Patents

Literature

71 results about "Pvdf hfp" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

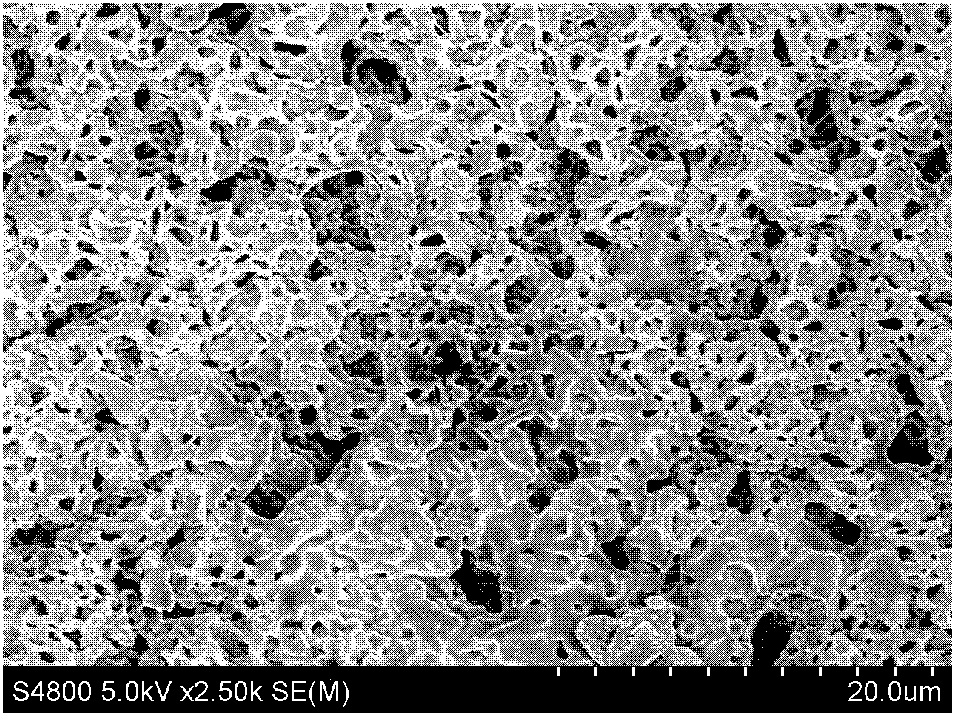

Carbon material modified porous polymer electrolyte membrane and preparation method thereof

InactiveCN102585280ASmall apertureEvenly distributedCell component detailsPolymer scienceHexafluoropropylene

The invention discloses a carbon material modified porous polymer electrolyte membrane and a preparation method thereof, and relates to the polymer electrolyte membrane and the preparation method thereof. The invention aims at solving the problems of low ionic conductivity, small lithium ion transference number and poor electrochemical stability of the conventional porous polymer electrolyte membrane. The carbon material modified porous polymer electrolyte membrane is prepared by soaking the porous polymer membrane in an electrolyte of a lithium ion battery for 1h-4h; and the porous polymer membrane is prepared from PVDF-HFP (polyvinylidene fluoride-hexafluoropropylene), a solvent, a plasticizer and a modified carbon material. The method comprises the following steps of: (1) preparing theporous polymer membrane; and (2) performing soaking treatment to get the carbon material modified porous polymer electrolyte membrane. The carbon material modified porous polymer electrolyte membranehas the advantages that the ionic conductivity achieves 10-3S / cm order of magnitude, the lithium ion transference number is 0.80-0.95, and an electrochemical stability window is 5.5V-6.0V. The preparation method disclosed by the invention is mainly used for preparing the carbon material modified porous polymer electrolyte membrane.

Owner:DAQING BRANCH OF HEILONGJIANG ACAD OF SCI

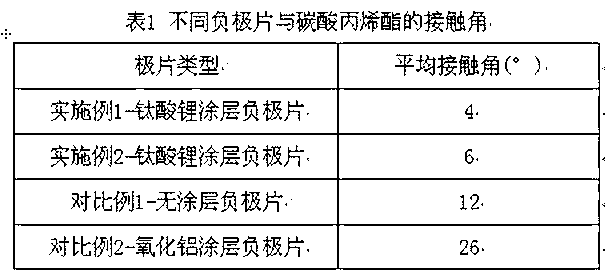

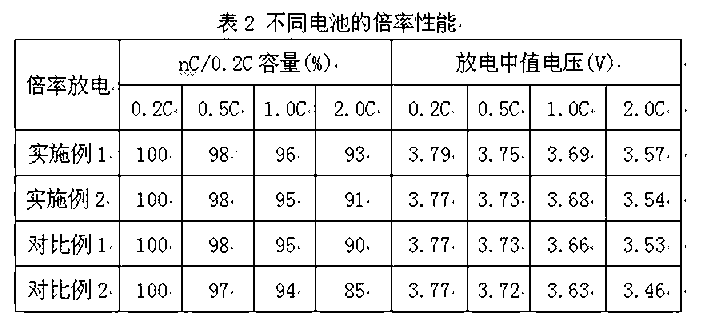

Lithium titanate coated cathode and lithium ion battery using cathode

InactiveCN103050705ADoes not affect security featuresImproved magnification performanceSecondary cellsNon-aqueous electrolyte accumulator electrodesHexafluoropropyleneNano al2o3

The invention discloses a lithium titanate coated cathode and a lithium ion battery using the cathode. The lithium titanate coated cathode comprises a cathode piece and a lithium titanate coating, wherein the lithium titanate coating comprises the following components by weight ratio: 90-97% of nanomaterial and 3-10% of adhesive agent; the nanomaterial is nano lithium titanate, or a combination of nano lithium titanate and nano alumina and / or nano aluminium nitride; the adhesive agent is one of a combination of SBR (Styrene Butadiene Rubber) and CMC (Carboxyl Methyl Cellulose), PVDF (Polyvinylidene Fluoride), PVDF-HFP (Polyvinylidene Fluoride-Hexafluoropropylene), and polyacrylate; pulp of the lithium titanate coating comprises a solvent; the solvent is one of deionized water and NMP (N-Methyl Pyrrolidone); the solid content of the pulp of the lithium titanate coating is 20-60%; and the two sides of the cathode piece are coated with the pulp of the lithium titanate coating. The lithium ion battery using the lithium titanate coated cathode has better electrolyte wettability on the premise that a safety feature of the battery is unaffected, and can form a fully contacted liquid-phase interface with a diaphragm, and the multiplying power performance and the cycle performance of the battery can be improved.

Owner:TIANJIN ENERGIES

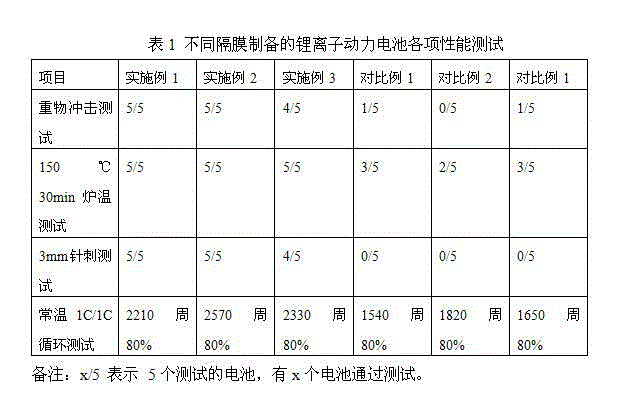

A preparing method of a lithium ion battery composite separating membrane

ActiveCN104681762AImprove mechanical propertiesImprove heat resistanceCell seperators/membranes/diaphragms/spacersPolyamide coatingsHeat resistanceResin coating

A preparing method of a lithium ion battery composite separating membrane is disclosed. A common PP or PE separating membrane is coated with an oxide coating, an aramid fiber resin coating and a PVDF-HFP copolymer layer to obtain the composite separating membrane. The composite separating membrane enhances mechanical performance and heat resistance of the separating membrane and enhances safety performance of batteries.

Owner:WANXIANG 123 CO LTD

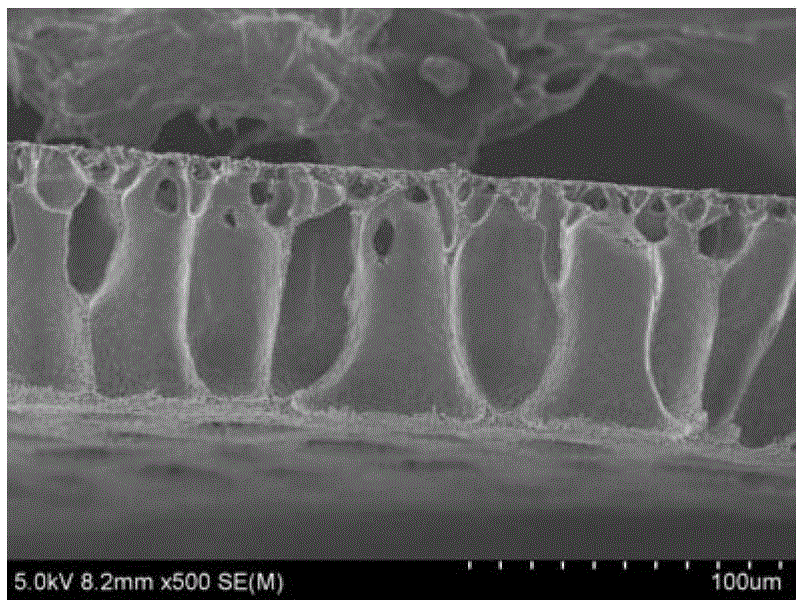

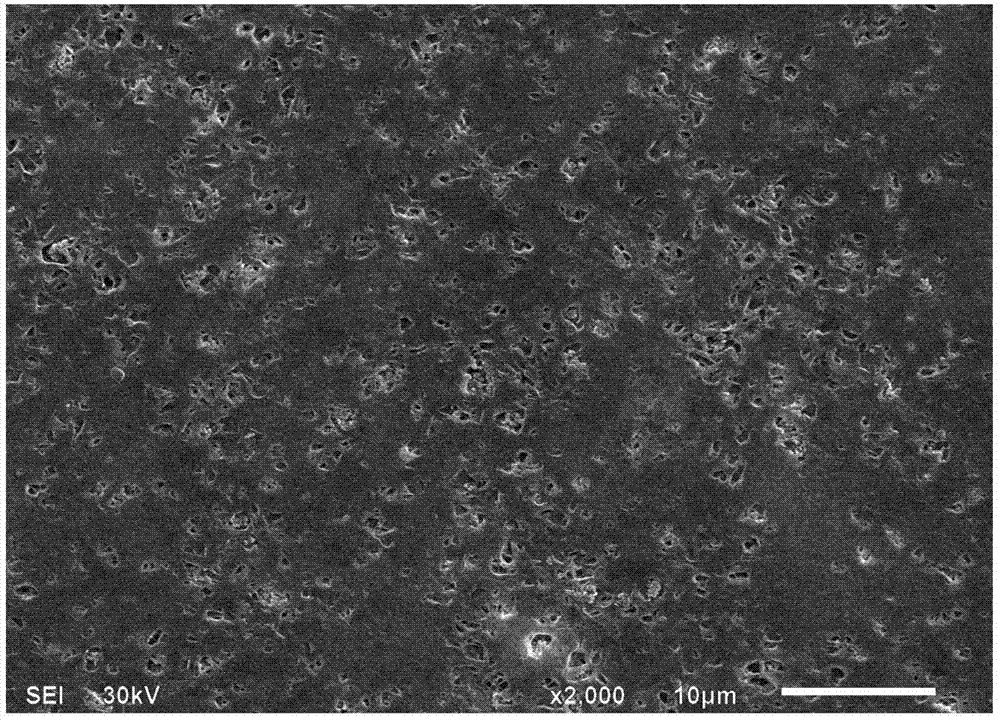

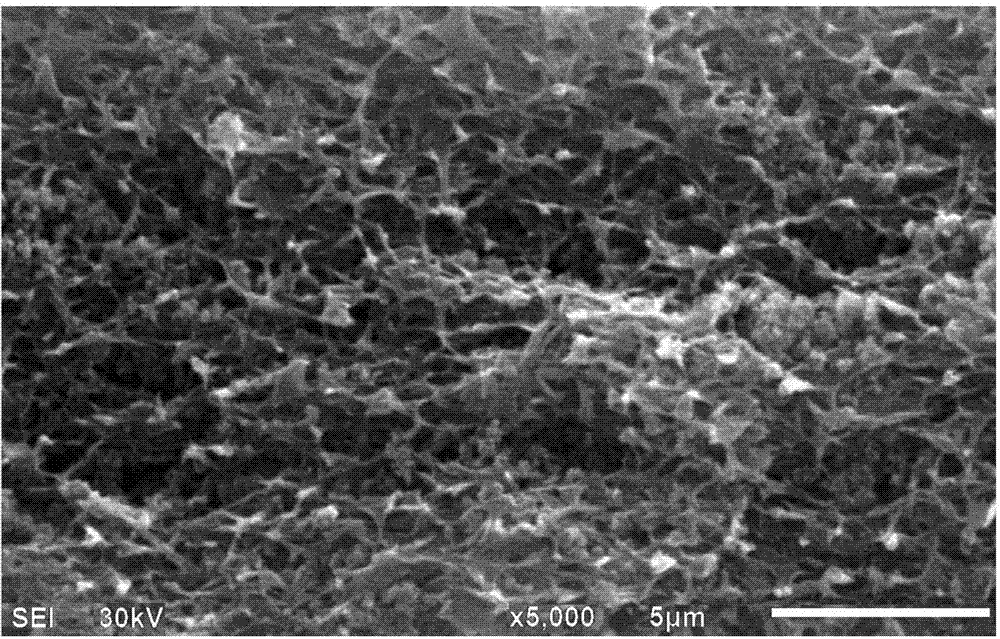

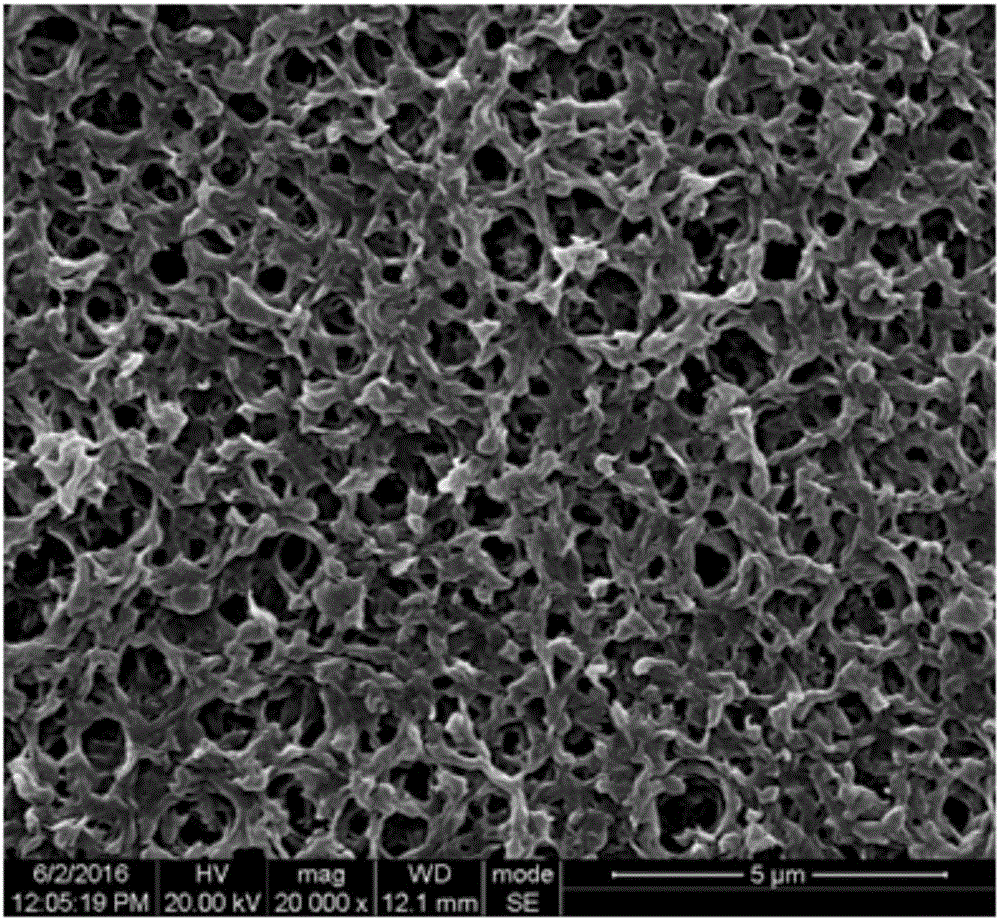

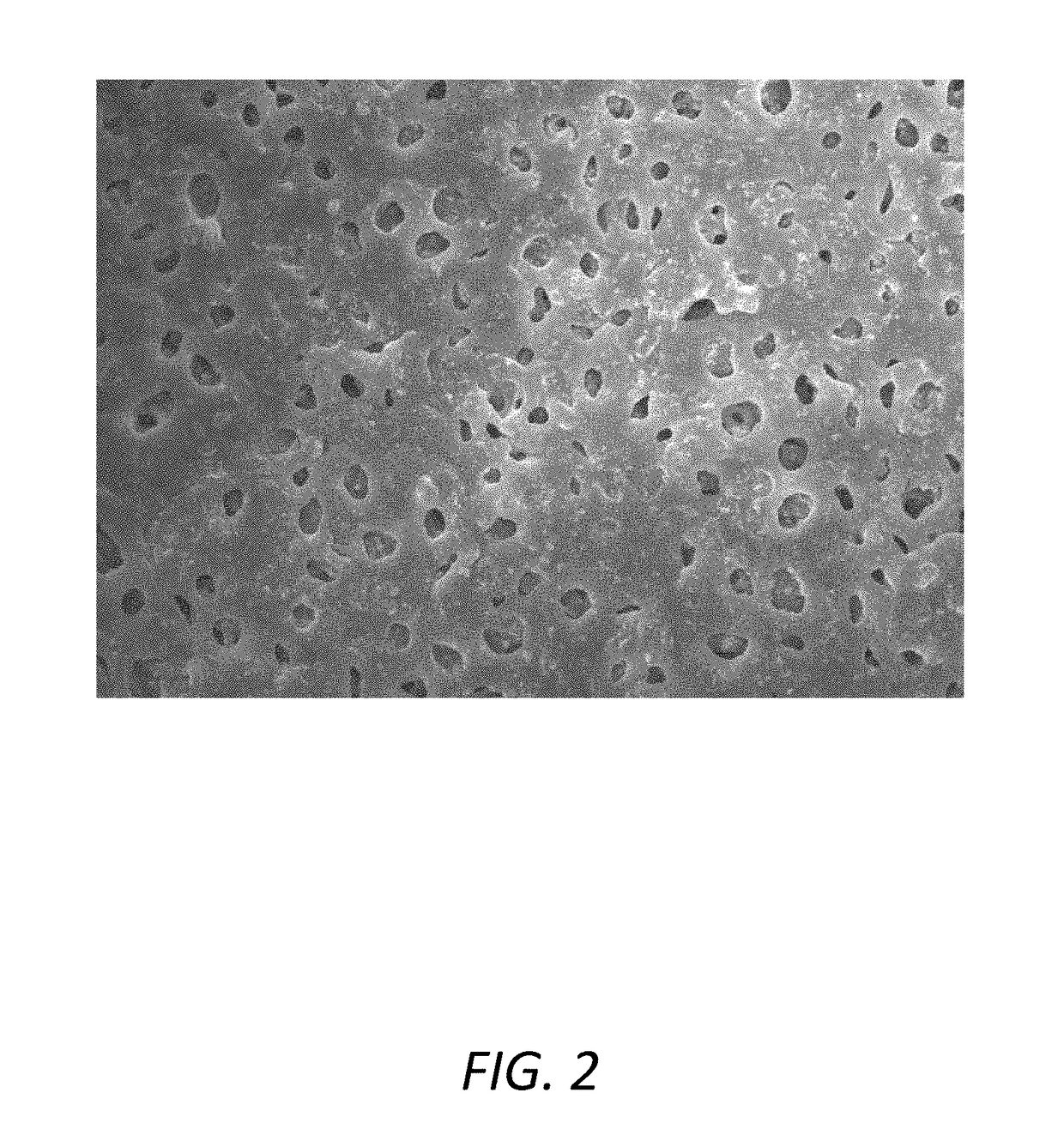

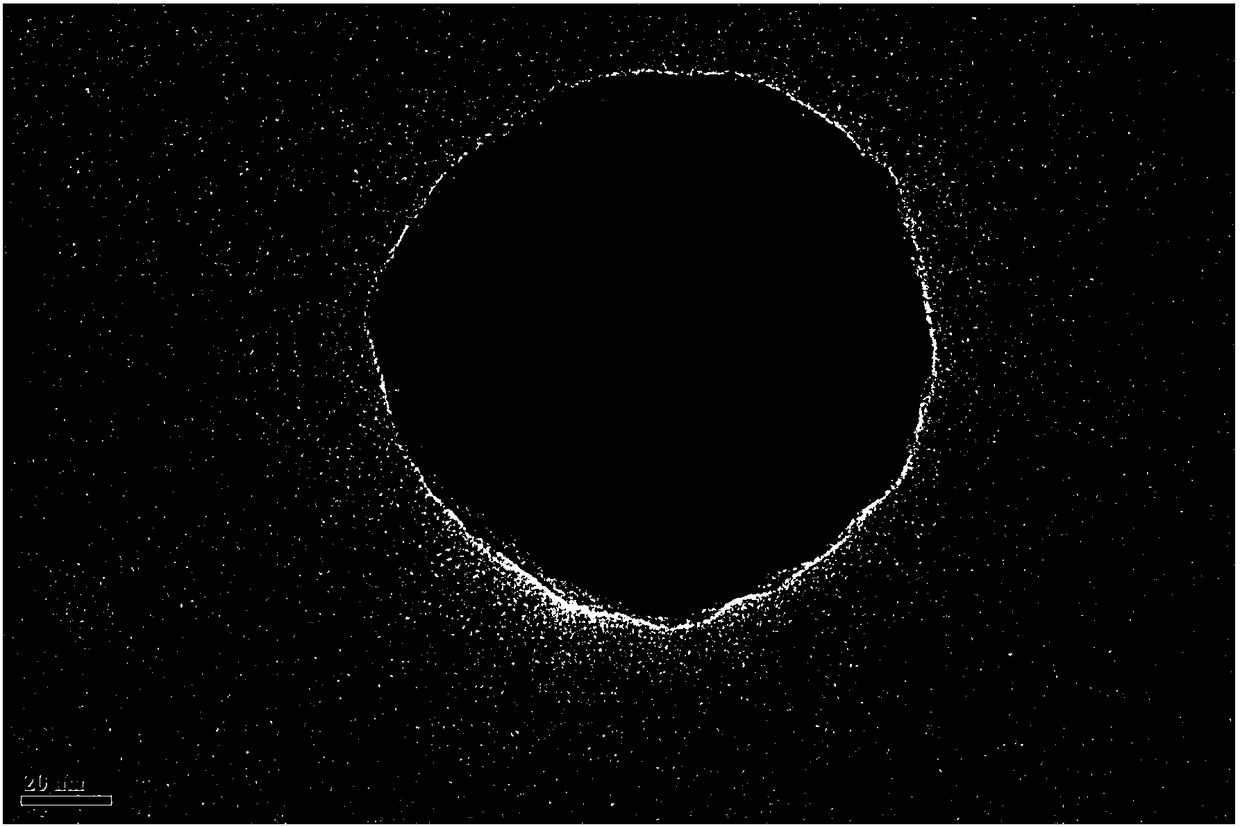

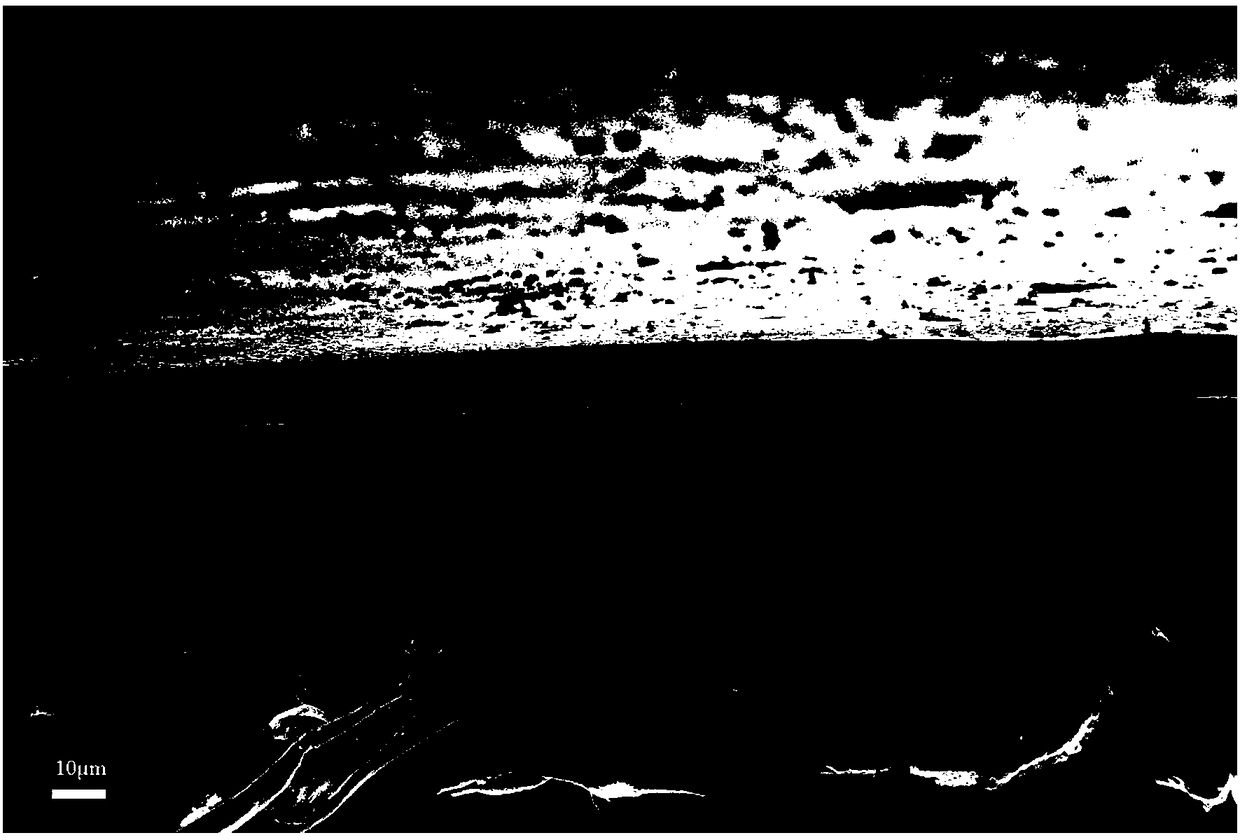

Preparation method of large-rate discharge porous diaphragm material and application of material

