Steam-cured concrete member repairing agent and preparation method and application thereof

A repairing agent and concrete technology, which is applied in the field of steam-cured concrete member repairing agent and its preparation, can solve the problems of powder dropping, low strength of the repaired part, large color difference between the repaired part and the member, etc., and achieve the purpose of increasing the hydration rate, increasing the strength, The effect of promoting cement hydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

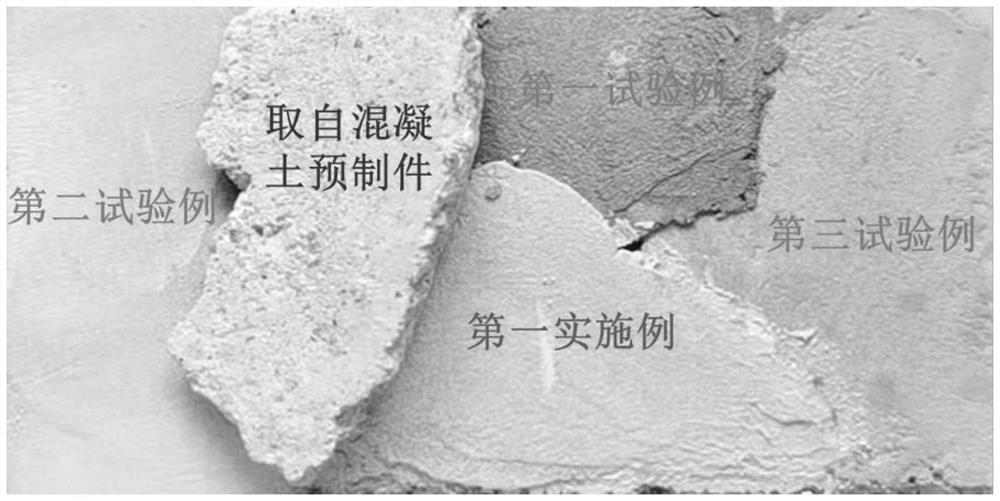

Image

Examples

no. 1 example

[0028] A preparation method of a steam curing concrete component repair agent, comprising the following steps:

[0029] (1) Take 12 parts by weight of white Portland cement, 13 parts by weight of white α hemihydrate gypsum, 8 parts by weight of 42.5 ordinary Portland cement, 6 parts by weight of 42.5 quick-hard sulfoaluminate cement, 60 parts by weight of sand, 1 part by weight of diatomaceous earth, 0.2 part by weight of retarder, 0.05 part by weight of water reducing agent, 1.0 part by weight of water retaining agent, and 15 parts by weight of water, for later use.

[0030] Wherein: the retarder is a mixture of tartaric acid and PE retarder in a mass ratio of 1:1. The water-reducing agent is a high-efficiency water-reducing agent of polycarboxylic acid. The water-retaining agent is polyacrylamide. The diatomite is an industrial raw material, and the diatomite is treated as follows: soaking in water and then blowing the air until the surface is slightly dry. The fineness m...

no. 2 example

[0035] A preparation method of a steam curing concrete component repair agent, comprising the following steps:

[0036](1) Take 10 parts by weight of white Portland cement, 10 parts by weight of white α hemihydrate gypsum, 7 parts by weight of 42.5 ordinary Portland cement, 7 parts by weight of 42.5 quick-hard sulfoaluminate cement, 55 parts by weight of sand, 2 parts by weight of diatomaceous earth, 0.05 part by weight of retarder, 0.1 part by weight of water reducing agent, 0.5 part by weight of water retaining agent, and 20 parts by weight of water, for subsequent use.

[0037] Wherein: the retarder is a mixture of tartaric acid and PE retarder in a mass ratio of 1:2. The water-reducing agent is a high-efficiency water-reducing agent of polycarboxylic acid. The water-retaining agent is sodium polyacrylamide. The diatomite is a chemically pure reagent, and the diatomite is treated as follows: soaking in water and then blowing the air until the surface is slightly dry. The...

no. 3 example

[0042] A preparation method of a steam curing concrete component repair agent, comprising the following steps:

[0043] (1) Take 15 parts by weight of white Portland cement, 15 parts by weight of white α hemihydrate gypsum, 10 parts by weight of 42.5 ordinary Portland cement, 10 parts by weight of 42.5 quick-hard sulfoaluminate cement, 50 parts by weight of sand, 2 parts by weight of diatomaceous earth, 0.05 part by weight of retarder, 0.1 part by weight of water reducing agent, 1.0 part by weight of water retaining agent, and 20 parts by weight of water, for subsequent use.

[0044] Wherein: the retarder is a mixture of tartaric acid and PE retarder in a mass ratio of 1:1.5. The water-reducing agent is a high-efficiency water-reducing agent of polycarboxylic acid. The water-retaining agent is ammonium polyacrylate. The diatomite is a chemically pure reagent, and the diatomite is treated as follows: soaking in water and then blowing the air until the surface is slightly dry....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com