PVDF-HFP base composite porous polymer membrane and preparation method thereof

A PVDF-HFP, porous polymer technology, applied in the direction of structural parts, battery pack parts, electrical components, etc., can solve the problem of easy agglomeration of superfine powder fillers, poor interface compatibility, low ion migration number, etc. problem, to achieve the effect of improving interface performance and processing performance, improving mechanical strength, and increasing Li+ ion migration number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

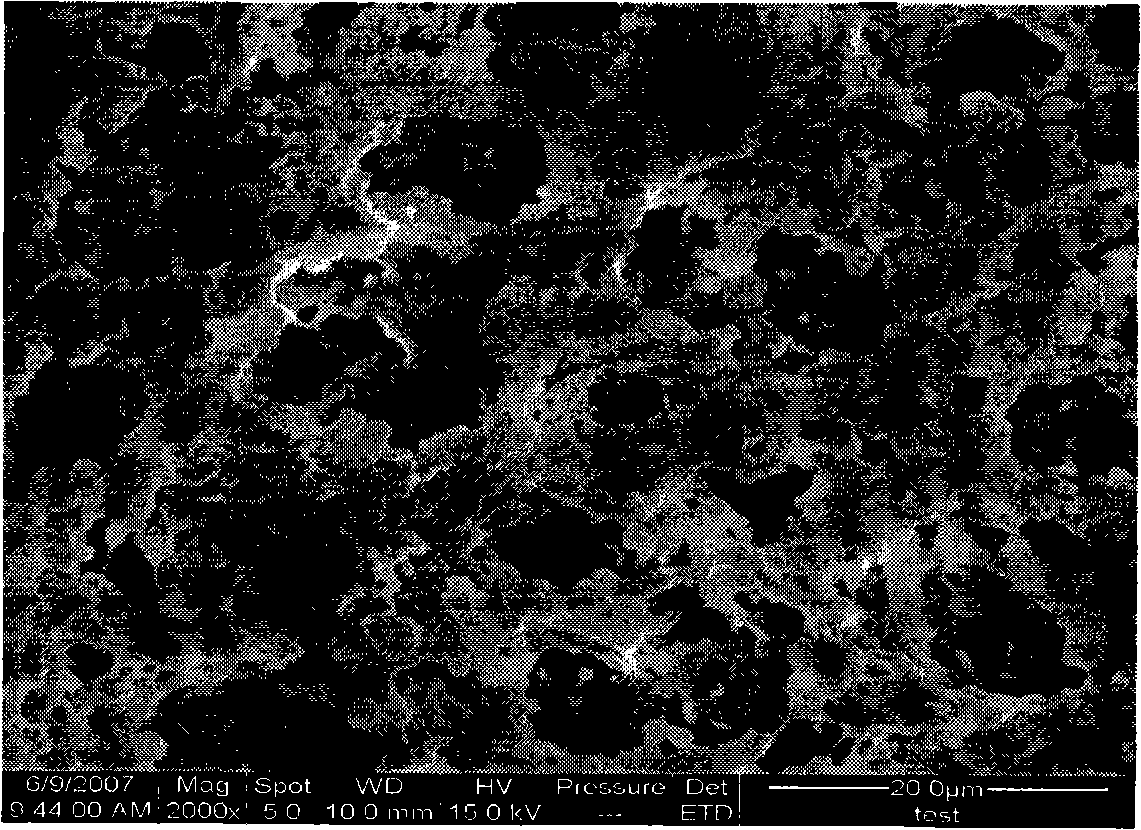

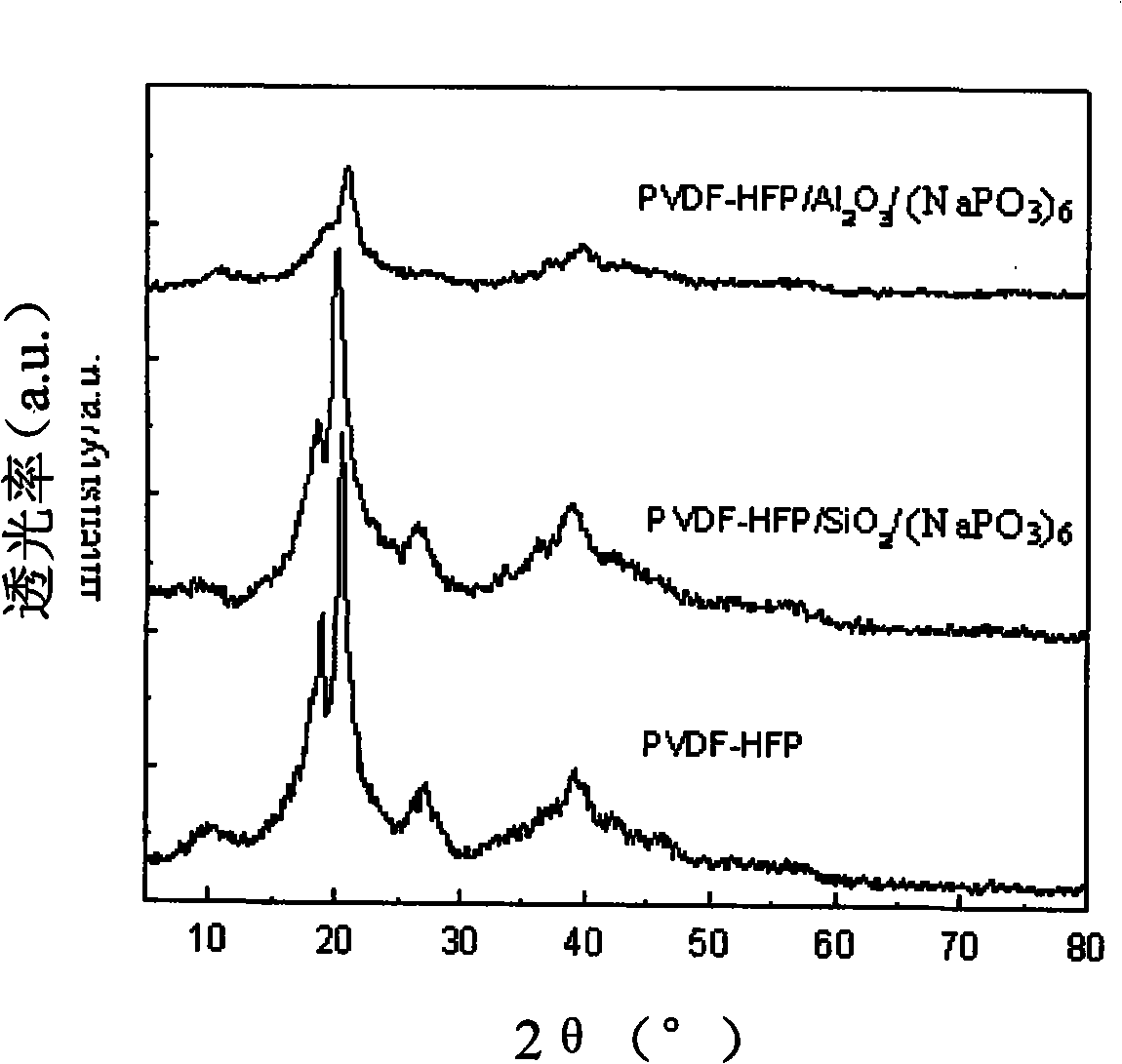

[0010] Embodiment 1: In this embodiment, the PVDF-HFP-based composite porous polymer diaphragm is made of poly(vinylidene fluoride-hexafluoropropylene) (abbreviated as PVDF-HFP), polyvinylpyrrolidone and ultrafine powder filler; The mass ratio of sodium phosphate to poly(vinylidene fluoride-hexafluoropropylene) is 0.2-0.4:1, and the mass ratio of superfine powder filler to sodium hexametaphosphate is 0.5-1:1.

[0011] After testing, the conductivity of the product in this embodiment is high (the conductivity can reach 6.5×10 at 20° C. -3 S cm -1 ), its Li + The ion mobility number is as high as 0.85, and its electrochemical stability window is as high as 5.8V.

specific Embodiment approach 2

[0012] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the superfine powder filler is Al with a particle size of 10-100 nm. 2 o 3 、TiO 2 , ZrO 2 or SiO 2 . Others are the same as in the first embodiment.