The invention relates to the film material field, and especially relates to a preparation method of a large-rate discharge porous diaphragm material and an application of the material. The preparation method of the large-rate discharge porous diaphragm material comprises the following steps: preparing a porous film through utilizing polyvinylidene fluoride (PVDF) or poly(vinylidene fluoride-co-hexafluoropropene) (PVDF-HFP) by adopting an immersion precipitation method or a thermotropic phase separation method; and carrying out post-treatment of the surface of the prepared PVDF or PVDF-HFP porous film through an ion technology to form a nano-micro hole controllable high-hole-ratio porous diaphragm having fingerlike tunnels penetrating to the bottom. The morphology of the porous film prepared in the invention is composed of a uniform nano / micro hole surface layer, thumb-like tunnels and a sponge hole bottom layer, and the porous film having the above structure provides an enough space for accommodating an electrolyte, so the tunnels are full of the electrolyte, the electrolyte and the PVDF form a gel electrolyte in a largest area mode, and the accommodating capability of the porous diaphragm to the electrolyte is increased.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

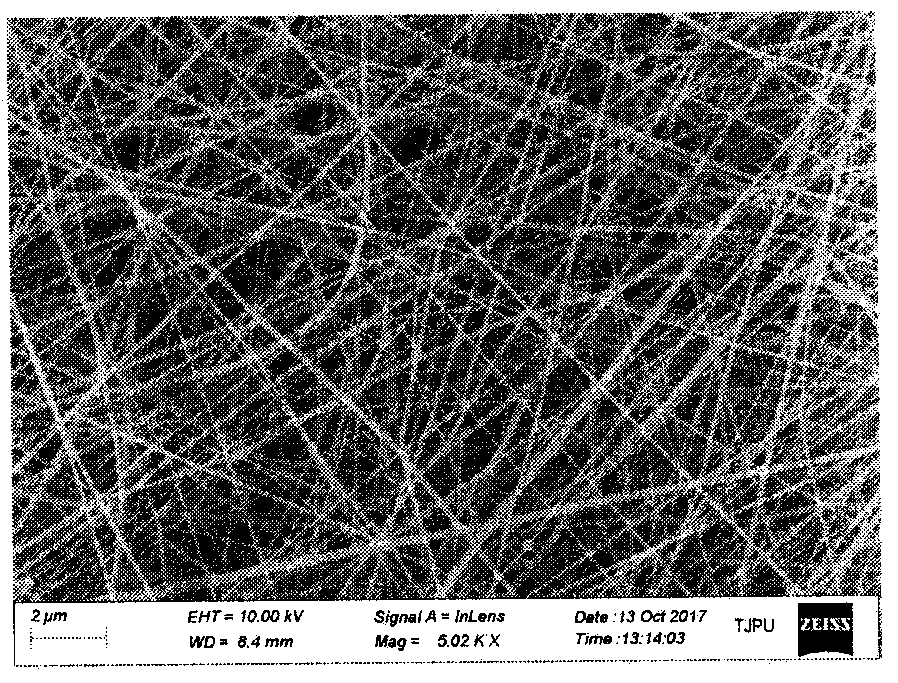

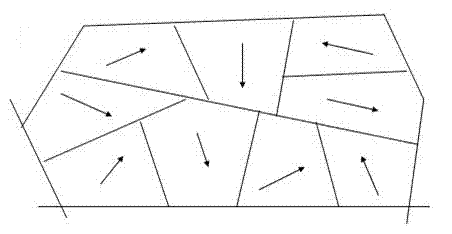

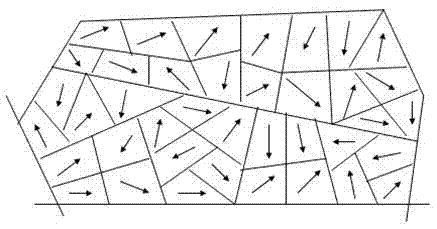

Cross-linked modified PVOF-HFP superfine fiber film and preparing method

The present invention relates to a crosslinking modified PVDF-HFP superfine fibre membrane and its preparation method. The described crosslinking modified PVDF-HFP superfine fibre membrane is a superfine fibre membrane whose thickness is 10 micrometers-60 micrometers which is made up by using superfine fibres of PEGDMA whose mass content is 10-35% and PVDF-HFP whose mass content is 90-65% and whose diameter is 50nm-500nm. Its preparation method includes the following steps: in the DMF and acetone mixed solvent adding PVDF-HFP, PEGDMA and AIBN initiating agent to prepare electric spinning solution, utilizing said electric spinning solution to make electrostatic spinning so as to obtain the membrane formed from superfine fibre whose diameter is 50nm-500nm, then making the formed superfine fibre membrane undergo the processes of vacuum-drying, removing residual solvent and crosslinking reaction for 0.5-15h at 80-135deg.C so as to 8obtain the invented crosslinking modified PVDF-HFP superfine fibre membrane.

Owner:TIANJIN UNIV

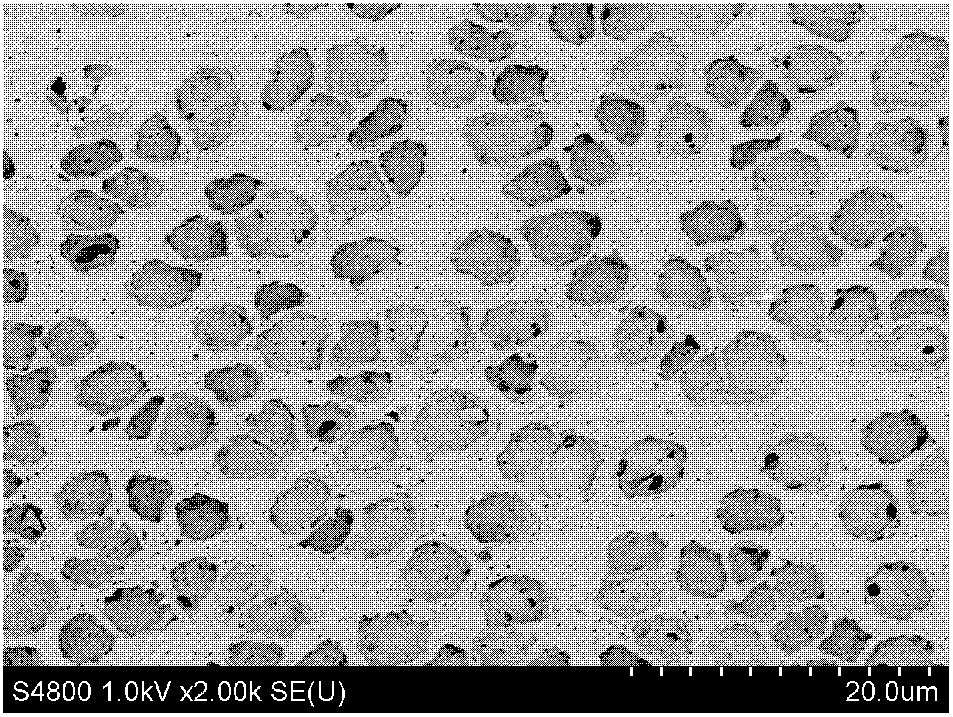

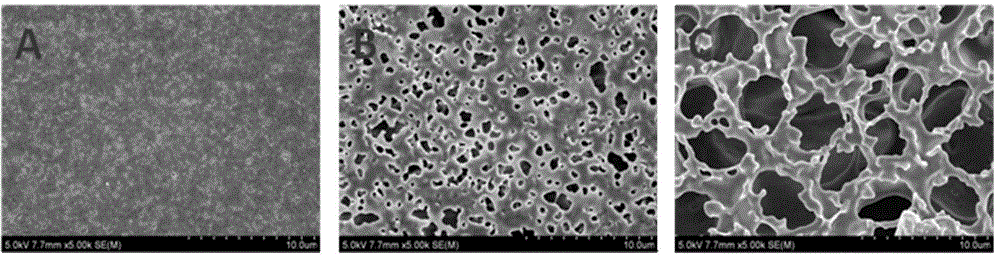

PVDF-HFP-based composite porous polymer diaphragm and preparation method thereof

ActiveCN103840112ANo extractionSimple preparation processSecondary cellsCell component detailsOrganic solventHexafluoropropylene

The invention relates to a poly(vinylidene fluoride-hexafluoropropylene)-based lithium-ion battery diaphragm and a preparation method thereof. The diaphragm is prepared by a phase inversion method comprising the following steps of dissolving poly(vinylidene fluoride-hexafluoropropylene), a modified polymer and nanometer filler under the certain ratio in an organic solvent, adding a nonsolvent after stirring and mixing uniformly at the certain temperature, continuously stirring till the nonsolvent is dispersed uniformly, de-foaming, coating, drying and the like to obtain the poly(vinylidene fluoride-hexafluoropropylene)-based lithium-ion battery diaphragm. The poly(vinylidene fluoride-hexafluoropropylene)-based lithium-ion battery diaphragm disclosed by the invention has the advantages that the thickness is uniform and is easy to control, the cellular structure is uniform, the mechanical strength is high, and the industrialization is easy to be realized.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

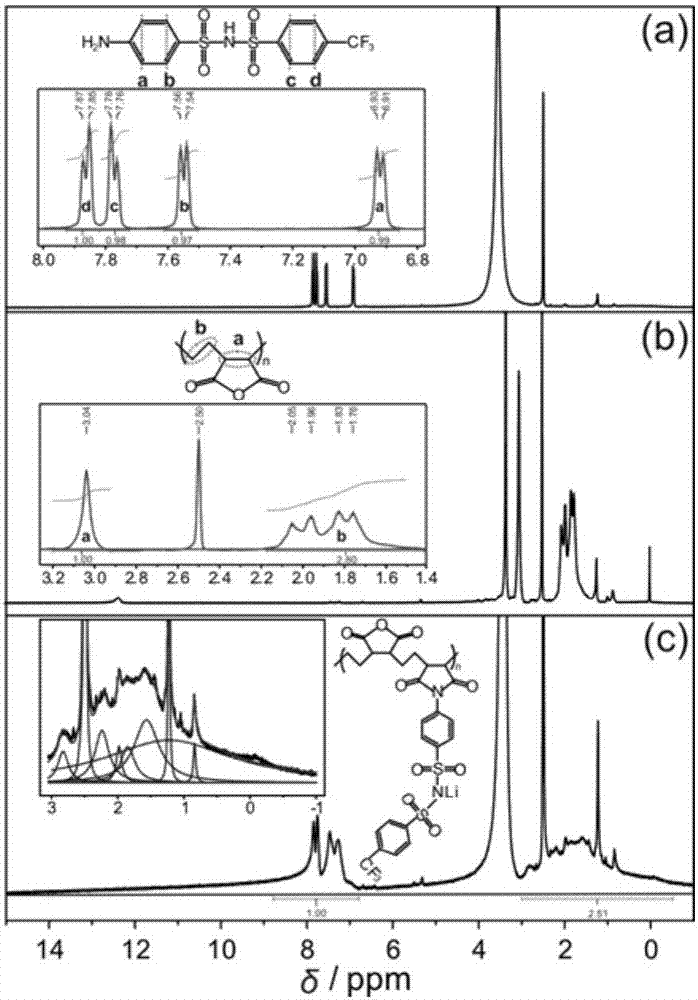

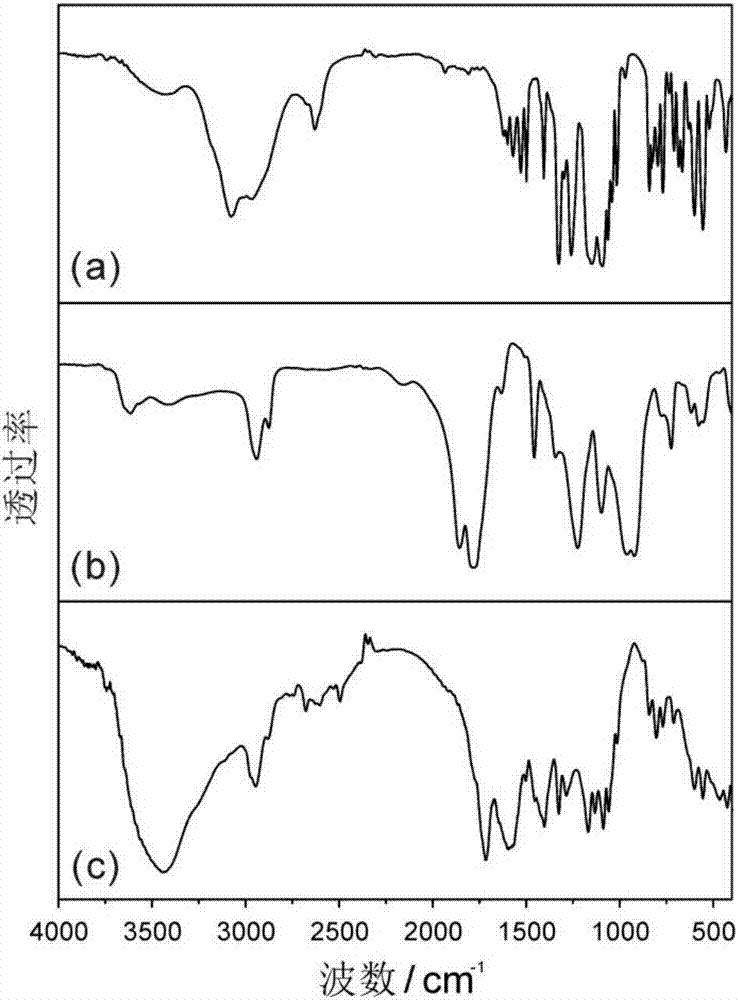

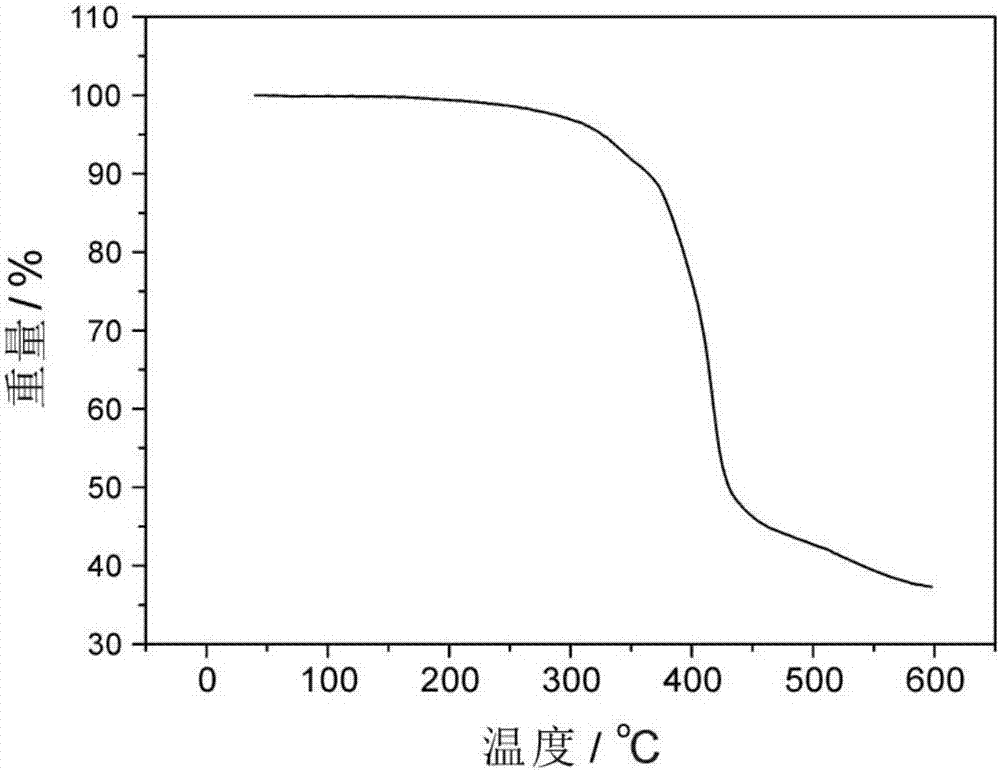

Side-chain bis(sulphonyl)imide grafted polyimide single-ion conductive polymer and application thereof

ActiveCN107459647AHelp buildBuild effectiveSecondary cellsCell component detailsPolymer scienceSide chain

The invention discloses a side-chain bis(sulphonyl)imide grafted polyimide single-ion conductive polymer, and a synthesis method and application thereof. The room temperature ionic conductivity of a polymer electrolyte membrane formed by blending the polymer and PVDF-HFP is 0.10mS.cm<-1>, and the maximum tensile strength at a dry state is 15.5MPa; and serving as an electrolyte / membrane for a gel-type lithium metal polymer secondary battery, the polymer electrolyte membrane shows excellent electrochemical stability.

Owner:萨尔法(武汉)新能源科技有限公司

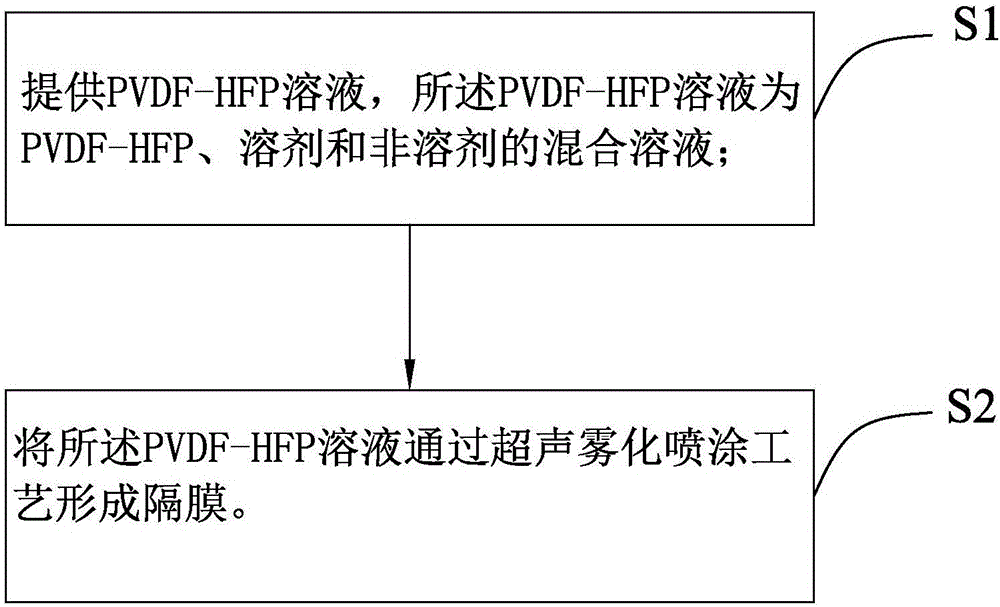

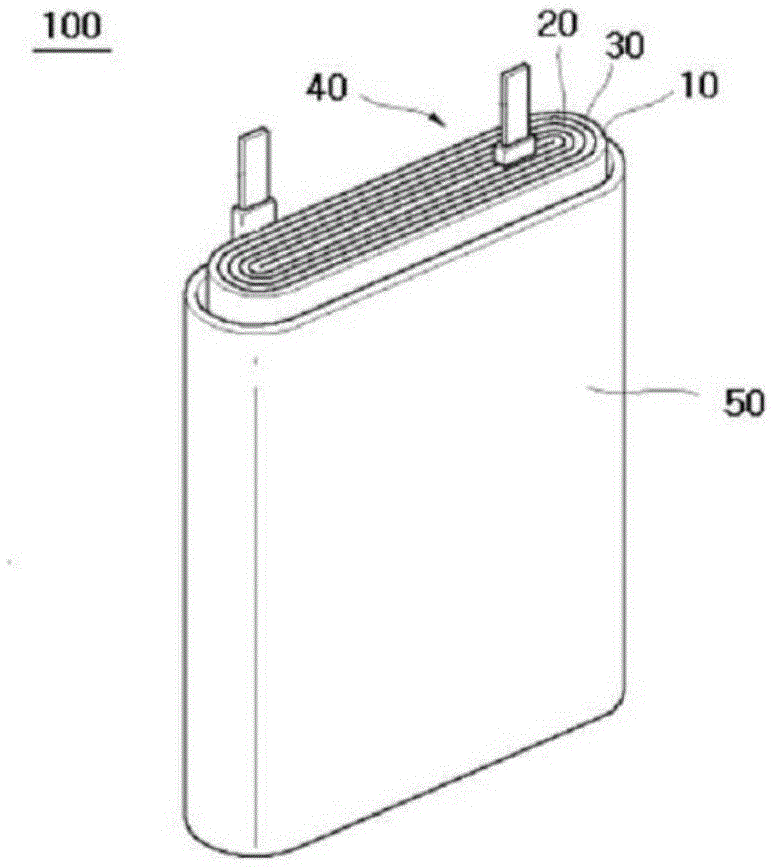

Lithium ion battery diaphragm, preparation method thereof and lithium ion battery

