Three-phase organic/inorganic composite gel state polymer electrolyte and preparation method thereof

A technology of composite gel state and electrolyte, which is applied in the direction of circuits, electrical components, secondary batteries, etc., can solve the problems such as the decline of the mechanical properties of the electrolyte membrane, and achieve the effect of improving the pore formation, improving the mechanical properties, and improving the electrochemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

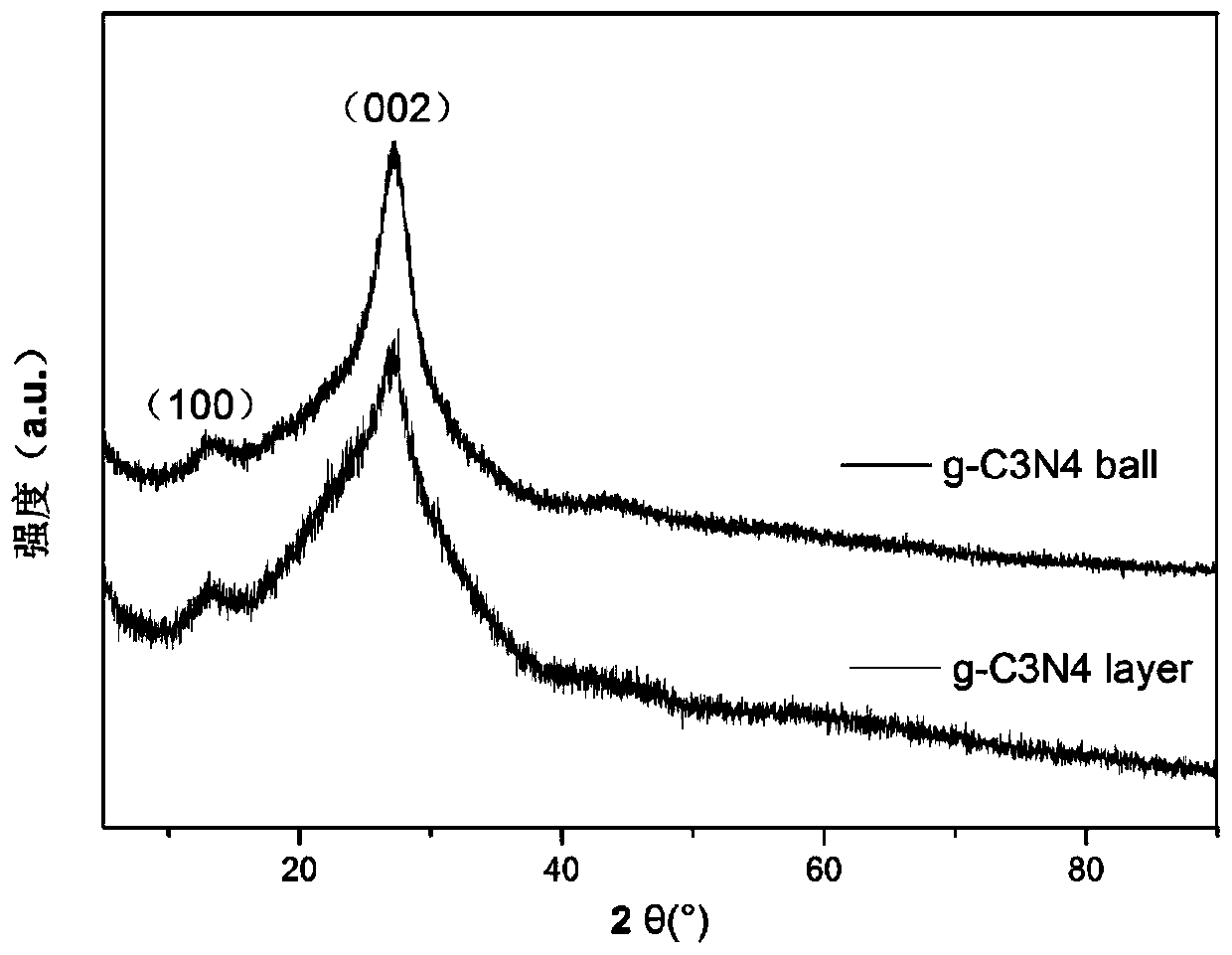

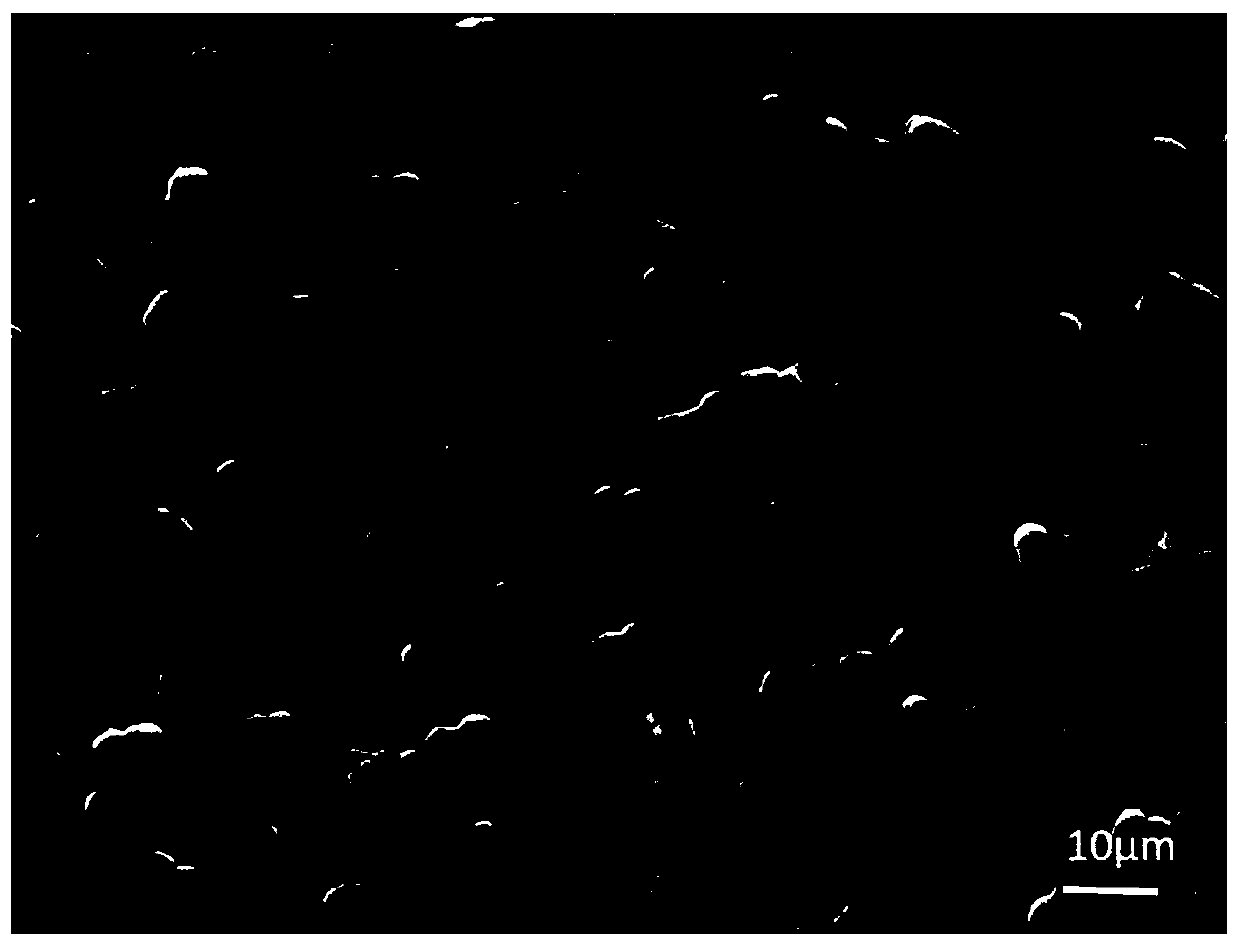

[0023] (1) Take 1g of urea powder and grind it in a mortar for 10-15 minutes until there are no large particles. Pour into a crucible and heat treat in a muffle furnace. The heating rate was 3°C / min, to 550°C, and the temperature was kept for 4 hours. That is, the g-C3N4 stacked in sheets is obtained.

[0024] (2) Take 60 mg of g-C3N4 obtained in (1), add 30 ml of isopropanol, and sonicate for 8 hours to obtain g-C3N4 white suspension dispersion.

[0025] (3) Take 0.8g of PVDF-HFP and 0.2g of PEO, add 2.5ml of the dispersion in (2), then add 8ml of DMF, and stir in a water bath at 60°C for 24 hours. Cast the solution on a polytetrafluoroethylene plate, wait for most of the solvent to volatilize, transfer to a vacuum oven at 80°C, and keep it warm for 12 hours. A thin film was obtained with a film thickness of about 100 μm.

[0026] (4) Transfer the film to the glove box, soak the electrolyte (the electrolyte is a mixed solution of lithium hexafluorophosphate mixed with dim...

Embodiment 2

