Iron sulfide@sulfur hybrid porous carbon positive electrode precursor material and preparation and application of sulfur-loaded positive electrode active material thereof

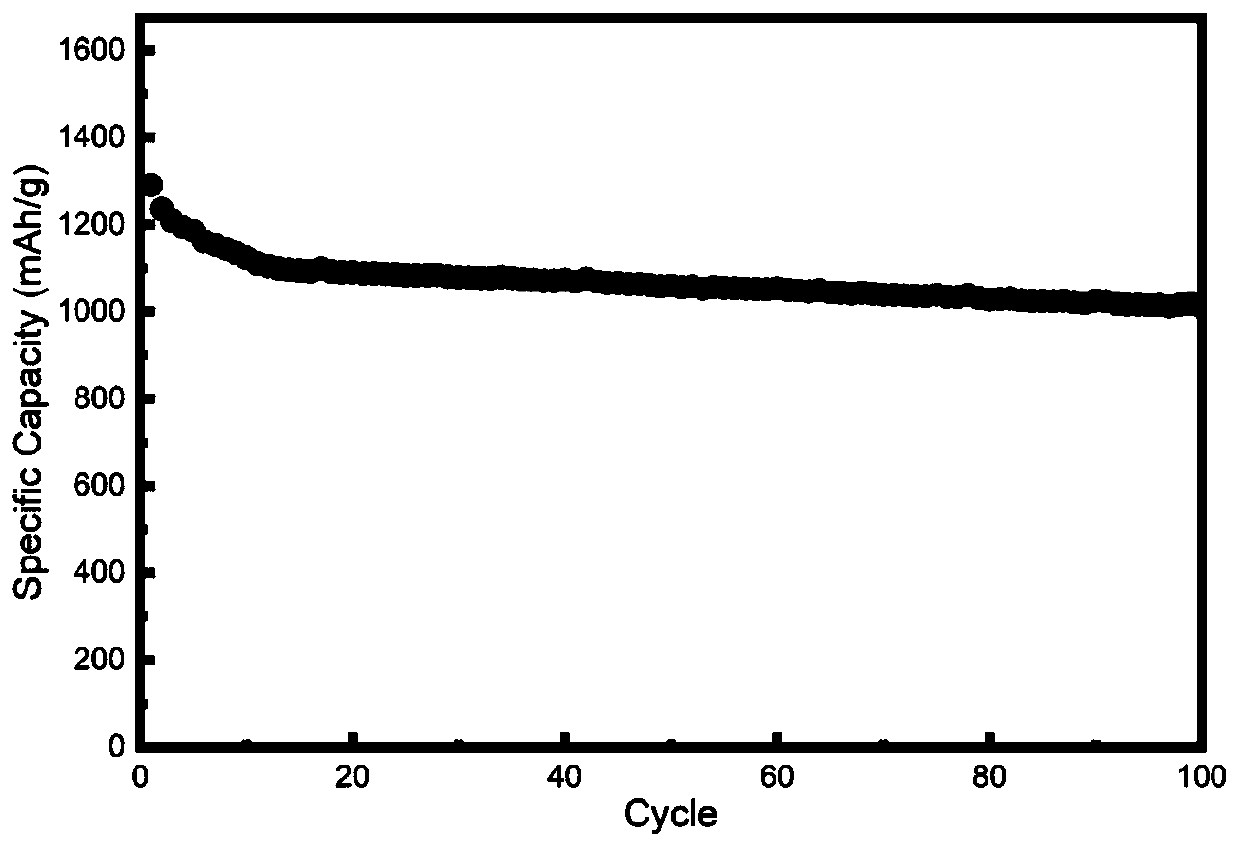

An iron sulfide, active material technology, applied in the preparation/purification of carbon, nanotechnology for materials and surface science, positive electrodes, etc. low, insufficient reaction interface, etc., to achieve the effect of inhibiting the shuttle effect, excellent capacity, and improving low capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

