Chamomile chewable tablet and preparation technology thereof

A chewable tablet and chrysanthemum technology, which is applied in the field of chrysanthemum chewable tablet and its preparation technology, can solve the problems of not conforming to the original color, flavor and shape, and the raw materials cannot be visually seen in the final product, so as to achieve a complete shape, moderate hardness, Smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of Chuju chewable tablets, 280g dextrin (28%), 140g microcrystalline cellulose (14%), 130g dry starch (13%), 220g milk powder (22%), 70g sucrose (7%) After crushing and sieving, mix well, add 100g of water to prepare soft material; pass the prepared soft material through a 40-mesh sieve, dry in an oven at 50°C until the water content is 3%, and pass the dry particles through a 40-mesh sieve again.

[0026] Mix the dry granules, 20g of vitamin C (2%), and 140g of chrysanthemum petals (14%) evenly, spray magnesium stearate on the mold, compress with 300N pressure, 0.8g / tablet, and vacuum pack.

Embodiment 2

[0028] A preparation method of Chuju chewable tablet, 290g dextrin (29%), 140g microcrystalline cellulose (14%), 130g dry starch (13%), 220g milk powder (22%), 70g sucrose (7%) After crushing and sieving, mix well, add 100g of water to prepare soft material; pass the prepared soft material through a 40-mesh sieve, dry in an oven at 50°C until the water content is 3%, and pass the dry particles through a 40-mesh sieve again; Granules, 18g vitamin C (1.8%), 132g chrysanthemum petals (13.2%), mixed evenly, spray magnesium stearate on the mold, 300N pressure compression, 0.8g / tablet, vacuum packaging.

Embodiment 3

[0030] A preparation method of Chuju chewable tablets, 300g dextrin (30%), 170g microcrystalline cellulose (17%), 120g dry starch (12%), 210g milk powder (21%), 80g sucrose (8%) After crushing and sieving, mix well, add 100g of water to prepare soft material; pass the prepared soft material through a 40-mesh sieve, dry in an oven at 50°C until the water content is 3%, and pass the dry particles through a 40-mesh sieve again; Granules, 10g vitamin C (1%), 110g chrysanthemum petals (11%), mix evenly, spray magnesium stearate on the mold, press 280N pressure tablet, 0.8g / tablet, vacuum pack.

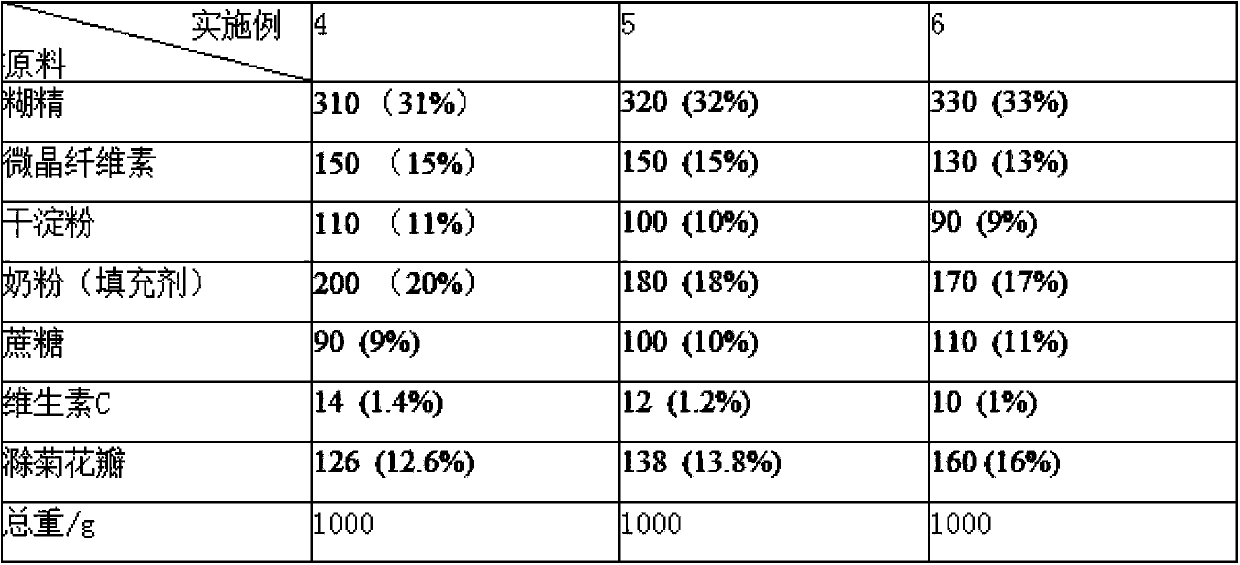

[0031] The raw and auxiliary materials adopted in embodiment 4 to embodiment 6 are as shown in table 1 (raw material unit: g)

[0032] The raw and auxiliary material batching list of table 1 embodiment 4-6

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com