Carbon material modified porous polymer electrolyte membrane and preparation method thereof

A porous polymer, electrolyte membrane technology, applied in circuits, electrical components, battery pack parts and other directions, can solve the problems of low ionic conductivity, poor electrochemical stability, small lithium ion migration number, etc. Conducive to absorption, improving ionic conductivity and lithium ion migration number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

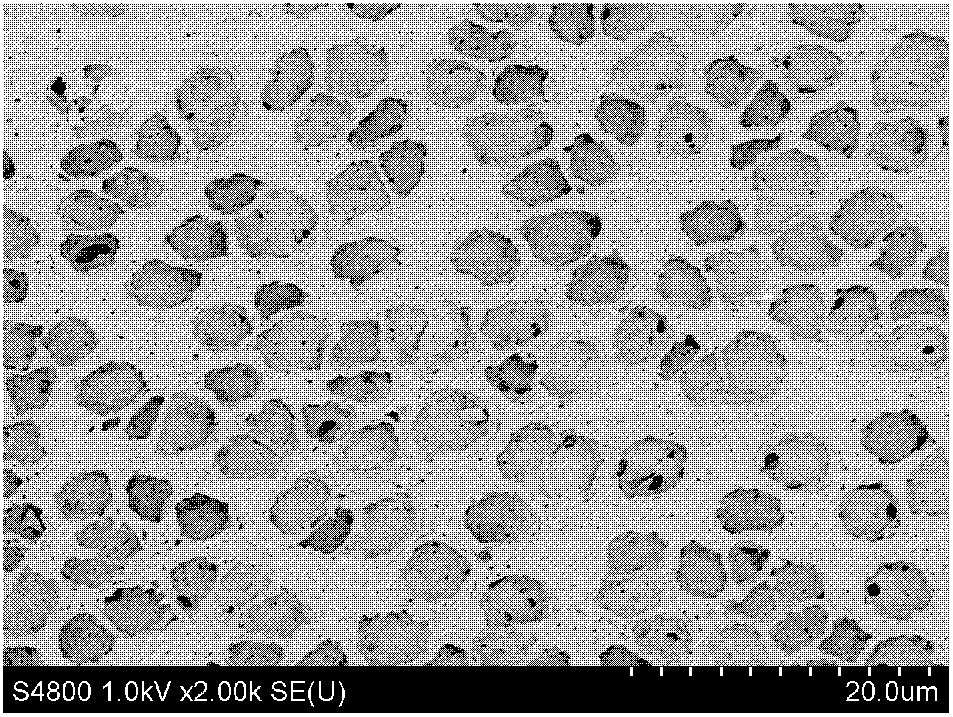

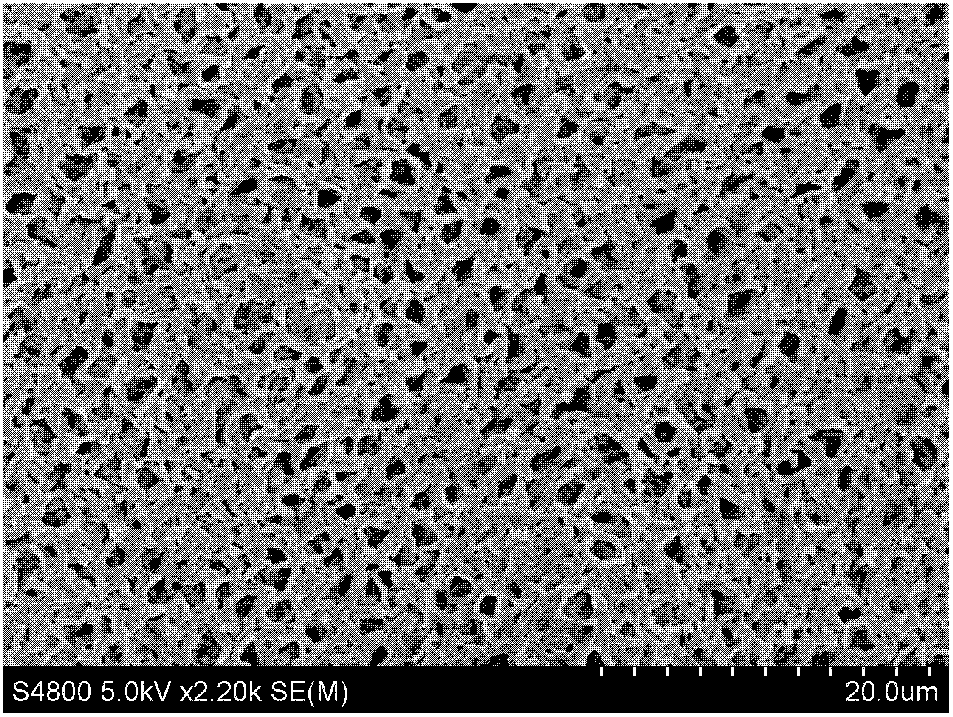

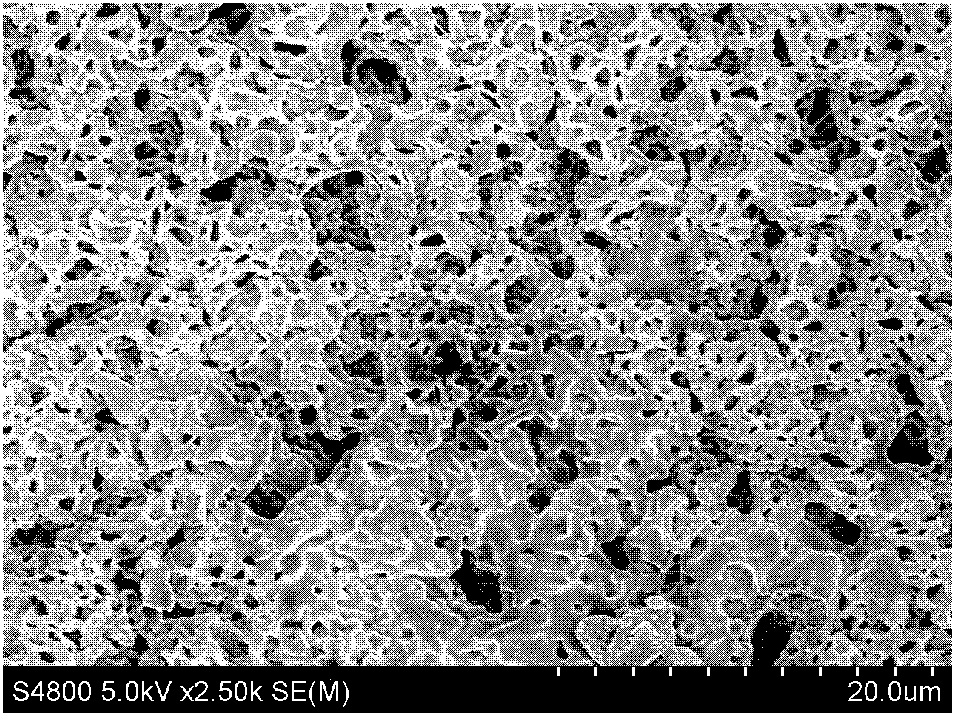

[0012] Embodiment 1: A carbon material-modified porous polymer electrolyte membrane in this embodiment is prepared by immersing the porous polymer membrane in the electrolyte solution of a lithium-ion battery for 1 to 4 hours.

[0013] The porous polymer membrane described in this embodiment is prepared from PVDF-HFP, solvent, plasticizer and modified carbon material, wherein the mass ratio of PVDF-HFP to solvent is 1: (6-20), The mass ratio of the plasticizer to the solvent is 1: (5-40), and the mass ratio of the modified carbon material to PVDF-HFP is 1: (10-100).

[0014] Modified carbon materials are added to the porous polymer membrane of this embodiment, which hinders the regular arrangement of polymer chains and reduces the crystallinity of the polymer electrolyte, thereby improving the ion conductivity and lithium ion migration number of the electrolyte membrane, improving and stabilizing the polymerization. Pore structure and electrical properties of electrolyte mem...

specific Embodiment approach 2

[0018] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the solvent is selected from acetone, butanone, acetonitrile, tetrahydrofuran, 1-methyl-2-pyrrolidone, N,N-dimethylformaldehyde Amides, Benzene, Toluene, Methanol and Ethanol. Others are the same as the first embodiment.

specific Embodiment approach 3

[0019] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the plasticizer is selected from dibutyl phthalate, propylene carbonate, ethylene carbonate and dimethyl carbonate. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ionic conductivity | aaaaa | aaaaa |

| Electrochemical stability window | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com