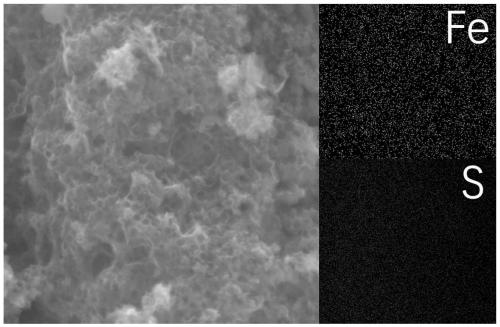

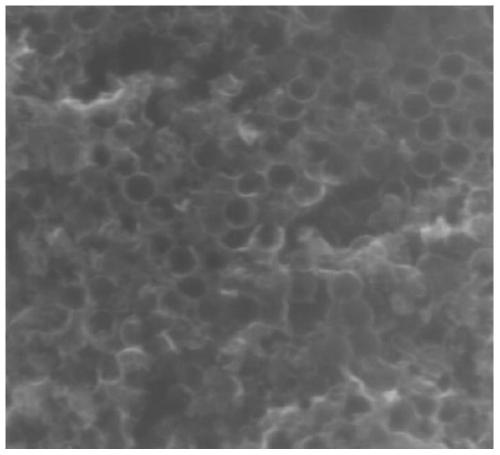

[0078] 5 kg of starch, 5 kg of 50nm SiO 2 Add the template dispersion, 30 grams of iron acetate and 50 grams of sodium dodecylsulfonate into 10L of deionized water, stir at 80°C for 5 hours, dry the slurry at 120°C, and pulverize the dried slurry Afterwards, carbonize in a carbonization furnace at 1200°C for three hours under an argon atmosphere; the carbonized product is washed with 10M sodium hydroxide solution at a temperature of 100°C to remove SiO 2 Template; wash repeatedly with deionized water until the pH of the washing solution is neutral. Then the carbon material was dried, mixed with 1 kg of sublimated sulfur powder and ball-milled evenly, and then heat treated in an argon atmosphere; the heat treatment temperature was 650°C, the time was 3 hours, and the heating rate was 5°C / min. A locally graphitized thiabridized porous carbon material with rich pore structure and in-situ growth of iron sulfide particles on the surface of the carbon material is obtained. from f...

Embodiment 2

[0082] Compared with Example 1, the only difference is that the particle size of the template is changed, specifically:

[0083] 5 kg of starch, 5 kg of 500nm SiO 2 Add the template dispersion, 30 grams of iron acetate and 50 grams of sodium dodecylsulfonate into 10L of deionized water, stir at 80°C for 5 hours, dry the slurry at 120°C, and pulverize the dried slurry Afterwards, carbonize in a carbonization furnace at 1200°C for three hours under an argon atmosphere; the carbonized product is washed with 10M sodium hydroxide solution at a temperature of 100°C to remove SiO 2 Template; wash repeatedly with deionized water until the pH of the washing solution is neutral. Then the carbon material was dried, mixed with 1 kg of sublimated sulfur powder and ball-milled evenly, and then heat treated in an argon atmosphere; the heat treatment temperature was 650°C, the time was 3 hours, and the heating rate was 5°C / min. A locally graphitized thiabridized porous carbon material with ...

Embodiment 3

[0086] Compared with Example 1, change the particle size of the template and the temperature of carbonization, specifically:

[0087] 5 kg of starch, 5 kg of 150nm SiO 2 Add the template dispersion, 30 grams of iron acetate and 50 grams of sodium dodecylsulfonate into 10L of deionized water, stir at 80°C for 5 hours, dry the slurry at 120°C, and pulverize the dried slurry Finally, carbonize in a carbonization furnace at 800°C for three hours under an argon atmosphere; the carbonized product is washed to remove SiO with 10M sodium hydroxide solution at a temperature of 100°C. 2 Template; wash repeatedly with deionized water until the pH of the washing solution is neutral. Then the carbon material was dried, mixed with 1 kg of sublimated sulfur powder and ball-milled evenly, and then heat treated in an argon atmosphere; the heat treatment temperature was 650°C, the time was 3 hours, and the heating rate was 5°C / min. A locally graphitized thiabridized porous carbon material wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com