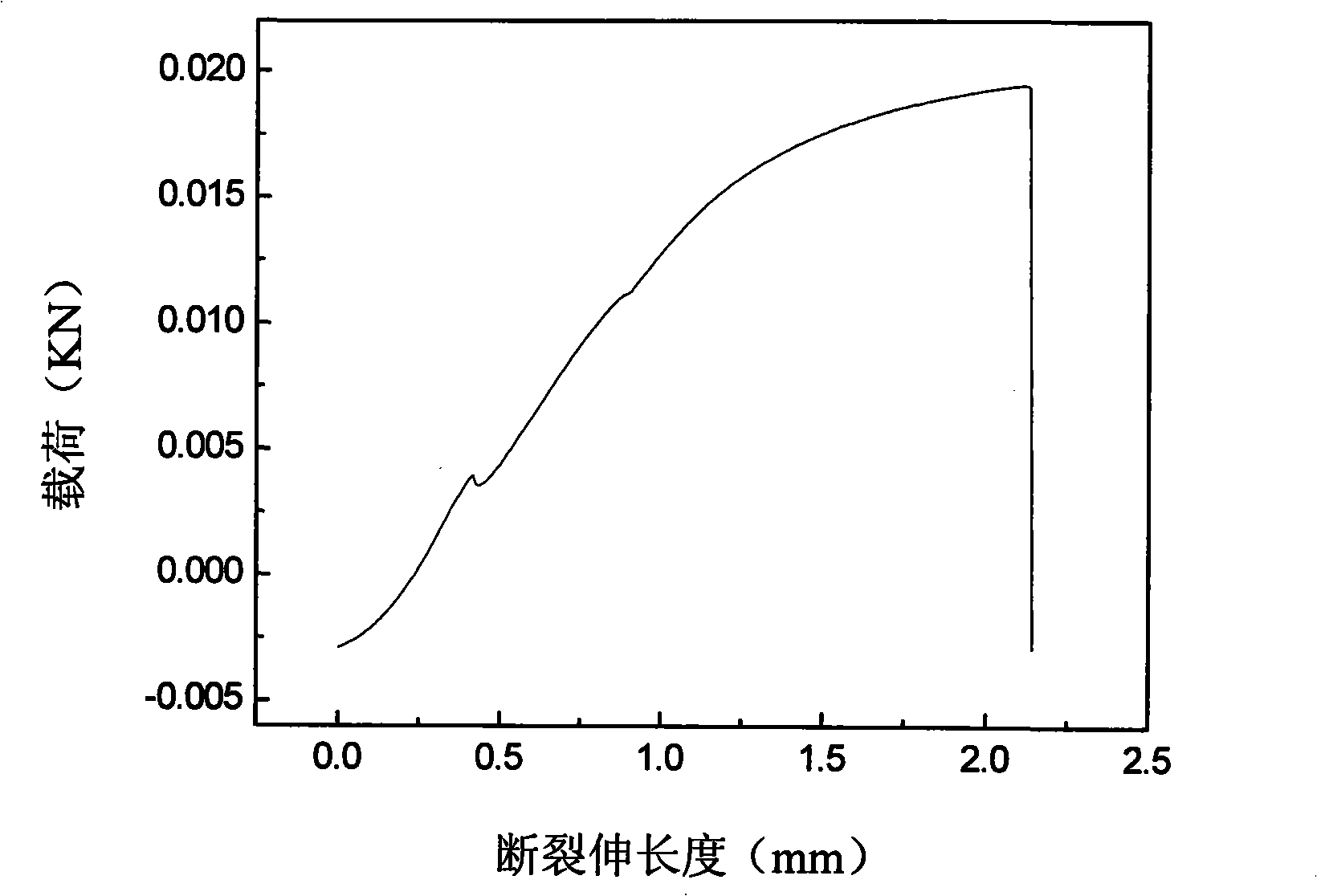

[0013] In this embodiment, the influence of the superfine powder filler on the mechanical properties of the diaphragm is shown in Table 1.

[0014] Table 1

[0015] diaphragm

specific Embodiment approach 3

[0016] Embodiment 3: This embodiment differs from Embodiment 2 in that: the particle size of the superfine powder filler is 15-40 nm. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com