Process for preparing blended micrometer TiO2 polymer electrolyte

A polymer and electrolyte technology, applied in circuits, electrical components, secondary batteries, etc., can solve problems affecting the performance of electrolyte membranes, electrolyte membrane inhomogeneity, high surface activity, etc., to facilitate absorption, improve mechanical properties, micro The effect of uniform hole distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

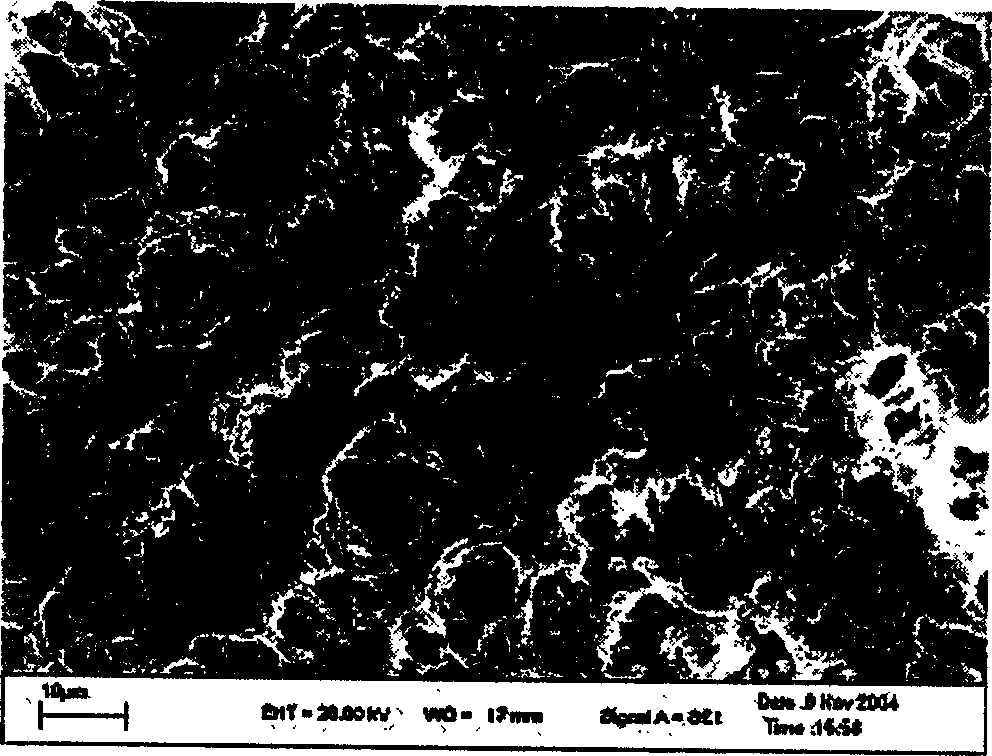

[0019] (1) Weigh PVDF-HFP (U.S. Elf atochem LBG-1) 3g and D 50 = 1.4 μm TiO 2 (Analytical pure) 0.13g was put into the Erlenmeyer flask, weighed 1.5g of deionized water and 30g of acetone, mixed them and added them to the polymer matrix PVDF-HFP and TiO 2 in the Erlenmeyer flask;

[0020] (2) The above mixture is placed in a water bath with a constant temperature of 60°C, heated and magnetically stirred for 2 hours, then cooled to room temperature while stirring, and a white viscous casting solution is obtained;

[0021] (3) After the above-mentioned casting solution is ultrasonically dispersed for 8 minutes, a milky white casting solution is obtained;

[0022] (4) casting the milky white casting solution in a mould, and obtaining a white uniform porous polymer electrolyte membrane after the solvent and non-solvent volatilize;

[0023] (5) placing the obtained porous polymer membrane in an oven at 50° C. for heat treatment for 6 hours;

[0024] (6) In a dry environment, im...

Embodiment 2

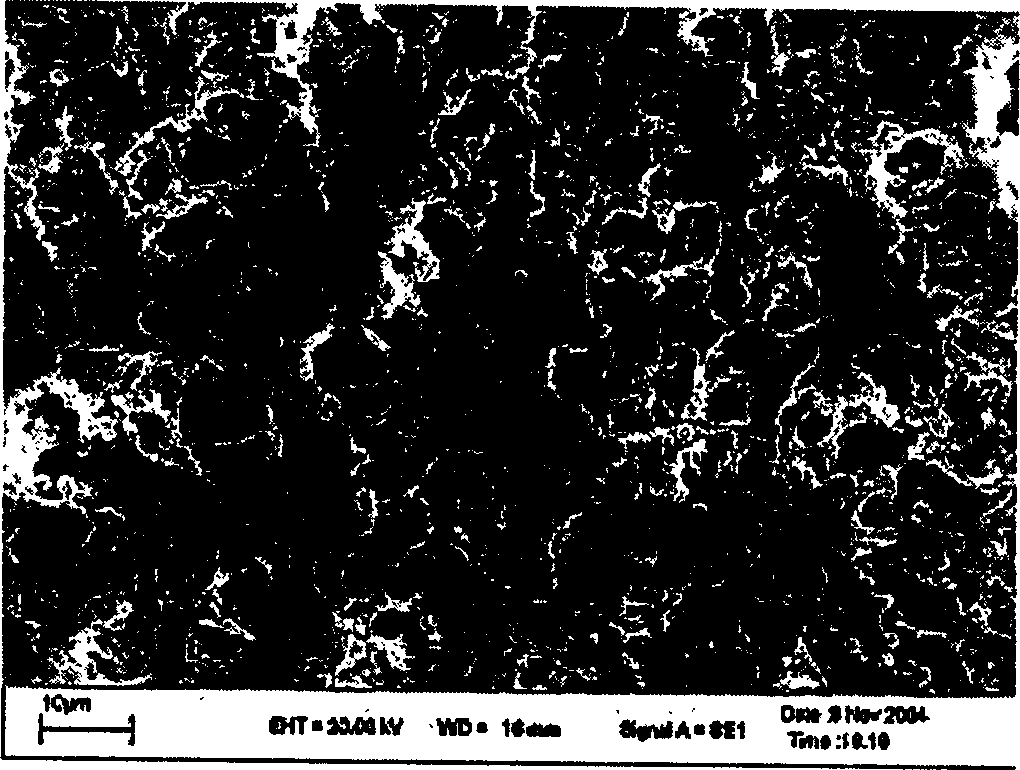

[0028] (1) Weigh PVDF-HFP (U.S. Elf atochem LBG-1) 3g and D 50 = 1.4 μm TiO 2 (Analytical pure) 0.08g is put into the Erlenmeyer flask, weighs 1.5g of deionized water, 30g of acetone, mixes and adds to the solution containing the polymer matrix PVDF-HFP and TiO 2 in the Erlenmeyer flask;

[0029] (2) Place the above mixture in a water bath with a constant temperature of 50°C, heat and magnetically stir for 4 hours, then cool to room temperature while stirring to obtain a white viscous casting solution;

[0030] (3) After the above-mentioned casting solution was ultrasonically dispersed for 16 minutes, a milky white casting solution was obtained;

[0031] (4) casting the milky white casting solution in a mould, and obtaining a white uniform porous polymer electrolyte membrane after the solvent and non-solvent volatilize;

[0032] (5) placing the obtained porous polymer film in an oven at 80° C. for heat treatment for 10 hours;

[0033] (6) In a dry environment, immerse the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com