Non-woven type power lithium battery diaphragm and preparation method thereof

A technology of lithium battery diaphragm and non-woven fabric, which is applied in the field of non-woven power lithium battery diaphragm and its preparation, which can solve the problems of low puncture resistance of the diaphragm and easy powder drop of the diaphragm, and achieve the improvement of electrical performance and The effect of safety and good liquid absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

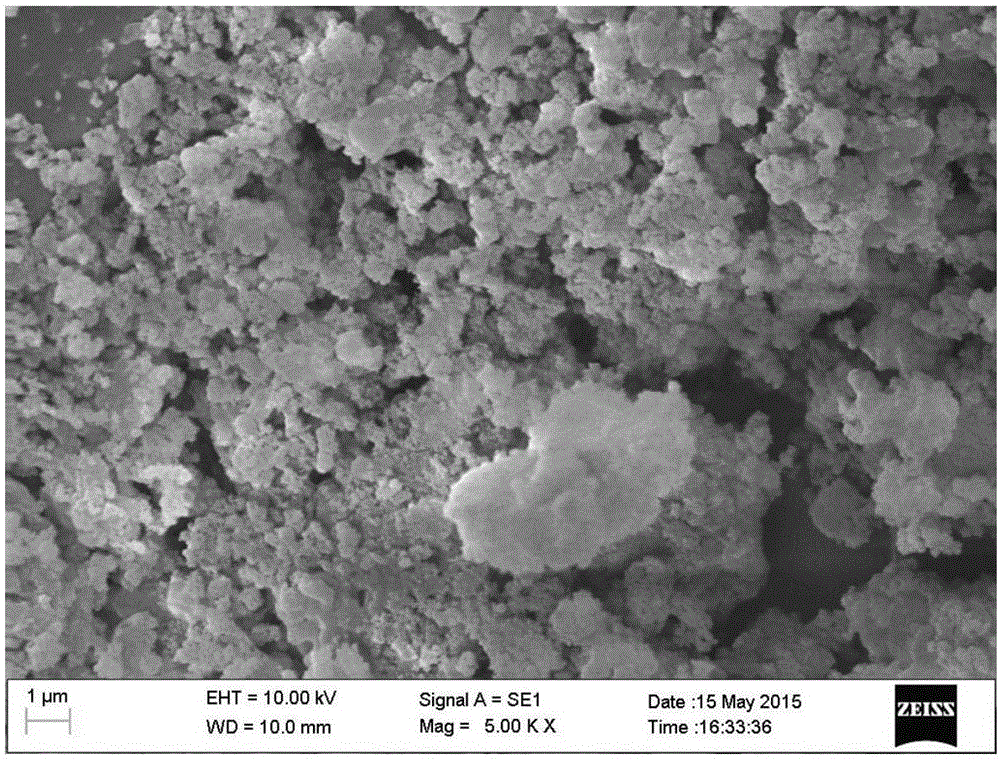

[0036] (1) Modification of silica: Weigh 1g of silica in a round bottom flask, add 30ml of methanol, γ-(methacryloyloxy)propyltrimethoxysilane accounting for 10% mass fraction of silica (KH570), ultrasonic dispersion is uniform, under the mechanical stirring of 1000r / min, add 1.0ml of ammonia water drop by drop, after stirring for 1h, adjust the speed to 60r / min, under the condition of reflux of the condenser tube, heat up to 70°C for 5h, The obtained product was centrifuged and washed three times with methanol, and vacuum-dried at 50°C for 12 hours to obtain a white powdery double-bond modified silica;

[0037] (2) Preparation of core-shell particles: ultrasonically disperse 1 g of the double-bond modified silica obtained in step (1) and 0.08 g of PVP-K30 in 55 ml of deionized water, transfer the above solution to a round bottom flask and add 2 g of decompressed For distilled methyl methacrylate, insert a condenser tube and turn on the magnetic stirrer to stir for 15 minutes ...