InactiveCN106299209AImprove ionic conductivityHigh porositySecondary cellsCell component detailsNon solventPorosity

The invention relates to the field of battery materials and preparation thereof, and particularly relates to a lithium ion battery diaphragm, a preparation method thereof and a lithium ion battery. The preparation method of the lithium ion battery diaphragm provided by the invention comprises the following steps: S1, providing a PVDF-HFP solution which is a mixed solution of PVDF-HFP, a solvent and a non-solvent; and S2, carrying out an ultrasonic atomization spaying process on the PVDF-HFP solution to form the diaphragm. The invention also provides the lithium ion battery diaphragm and the lithium ion battery. The lithium ion battery diaphragm provided by the invention cannot be dissolved into common electrolyte easily, and has the advantages of relatively high ionic conductivity and porosity and the like, and the lithium ion battery has relatively good electrochemical performance.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

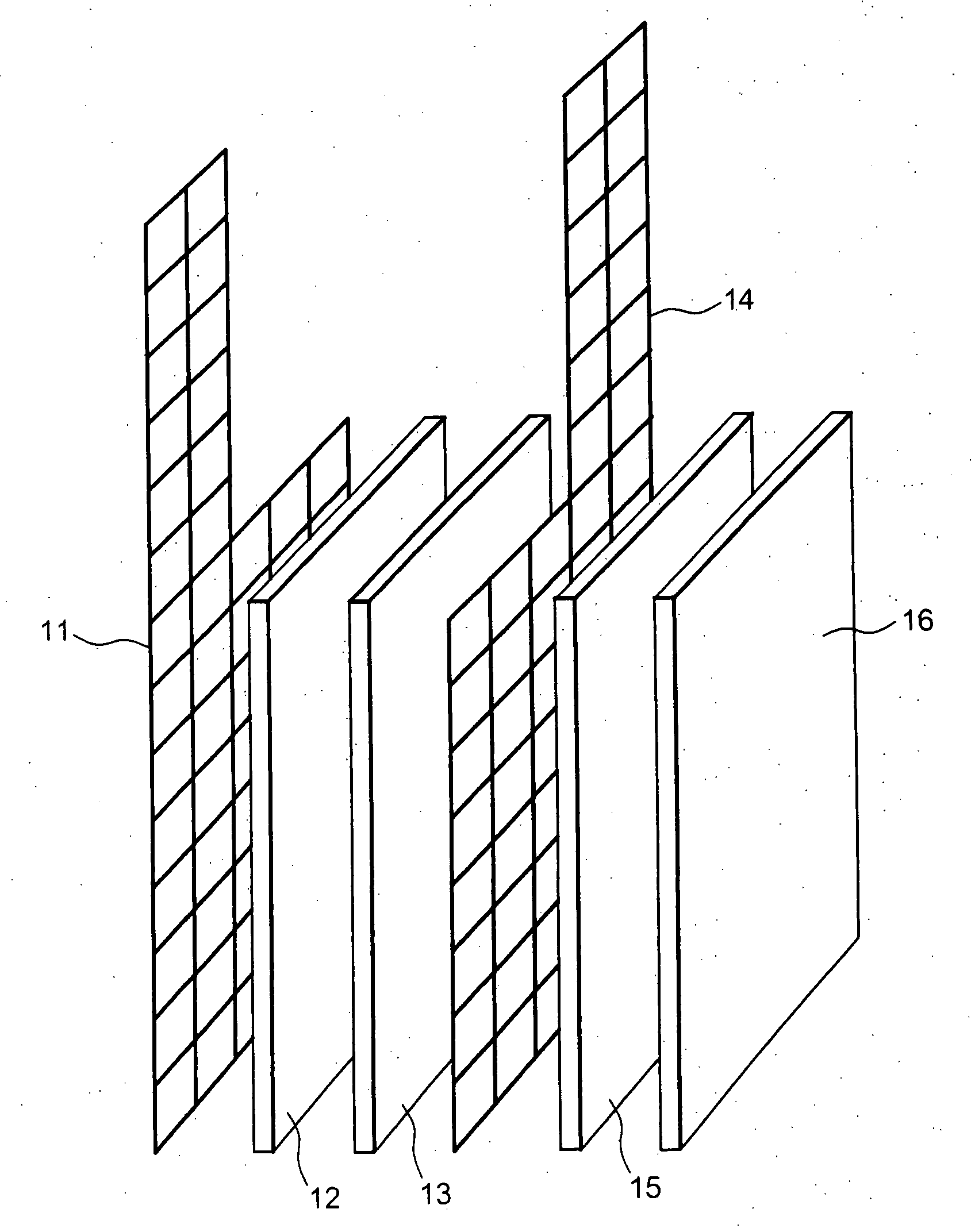

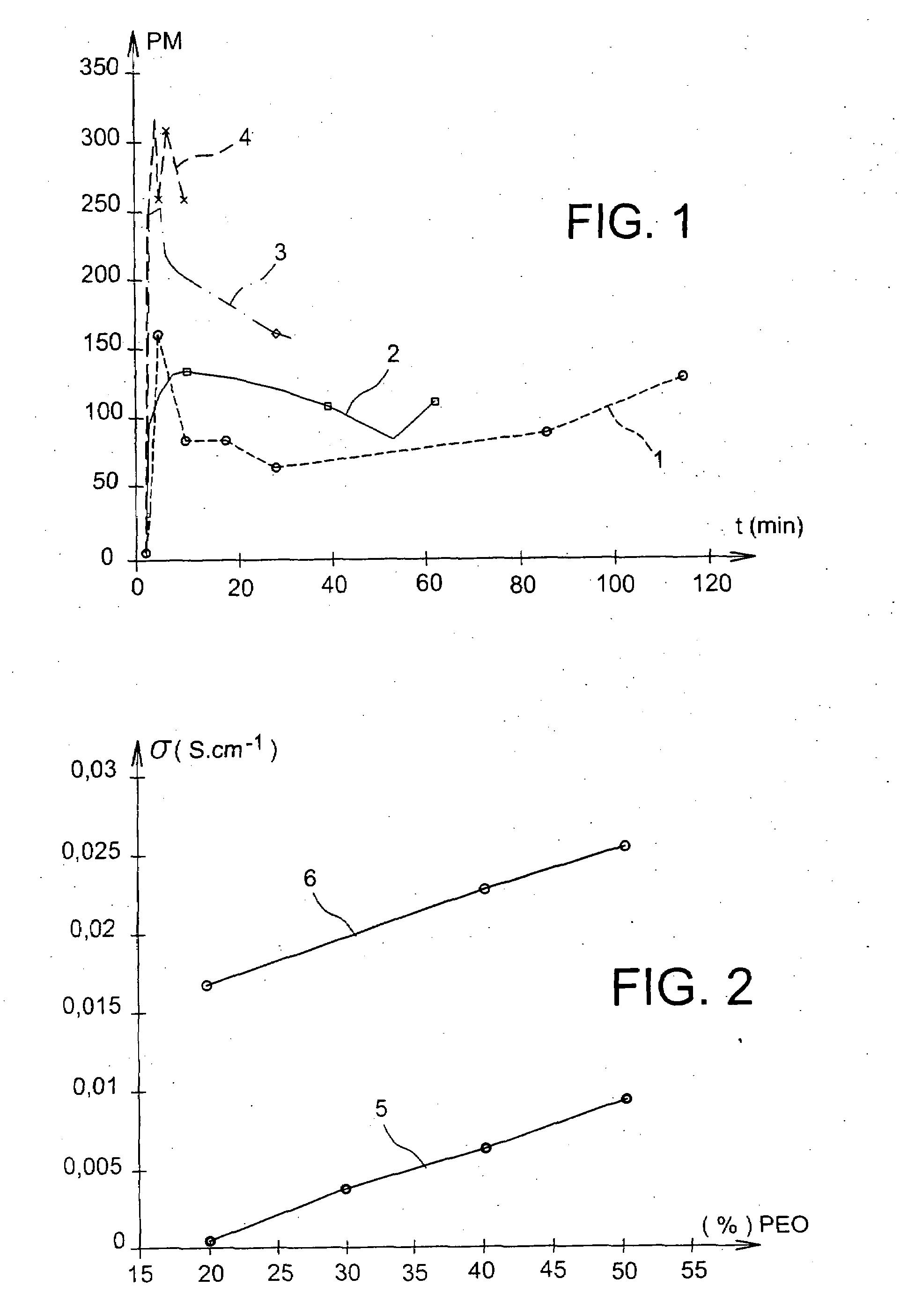

Flexible, Aqueous, Controlled Emission Electrochemical Cell

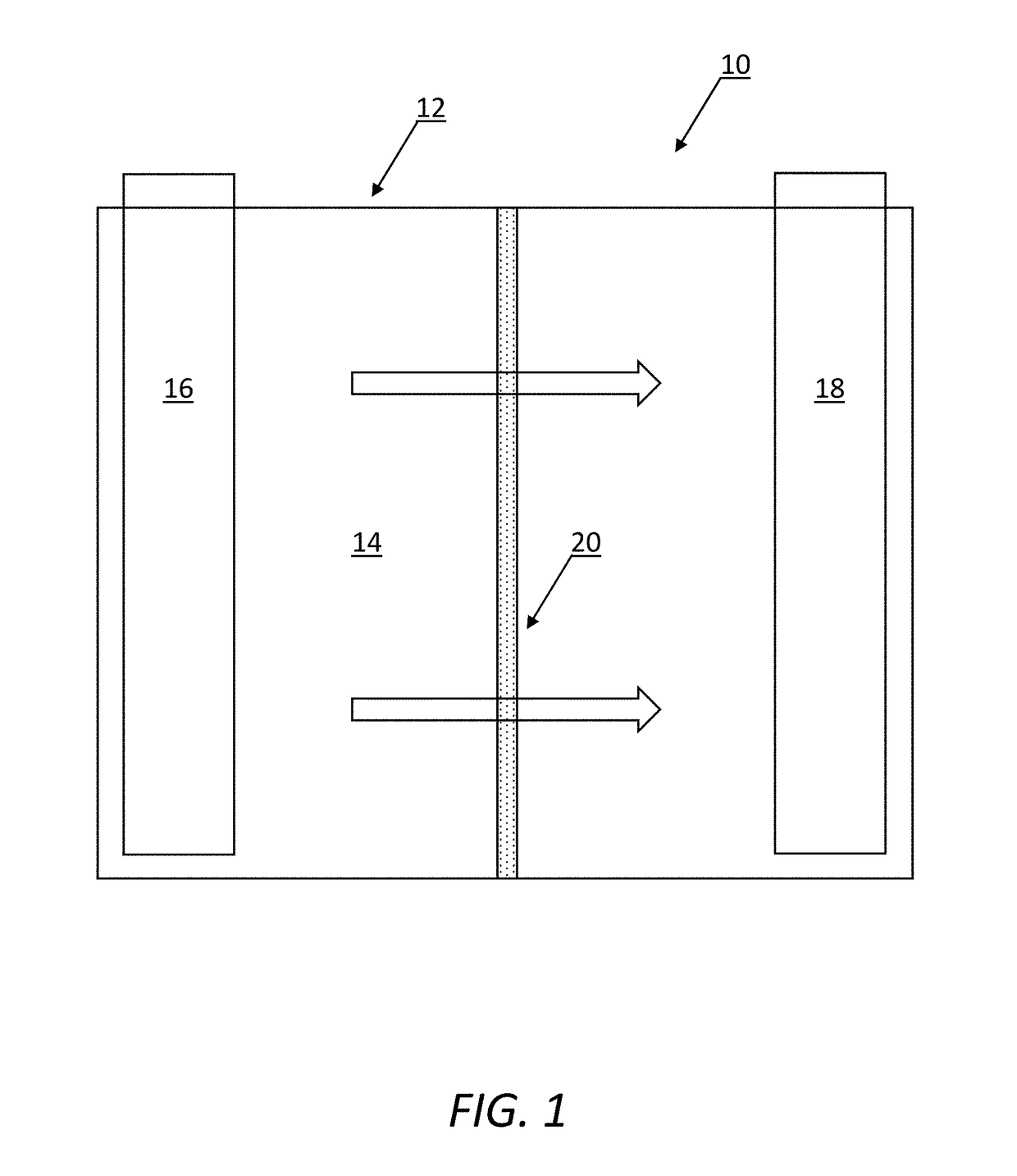

InactiveUS20080131773A1Quick exchangeImprove ionic conductivityActive material electrodesSecondary cellsEmissivityConductive materials

