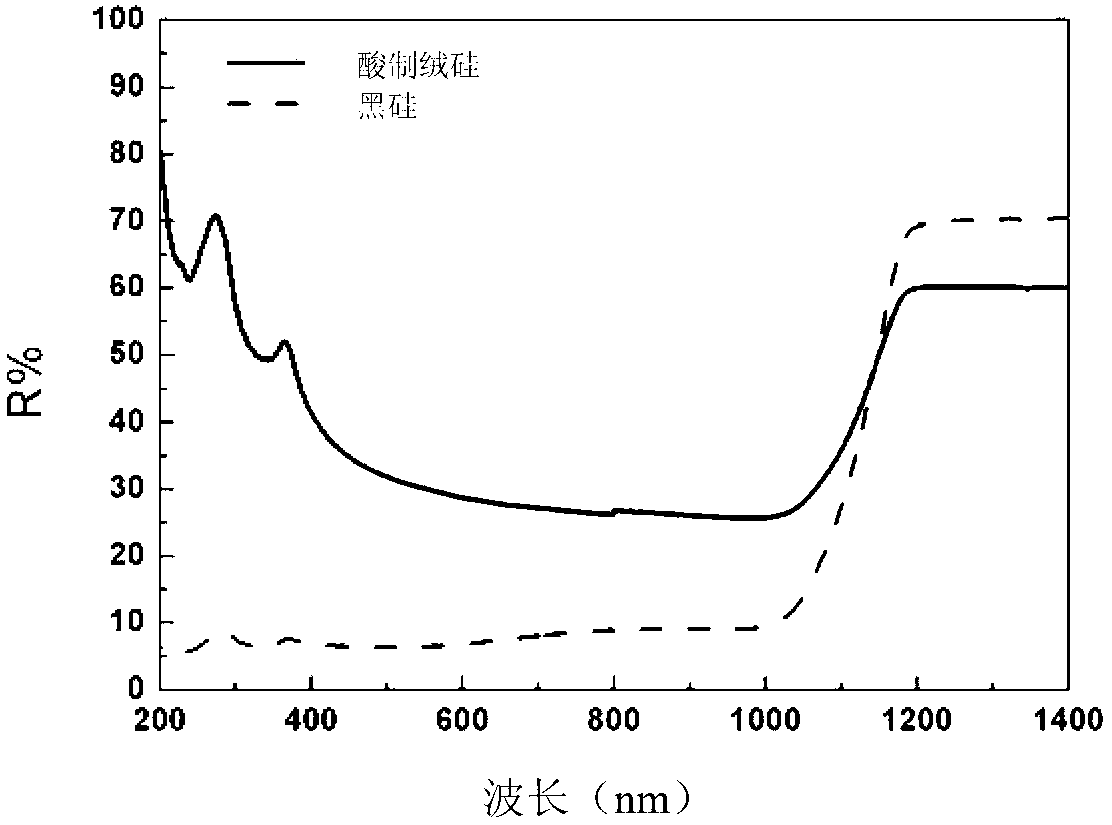

Method for reducing reflection of black silicon in wide band scope

A wide-band, anti-reflection technology, applied in sustainable manufacturing/processing, electrical components, climate sustainability, etc., to achieve low-cost, anti-reflection, and low-reflection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment provides a method for reducing the reflectivity of silicon wafers in a wide spectral range, including:

[0041] 1) Perform surface isolation and protection treatment on black silicon with nano-column structure, and deposit 30nm thick SiN on its surface by PECVD (that is, plasma chemical vapor deposition method) x middle layer;

