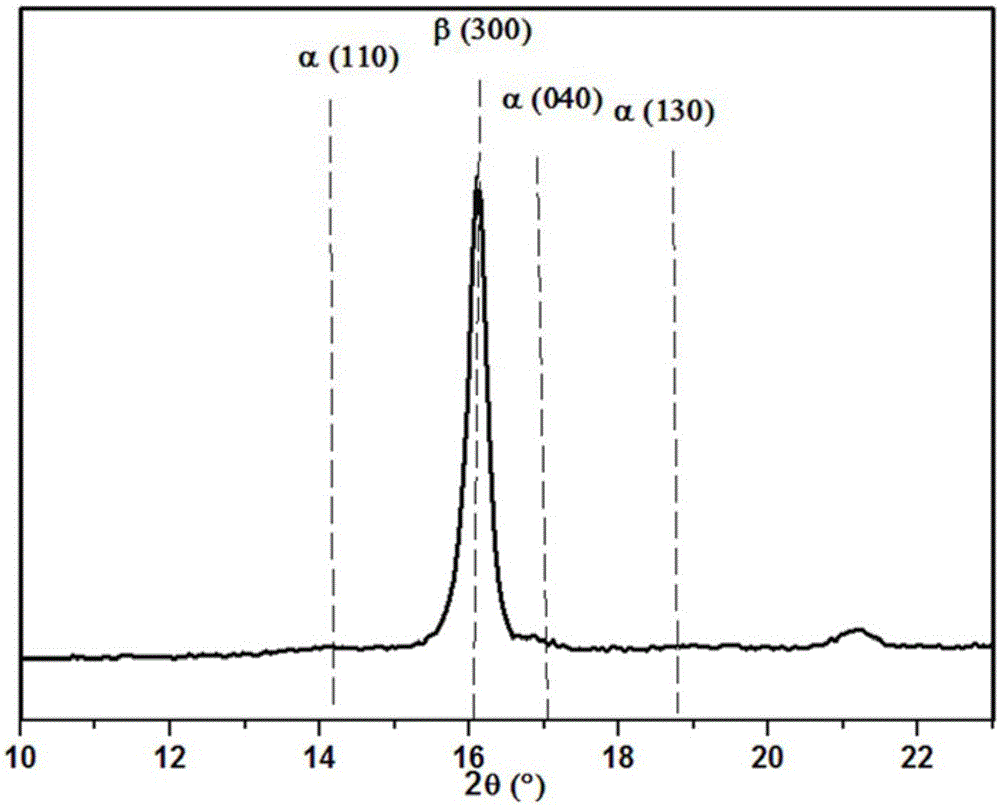

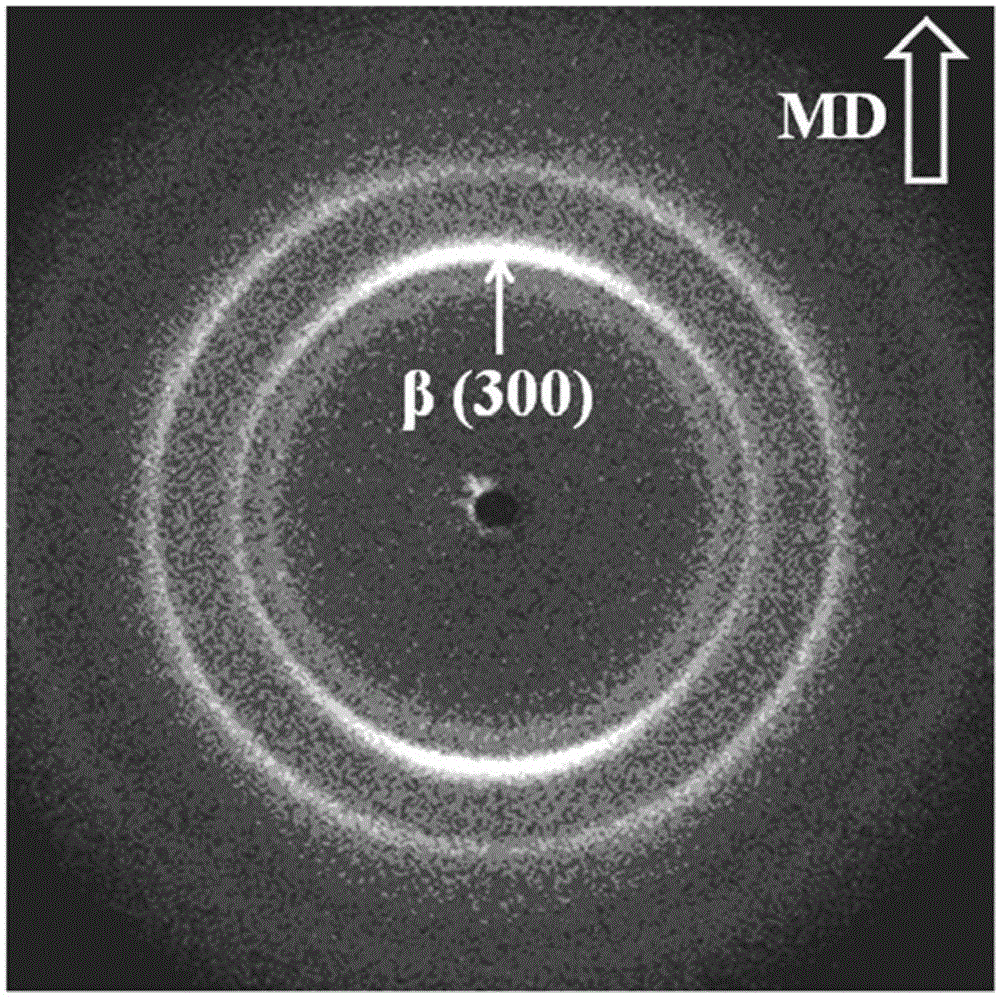

[0031] In this example, an oriented β-polypropylene base film was prepared, and a polypropylene microporous film was further prepared from the base film, and the steps were as follows:

[0032](1) After mixing raw material polypropylene and β crystal form nucleating agent calcium pimelate, a mixture is formed, and the content of calcium pimelate in the mixture is 0.1wt%, and the mixture is added to a twin-screw extruder Medium-melt plasticization, the temperature of the five sections of the twin-screw extruder from the hopper to the die is set to 160°C, 200°C, 240°C, 240°C, and 230°C, and the melt obtained by melting and plasticizing is set at a screw speed of 30rpm Extrude through an annular die with a diameter of 1.5mm to form a tube blank, and at the same time supply air to the annular die to inflate the tube blank to form a film tube. The film tube is cooled and flattened to obtain an oriented β-polypropylene base film.

[0033] (2) The oriented β-polypropylene base film ...

Embodiment 2

[0037] In this example, an oriented β-polypropylene base film was prepared, and a polypropylene microporous film was further prepared from the base film, and the steps were as follows:

[0038] (1) After mixing raw material polypropylene and β crystal form nucleating agent calcium pimelate, a mixture is formed, and the content of calcium pimelate in the mixture is 0.2wt%, and the mixture is added to a twin-screw extruder Medium-melt plasticization, the temperature of the five