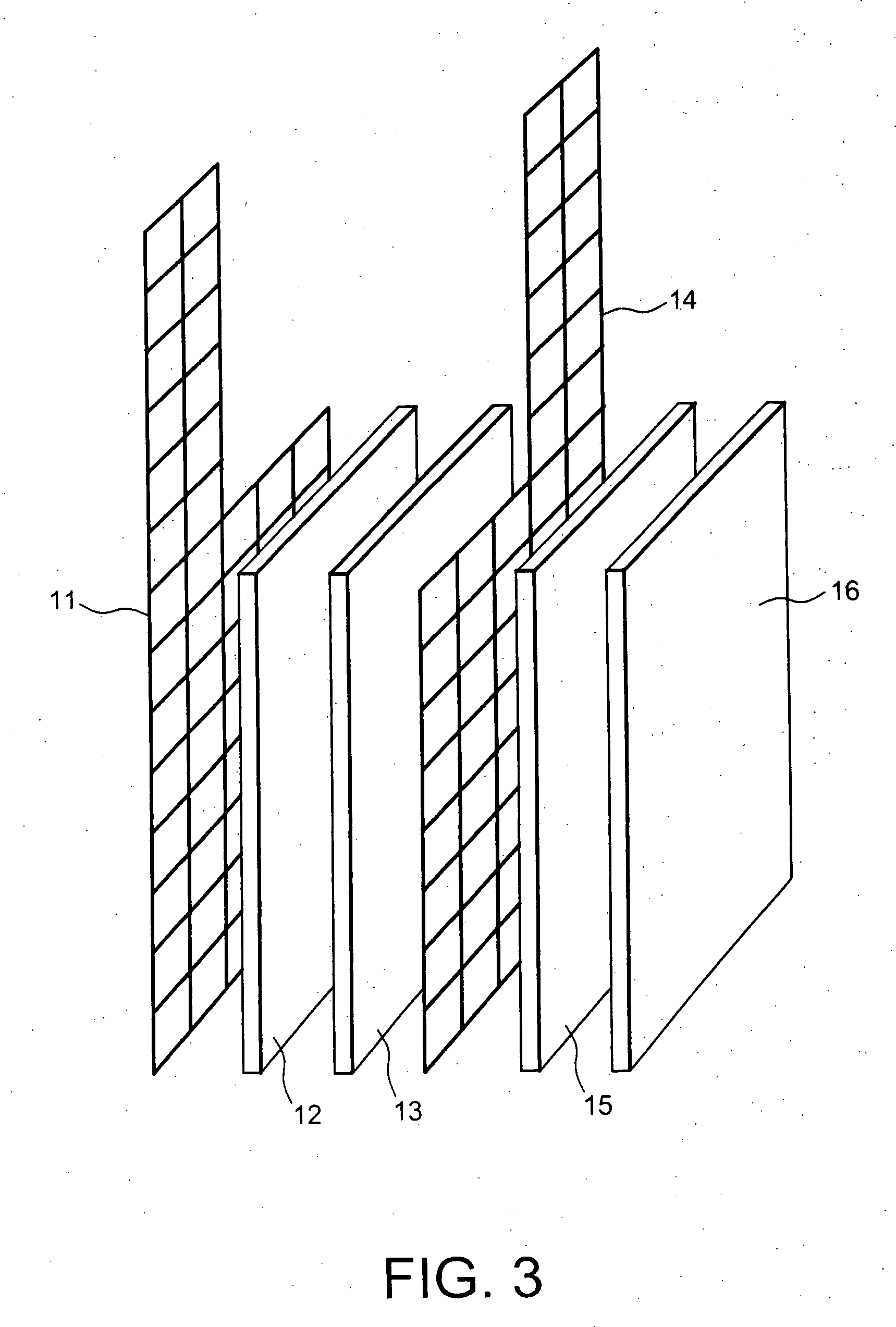

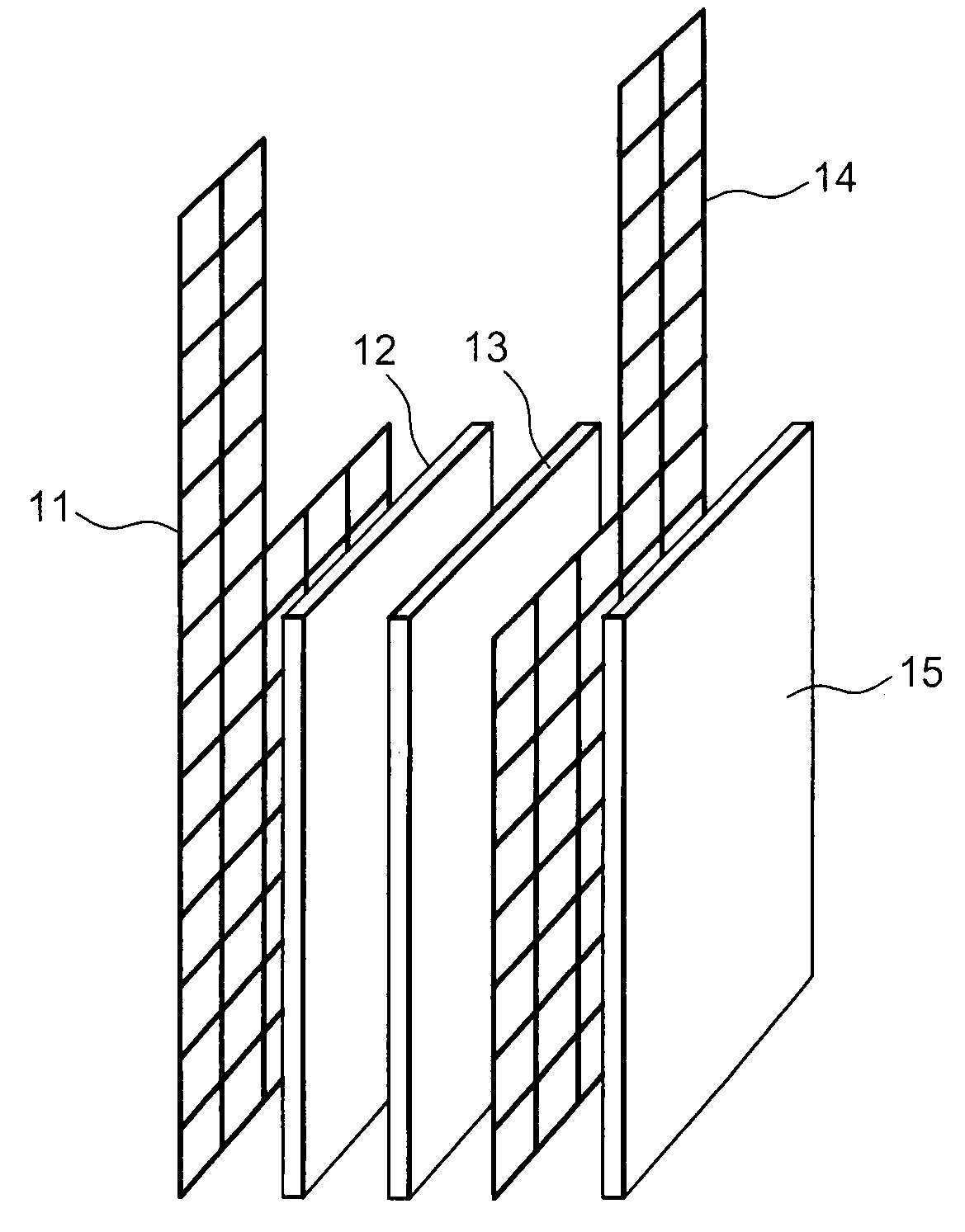

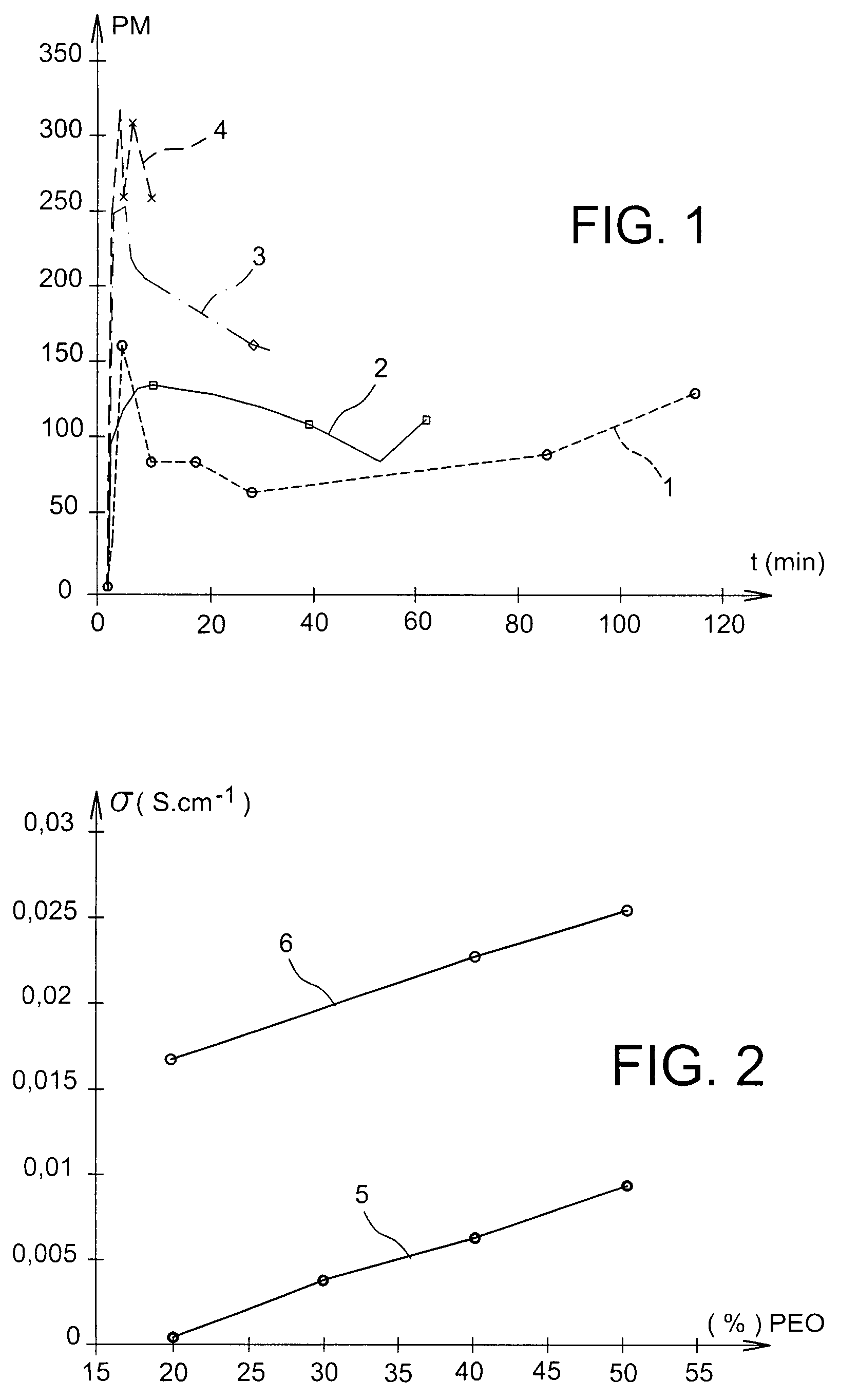

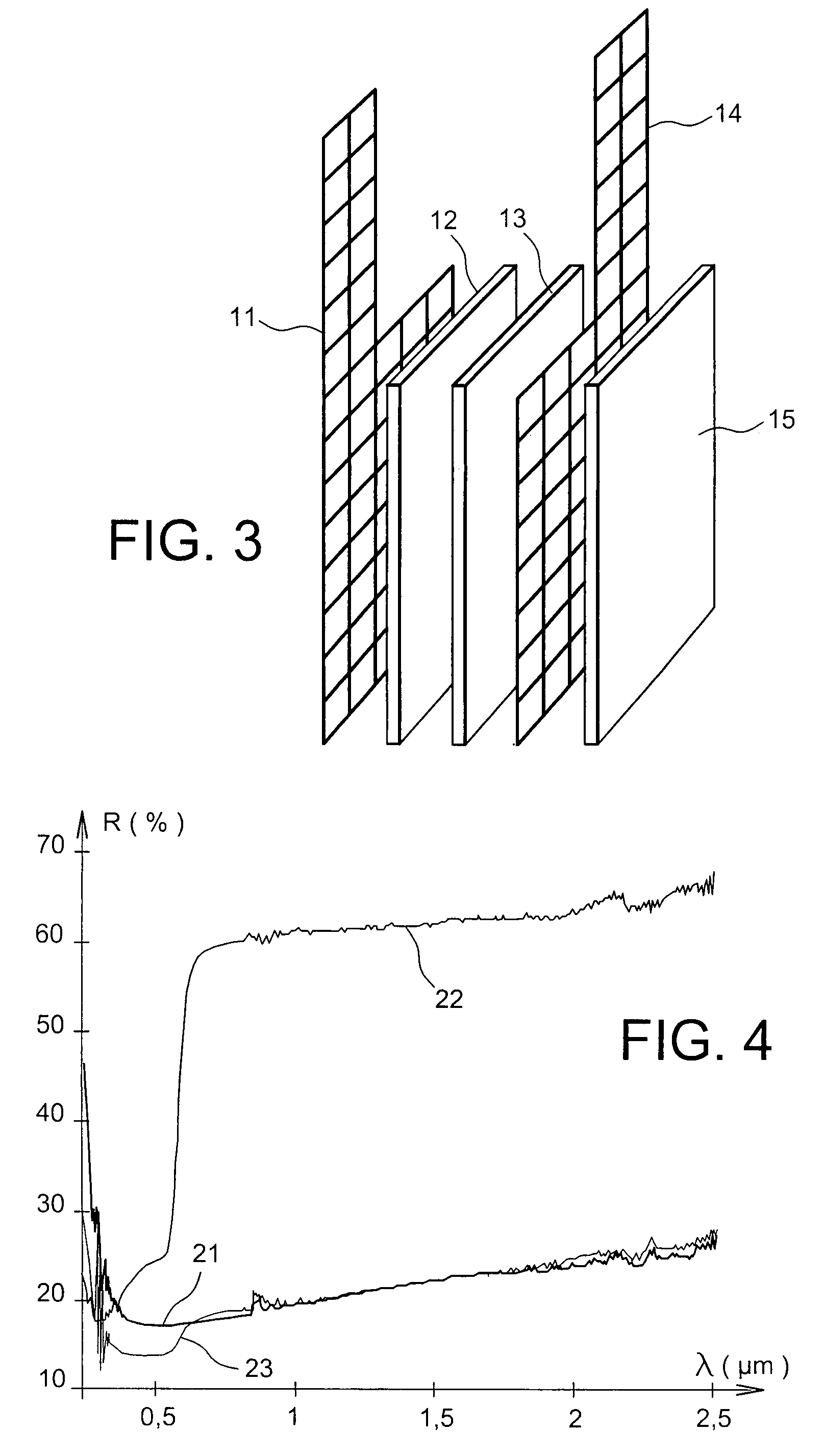

The invention concerns an electrochemical cell in thin films and aqueous electrolyte, with an emissivity that varies as a function of an applied control voltage. It is formed of the following flexible elements, superimposed and respectively in intimate contact:a first current collector (11) in electrically conducting material and intended to be connected to a first potential of the control voltage,a porous counter electrode (12) formed of a mixture of PVDF-HFP, PEO and a powder of a compound comprising complementary ions of an insertion material,a porous separator (13) formed of a mixture of PVDF-HFP and PEO,a second current collector (14) in electrically conducting material, intended to be connected to a second potential of the control voltage and capable of being traversed by ions,a porous electronic conduction layer (15) formed of a mixture of PVDF-HFP, PEO and a powder of an electrically conducting material,a porous active layer (16) formed of a mixture of PVDF-HFP, PEO and a powder of an insertion material.

Owner:EURON AERONAUTIC DEFENCE & SPACE

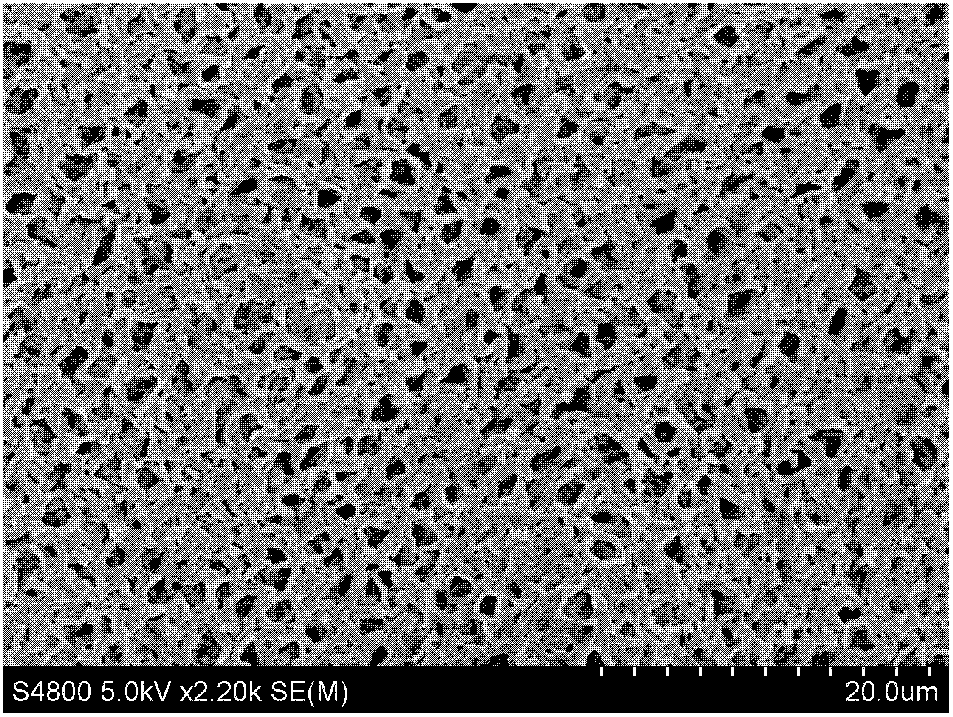

PVDF-HFP base composite porous polymer membrane and preparation method thereof

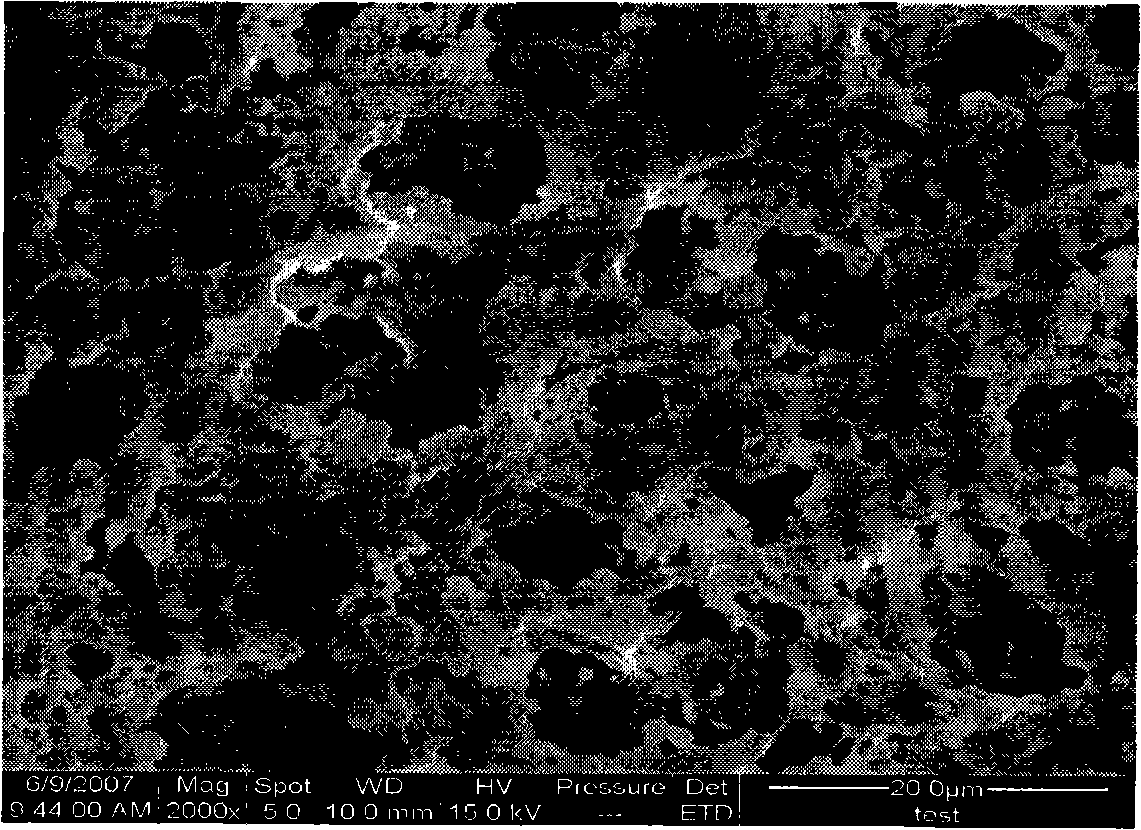

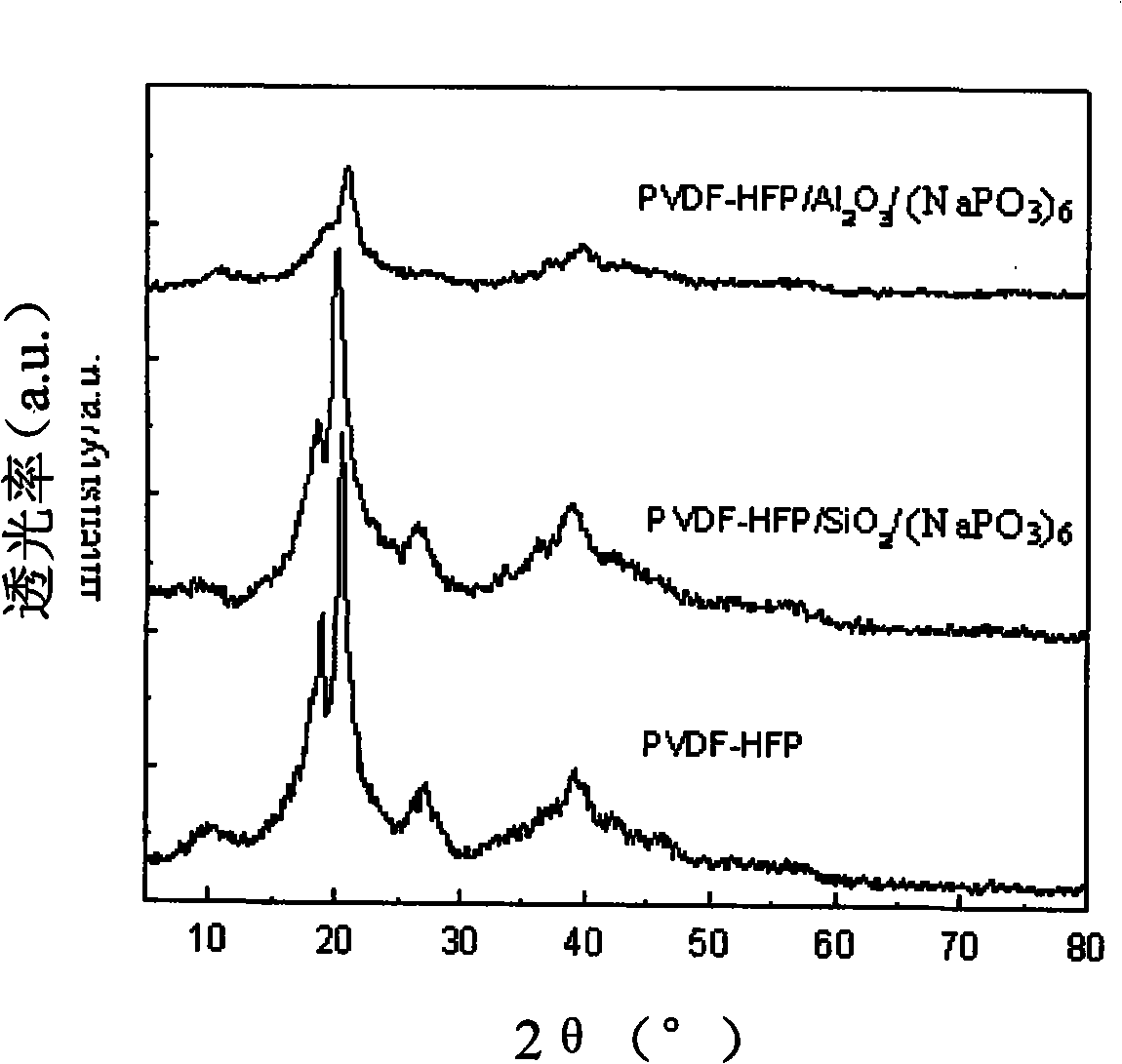

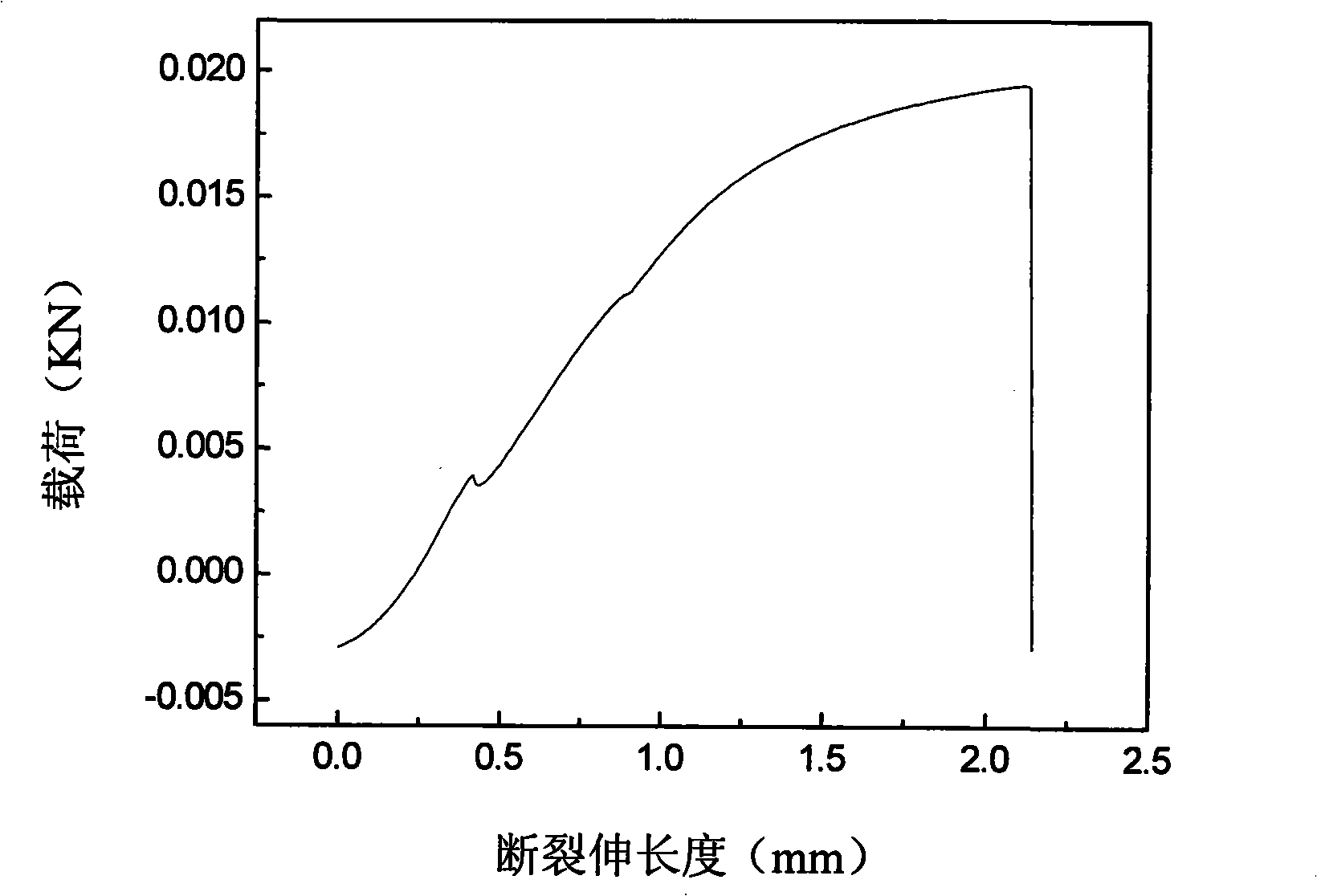

InactiveCN101260216AIncrease the amount of participationHigh mechanical strengthCell component detailsPolymer scienceIon transport number

A PVDF-HFP group composite porous polymer membrane and a preparation method thereof relate to a composite porous polymer membrane and a preparation method thereof, and solve the problems that the prior PVDF-HFP group composite porous polymer membrane has poor interface compatibility, smaller transference number of ions, easy agglomeration of ultrafine powder filler and limited adding amount. The product is made from PVDF-HFP, sodium hexametaphosphate and ultrafine powder filler. The preparation method is as follows: (1) PVDF-HFP is dissolved in organic solvent; (2) sodium hexametaphosphate, ultrafine powder filler and distilled water are mixed and stirred; (3) the mixed solution obtained by step (2) is dripped into the mixed solution obtained by step (1) and then is evenly stirred, thereby obtaining the product through molding and drying forming. The dosage of the ultrafine powder filler occupies more than 41.7 percent of the total weight of raw materials and is evenly dispersed in the polymer matrix; meanwhile, the polymer electrolyte membrane has reinforced mechanical strength, high interface performance and excellent processability; moreover, the product has high conductivity with the transference number of ion Li+ reaching 0.85 and the electrochemical stability window as high as 5.8V.

Owner:HARBIN INST OF TECH

Non-woven type power lithium battery diaphragm and preparation method thereof

ActiveCN105070862ANo powder sheddingUniform porosityCell component detailsPolyethylene glycolDouble bond

The invention belongs to the technical field of battery diaphragm materials, and discloses a non-woven type power lithium battery diaphragm and a preparation method thereof. The preparation method comprises the following steps: modifying silicon dioxide with a silane coupling agent, forming double bonds on the silicon dioxide, initiating methyl methacrylate (MMA) polymerization, grafting and coating the silicon dioxide with polymethyl methacrylate (PMMA) and forming core-shell particles with good heat stability and good wettability on electrolyte; preparing a suspension liquid from the prepared core-shell particles, adding polyethylene glycol dimethacrylate as a fixing agent, immersing non-woven fabrics into the solution, and taking out and drying the non-woven fabrics to obtain a porous diaphragm; and immersing the diaphragm into a poly(vinylidene fluoride)-hexafluoropropene (PVDF-HFP) solution, volatilizing the solvent and baking the diaphragm at a high temperature of 120-140 DEG C, carrying out thermo-crosslinking on the polyethylene glycol dimethacrylate, and drying the polyethylene glycol dimethacrylate to obtain the non-woven type power lithium battery diaphragm. The diaphragm disclosed by the invention has the advantages of excellent heat stability and electrochemical property and has a good application prospect.