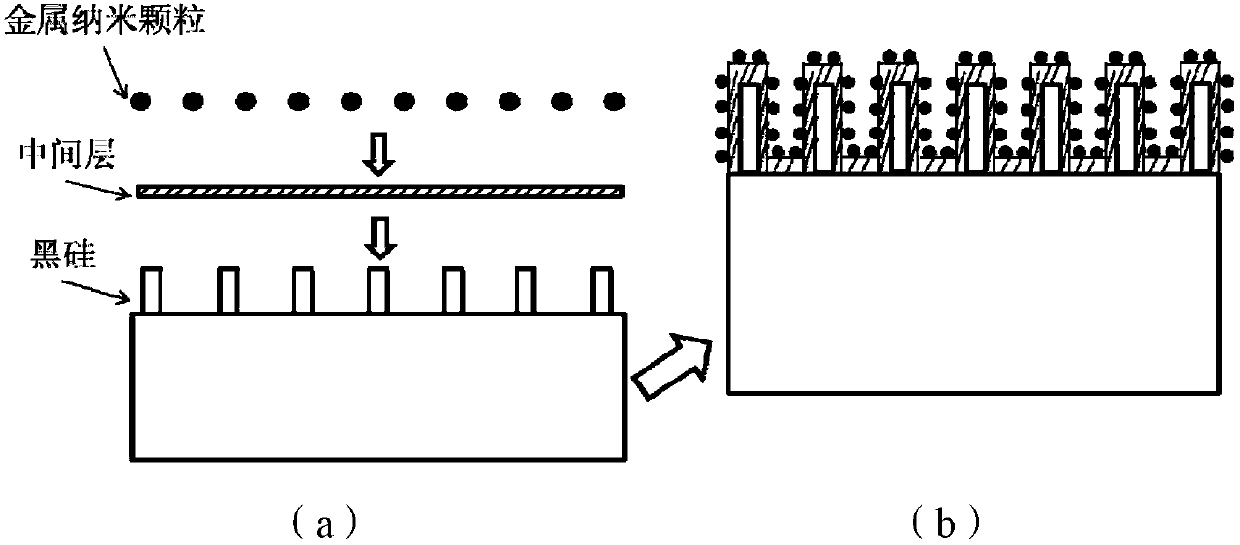

[0042] 2) On the black silicon surface after the intermediate layer is prepared, Ag with a thickness of 5nm is deposited by thermal evaporation to obtain discontinuous Ag metal particles (above step 1) and 2) are reflected in image 3 a);

[0043] 3) Put the sample into an annealing furnace, blow nitrogen, and anneal at 200°C for 30 minutes to obtain Ag metal nanoparticles with more regular shape and uniform distribution, and the average diameter of Ag metal nanoparticles is about 25nm.

[0044] The schematic diagram of the black silicon-based surface plasmon wide-band anti-reflection structure obtained after the above steps is...

Embodiment 2

[0048] This embodiment provides a method for reducing the reflectivity of silicon wafers in a wide spectral range, including:

[0049] 1) Perform surface isolation protection treatment on black silicon with nanowire structure, and deposit 25nm thick SiN on its surface by PECVD x middle layer;

[0050] 2) On the black silicon after the intermediate layer was prepared, Ag with a thickness of 10nm was deposited by thermal evaporation to obtain discontinuous Ag metal particles;

