Coaxial microwave plasma film-deposition equipment

A microwave plasma, microwave plasma technology, applied in the field of ions, to achieve the effect of effective process control and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

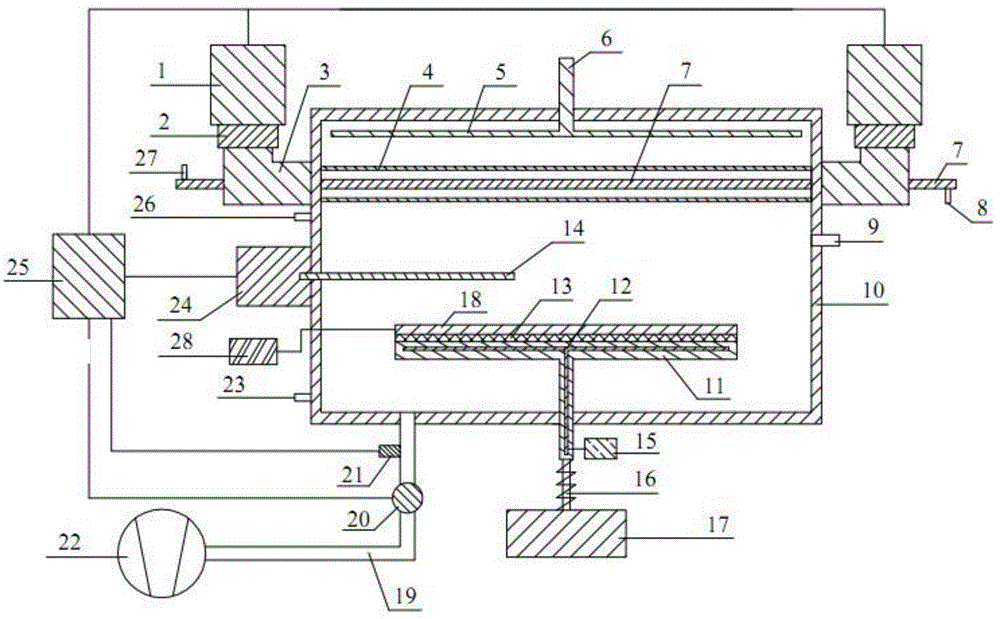

[0031] Such as figure 1 The device for coaxial microwave plasma deposition of thin films shown includes a vacuum chamber on which a coaxial microwave plasma source is fixedly installed, and the coaxial microwave plasma source includes a microwave generator, a waveguide, a coaxial cable Converter, quartz tube and inner electrode, wherein, the quartz tube is located inside the vacuum chamber and is fixedly installed on the two side walls of the vacuum chamber, and the coaxial converter is coaxially and symmetrically fixedly installed on both sides of the quartz tube through the outer side wall of the vacuum chamber. At the same time, the coaxial transformer is connected to the microwave generator through the waveguide, the inner electrode passes through the quartz tube and is fixed on the coaxial transformer, the inner electrode, the coaxial transformer, and the quartz tube are coaxial, and the vacuum chamber There is an inlet pipe on the top of the chamber, and the discharge ga...

Embodiment 2

[0044] Identical with embodiment 1 content, different technical parameters are:

[0045] (1) The bottom and top of the vacuum chamber are movably installed with a support platform, the lower end of the support platform protrudes from the vacuum chamber wall to connect with the position adjustment device, the position adjustment device is connected with the position control device, and the sample platform is detachably installed on the support platform, An insulating layer is arranged between the supporting platform and the sample platform;

[0046] (2) The microwave trigger mode of the microwave generator is external trigger, the microwave output mode is continuous mode, and the maximum output power of the continuous mode is 1500W.

[0047] (3) The coaxial microwave plasma sources fixedly installed on the vacuum chamber are arranged in parallel and equally spaced in 4 groups.

[0048] (4) 3 air guide tubes are installed at the lower end of the intake pipe, the air guide tubes...

Embodiment 3

[0053] Identical with embodiment 1 content, different technical parameters are:

[0054] (1) The bottom and side of the vacuum chamber are movably installed with a support platform, the lower end of the support platform protrudes from the vacuum chamber wall to connect with the position adjustment device, the position adjustment device is connected with the position control device, and the sample platform is detachably installed on the support platform , an insulating layer is set between the support platform and the sample platform;

[0055] (2) The microwave trigger mode of the microwave generator is external trigger, the microwave output mode is continuous mode, and the maximum output power of the continuous mode is 2000W.

[0056] (3) The coaxial microwave plasma sources fixedly installed on the vacuum chamber are arranged in 8 groups horizontally parallel and equally spaced.

[0057] (4) Seven air guide tubes are installed at the lower end of the intake pipe, each air gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com