Preparation method of large-rate discharge porous diaphragm material and application of material

A technology of porous diaphragm and porous film, applied in the field of membrane materials, can solve the problems of low open porosity, unfavorable electrolyte full penetration, low electrolyte holding capacity, etc., and achieves the effect of increasing the holding capacity and enhancing the high-rate discharge performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

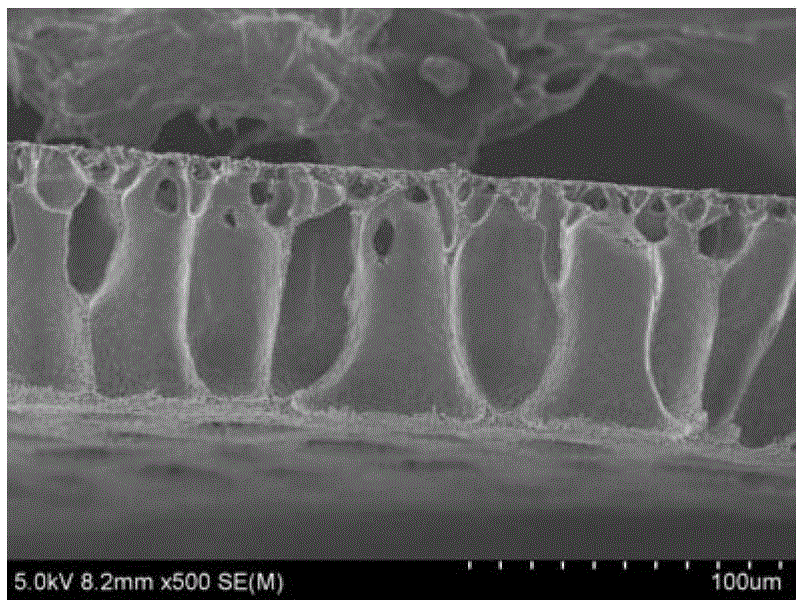

[0070] Prepare a homogeneous and clear casting solution as follows: Dissolve 15g PVDF and 8.5g glycerol in 76.5g NMP, heat at 45°C, stir at 120r / min for 12h, until uniform and clear, seal and vacuum defoam, After standing for 6 hours, scrape the obtained homogeneous casting solution evenly on the glass plate at ambient temperature (25±2)°C and humidity (55±10)% to form a nascent film, and then immerse it in 45° The film is solidified in the gel bath of C, the porosity of the prepared film is 80%, the bubble point pore size is 0.106 μm, and the average pore size is 0.0259 μm. LiPF 6 (EC:DMC=1:1) is the electrolyte, which is discharged at a high rate in the lithium / air battery, and the current density i=5mA / cm 2 Below, the average first discharge time is 135s.

Embodiment 2

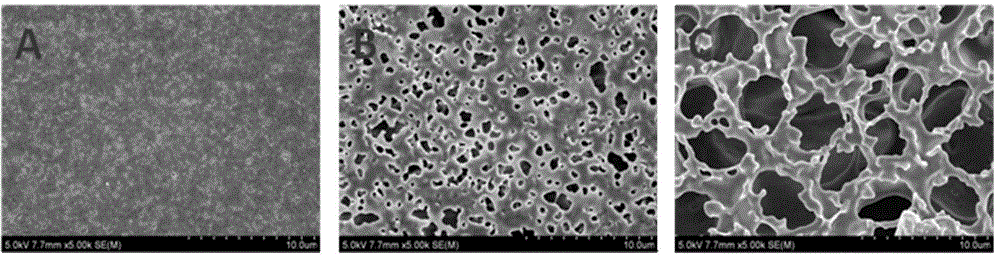

[0072] Dissolve 18g of PVDF-HFP and 15g of polyethylene glycol 200 in 67g of DMF, heat and stir at 65°C for 12h, until it reaches a uniform and clear state, seal it for vacuum defoaming, and let it stand for 6h. Temperature (25±2)°C, humidity (55±10)%, use a 100-400μm scraper to scrape on a glass plate to form a nascent eco-film, pre-evaporate in the air for 10s-3min, and place in a 40-90°C oven 2-24h. The prepared membrane has a porosity of 73-89%, a bubble point pore size of 0.106-0.137μm, and uses LiPF 6 (EC:DMC=1:1) is the electrolyte, which is discharged at a high rate in the lithium / air battery, and the current density i=5mA / cm 2 Under normal circumstances, the average first discharge time is 110-177s. Its topography is as figure 2 -A shown.

Embodiment 3

[0074] As described in Example 2, argon atmosphere is used for plasma treatment, the treatment power is 400w, the treatment time is 1min-15min, the treatment temperature is 40-90°C, and the bubble point aperture of the prepared porous membrane is 0.1μm-3.7μm, The average pore size can be controlled within 0.07μm-2.5μm, using commonly used LiFP 6 (EC:DMC=1:1) is soaked in the electrolyte for 12 hours, and the carbon paper material coated with the mixture of carbon material and PTFE emulsion is used as the air electrode material. The Swagelok-type mold with a hollow end is a battery model, which is assembled into a lithium / air battery under air-isolated conditions, and then subjected to a high-rate discharge test with a current density of i=5mA / cm 2 Next, the first discharge time is 167-240s. Its topography is as figure 2 -B (average pore size is 1.19 μm).

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com