Biological cell wall breaking system and biological effective component extracting system based on pulsed discharge plasma technology

A plasma and pulse discharge technology, applied in the field of biological cell wall breaking system, can solve the problem of low extraction rate and achieve the effect of high extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

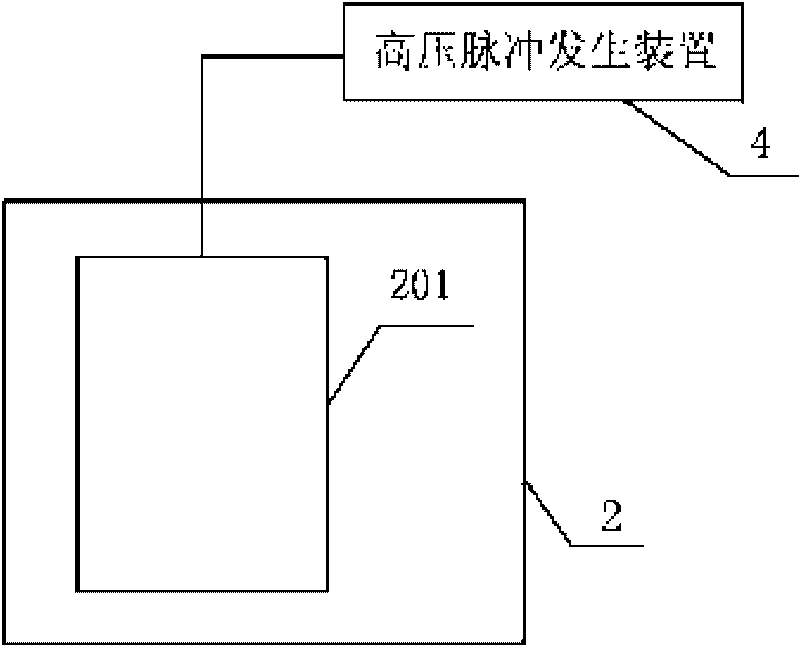

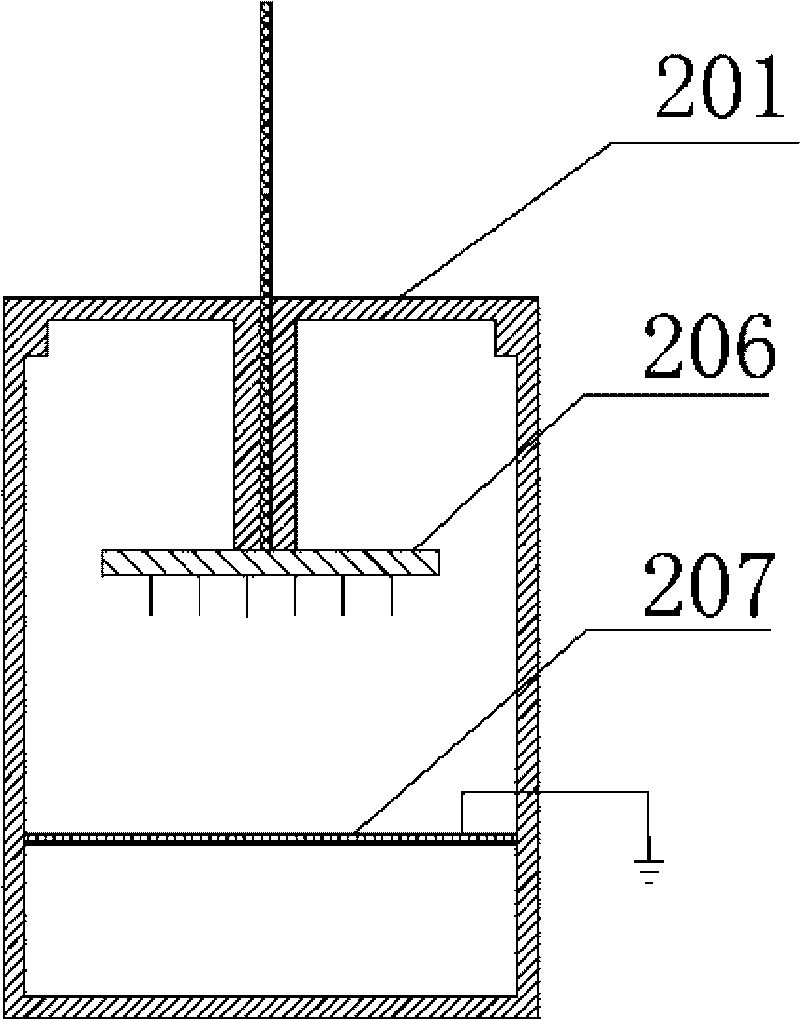

[0009] Specific implementation mode one: combine figure 1 , figure 2 Describe this embodiment, the biological cell wall breaking system based on pulsed discharge plasma technology of this embodiment, it comprises treatment device 2 and high-voltage pulse generation device 4, and described treatment device 2 comprises treatment chamber 201, first electrode 206 and the first electrode 206 Two electrodes 207, the first electrode 206 and the second electrode 207 are all placed in the processing chamber 201, and the pole plate of the first electrode 206 is opposite and parallel to the pole plate of the second electrode 207, and the first electrode 206 is connected by a conductor It is connected with the high-voltage pulse generating end of the high-voltage pulse generating device 4, and the second electrode 207 is grounded.

