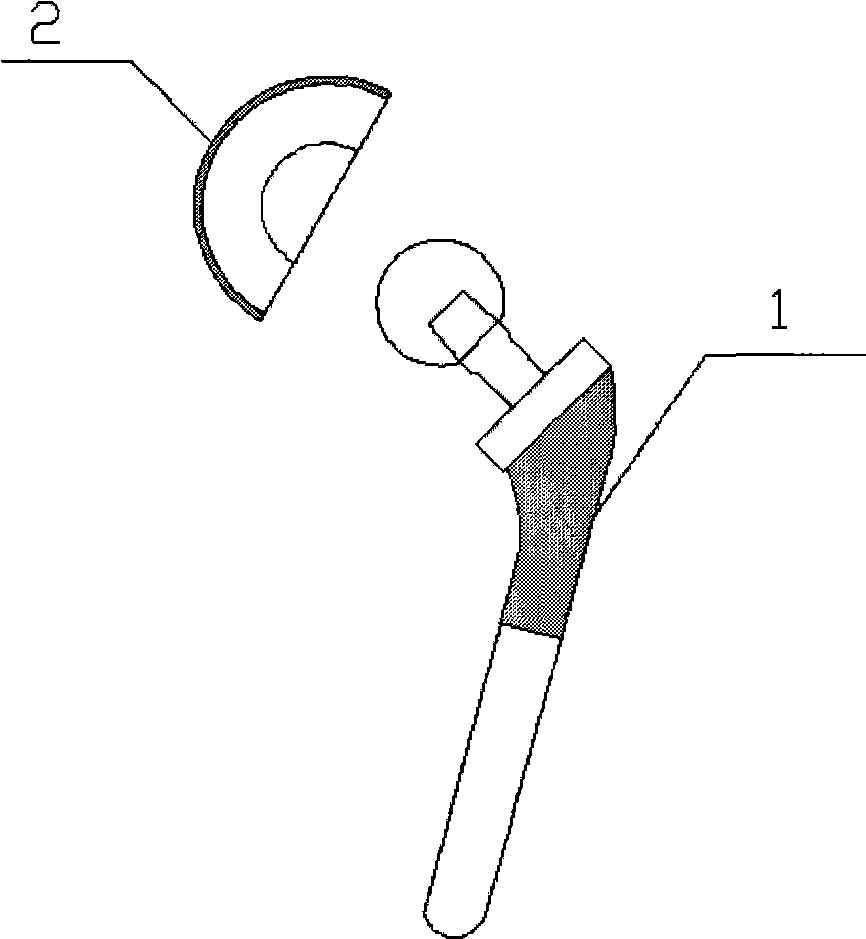

Artificial hip joint with nano and porous structure on surface and preparation method thereof

A porous structure, hip joint technology, used in hip joints, joint implants, joint implants, etc., can solve the problems of inability to apply joint replacement, lack of mechanical properties such as strength, and achieve high hardness and strength. Stress shielding, overcoming the effect of material shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Fix the titanium alloy artificial hip joint on the processing machine and rotate it. Using Al 2 o 3 Particles (diameter 1 μm) bombard the joint surface, Al 2 o 3 The average jet velocity is 300m / s, and the energy of the average single particle bombardment is about 10 -10 J, making it obtain a gradient nanostructure, the surface grain size is about 500nm, and the thickness of the nanolayer is about 1 μm.

[0027] Then, hydrochloric acid is used to treat the surface of the nanometer, so that the surface has a porous structure, the pore diameter is about 100 nm to 10 μm, and the micropore distribution is uniform.

Embodiment 2

[0029] Fix the titanium alloy artificial hip joint on the processing machine and rotate it. Using Al 2 o 3 Particles (10 μm in diameter) bombard the joint surface, Al 2 o 3 The average jet velocity is 500m / s, and the energy of the average single particle bombardment is about 10 -7 J, making it obtain a gradient nanostructure, the surface grain size is about 100nm, and the thickness of the nanolayer is about 10μm.

