Preparation method of p-chlorophenol

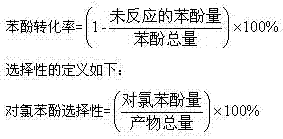

A technology for p-chlorophenol and phenol, applied in the field of preparation of p-chlorophenol, can solve problems such as a large number of by-products, low para-selectivity, easy environmental pollution, etc., and achieve the effect of high para-selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Under normal pressure, add 20g of phenol, 36g of copper chloride and 60g of hydrochloric acid to the chlorination reactor respectively, heat to the reaction temperature of 90°C, pass chlorine gas under the protection of nitrogen to react until the phenol is completely chlorinated, cool, and take out the upper organic phase , to obtain mixed chlorinated phenols, sampling GC analysis content, phenol conversion rate is 97.6%, p-chlorophenol selectivity is 81.1%, ortho-chlorophenol selectivity is 7.6%, and p-o-ratio reaches 10:1; Lower hydrochloric acid-chlorination After copper was added to phenol, the chlorination reaction was repeated under the same conditions, and the selectivity of p-chlorophenol remained stable at about 80% after repeated 8 times.

Embodiment 2

[0029] Under normal pressure, add 20g of phenol, 60g of copper chloride and 120g of dimethyl sulfoxide to the chlorination reactor respectively, heat the oil bath to 110°C, react for a certain period of time under the protection of nitrogen, cool and filter to obtain copper chloride Solid, sampling GC analysis content, the phenol conversion rate is 90.0%, the selectivity of p-chlorophenol is 82.0%, the selectivity of o-chlorophenol is 6.1%, and the ratio of o-to-o is as high as 12:1.

Embodiment 3

[0031] Under normal pressure, 20g of phenol, 36g of copper chloride, 40g of hydrochloric acid and 8g of dimethyl sulfoxide were respectively added to the chlorination reactor, heated to a reaction temperature of 90°C, and chlorine gas was introduced under the protection of nitrogen to react until the phenol was chlorinated completely. Cooling, take out upper organic phase, obtain organic solvent and mixed chlorinated phenol, sample GC analysis content, phenol transformation rate is 99.6%, p-chlorophenol selectivity is 83.5%, ortho-chlorophenol selectivity is 5.9%, para-ortho ratio reaches 12:1; the lower layer of hydrochloric acid-copper chloride was added to phenol and dimethyl sulfoxide and the chlorination reaction was repeated under the same conditions. After repeating 5 times, the selectivity of p-chlorophenol was maintained at about 82.5%, and the ratio of ortho was maintained at 12:1. keep it steady.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com