High density polyethylene lithium-ion battery separator with high porosity, and preparation method thereof

A technology of high-density polyethylene and lithium-ion batteries, which is applied to battery pack parts, circuits, electrical components, etc., can solve the problems of different pore sizes, uneven distribution, and excessive local resistance, etc. Different sizes, uniform micropore distribution, and the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

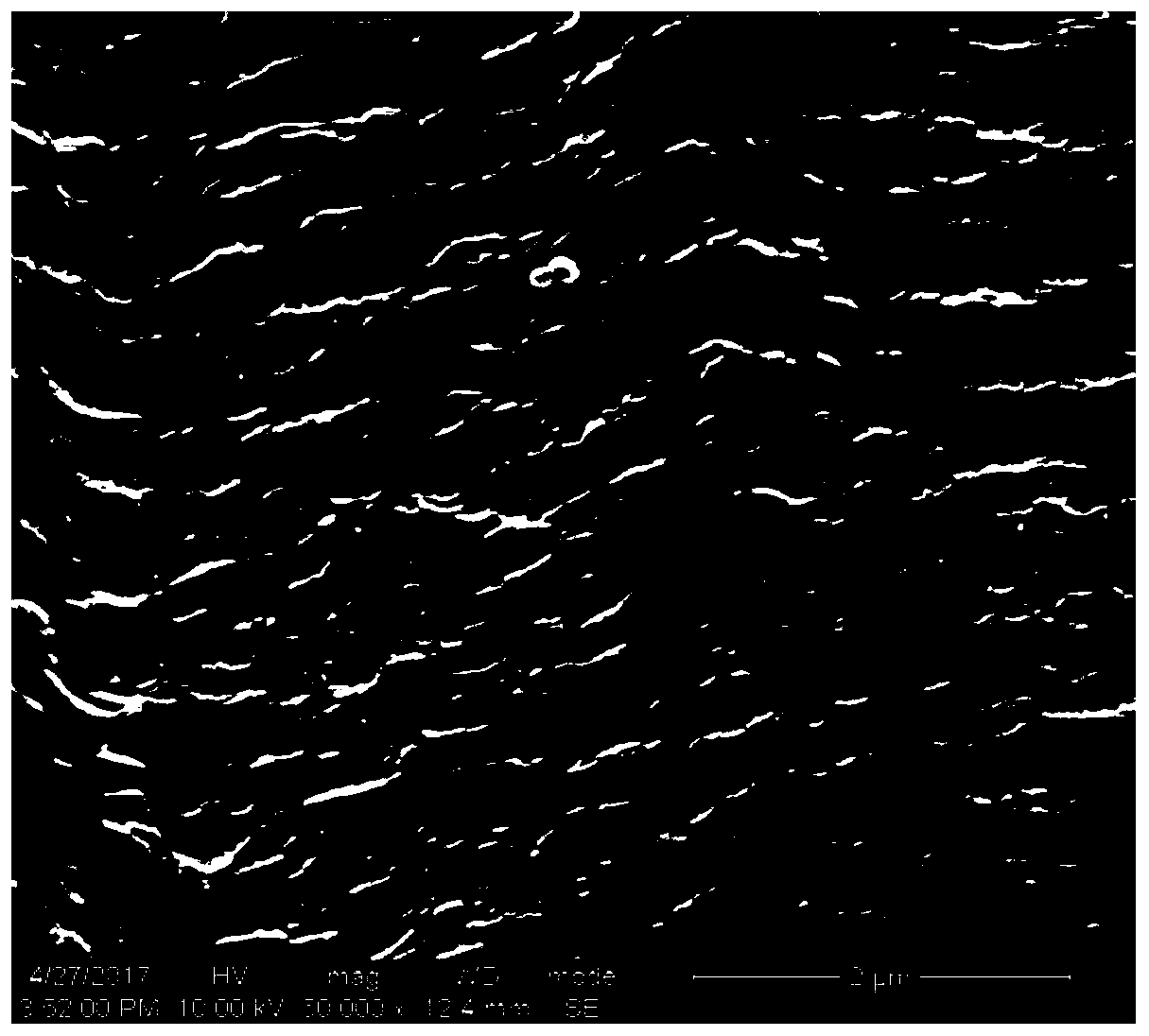

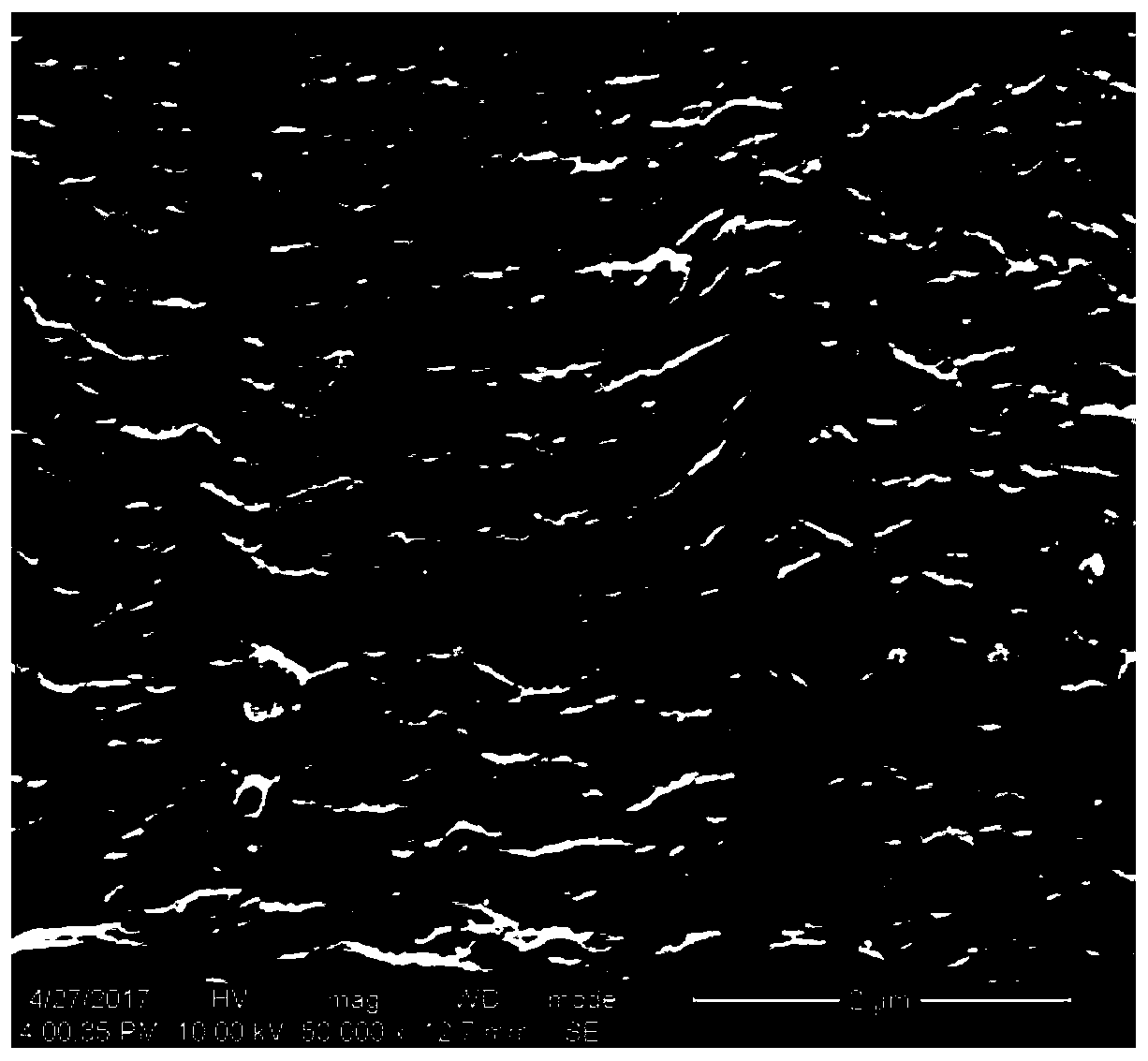

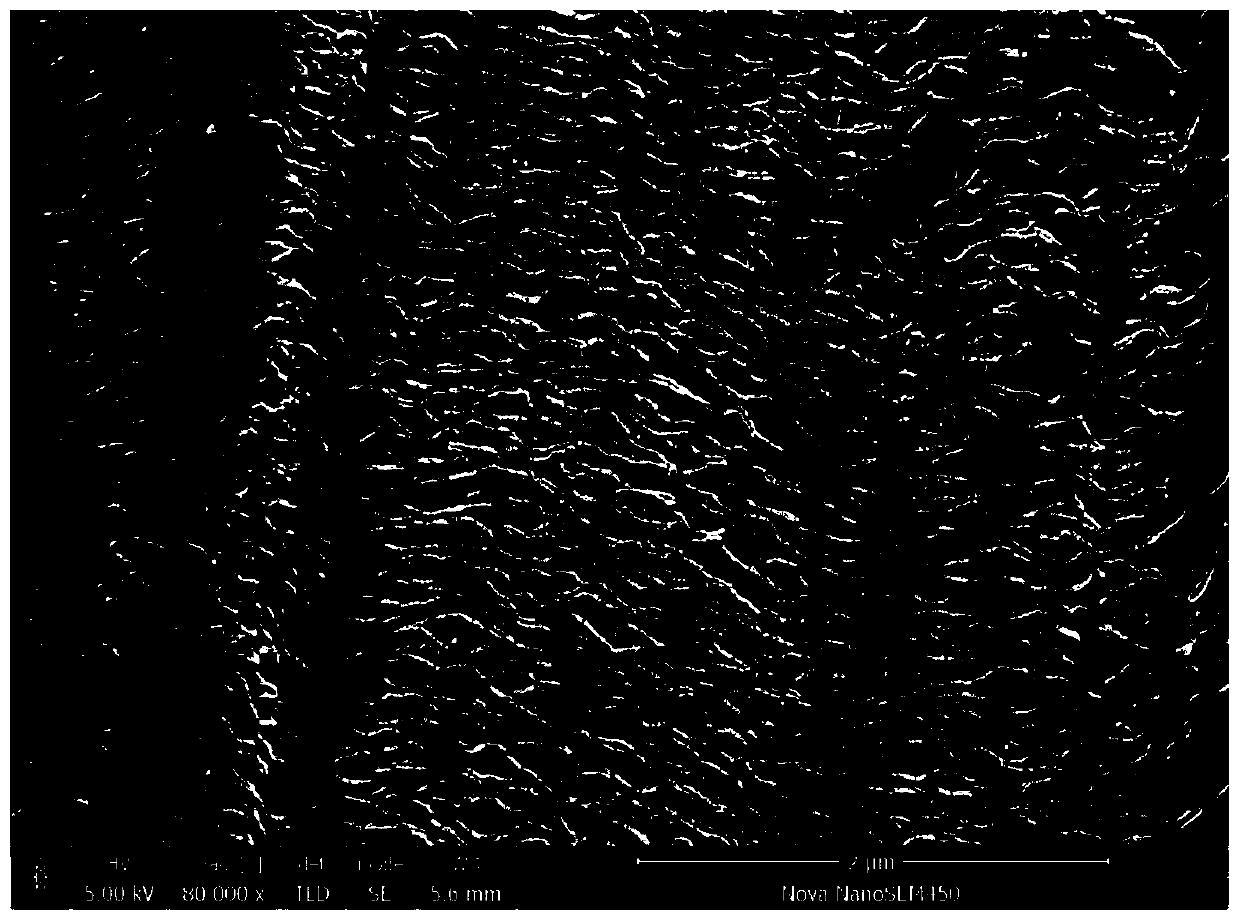

[0031] The invention provides a preparation method of a high-density polyethylene lithium-ion battery diaphragm, including extrusion casting and stretching, wherein the stretching process adopts a uniaxial stepwise stretching method, specifically: The oriented casting base film prepared by casting is stretched at a stretching rate of 100 mm / min to 300 mm / min at room temperature to obtain a strain of 10% to 60% along the casting direction to obtain initial micropores, and then stretched at 120 Fix the initial micropores by heat setting at ℃~130℃; then cool down to room temperature, and then continue to stretch along the casting direction