[0030] Then, hydrochloric acid is used to treat the surface of the nanometer, so that the surface has a porous structure, the pore diameter is about 100 nm to 10 μm, and the micropore distribution is uniform.

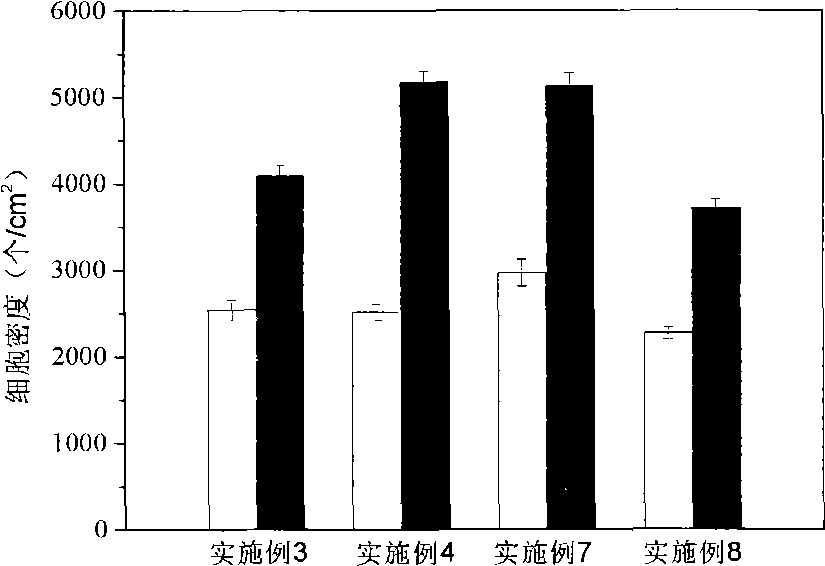

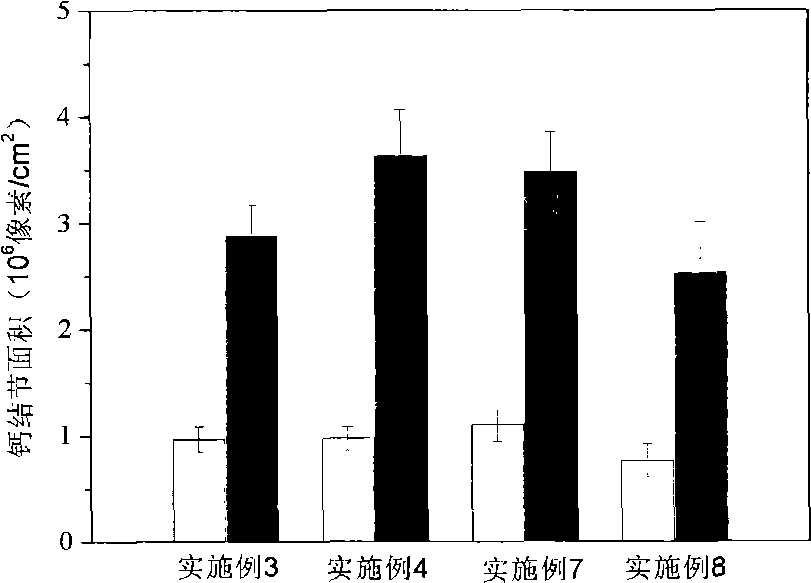

Embodiment 3

[0032] Fix the titanium alloy artificial hip joint on the processing machine and rotate it. Using Al 2 o 3 Particles (diameter 20 μm) bombard the joint surface, Al 2 o 3 The average jet velocity is 500m / s, and the energy of the average single particle bombardment is about 10 -6 J, making it obtain a gradient nanostructure, the surface grain size is about 80nm, and the thickness of the nanolayer is about 50μm.

[0033]Then, hydrochloric acid is used to treat the surface of the nanometer, so that the surface has a porous structure, the pore diameter is about 100 nm to 10 μm, and the micropore distribution is uniform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Scale | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com