PVDF-HFP-based composite porous polymer diaphragm and preparation method thereof

A diaphragm and lithium-based technology, which is applied in the field of fluoropolymer-based composite porous polymer diaphragm and its preparation, can solve the problems of complex film-making process and simple diaphragm mechanical strength, and achieve the effect of simple preparation process and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

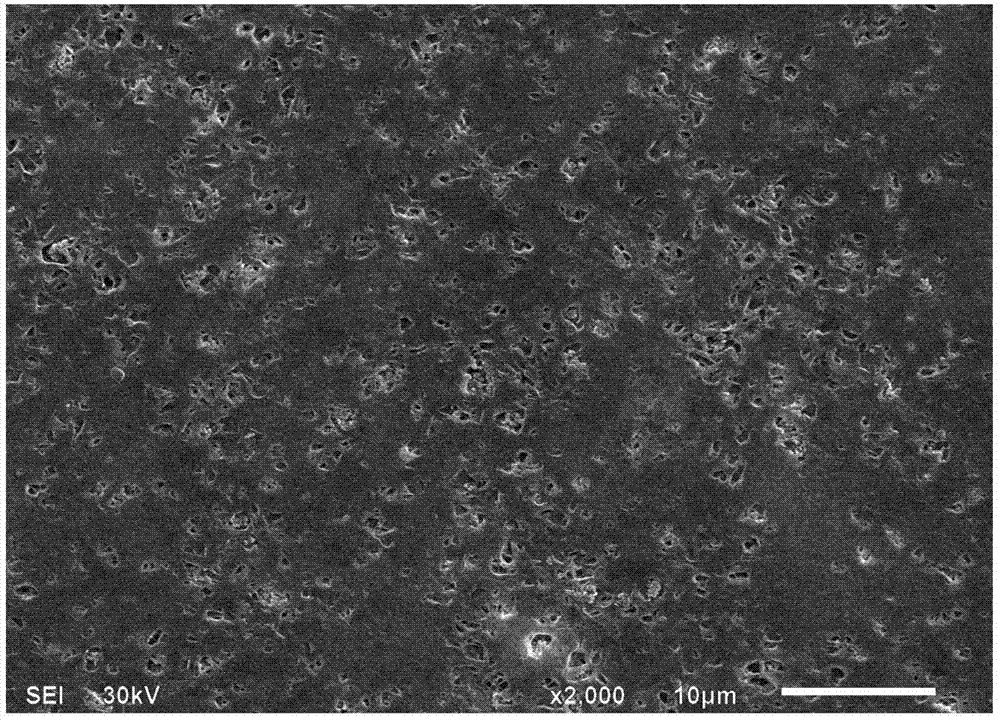

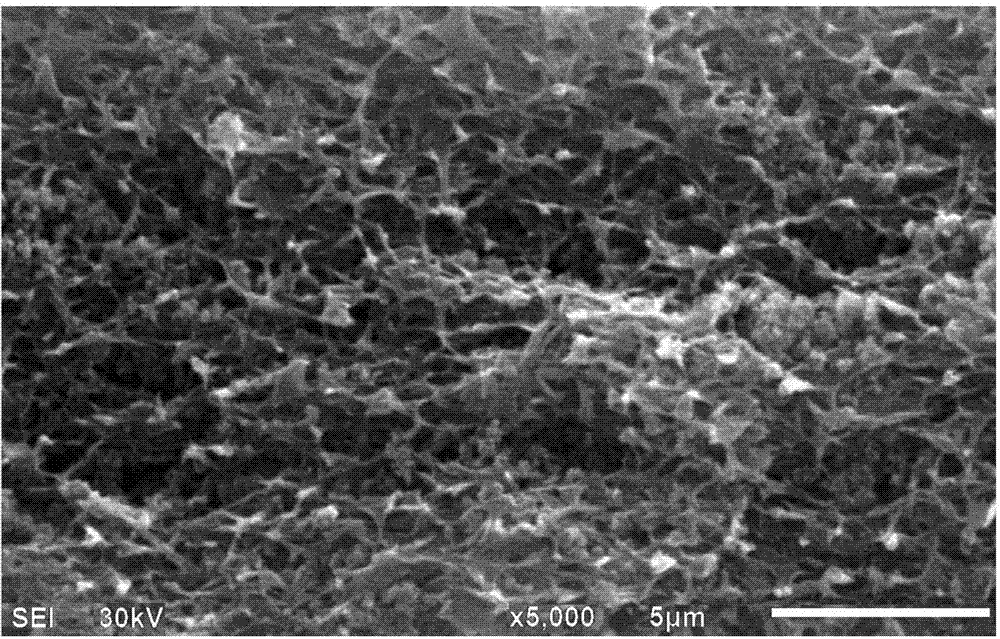

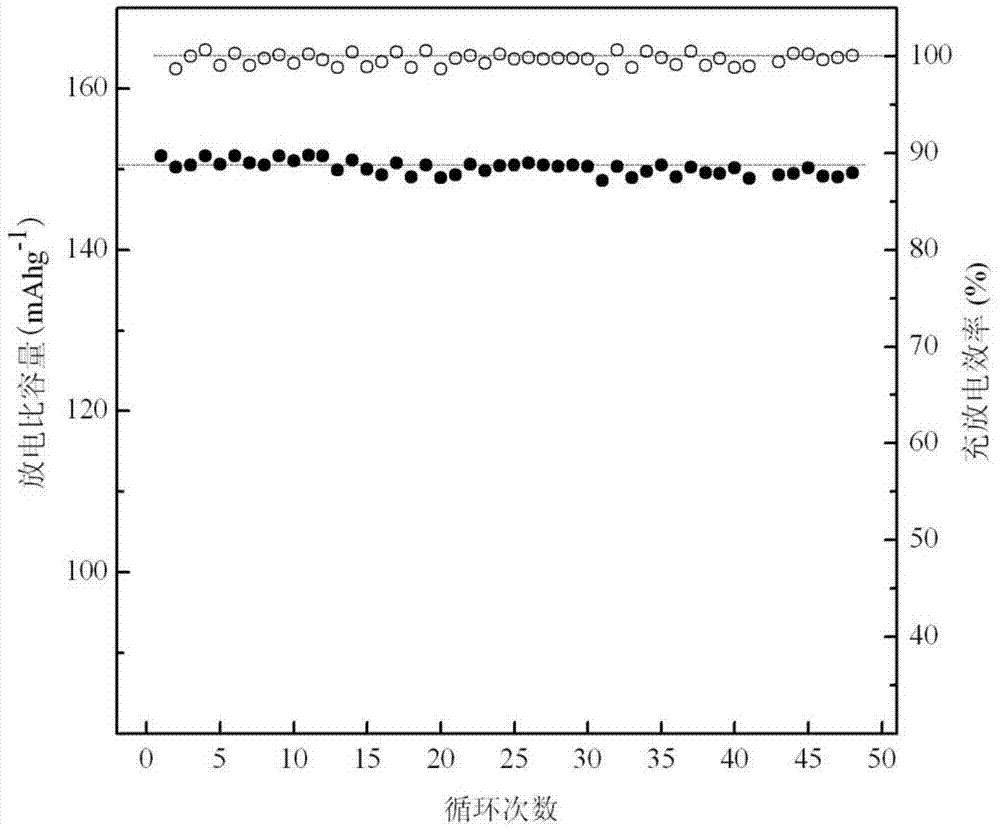

Embodiment 1

[0045] Take 50 mL of tetrahydrofuran and acetone and mix them as an organic solvent for the composite component, add 19 g of vinylidene fluoride-hexafluoropropylene (Arkema, KYNAR2801) and mix, and stir mechanically at a constant temperature at 50 ° C for 1.5 hours to obtain a clear and viscous sol; add 1.5 g Nano filler SiO 2 (particle size 20-50nm), continue to stir for 1.5 hours; take 7mL of ethanol and 3mL of water and mix it as a composite component anti-solvent, drop it into the above-mentioned sol with a constant pressure dropping funnel, continue to stir for 1.5 hours, and obtain a milky white viscous casting Film liquid; after defoaming, use an automatic film applicator to coat a glass plate at a temperature of 15°C and a humidity of 80%; Take it off and dry it in a vacuum oven at 50° C. for 24 hours to obtain the poly(vinylidene fluoride-hexafluoropropylene)-based lithium-ion battery separator of the present invention. Among them, by adjusting the gap of the scraper...

Embodiment 2

