Side-chain bis(sulphonyl)imide grafted polyimide single-ion conductive polymer and application thereof

A bissulfonimide and polyimide type technology is applied in the field of polyimide type single ion conducting polymers to achieve the effects of excellent electrochemical stability, good cycle performance and excellent chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

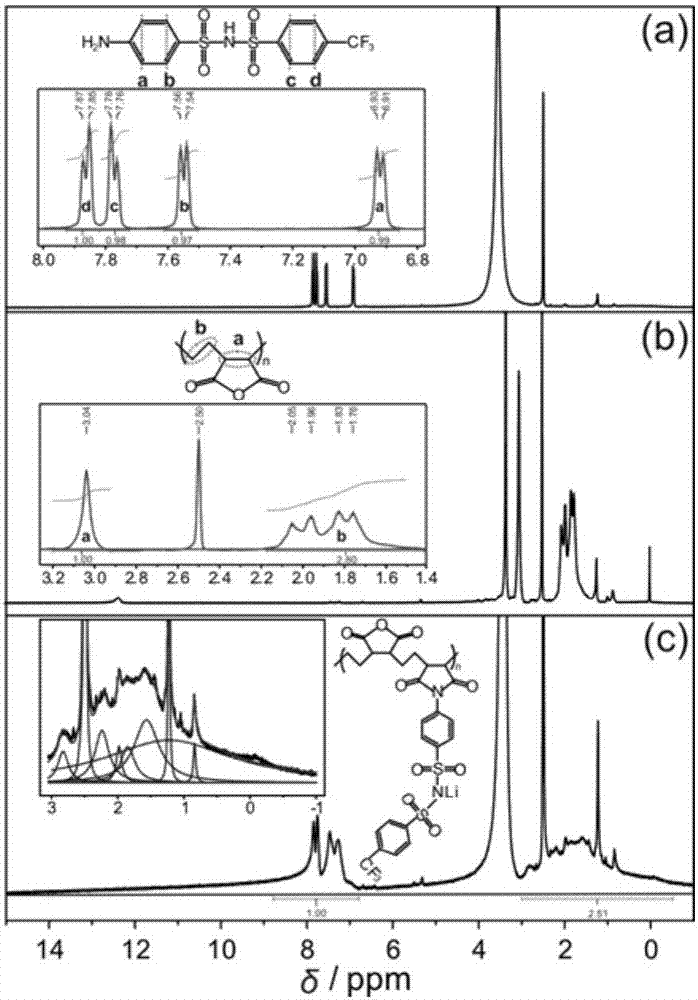

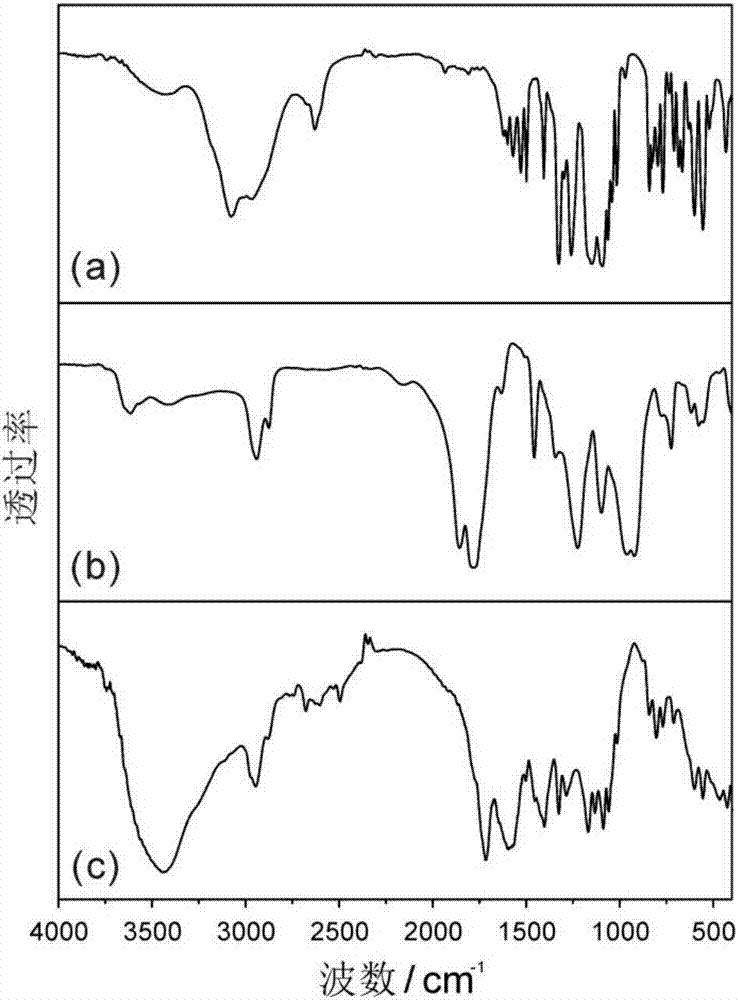

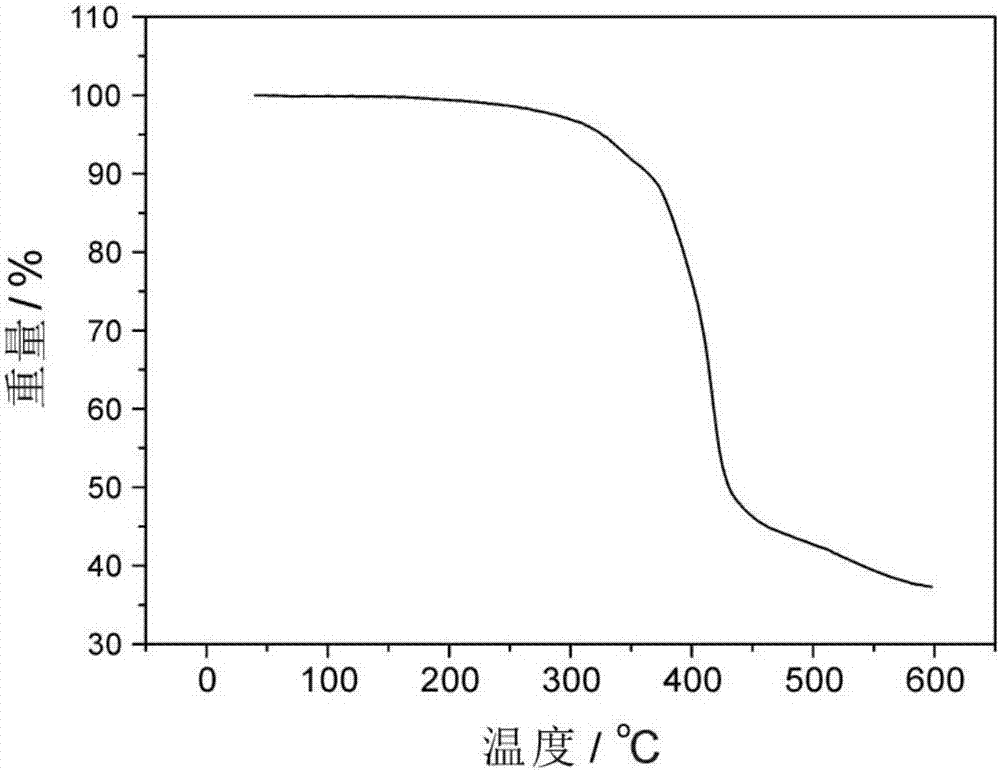

[0031] Example 1, this example synthesizes polyethylene maleic anhydride side chain grafted bis-sulfonimide polymer, the steps are as follows:

[0032] (1) Synthesizing bis-sulfonimides substituted with one-sided para-amino groups according to the prior art, the synthetic route is as follows:

[0033]

[0034] Specifically include the following steps:

[0035] (1.1) Preparation of 4-nitro 4'-trifluoromethyl bisbenzenesulfonimide

[0036] p-Nitrobenzenesulfonamide and p-trifluoromethylbenzenesulfonyl chloride were stirred in alkaline solution at 90°C for 12h at a feed ratio of 2:1. Stirring was stopped, filtered and the filtrate collected. HCl was added to the filtrate to obtain a white precipitate, which was filtered, and the product was recrystallized and dried for later use. The yield was 40%.

[0037] (1.2) Preparation of 4-amino 4'-trifluoromethyl bisbenzenesulfonimide

[0038] The product of step 1.1 was dissolved in 80 mL of dichloromethane solution, poured into t...

Embodiment 2

[0058] Example 2: In this example, the poly(vinylidene fluoride-co-hexafluoropropylene) (PVDF-HFP) is mixed with polyethylene maleic anhydride side chain grafted bis-sulfonimide polymer lithium salt prepared in Example 1 The composite film is obtained as the separator of the battery and also as the electrolyte, and the polymer lithium salt, LiFePO 4 Mix it with conductive carbon powder as the positive electrode material of the battery, and use metal lithium as the negative electrode material to obtain a gel-type single-ion conductive metal lithium polymer secondary battery. The steps are as follows:

[0059] Preparation of positive electrode: Active material, activated carbon and polymer lithium salt are weighed according to the mass ratio of 6:2:2, mixed evenly after adding N-methylpyrrolidone, coated on metal aluminum foil with a scraper, dried, cut into pieces, vacuum dry.

[0060] Battery assembly: Place the positive electrode sheet, PP film and metal lithium sheet in a 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com