A PVDF-HFP-based composite porous polymer diaphragm and preparation method thereof

A polymer and membrane technology, applied in the field of fluorine-containing polymer-based composite porous polymer membrane and its preparation, can solve the problems of complex membrane production process and simple membrane mechanical strength, and achieve the effect of simple preparation process and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

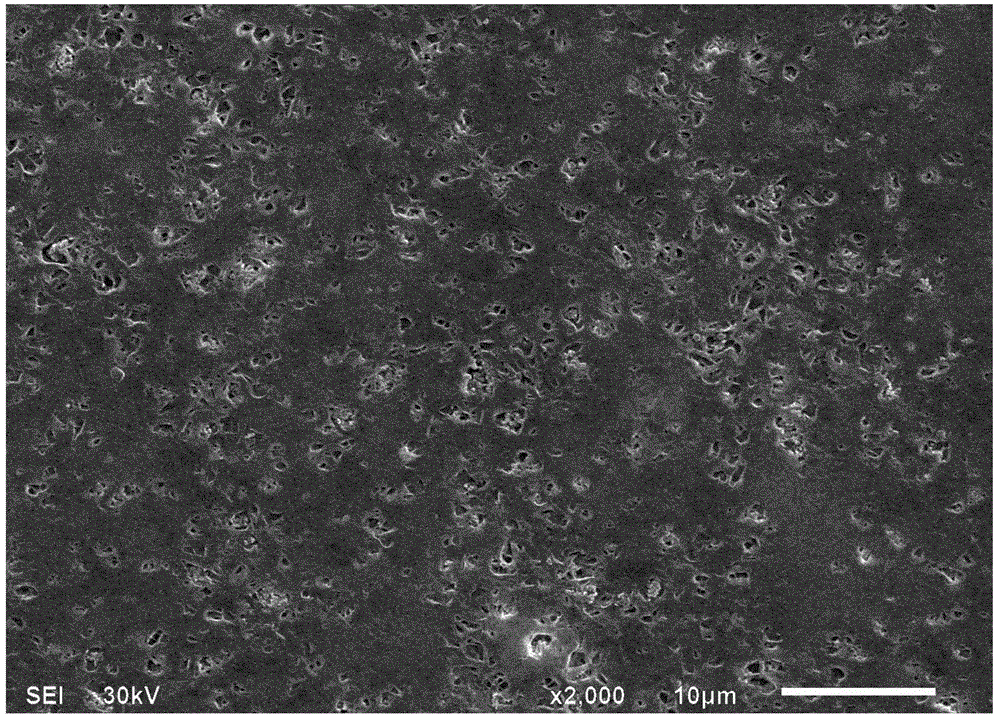

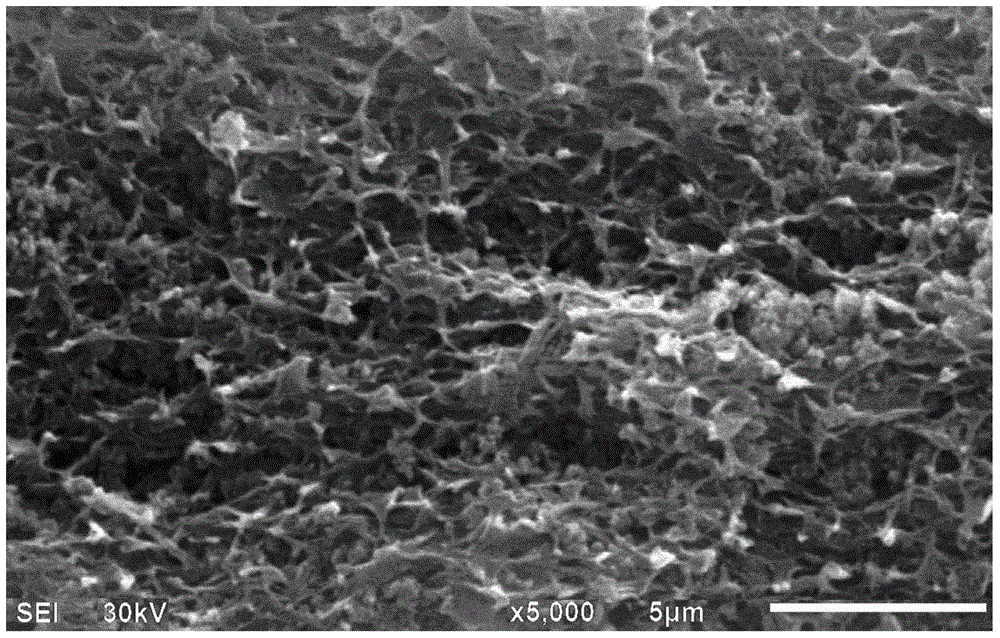

Embodiment 1

[0045] Take 50 mL of tetrahydrofuran and acetone and mix them as an organic solvent for the composite component, add 19 g of vinylidene fluoride-hexafluoropropylene (Arkema, KYNAR2801) and mix, and stir mechanically at a constant temperature at 50 ° C for 1.5 hours to obtain a clear and viscous sol; add 1.5 g Nano filler SiO 2 (particle size 20-50nm), continue to stir for 1.5 hours; take 7mL of ethanol and 3mL of water and mix it as a composite component anti-solvent, drop it into the above-mentioned sol with a constant pressure dropping funnel, continue to stir for 1.5 hours, and obtain a milky white viscous casting Film liquid; after defoaming, use an automatic film applicator to coat a glass plate at a temperature of 15°C and a humidity of 80%; Take it off and dry it in a vacuum oven at 50° C. for 24 hours to obtain the poly(vinylidene fluoride-hexafluoropropylene)-based lithium-ion battery separator of the present invention. Among them, by adjusting the gap of the scraper...

Embodiment 2