[0048] Take 50 mL of tetrahydrofuran and acetone and mix them as an organic solvent for the composite component, add 19 g of vinylidene fluoride-hexafluoropropylene (Arkema, KYNAR2801) and mix, and stir mechanically at a constant temperature at 60°C for 1.0 hour to obtain a clear and viscous sol; add 1.5 g Nano filler Al 2 o 3 (particle size 50-100nm), continue to stir for 1.5 hours; take n-butanol 8mL and water 2mL and mix it as a composite component anti-solvent, drop it into the above-mentioned sol with a constant pressure dropping funnel, and continue to stir for 1.5 hours to obtain a milky white viscous Thick casting film solution; after standing defoaming, in an environment with a temperature of 20°C and a humidity of 40%, use an automatic film applicator to coat a glass plate as a substrate; naturally volatilize the solvent and anti-solvent, and form The film was removed and dried in a vacuum oven at 60° C. for 16 hours to obtain the poly(vinylidene fluoride-hexafluoro...

Embodiment 3

[0051] Take 100mL of acetone as a solvent, add 19g of vinylidene fluoride-hexafluoropropylene (Arkema, KYNAR2801) to mix, and stir mechanically at a constant temperature at 50°C for 1.5 hours to obtain a clear and viscous sol; 1.5g of nano-filler SiO 2 (particle size 20-50nm), continue to stir for 1.5 hours; drip anti-solvent water 6mL with a constant pressure dropping funnel, continue to stir for 1.5 hours to obtain milky white viscous casting solution; ℃, the humidity is 80%, the glass plate is used as the substrate, and the automatic film applicator is used to coat the film; the solvent and anti-solvent are naturally volatilized, the formed film is removed, and dried in a vacuum oven at 50 ℃ for 36 hours. That is, the poly(vinylidene fluoride-hexafluoropropylene)-based lithium ion battery separator described in the present invention is obtained. Among them, by adjusting the gap of the scraper, a series of poly(vinylidene fluoride-hexafluoropropylene)-based lithium-ion batte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com