Owner:SOUTH CHINA UNIV OF TECH

Three-phase organic/inorganic composite gel state polymer electrolyte and preparation method thereof

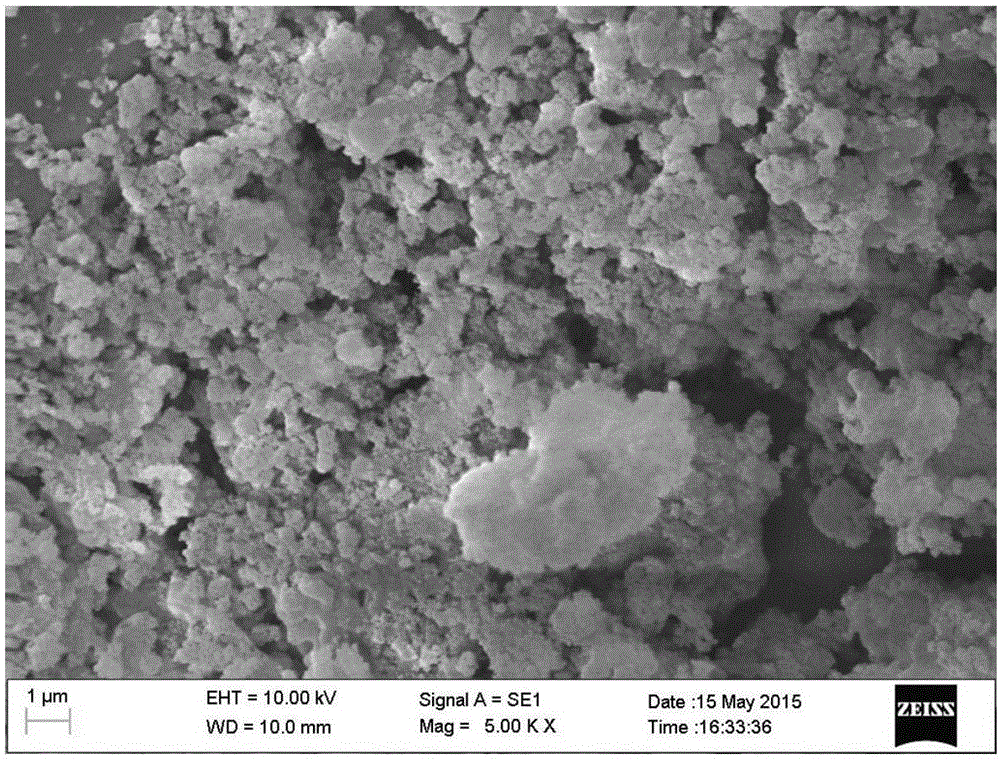

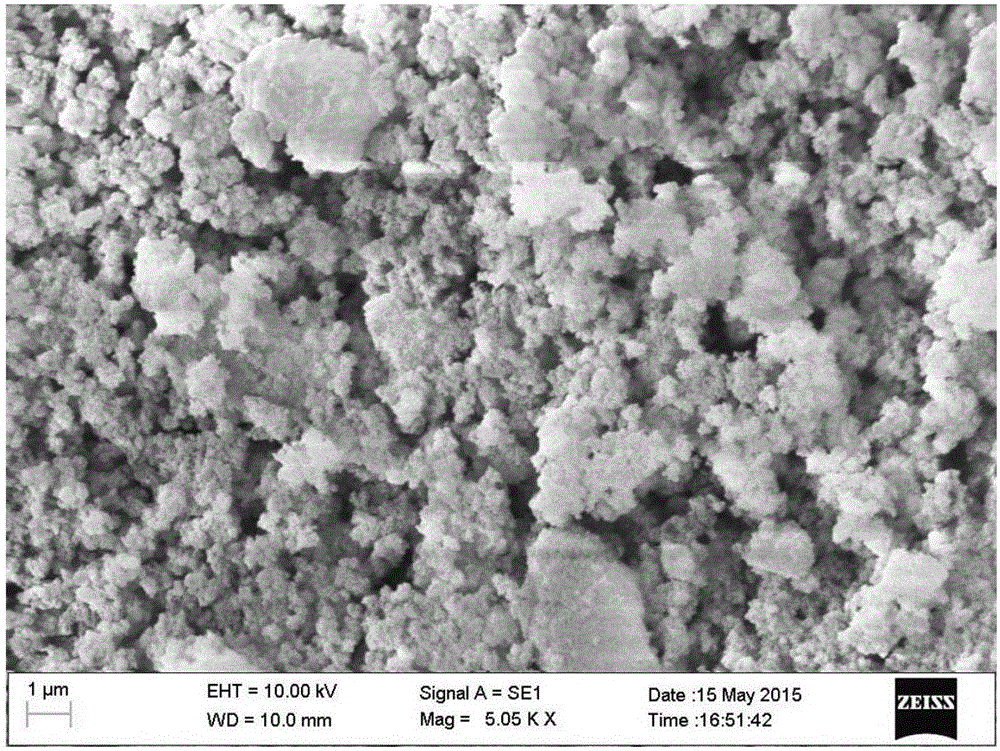

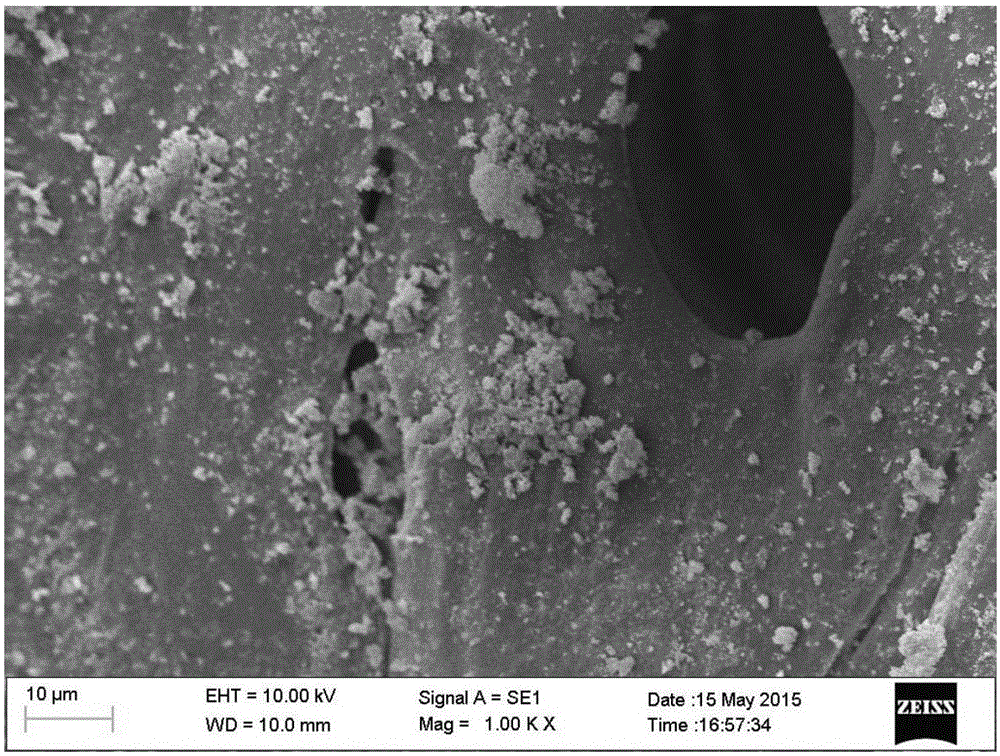

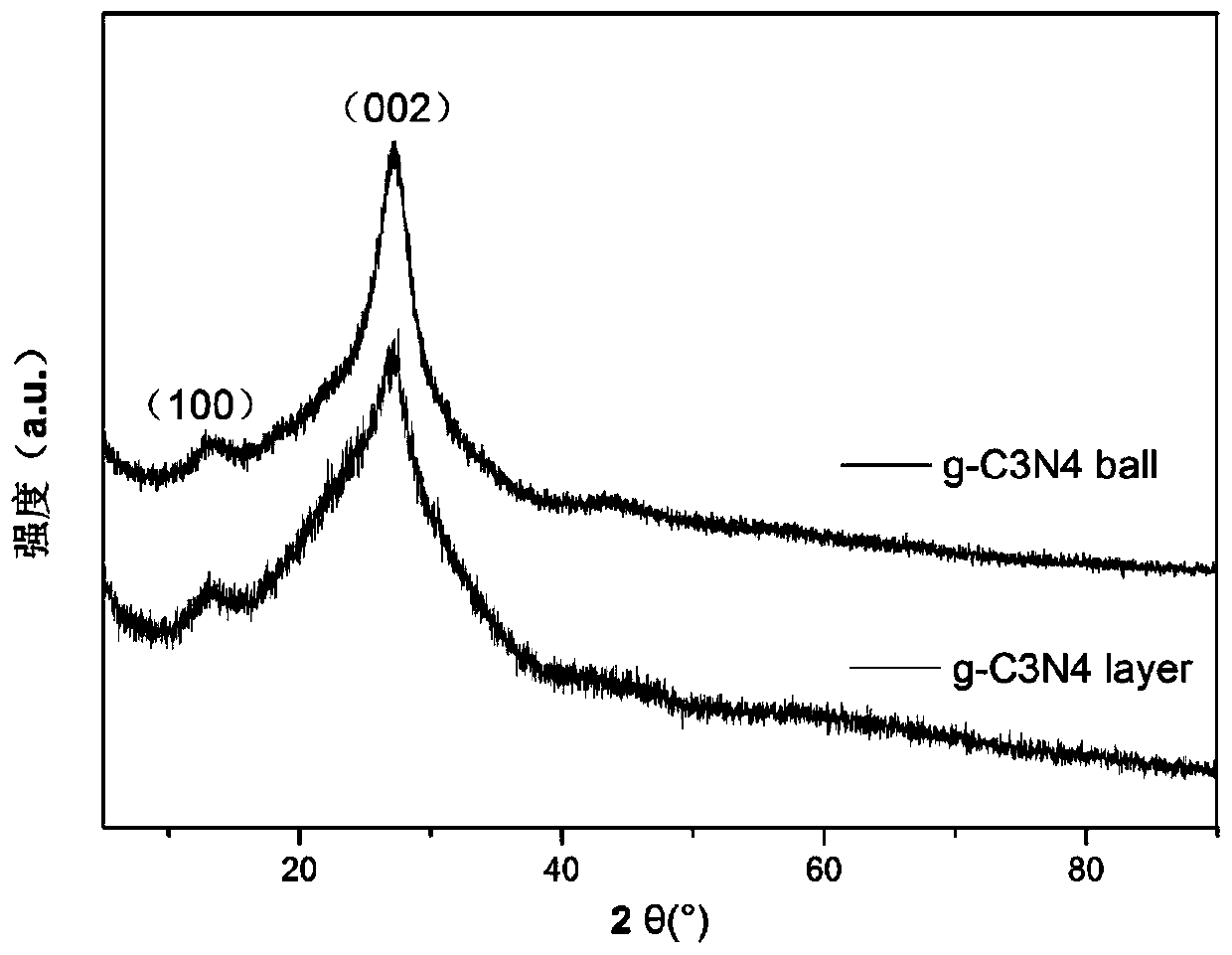

ActiveCN109802173AReduce crystallinityImprove generationSecondary cellsPolymer electrolytesPolymer science

The invention relates to a three-phase organic / inorganic composite gel state polymer electrolyte and a preparation method thereof to solve the technical problem that the mechanical property of an electrolyte membrane is degraded by introducing PEO. The three-phase organic / inorganic composite gel state polymer electrolyte comprises g-C3N4, PVDF-HFP and PEO, The g-C3N4 is in a lamellar and microsphere shape, and is distributed in PVDF-HFP and PEO systems. The mass of g-C3N4 accounts for 0.1%-20% of the total mass of the electrolyte. The invention also provides a method for preparing the three-phase organic / inorganic composite gel state polymer electrolyte. The three-phase organic / inorganic composite gel state polymer electrolyte can be used in the field of preparation of quasi-solid state lithium ion batteries.

Owner:BEIJING UNIV OF CHEM TECH

Prepn of polyvinylidene difluoride film for secondary lithium ion battery

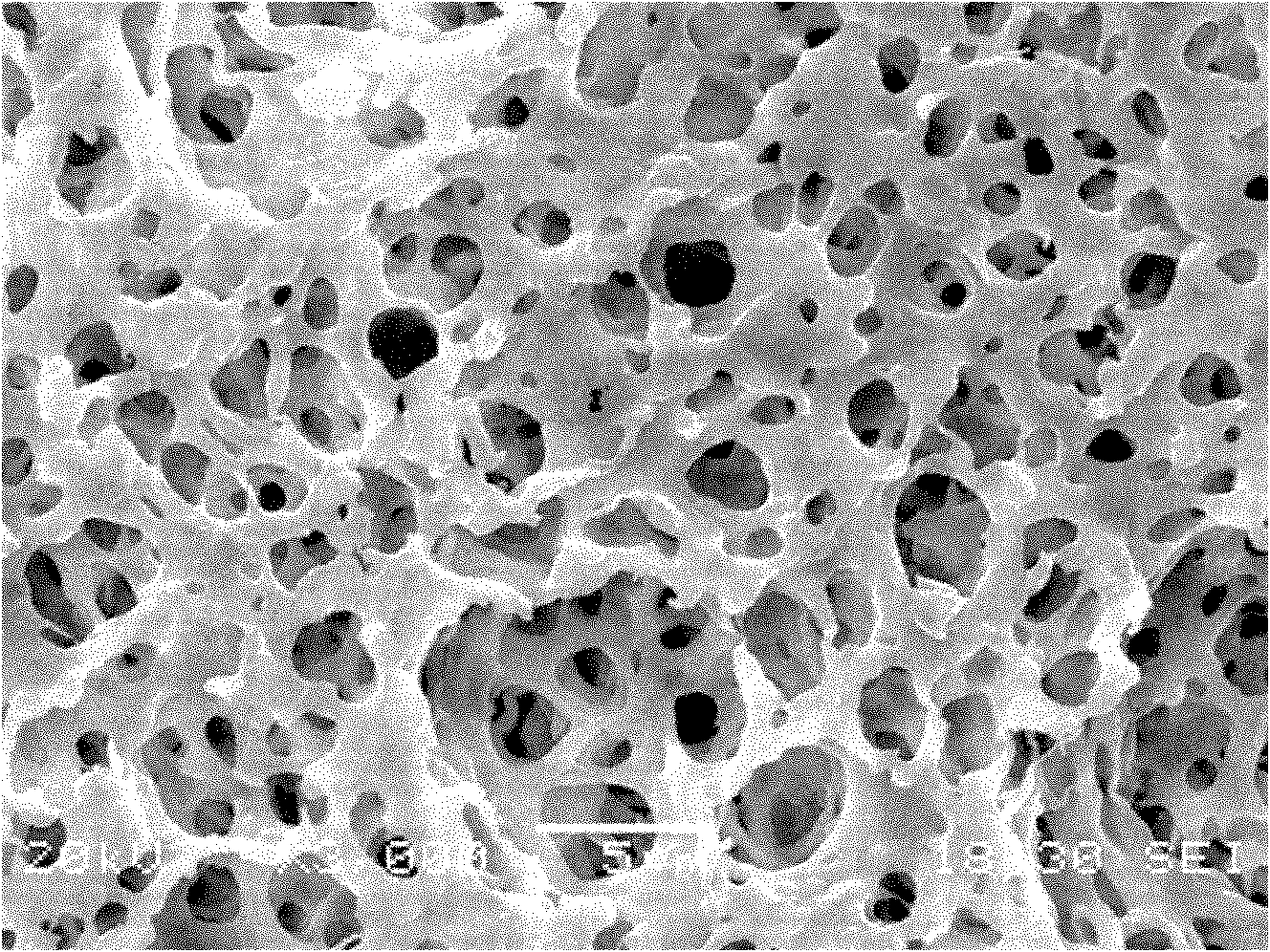

InactiveCN1441507AHigh liquid absorptionSmall apertureCell component detailsAlcoholNetwork structure

This invention relates to a method for preparing PVDF film used in Li ion secondary battery, mixing TFH with acetone to complex component solvent then mixing water with alcohol to complex component unsolvent, mixing the two solvents in 84:8 weight ratio evenly, then to mix PVDF-HFP with the mixture of the two solvents according to 8:92 weight ratio to get this invented PVDF film after stirring up, coating and dry. This invented electrolyte film has small aperture, unregular network structure good for absorbing electrolyte, stable chemical and electric chemical performance and good ionic conductivity.

Owner:QINGNIAO HUAGUANG BATTERY WEIFANG

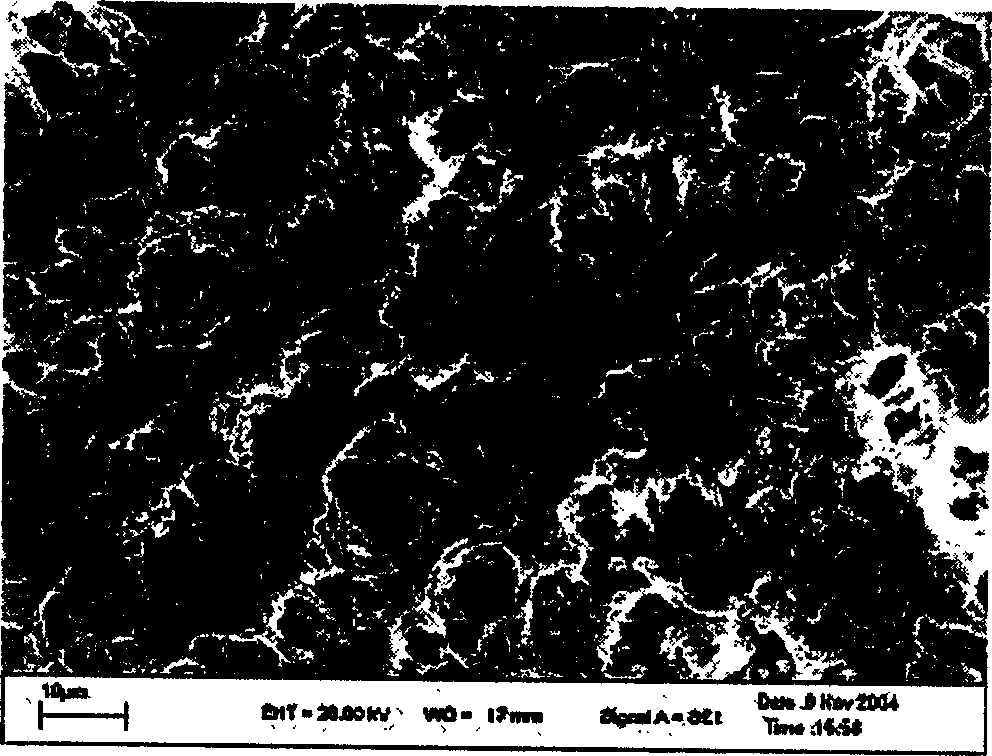

Method for preparing electrolyte of porous compound polymer doped by titanium dioxide through hydrolysis method in situ

InactiveCN1916069AImprove the porous network structureImprove uniformitySecondary cellsComposite electrolyteN-Butanol

This invention relates to an in-situ hydrolysis method for preparing TiO2-doped porous composite polymer electrolyte for Li-ion batteries. The method comprises: (1) dropping diluted tetrabutyl titanate (TBT) solution into mixed acetone solution under stirring to obtain white TiO2 sol; (2) adding PVDF-HFP and n-butanol into white TiO2 sol, heating to 40-60 deg.C and stirring for 2-4 h; (3) preparing TiO2-doped porous composite polymer membrane, and immersing in Li-ion battery electrolytic solution to obtain ion-conductive electrolyte membrane. The method improves the porous network strcture of the electrolyte membrane, and TiO2 is uniformly distributed without forming aggregates. Besides, TiO2 is closely linked with the polymer matrix, thus improving the electrochemical and mechanical properties of the electrolyte membrane.

Owner:UNIV OF SCI & TECH BEIJING

Method for manufacturing ceramic diaphragm for high-safety lithium ion battery

InactiveCN103515563AHigh strengthDimensionally stableCell seperators/membranes/diaphragms/spacersSecondary cellsElectrical conductorTotal solid content

A method for manufacturing a ceramic diaphragm for a high-safety lithium ion battery relates to the technical field of manufacturing methods of ceramic diaphragms for lithium ion batteries, and overcomes the technical defect that a conventional diaphragm for the lithium ion battery cannot be thinned to be 16 micrometers. The method comprises the following steps: 1) batching: at first, dissolving PVDF-HFP in NMP to form a glue solution with the solid content of 5-10%, then adding ceramic powder accounting for 1-3% of the weight of the glue solution in the glue solution, stirring to form a suspension, and adding acetone while stirring, diluting till the total solid content is 1-3%, and at last, forming a suspension for standby application through a sand grinding machine; 2) coating: coating the prepared suspension from the step 1) on a polyolefine film through adopting an infiltrating and lifting method; 3) curing: at first, preliminarily drying the coated suspension coating at the drying temperature of 50-80 DEG C, and then extracting NMP in an extraction solvent slot to obtain a ceramic layer with the thickness of 2-4 micrometers through stacking. The strength and the size stability of the diaphragm can be kept, the ceramic is a bad thermal conductor; when a certain point of the battery is short-circuited, heat cannot be diffused to the whole battery, without causing fires and explosion.

Owner:杨海燕

Multi-hole diaphragm making method for lithium ion battery

The present invention discloses a method for preparing a lithium ion battery used porous diaphragm, and the method of the invention adopts the following steps: mixing PVDF-HFP and dissolvent and nonsolvent according to the proportion, constant-temperature stirring for 2-6h in the temperature 50-80 DEG C to obtain the clear and viscous colloidal sol, afterwards coating and removing the coated film after drying, and last embedding into the baking oven with temperature 60-80 DEG C for furnace drying. The battery separator prepared by the method of the invention has high liquid absorption rate and good charging-and-discharging capability.

Owner:SHENZHEN SENIOR TECH MATERIAL

Aluminum oxide modified polymer electrolyte thin film and preparation method thereof

InactiveCN102134329AReduce crystallinityImprove mechanical propertiesSecondary cellsPVP polymerHexafluoropropylene

The invention provides an aluminum oxide modified polymer electrolyte thin film and a preparation method thereof. The preparation method comprises: mixing polyvinylidene fluoride (PVDF) and hexafluoropropylene (HFP) polymer with aluminum-iso-butoxide, polyvinyl pyrrolidone (PVP) and dimethylacetamide (DMAC), stirring to obtain uniform gel, standing, vacuumizing to remove air bubbles from the gel, uniformly coating the gel on a substrate, controlling temperature to volatilize solvent to obtain a film, namely the nano aluminum oxide modified PVDF-HFP / PVP polymer electrolyte thin film generated in situ. After being soaked in lithium salt solution ofcarbonate(EC)-dimethyl carbonate (DMC)-ethylmethyl carbonate (EMC) to be activated and plasticized, the polymer electrolyte thin film demonstrates high electrochemical performance. The polymer electrolyte thin film prepared by the invention has high mechanical strength, high flexibility, high ionic conductivity and high electrochemical performance and is easy for industrial production.

Owner:CENT SOUTH UNIV

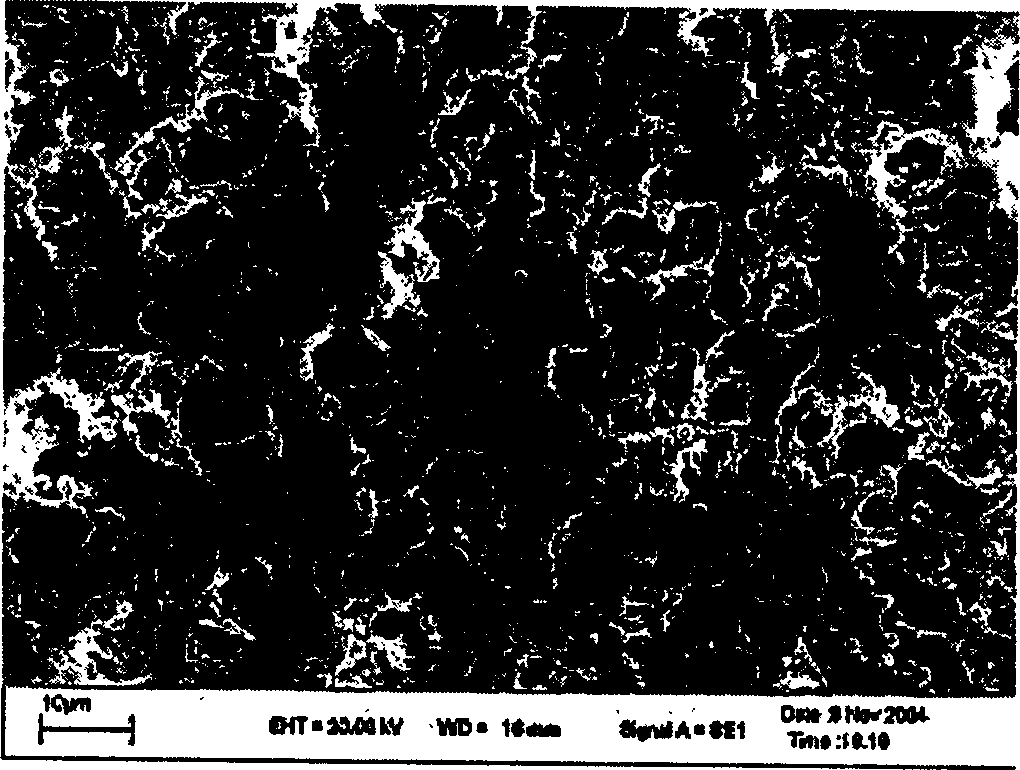

Process for preparing blended micrometer TiO2 polymer electrolyte

The present invention relates to the preparation process of electrolyte for polymer lithium ion cell. The present invention uses micron level TiO2 powder as stuffing for polymer electrolyte film, and prepares PVDF-HFP base polymer electrolyte film via phase transfer process. In the weight ratio of PVDF-HFP to TiO2 in 9-49, weight ratio of PVDF-HFP to deionized water to acetone in 1 to 0.25-1.25 to 5-15, the mixture of solvent and non-solvent is added into the mixture of polymer matrix PVDF-HFP and micron stuffing TiO2 to obtain while homogeneous porous polymer film, which is then soaked in electrolyte liquid for lithium ion cell to obtain electrolyte film with ionic conducting performance and finally heat treated. The present invention has improved and stabilized pore structure of polymer electrolyte film and raised electrochemical performance and mechanical performance of electrolyte film.