sections of the twin-screw extruder from the hopper to the die is set to 160°C, 200°C, 240°C, 240°C, and 230°C, and the melt obtained by melting and plasticizing is set at a screw speed of 30rpm Extrude through an annular die with a diameter of 1.5mm to form a tube blank, and at the same time supply air to the annular die to inflate the tube blank to form a film tube. The film tube is cooled and flattened to obtain an oriented β-polypropylene base film.

[0039] (2) The oriented β-polypropylene base film...

Embodiment 3

[0043] In this example, an oriented β-polypropylene base film was prepared, and a polypropylene microporous film was further prepared from the base film, and the steps were as follows:

[0044] (1) raw material polypropylene is mixed with beta crystal form nucleating agent calcium suberate to form compound, the content of calcium suberate in this compound is 0.3wt%, described compound is added twin-screw extruder Medium-melt plasticization, the temperature of the five sections of the twin-screw extruder from the hopper to the die is set to 160°C, 200°C, 240°C, 240°C, and 230°C, and the melt obtained by melting and plasticizing is set at a screw speed of 30rpm Extrude through an annular die with a diameter of 1.5mm to form a tube blank, and at the same time supply air to the annular die to inflate the tube blank to form a film tube, control the inflation ratio to 6, and the height of the condensation line to be 5cm, and then pass through the chill roll. The film tube is cooled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com