[0028] (1) Take 0.378g of melamine powder and 0.387g of cyanuric acid powder and dissolve them in dimethyl sulfoxide with heating and stirring until the solution is clear. The two cups of solutions were mixed to obtain a white precipitate, which was filtered and placed in an oven at 80°C for 24 hours. Pour into a crucible and heat treat in a carbonization furnace. Argon atmosphere, heating rate 3°C / min, to 550°C, keep warm for 4 hours. That is, the g-C3N4 stacked in sheets is obtained.

[0029] (2) Take 60 mg of g-C3N4 obtained in (1), add 30 ml of isopropanol, and sonicate for 8 hours to obtain a light yellow suspension of g-C3N4.

[0030] (3) Take 0.85g of PVDF-HFP and 0.15g of PEO, add 2.5ml of the dispersion in (2), then add 8ml of DMF, and stir in a water bath at 60°C for 24 hours. Cast the solution on a polytetrafluoroethylene plate, wait for most of the solvent to volatilize, transfer to a vacuum oven at 80°C, and keep it warm for 12 hours. A thin film was obtained ...

Embodiment 3

[0033] (1) Take 0.378g of melamine powder and 0.387g of cyanuric acid powder and dissolve them in dimethyl sulfoxide with heating and stirring until the solution is clear. The two cups of solutions were mixed to obtain a white precipitate, which was filtered and placed in an oven at 80°C for 24 hours. Pour into a crucible and heat treat in a carbonization furnace. Argon atmosphere, heating rate 3°C / min, to 550°C, keep warm for 4 hours. That is, the g-C3N4 stacked in sheets is obtained.

[0034] (2) Take 60 mg of g-C3N4 obtained in (1), add 30 ml of DMF, and sonicate for 8 hours to obtain a light yellow suspension of g-C3N4.

[0035] (3) Take 0.75g of PVDF-HFP and 0.25g of PEO, add 2.5ml of the dispersion in (2), then add 8ml of DMF, and stir in a water bath at 60°C for 24 hours. Cast the solution on a polytetrafluoroethylene plate, wait for most of the solvent to volatilize, transfer to a vacuum oven at 80°C, and keep it warm for 12 hours. A thin film was obtained with a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com