at 80℃~100℃ at a tensile speed of 30mm / min~50mm / min for 30%~150 % strain to expand the initial micropores, and then heat-fixed at 120°C to 130°C (that is, stretching and heat-fixing steps again), and finally cooled to obtain a high-density polyethylene lithium-ion battery separator.

[0032] The purpose of the present invention is to solve the ...

Embodiment 1

[0042] A preparation method of a high-porosity HDPE lithium-ion battery separator, comprising the steps of:

[0043] 1) Preparation of highly oriented HDPE preset film: Add the screened HDPE (weight-average molecular weight of 200,000-500,000, Mw / Mn=5-12) into a twin-screw extruder for pre-mixing to form a HDPE pre-mixed master material; then the prepared masterbatch is uniformly plasticized by a single-screw extruder, the temperature of the single-screw extruder is set to 120°C, 190°C, 200°C, and the die temperature is 190°C; the speed of the extruder is 20rpm / min; the roll speed of the three-roll calender is 50mm / s, the roll temperature of the upper and middle rolls of the calender is set at 90°C, adjust the speed of the three-roll calender, and the prepared preset film The thickness is controlled at 40μm; the degree of orientation is 0.34;

[0044] 2) Preparation of microporous membrane: Stretch the prepared preset membrane to a strain of 30% at a stretching rate of 200mm / ...

Embodiment 2

[0046] A preparation method of a high-porosity HDPE lithium-ion battery separator, comprising the steps of:

[0047] 1) Preparation of highly oriented HDPE preset film: Add the screened HDPE to a twin-screw extruder for premixing to form a HDPE premix masterbatch; then uniformly plasticize the prepared masterbatch through a single-screw extruder. The temperature of the screw extruder is set to 120°C, 190°C, 200°C, and the die temperature is 190°C; the speed of the extruder is 10rpm / min; the roll speed of the three-roll calender is 50mm / s, Set the roll temperature of the middle two rolls to 90°C, adjust the speed of the three-roll calender, and control the thickness of the prepared preset film at 20 μm;

[0048] 2) Preparation of microporous membrane: Stretch the prepared pre-membrane to a strain of 20% at a stretching rate of 200mm / min at room temperature, heat-set at 120°C for 10min, and then cool down to room temperature , and at this temperature, continue to stretch 20% of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impedance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com