[0010] In this specific embodiment, the biological material to be treated is composed of plant body, animal body or microbial material, and a space discharg...

specific Embodiment approach 2

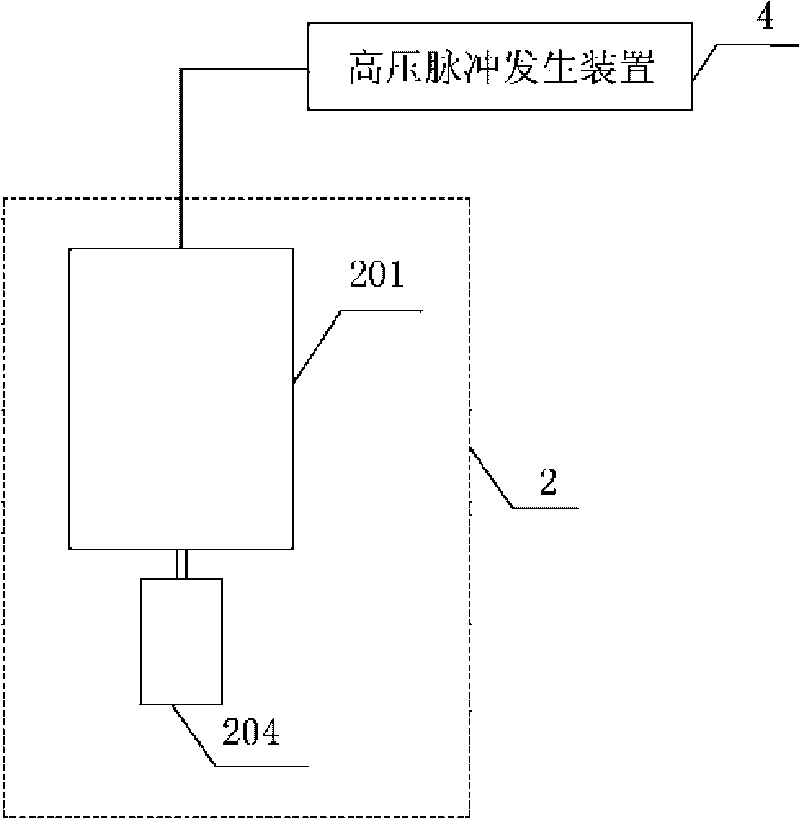

[0011] Specific implementation mode two: combination image 3 , Figure 4 To illustrate this embodiment, the difference from Embodiment 1 is that the processing device 2 of this embodiment also includes a first agitator 204, and the stirring blades of the first agitator 204 are placed in the processing chamber 201 and located in the processing chamber 201. bottom.

[0012] The stirring paddles of the first stirrer 204 can stir the biological material in the processing chamber 201, so that it can be uniformly mixed with the air in the stirring chamber 201, which can make the subsequent high-voltage discharge more uniform in space, thereby enabling So that the cells in the biological material can be destroyed more fully. Disposing the stirring blades of the first stirrer 204 between the second electrode 207 and the bottom of the processing chamber 201 can avoid the problem of uneven distribution of materials in the processing chamber 201 caused by material deposition at the bo...

specific Embodiment approach 3

[0013] Specific implementation mode three: combination Figure 5 To illustrate this embodiment, the difference from Embodiment 1 or 2 is that the processing device 2 of this embodiment also includes a one-dimensional moving frame 210, which is connected to the inner wall of the processing chamber 201, and the one-dimensional moving frame 210 The moving arm is connected with the first electrode 206 to realize one-dimensional movement of the first electrode 206 in a direction perpendicular to the plate of the first electrode 206 .

[0014] Figure 5 It is a sectional view of the processing apparatus 2 in this embodiment. In this embodiment, the one-dimensional moving frame 210 is used, so that the distance between the plates of the first electrode 206 and the second electrode 207 can be adjusted.

[0015] Specific implementation mode four: combination Image 6 , Figure 7 as well as Figure 14 To describe this embodiment, the difference from Embodiments 1, 2 and 3 is that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com