Embodiment 2

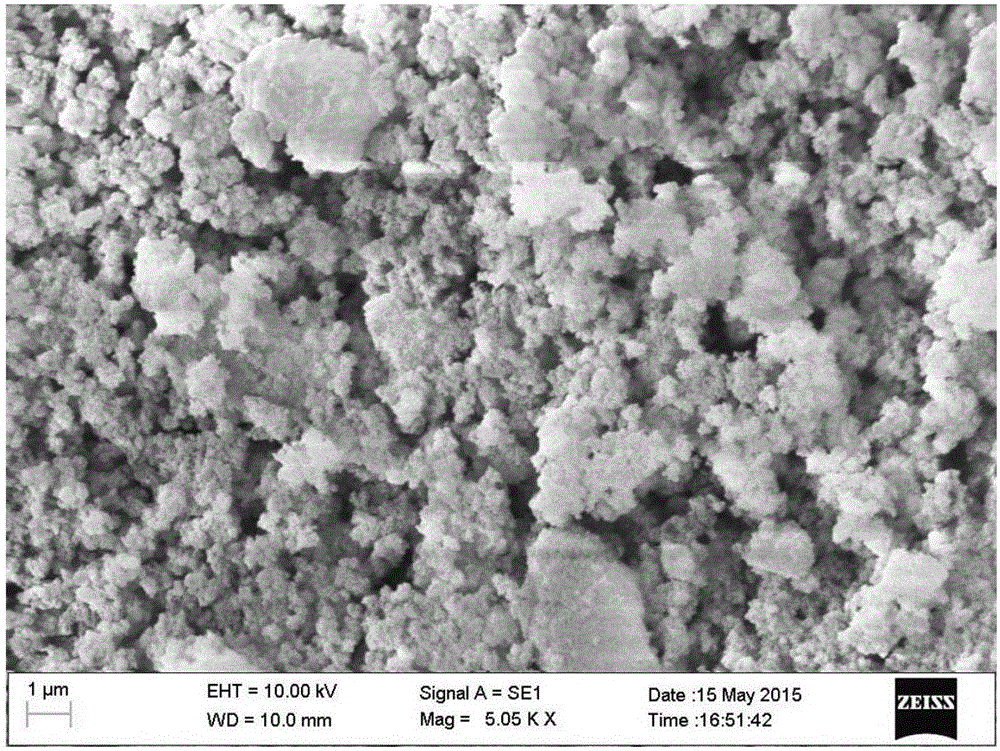

[0043] (1) Modification of silica: Weigh 1g of silica in a round bottom flask, add 25ml of methanol, γ-(methacryloyloxy)propyltrimethoxysilane accounting for 12% mass fraction of silica (KH570), ultrasonic dispersion is uniform, under the mechanical stirring of 1000r / min, add 0.8ml of ammonia water drop by drop, after stirring for 1h, adjust the speed to 60r / min, under the condition of reflux of the condenser tube, heat up to 70°C for 5h, The obtained product was centrifuged and washed three times with methanol, and vacuum-dried at 50°C for 12 hours to obtain a white powdery double-bond modified silica;

[0044] (2) Preparation of core-shell particles: ultrasonically disperse 1 g of the double-bond modified silica obtained in step (1) and 0.12 g of PVP-K30 in 90 ml of deionized water, transfer the above solution to a round bottom flask and add 3 g of decompressed For distilled methyl methacrylate, insert a condenser tube and turn on the magnetic stirrer to stir for 15 minutes ...

Embodiment 3

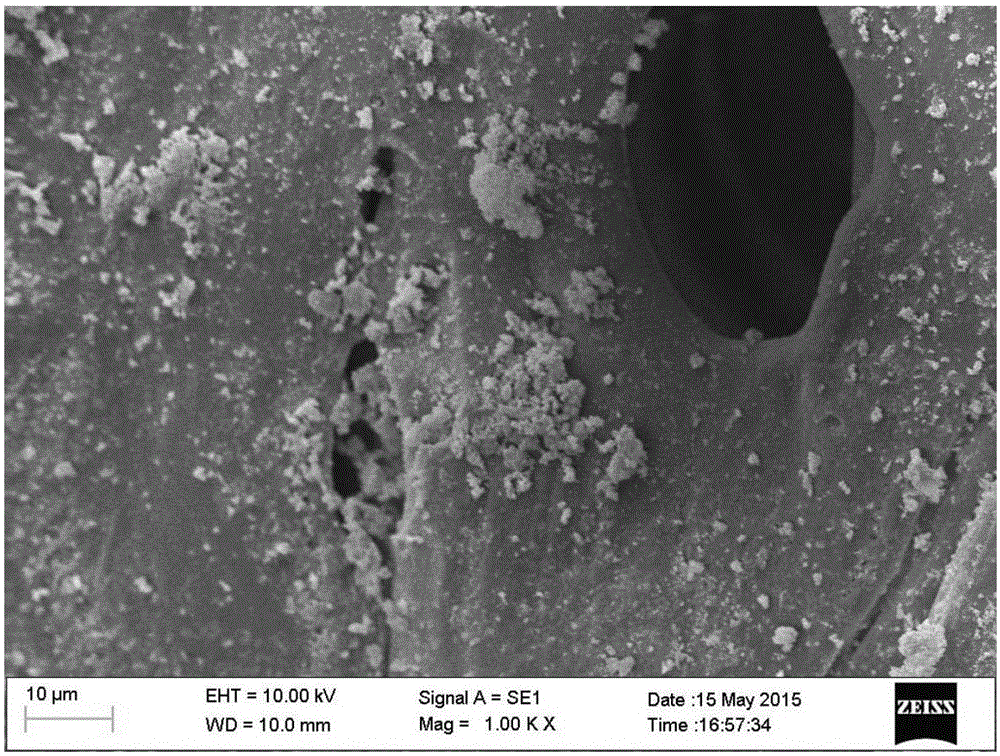

[0050] (1) Modification of silica: Weigh 1g of silica in a round bottom flask, add 20ml of methanol, γ-(methacryloyloxy)propyltrimethoxysilane accounting for 8% mass fraction of silica (KH570), ultrasonic dispersion is uniform, under the mechanical stirring of 1100r / min, add 0.6ml of ammonia water drop by drop, after stirring for 1h, adjust the speed to 60r / min, under the condition of reflux of the condenser tube, raise the temperature to 75°C for 5h, The obtained product was centrifuged and washed three times with methanol, and vacuum-dried at 50°C for 12 hours to obtain a white powdery double-bond modified silica;

[0051] (2) Preparation of core-shell particles: ultrasonically disperse 1 g of the double-bond modified silica obtained in step (1) and 0.16 g of PVP-K30 in 120 ml of deionized water, transfer the above solution to a round bottom flask and add 4 g of decompressed For distilled methyl methacrylate, insert a condenser tube and turn on the magnetic stirrer to stir f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com