Owner:UNIV OF SCI & TECH BEIJING

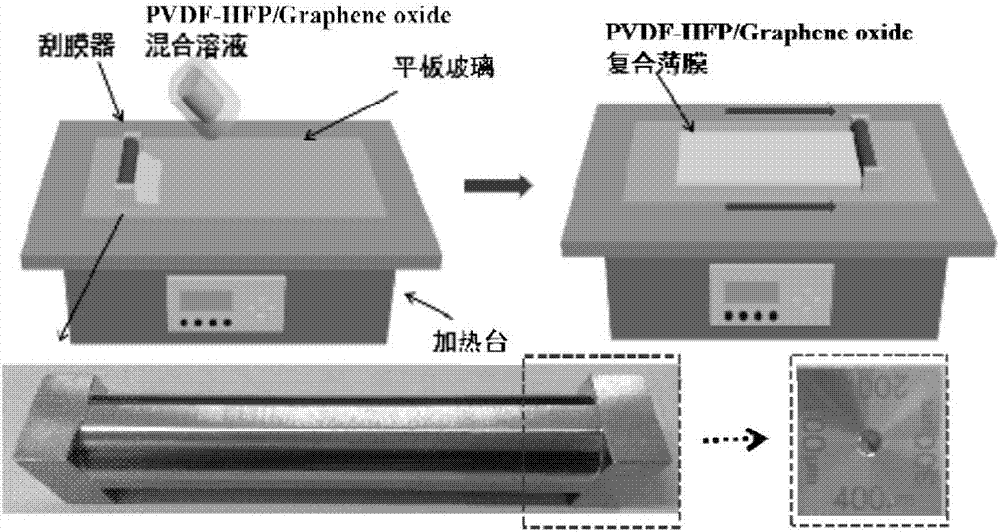

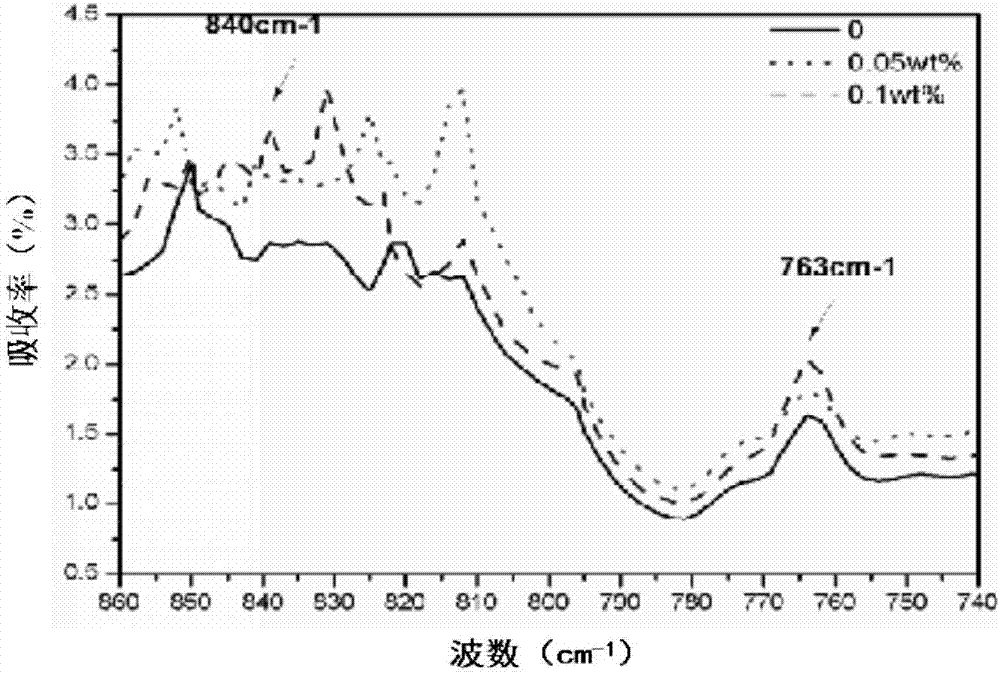

Preparation method of PVDF-HFP/GO composite film for increasing content of beta crystalline phase

The invention discloses a preparation method of a PVDF-HFP / GO composite film for increasing a content of beta crystalline phase, and particular relates to a preparation method of a composite film forincreasing the content of beta crystalline phase in a PVDF-HFP / Graphene oxide composite film, and aims at providing a method for increasing the content of beta crystalline phase of a PVDF-HFP piezoelectric composite film, which solves the problem that the single PVDF-HFP composite film is low in crystallization degree and low in content of the beta crystalline phase. The PVDF-HFP / Graphene oxide composite film is prepared from a piezoelectric material PVDF-HFP and a graphene oxide material by virtue of a scraping process. The method is simple and convenient in film formation and low in cost. The preparation method comprises the following steps: cleaning flat glass; preparing a PVDF-HFP piezoelectric material and graphen oxide material mixed precursor solution; vacuum defoaming; and growingthe piezoelectric composite film on a flat glass substrate by virtue of the scraping process; and stretching and polarizing the piezoelectric composite film.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

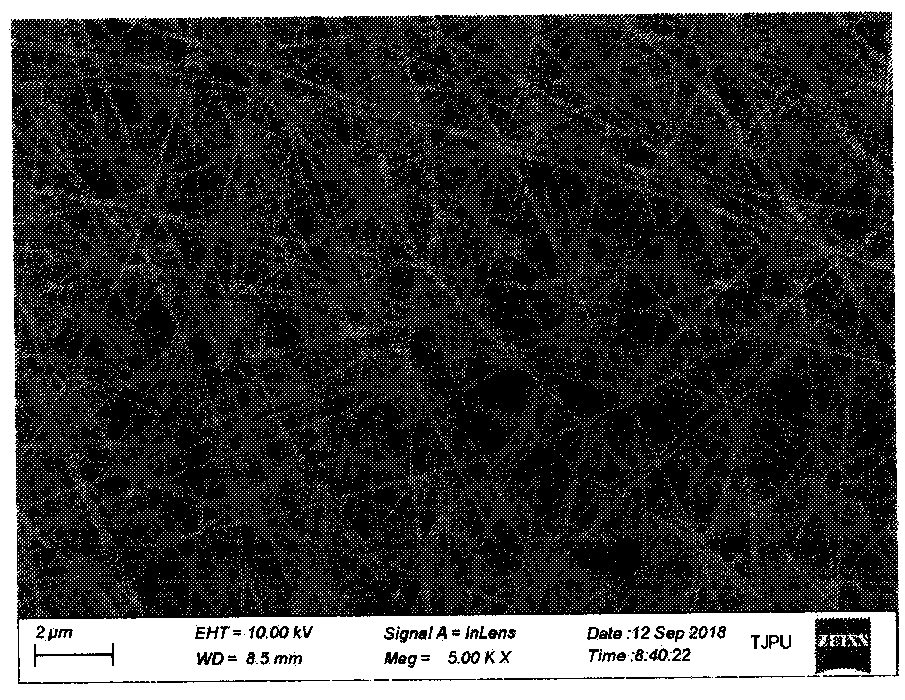

Lithium ion battery electrolyte with multistage structure and preparation method of lithium ion battery electrolyte

InactiveCN109818054AImprove cycle stabilityImprove securitySecondary cellsComposite filmElectrolysis

The invention relates to a preparation method of a polymer electrolyte of a lithium ion battery. The electrolyte is prepared from a gelled polyvinylidene fluoride-hexafluoropropylene / aramid fiber composite film with a multistage structure and an electrolysis solution. The preparation method of the polymer electrolyte comprises the following steps: 1) uniformly stirring an aramid fiber emulsion, adimethylacetamide solvent and polyvinylidene fluoride-hexafluoropropylene (PVDF-HFP) according to a certain proportion, and adding a certain amount of hydrophobic salt tetrabutylammonium hexafluorophosphate to obtain a spinning solution; 2) preparing the polyvinylidene fluoride-hexafluoropropylene / aramid nanofiber composite film with a thickness of 30-50 [mu]m by utilizing an electrostatic spinning technology; and 3) immersing the composite film into a mixed solution of ethylene carbonate, lithium hexafluorophosphate and diethyl carbonate in a volume ratio of 1:1:1, and standing for 8 hours toprepare the polyvinylidene fluoride-hexafluoropropylene / aramid fiber polymer electrolyte. The prepared polymer electrolyte with the multistage structure for the lithium ion battery is good in lyophilic property, resistant to high temperature and high in strength, and has important significance for improving the electrochemical performance and the safety performance of the lithium ion battery.

Owner:TIANJIN POLYTECHNIC UNIV

Preparation method of ion liquid gel-based all-gel supercapacitor

ActiveCN108630461AEnhanced electron-ion conductivityClose contactHybrid capacitor electrolytesHybrid capacitor electrodesCarbon nanotubeUltraviolet lights

The invention relates to a preparation method of an ion liquid gel-based all-gel supercapacitor. The preparation method comprises the following steps of performing mixing and grinding on a carbon nanotransistor and an ion liquid, and then enabling PVDF-HFP and acetylene black to be mixed, and carrying out high-temperature stirring and then solvent evaporation to obtain a gel electrode; performingmixing on a monomer, a crosslinking agent and the high-electrical conductivity ion liquid at the room temperature, and next, adding a photoinitiator to perform glue forming under ultraviolet light toobtain an ion gel electrolyte; and coating the upper and lower surfaces of the ion gel electrolyte with the gel electrodes uniformly through a coating mode, and carrying out high-temperature drying toobtain an integrated all-gel material with a gel electrode-gel electrolyte-gel electrode sandwich structure, and by adopting an aluminum foil as a current collector to be connected with an external circuit to obtain the product. Compared with the prior art, the electrode-electrolyte interface electron-ion conduction capability is reinforced, so that fusion of the electrode-electrolyte interface is promoted, interface resistance is lowered, and the tolerant temperature range is wider.

Owner:TONGJI UNIV

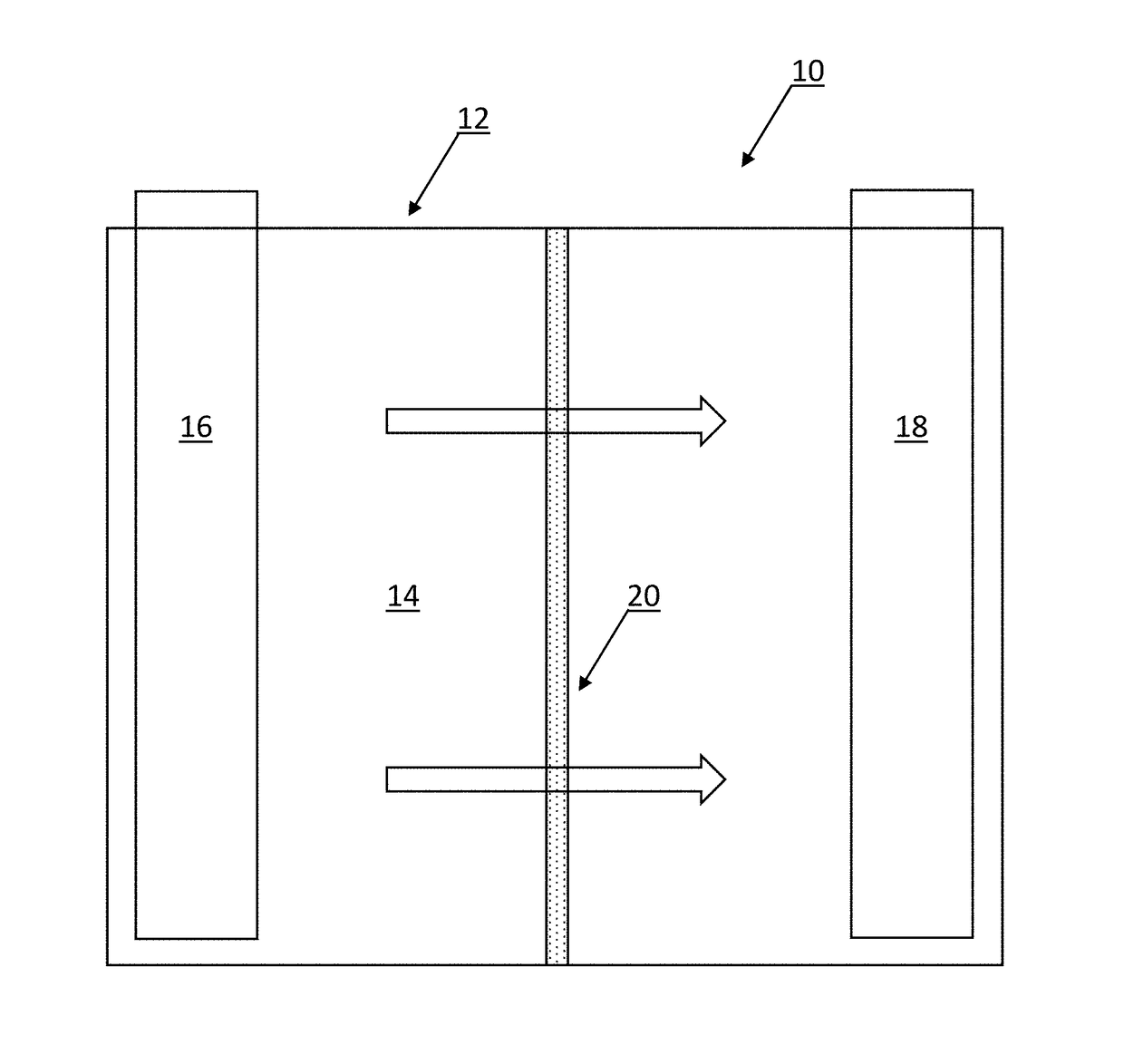

Electrochemical cell with emission controlled by electrodeposition of copper

ActiveUS7736813B2Increase contrastShort timeNon-aqueous electrolyte accumulator electrodesNon-linear opticsActivated carbonPorous layer

The invention concerns an electrochromic cell with emission controlled by electrodeposition under the action of a control voltage. The cell comprises the following flexible elements, superimposed and respectively in intimate contact:a first electrode (11) intended to be connected to a first potential of the control voltage,a first porous layer (12), formed of a mixture of PVDF-HFP, PEO and an activated carbon powder,a porous separator (13), formed of a mixture of PVDF-HFP and PEO,a second electrode (14) formed of a grid and connected to a second potential of the control voltage,a second porous layer (15), formed of a mixture of PVDF-HFP, PEO and carbon powder,an aqueous electrolytic solution containing a copper salt being contained in the first flexible layer (12), in the separator (13) and in the second flexible layer (15).