[0048] Take 50 mL of tetrahydrofuran and acetone and mix them as an organic solvent for the composite component, add 19 g of vinylidene fluoride-hexafluoropropylene (Arkema, KYNAR2801) and mix, and stir mechanically at a constant temperature at 60°C for 1.0 hour to obtain a clear and viscous sol; add 1.5 g Nano filler Al 2 o 3 (particle size 50-100nm), continue to stir for 1.5 hours; take n-butanol 8mL and water 2mL and mix it as a composite component anti-solvent, drop it into the above-mentioned sol with a constant pressure dropping funnel, and continue to stir for 1.5 hours to obtain a milky white viscous Thick casting film solution; after standing defoaming, in an environment with a temperature of 20°C and a humidity of 40%, use an automatic film applicator to coat a glass plate as a substrate; naturally volatilize the solvent and anti-solvent, and form The film was removed and dried in a vacuum oven at 60° C. for 16 hours to obtain the poly(vinylidene fluoride-hexafluoro...

Embodiment 3

[0051] Take 100mL of acetone as a solvent, add 19g of vinylidene fluoride-hexafluoropropylene (Arkema, KYNAR2801) to mix, and stir mechanically at a constant temperature at 50°C for 1.5 hours to obtain a clear and viscous sol; 1.5g of nano-filler SiO 2 (particle size 20-50nm), continue to stir for 1.5 hours; drip anti-solvent water 6mL with a constant pressure dropping funnel, continue to stir for 1.5 hours to obtain milky white viscous casting solution; ℃, the humidity is 80%, the glass plate is used as the substrate, and the automatic film applicator is used to coat the film; the solvent and anti-solvent are naturally volatilized, the formed film is removed, and dried in a vacuum oven at 50 ℃ for 36 hours. That is, the poly(vinylidene fluoride-hexafluoropropylene)-based lithium ion battery separator described in the present invention is obtained. Among them, by adjusting the gap of the scraper, a series of poly(vinylidene fluoride-hexafluoropropylene)-based lithium-ion batte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com