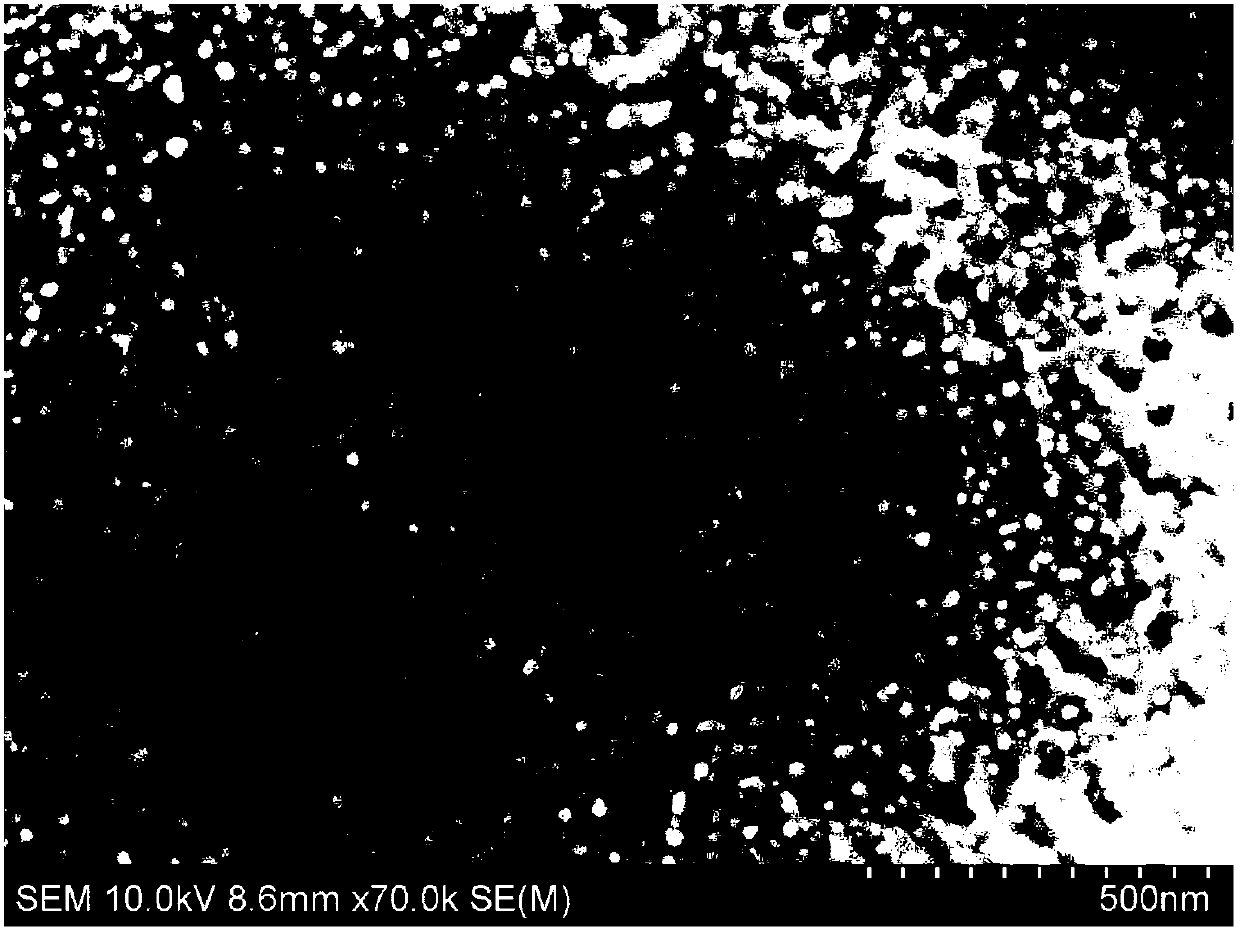

[0051] 3) Put the sample into an annealing furnace, blow nitrogen, and anneal at 150°C for 20 minutes to obtain Ag metal nanoparticles with more regular shape and uniform distribution, and the average diameter of Ag nanoparticles is about 30nm.

[0052] The SEM topography of the black silicon-based surface plasmon broadband anti-reflection structure obtained after the above steps is as follows Figure 7 shown. Figure 8 It is the reflectance spectrum of the polycrystalline silicon chip after the acid t...

Embodiment 3

[0054] This embodiment provides a method for reducing the reflectivity of silicon wafers in a wide spectral range, including:

[0055] 1) Carry out surface isolation and protection treatment on black silicon with nanoporous structure, and obtain SiO with a thickness of about 15nm after ozone oxidation for 30 minutes 2 middle layer;

[0056] 2) On the black silicon after the intermediate layer was prepared, Ag with a thickness of 10nm was deposited by thermal evaporation to obtain discontinuous Ag metal particles;

[0057] 3) Put the sample into an annealing furnace, and after vacuuming, anneal at 250°C for 60 minutes to obtain Ag metal nanoparticles with more regular shape and more uniform distribution.

[0058] The SEM topography of the black silicon-based surface plasmon wide-band anti-reflection structure obtained after the above steps is as follows: Figure 9 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com