Owner:EURON AERONAUTIC DEFENCE & SPACE

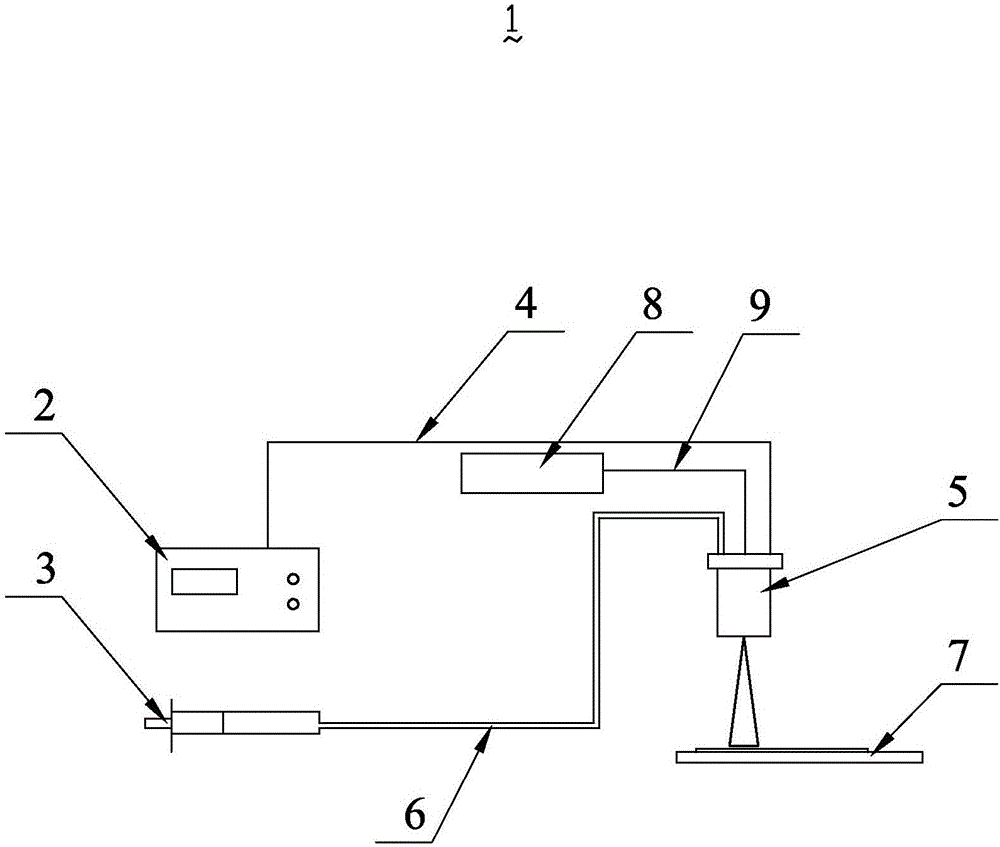

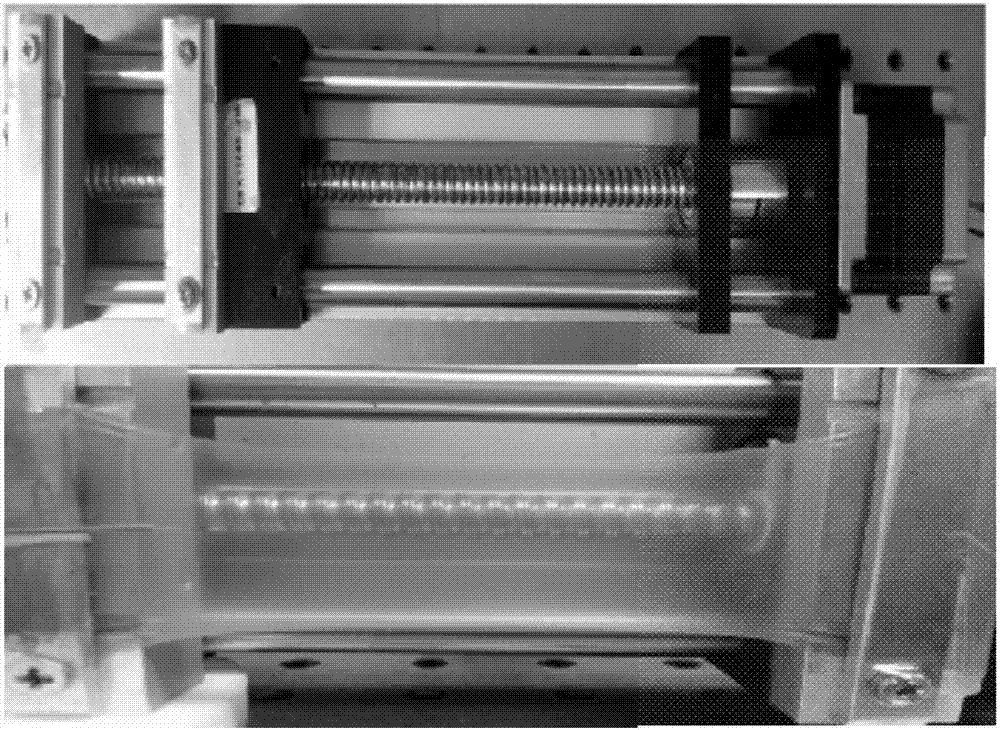

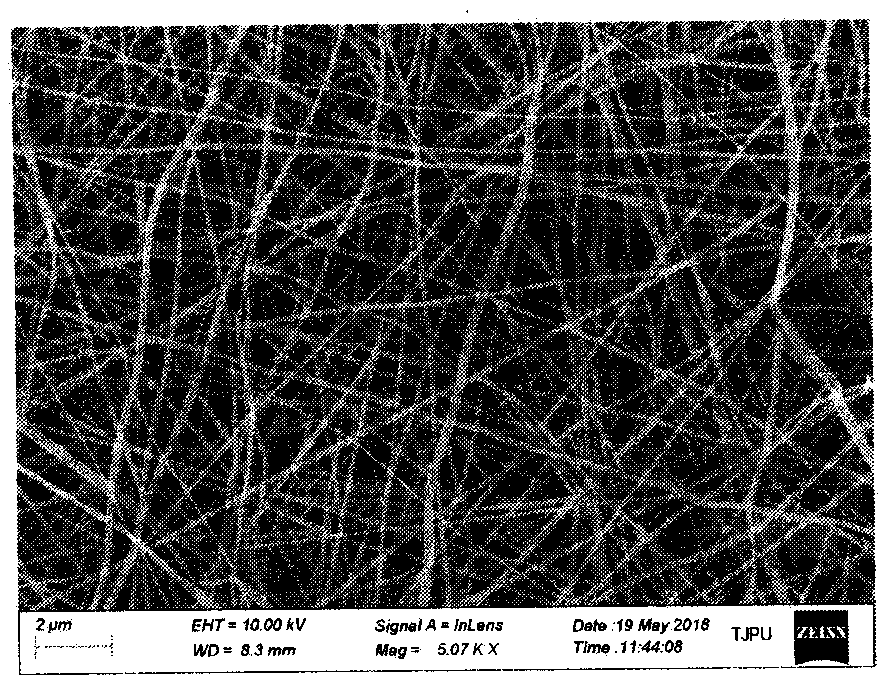

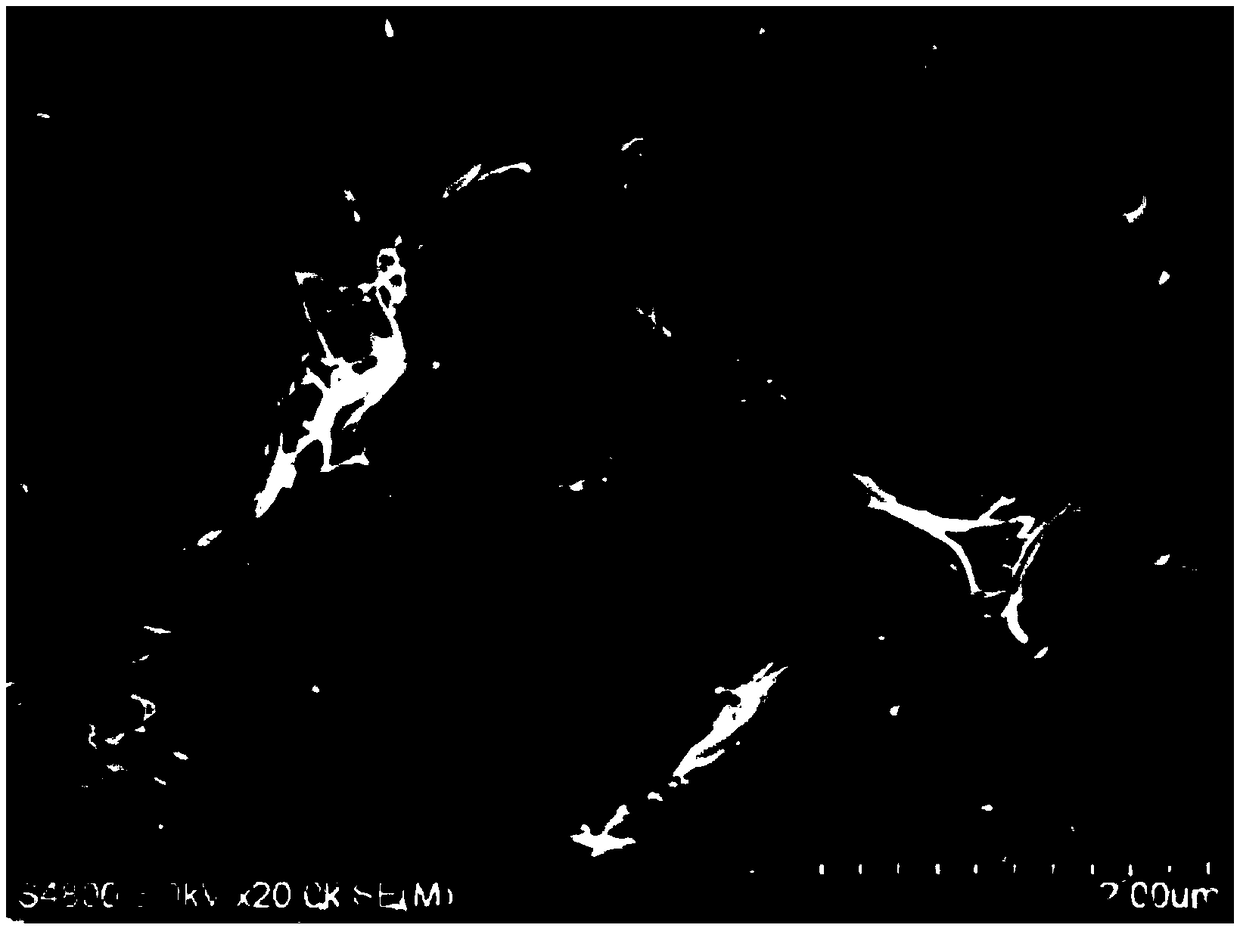

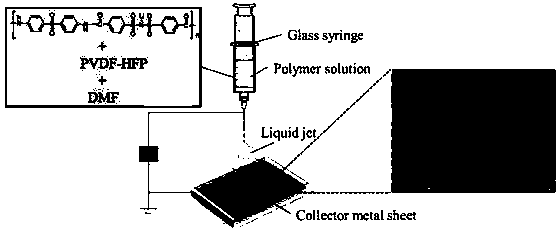

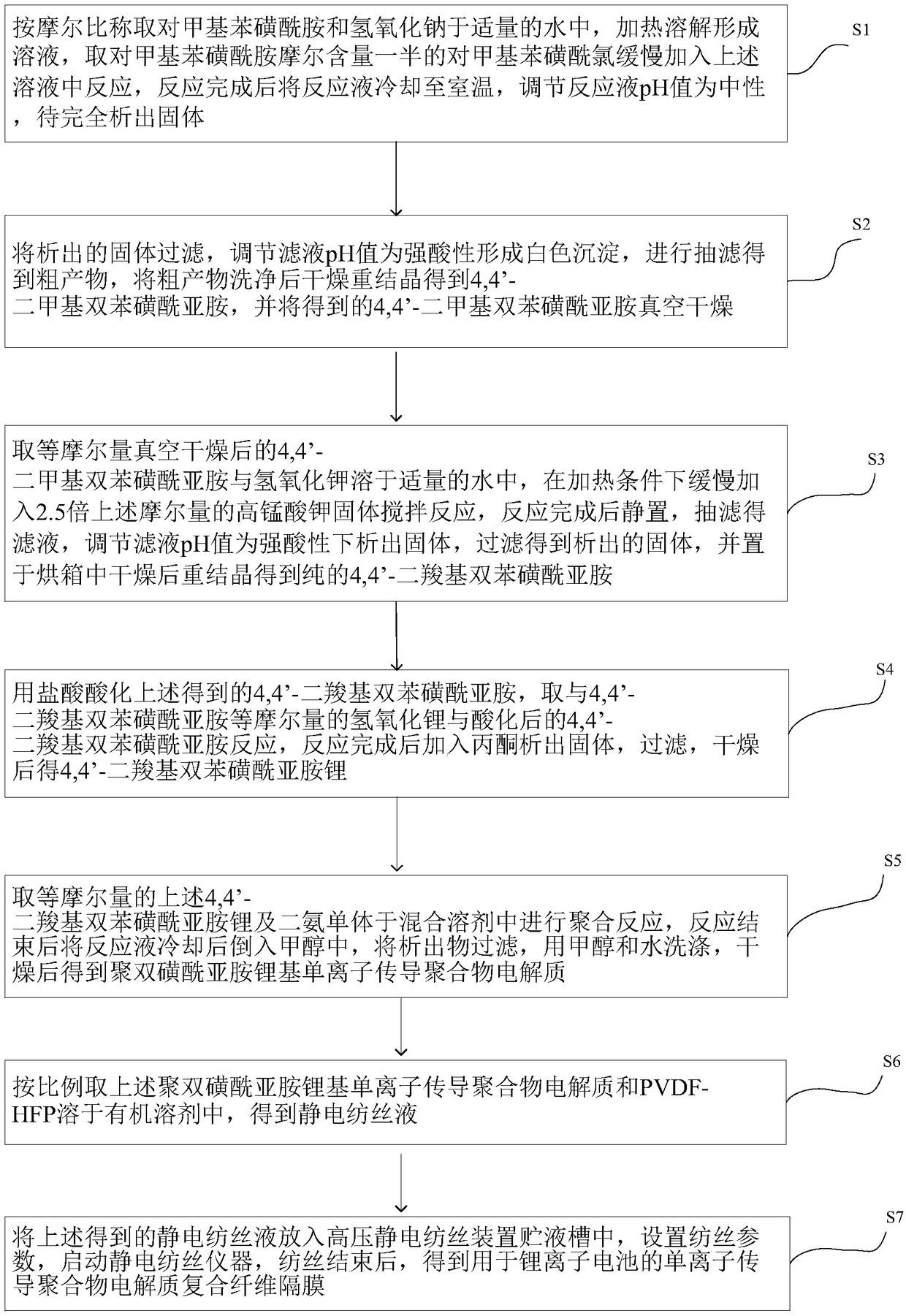

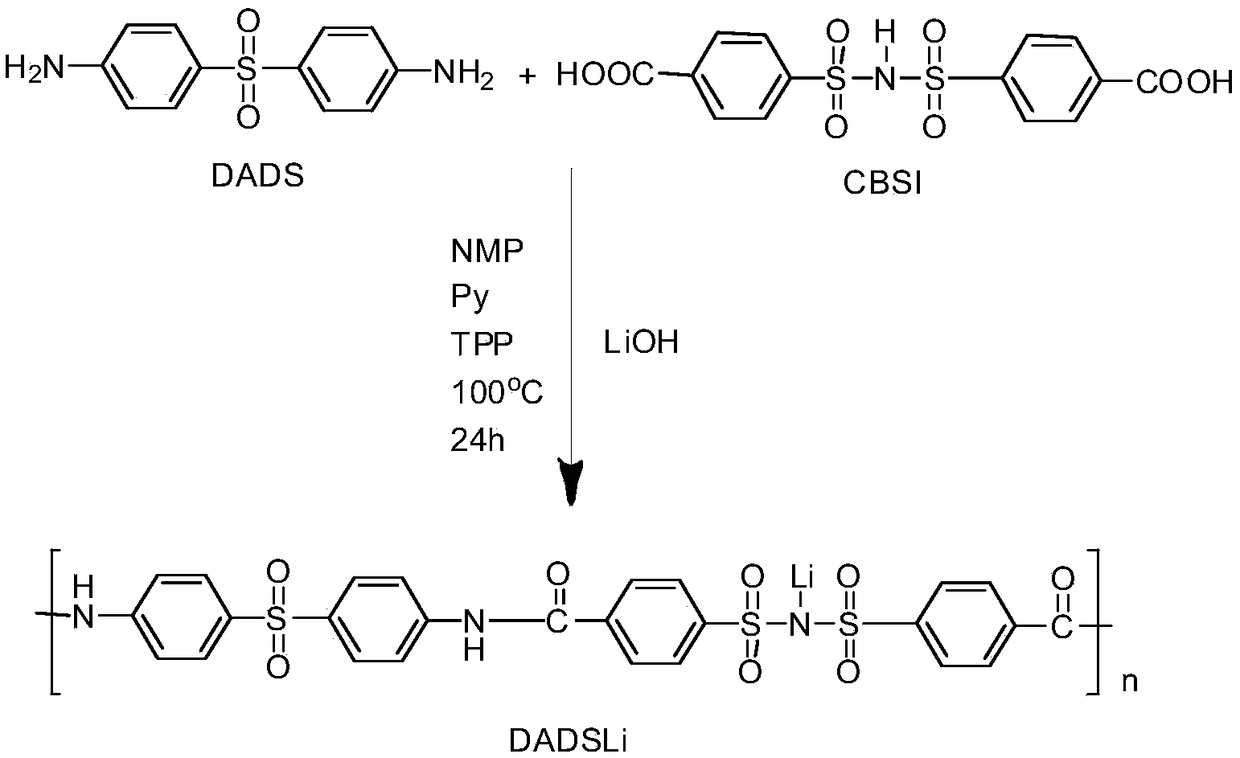

Method for preparing single-ion conductive polymer electrolyte composite fiber diaphragm by means of electrospinning

ActiveCN108716025AImprove cycle performanceSimple preparation processFilament/thread formingCell component detailsFiberPorosity

The invention discloses a method for preparing a single-ion conductive polymer electrolyte composite fiber diaphragm by means of electrospinning and belongs to the technical field of preparation of battery diaphragms. PVDF-HFP and a polybisulfonimide lithium-based single-ion conductive polymer electrolyte are dissolved in a certain solvent according to a certain ratio to obtain an electrospinningsolution; the electrospinning solution is used for preparing a nanofiber membrane through an electrospinning technology, and finally vacuum drying is conducted to obtain the composite fiber diaphragm.Composite fiber membranes of different diameters can be obtained by adjusting parameters such as concentration, flow rate, voltage and receiving distance of the electrospinning solution. The composite fiber diaphragm prepared by the method has high porosity, high ionic conductivity and a good application prospect and is conductive to cycle performance of batteries.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Heat activated microporous membrane and its application in battery

InactiveCN1439666AGood current charging and discharging abilityHigh porosityCell component detailsCalcium silicateFumed silica

PROBLEM TO BE SOLVED: To provide a porous membrane for use in fabricating a storage battery, and to provide a method for manufacturing the same.SOLUTION: The porous membrane comprises: (a) a hot melt adhesive agent such as poly(ethylene-vinyl acetate) or a poly(ethylene-alkyl acrylate) (b) an engineering plastic such as polysulfone, polycarbonate, or poly(styrene-methyl methacrylate). The membrane may also contain as required: (c) an adhesiveness providing agent such as an aromatically modified aliphatic hydrocarbon resin, aliphatic resin, hydrogenated alicyclic hydrocarbon resin, rosin resin, polyterpene resin, or PVdF-HFP; and / or (d) a filler such as fumed silica, alumina, titanium dioxide, molecular sieve, calcium carbonate, calcium silicate, glass, ceramic material, or polytetrafluoroethylene. The membrane is bonded to battery electrodes by thermal activation at approximately 35-125 °C and approximately 0.5-100 psi.

Owner:POLICELL TECH

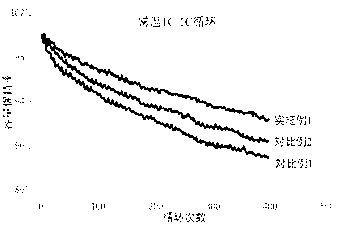

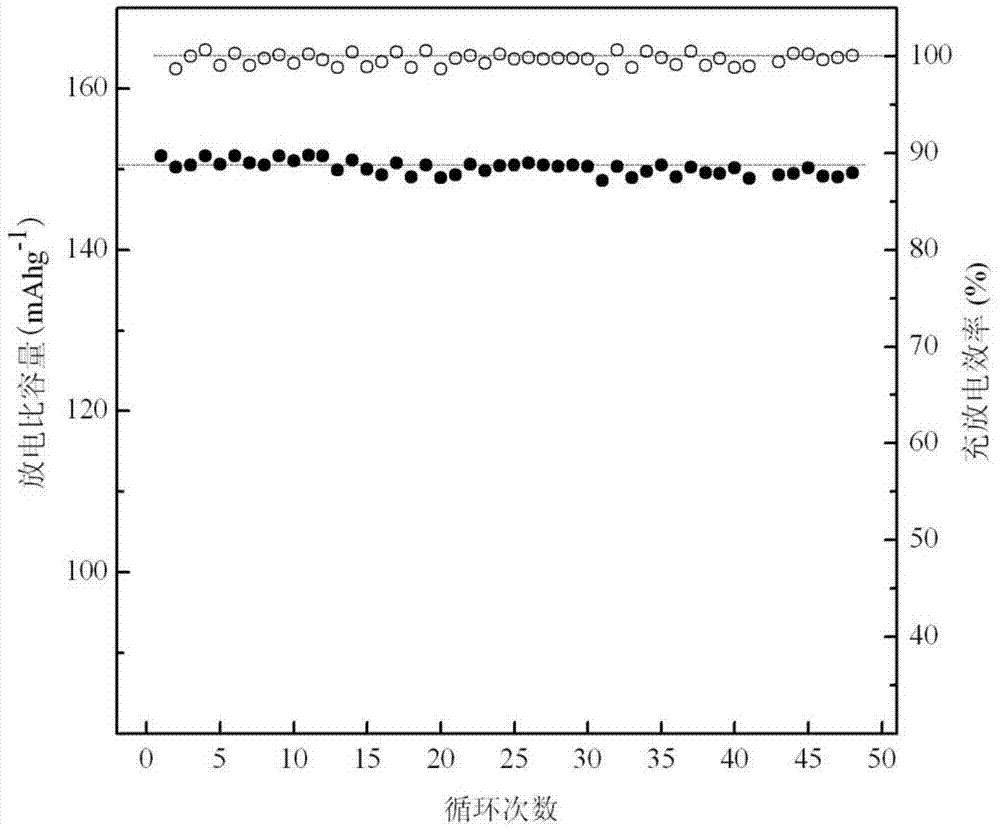

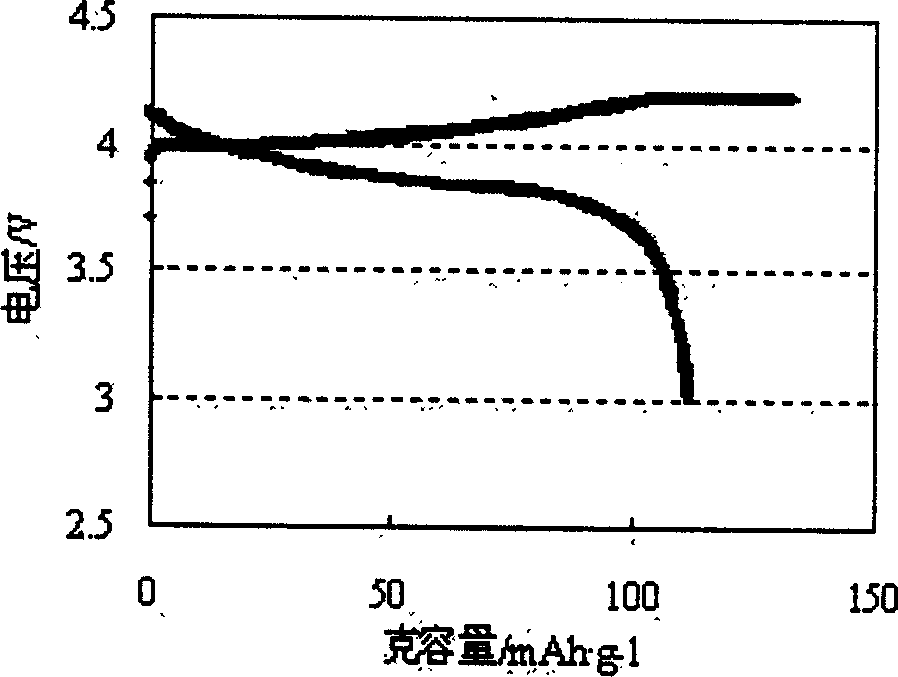

Compound lithium-ion battery diaphragm and preparation method thereof

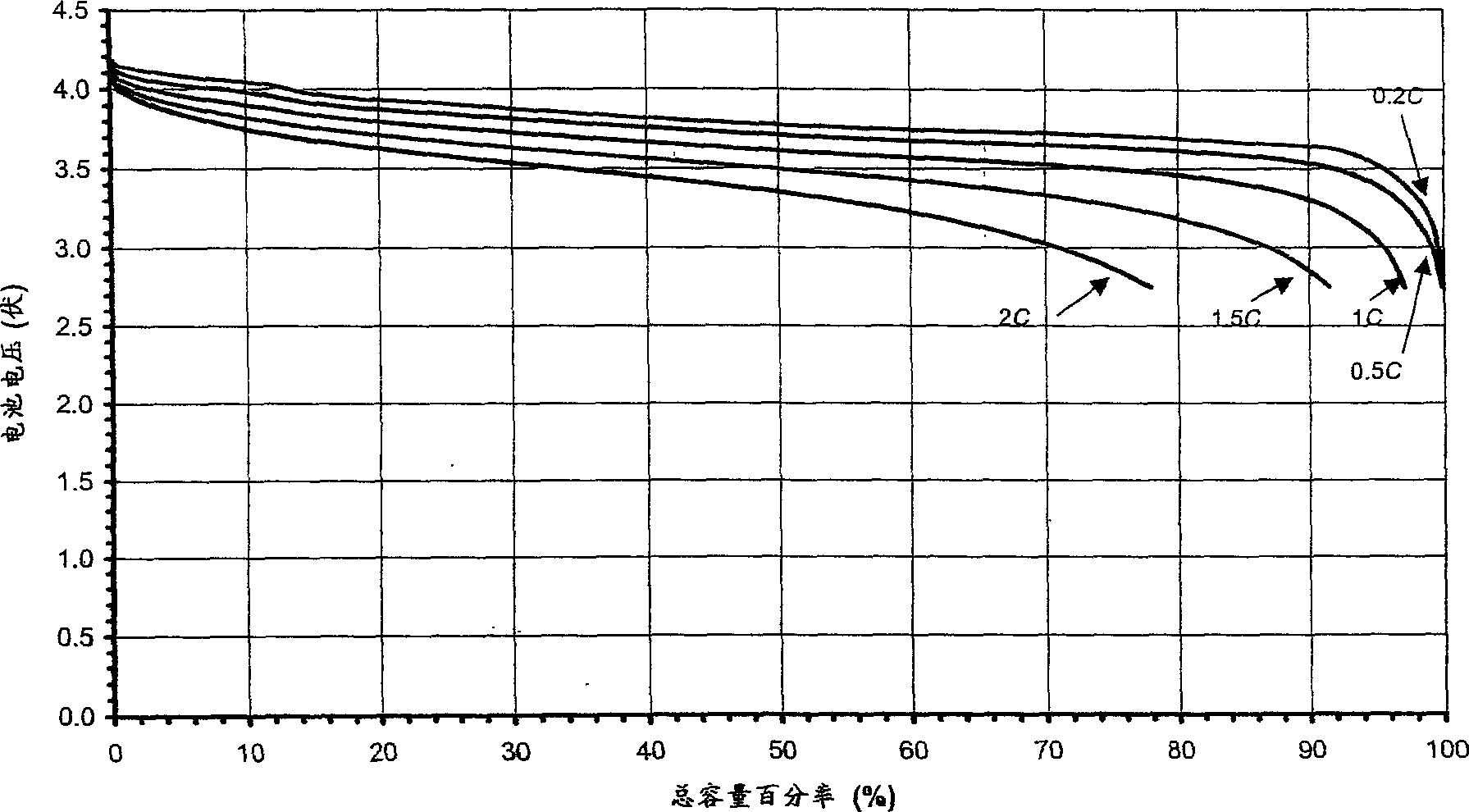

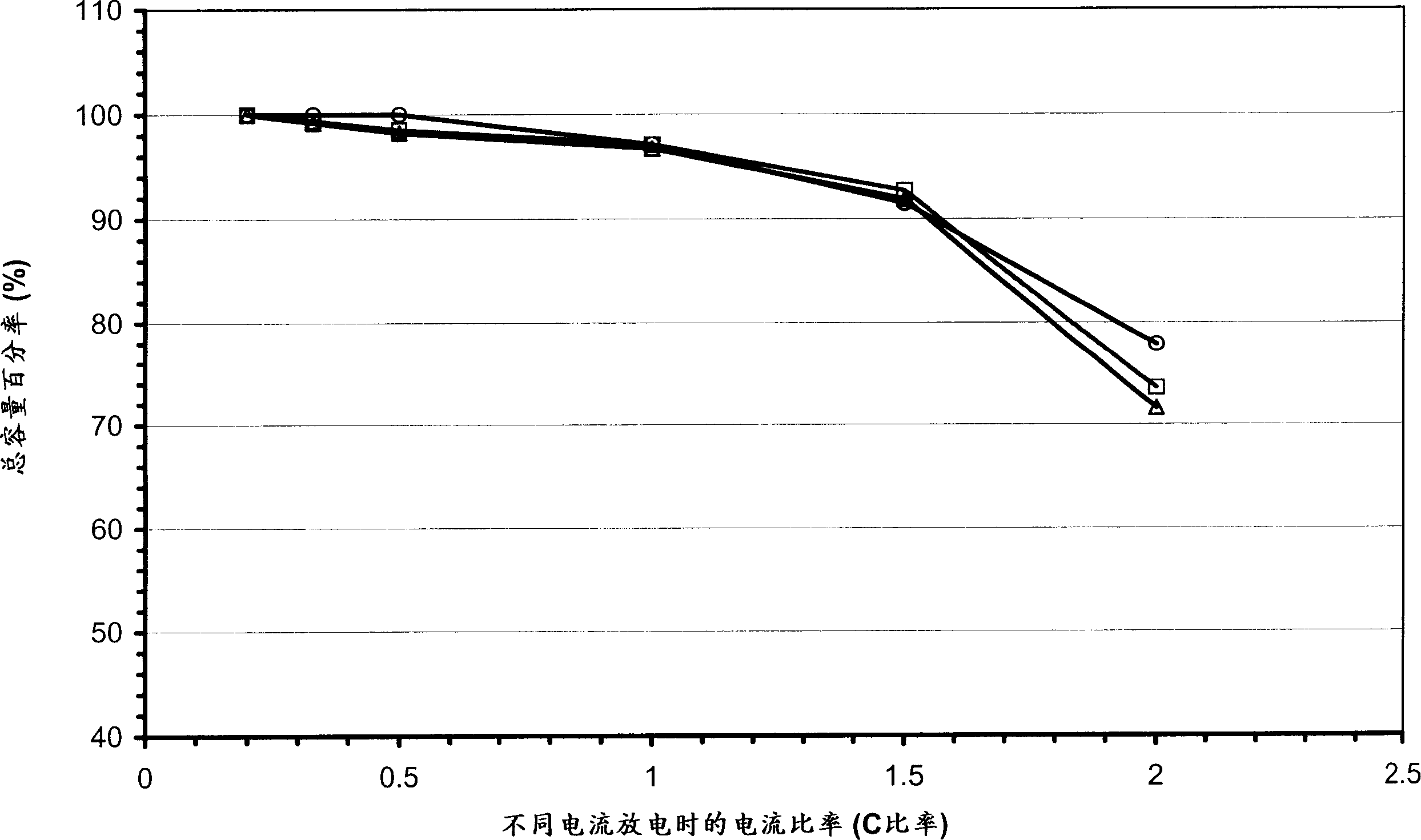

ActiveCN104362278AImprove electrochemical performanceImprove stabilityCell seperators/membranes/diaphragms/spacersPorosityHexafluoropropylene

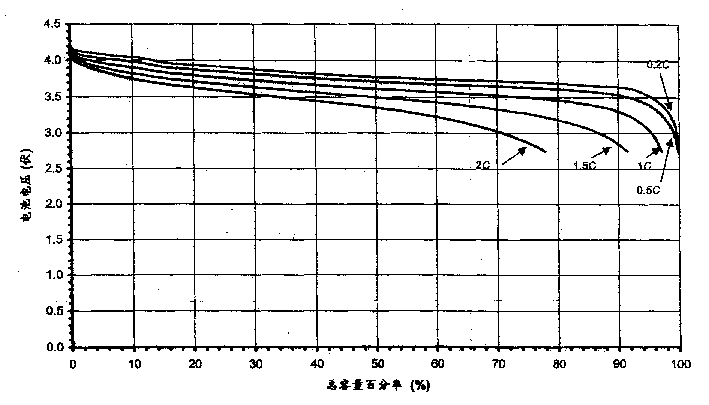

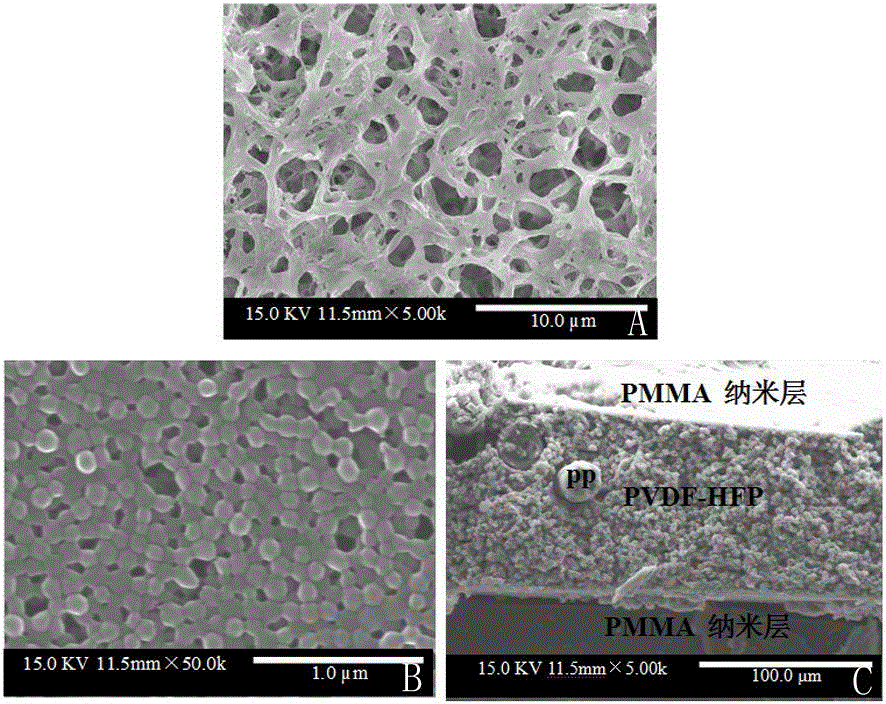

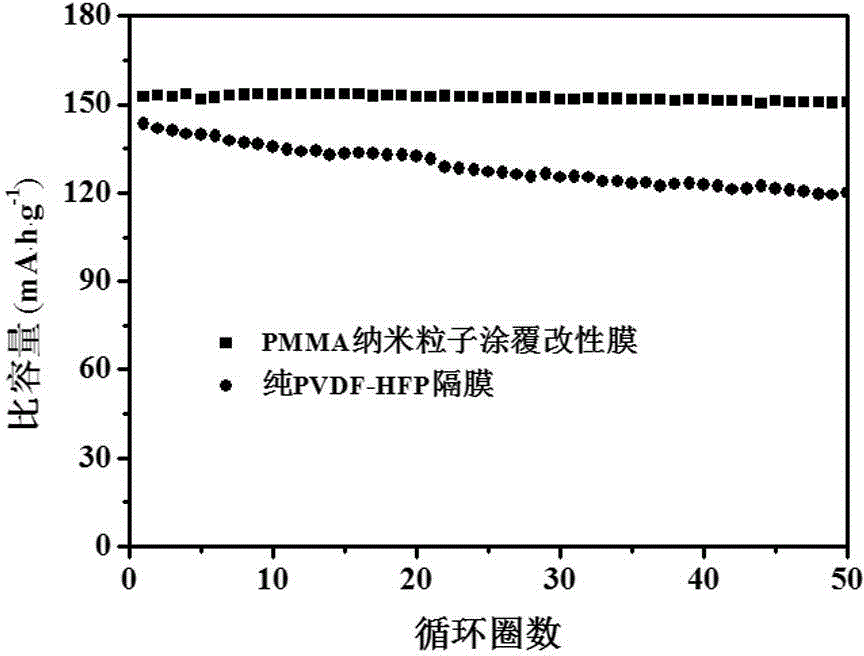

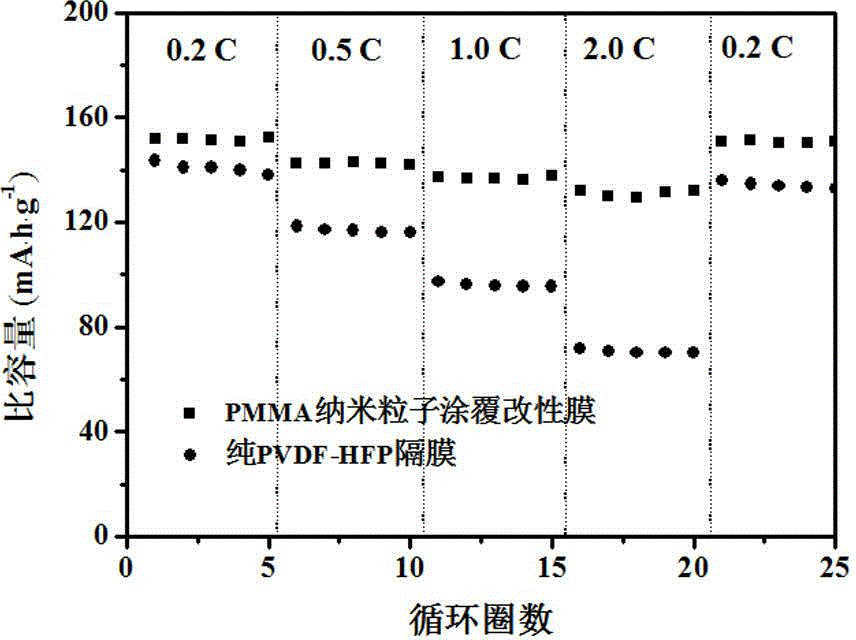

The invention relates to a compound lithium-ion battery diaphragm and a preparation method thereof, aiming to solve the problems of low ionic conductivity, poor rate discharge performance, poor heat resistance stability and the like of an existing battery diaphragm. The compound lithium-ion battery diaphragm has a sandwich type lamellar structure, the middle of the compound lithium-ion battery diaphragm is a PVDF-HFP (polyvinylidene fluoride-hexafluoropropylene) matrix layer supported by a PP (Propene Polymer) nonwoven fabric, and two sides of the compound lithium-ion battery diaphragm are nanometer layers uniformly covered by polymer nanoparticles. The compound lithium-ion battery diaphragm has a porosity of reaching 75 percent, a liquid absorbing rate of being greater than 200 percent, and an ionic conductivity of about 1.846-10<-3> S / cm. A LiFePO4 / CPE / Li battery is assembled by using the compound lithium-ion battery diaphragm, the discharge specific capacity at 0.2C / 0.2C reaches 150 mA.h.g<-1> (theoretical specific capacity is 170 mA.h.g<-1>), the coulombic efficiency of a battery reaches 99 percent; and the discharge at 2C / 0.2C can be always kept 90 percent of the original specific capacity.

Owner:SUZHOU UNIV

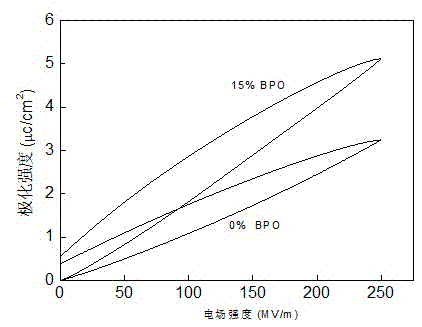

Method for preparing polyvinylidene fluoride (PVDF)-hexafluoropropylene (HFP) modification membrane of high energy density through hot pressing cross linking

The invention discloses a method for preparing a polyvinylidene fluoride (PVDF)-hexafluoropropylene (HFP) modification membrane of high energy density through hot pressing cross linking. The method comprises steps of dissolving cross linking agents benzoyl peroxide (BPO) and PVDF-HFP by using a solvent, preparing a transparent uniform solution, pouring the solution to a dispersed uniform BPO / PVDF-HFP binary composite material on the normal temperature condition, removing a residual solution through vacuum drying, placing the BPO / PVDF-HFP binary composite material in a tablet press, and on certain temperature and pressure conditions, preparing the PVDF-HFP cross linking modification membrane through the hot pressing cross linking. The method is simple in process, an expensive ultraviolet light cross linking method or an expensive electron irradiation method is not used, the energy density of the prepared cross linking modification membrane is improved and the dielectric loss is reduced.

Owner:NANJING UNIV

Shutdown and non-shutdown separators for electrochemical devices

ActiveUS20180309106A1High mechanical strengthImprove ionic conductivityCell component detailsImidePolyetherimide

The present invention provides a novel process that involves a reliable, robust, reproducible, and cost effective casting technique for a shutdown separator with, for example, a combination of poly(vinylidene fluoride-co-hexafluoropropylene) (PVdF-HFP) copolymer, polysulfonamide (PSA) / polyether imide (PEI), and CaCO3 powder, and for a non-shutdown separator with, for example, a combination of polysulfonamide (PSA) / polyether imide (PEI), filler / plasticizer, and metal oxide nanostructures (SiO2, TiO2, and Al2O3).

Owner:AVOMEEN ANALYTICAL SERVICES

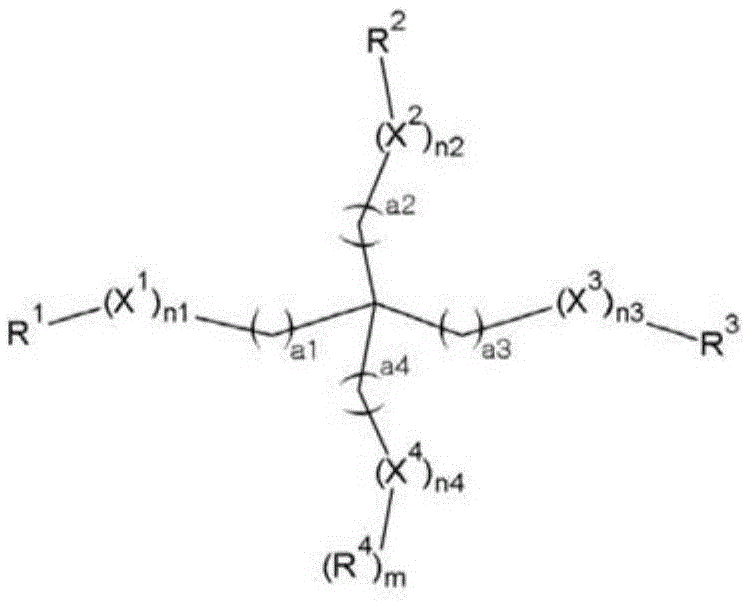

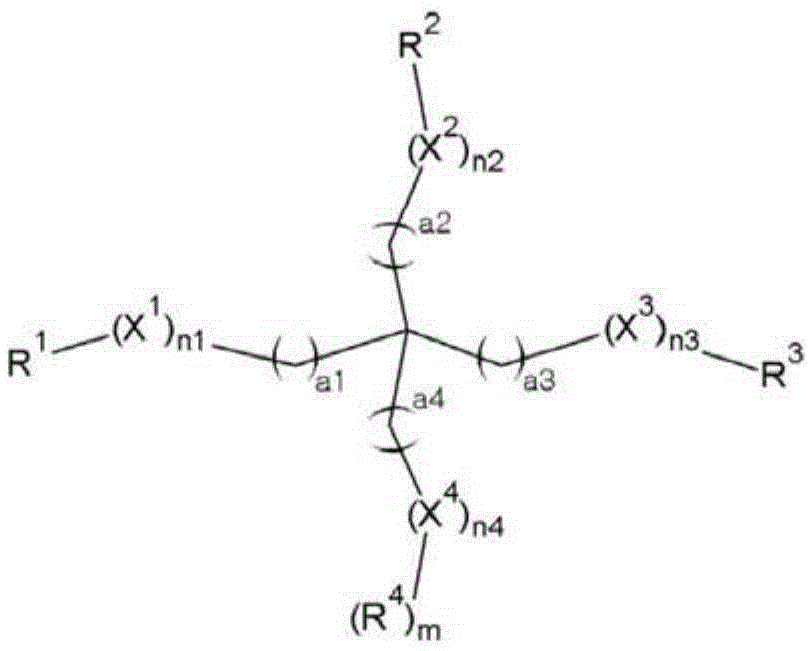

Composition For Heat-Resistant Porous Layer, Separator Comprising The Same And Electrochemical Battery Using The Same

ActiveCN105742546AGood resistance to ruptureImprove breathabilityLi-accumulatorsCell component detailsPorous substrateHexafluoropropylene

Disclosed herein is a composition for a heat resistant porous layer, a separator including the heat resistant porous layer formed from said composition, and an electrochemical battery including the separator. The composition for the heat resistant porous layer includes: at least one selected from the group consisting of a monomer, oligomer, and polymer represented by Formula 1, and a mixture thereof; at least one selected from the group consisting of a polyvinylidene fluoride (PVdF)-based homopolymer, a polyvinylidene fluoride-hexafluoropropylene-based copolymer, and a mixture thereof; an initiator; and a solvent, wherein a unit originating from hexafluoropropylene is present in an amount of >0 wt% to 15 wt% based on the total weight of the polyvinylidene fluoride-hexafluoropropylene-based copolymer, and the polyvinylidene fluoride-hexafluoropropylene-based copolymer has a weight average molecular weight of 600,000 g / mol. Furthermore disclosed herein is a separator comprising a porous substrate and a heat resistant porous layer wherein the heat resistant porous layer comprises polymers of PVdF and / or PVdF-HFP and a crosslinkable binder and the separator has a tensile strength of 50 kgf / cm 2 to 350 kgf / cm 2 , as measured after being left at 200 DEG C for 10 minutes. Furthermore disclosed is an electrochemical battery, comprising: an anode; a cathode; said separator; and an electrolyte.

Owner:SAMSUNG SDI CO LTD

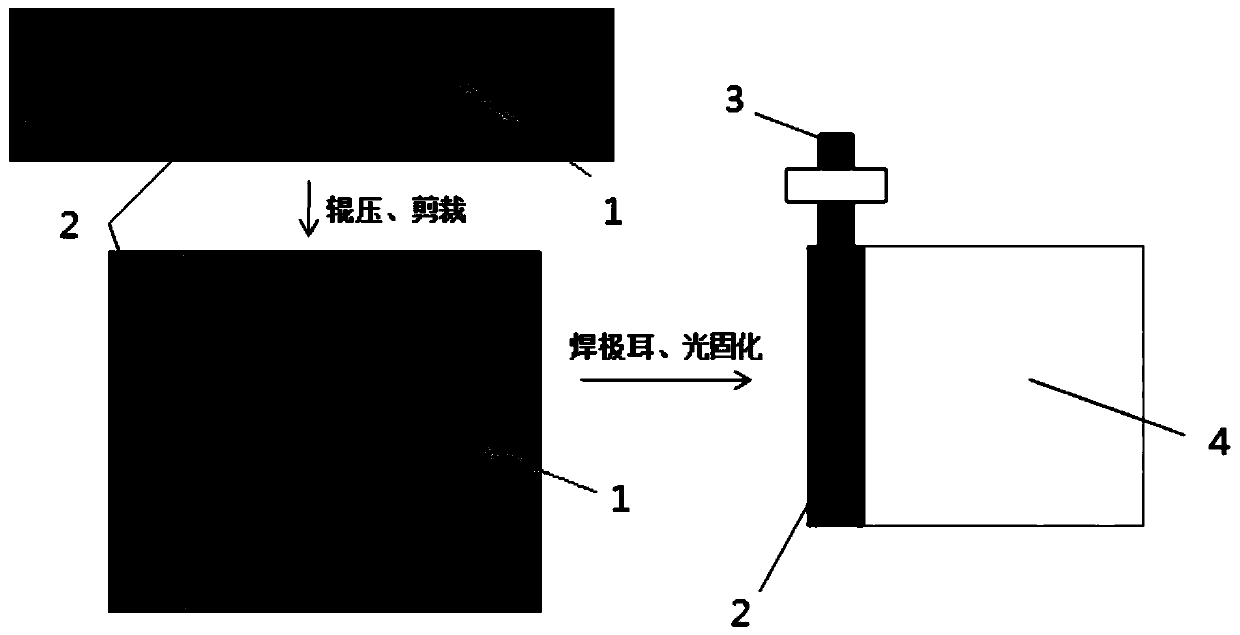

Gel composite lithium metal electrode and preparation method and application thereof

ActiveCN109841836AImproved deposition cross sectionFacilitate depositionElectrode manufacturing processesElectrode carriers/collectorsHigh current densityLithium-ion battery

The invention relates to a gel composite lithium metal electrode, and a preparation method and an application thereof, which belong to the technical field of lithium ion batteries. The electrode is composed of a current collector, a lithium metal layer and a gel layer arranged on the lithium metal layer, wherein the lithium metal layer is attached to the current collector, and is obtained by pressing a lithium sheet onto the current collector by means of a roller; the gel layer is formed by carrying out in-situ reaction on a polymeric precursor solution coated on the surface of the lithium metal layer by adopting an ultraviolet photopolymerization method, and the polymeric precursor solution is composed of a polymer PVDF-HFP, a photopolymerization agent EPTTA, a photoinitiator HMPP, lithium salt, a metal oxide nano additive and an ether solvent. The invention further discloses the gel composite lithium metal electrode and the application thereof in the preparation of a lithium metal battery. The preparation method of the invention is simple and easy to implement, the prepared gel composite lithium metal electrode can be directly used, and the lithium metal battery can cycle stablyunder high current density and high capacity without producing lithium dendrites; at the same time, the surface of the electrode is electronically insulated, a membrane can be removed when the batteryis assembled, and the energy density of the battery can be effectively increased.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

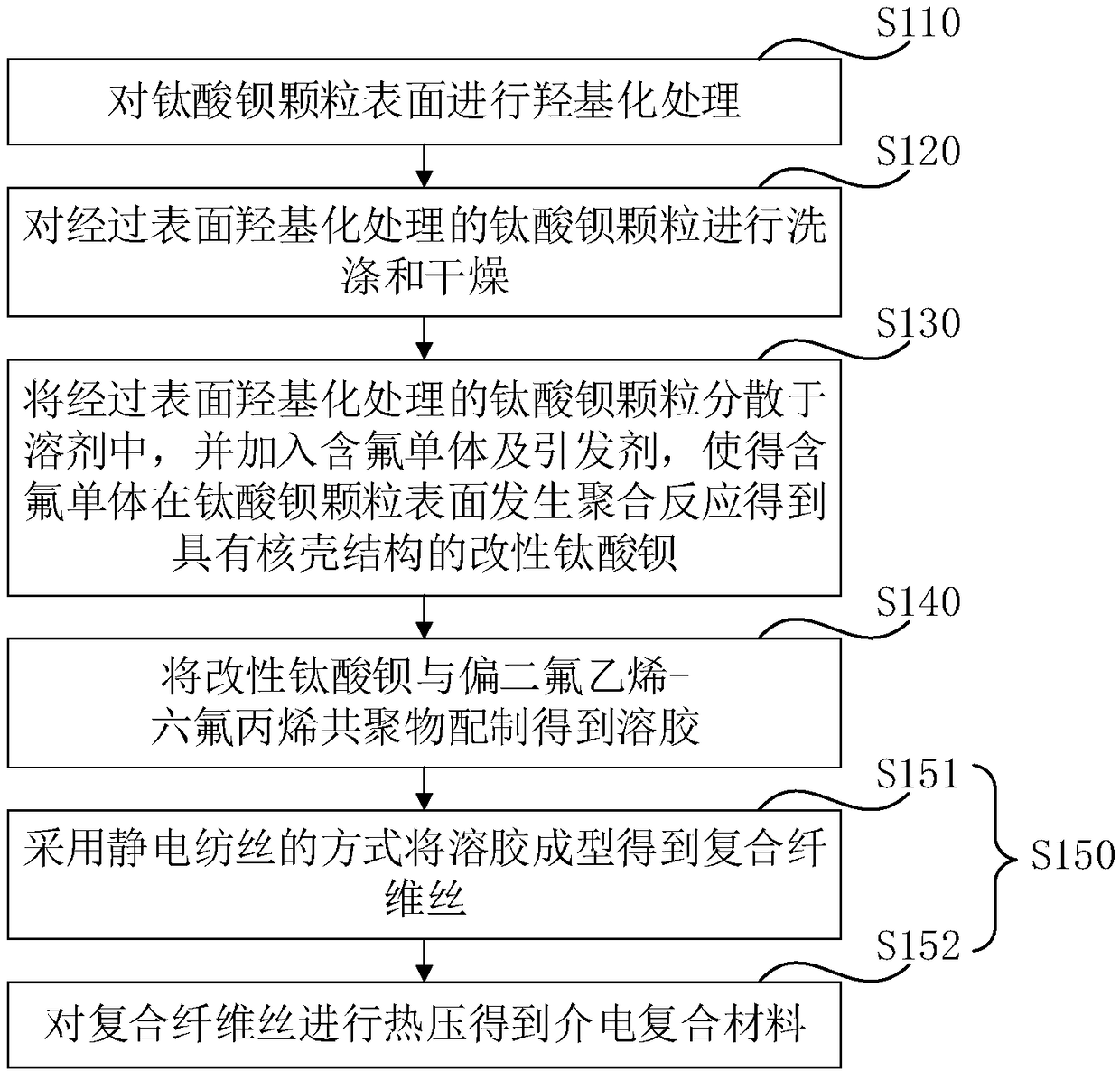

Dielectric composite material and preparation method thereof

InactiveCN108570201AHigh dielectric constantBreakdown field strengthElectro-spinningMonocomponent halogenated hydrocarbon artificial filamentDispersityHexafluoropropylene

The invention relates to a dielectric composite material and a preparation method thereof. The preparation method is characterized by comprising the following steps: carrying out hydroxylating treatment on the surfaces of barium titanate particles, then adding fluorine-containing monomers to initiate polymerization, and obtaining modified barium titanate with a core-shell structure; then using themodified barium titanate and a vinylidene fluoride-hexafluoropropylene copolymer to prepare and obtain an electrostatic spinning solvent, and then utilizing an electrostatic spinning process to obtain the dielectric composite material. The dielectric composite material and the preparation method have the beneficial effects that the barium titanate particles have a high dielectric constant, the vinylidene fluoride-hexafluoropropylene copolymer has a good breakdown property; by introduction of the fluorine-containing monomers, the monomer molecular chains have a certain quantity of fluorine atoms and are similar to a matrix polymer PVDF-HFP (Polyvinylidene Fluoride-Hexafluoropropylene) respectively, and the surfaces of the particles are coated with the monomers, so that the effect of mild transition is achieved, the compatibility between the particles and the matrix can be improved, further the particles have good dispersity, and the dielectric composite material has a high dielectric constant, high breakdown field strength and low dielectric loss.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com