Method for preparing single-ion conductive polymer electrolyte composite fiber diaphragm by means of electrospinning

A technology of electrospinning and composite fibers, which is applied in fiber processing, circuits, electrical components, etc., can solve the problems of complex process, difficult control of polymer membrane pore size and porosity, etc., achieve simple preparation process, improve battery cycle performance, The effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

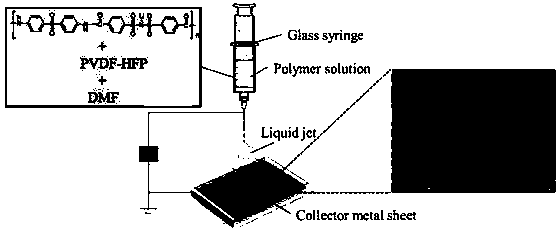

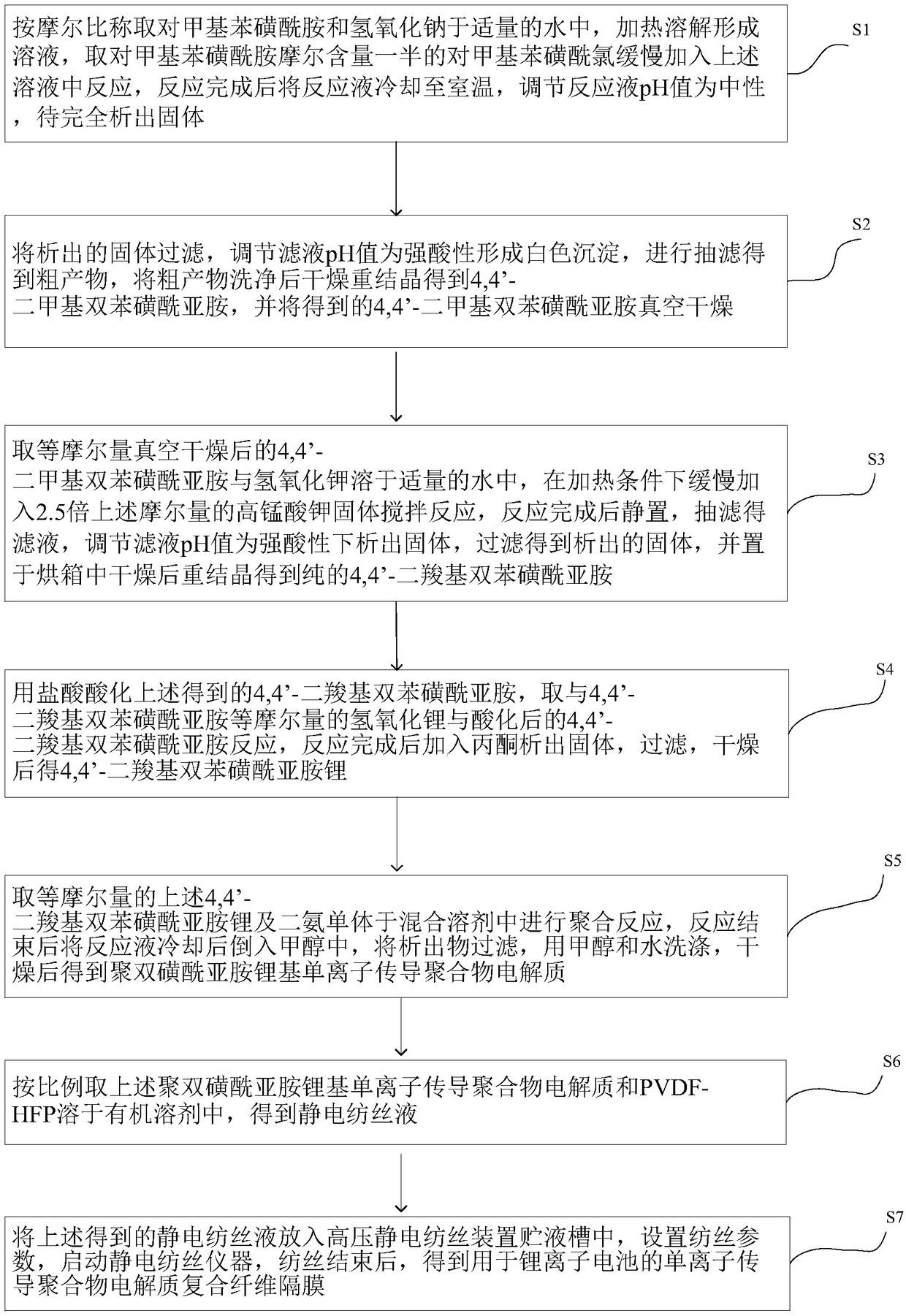

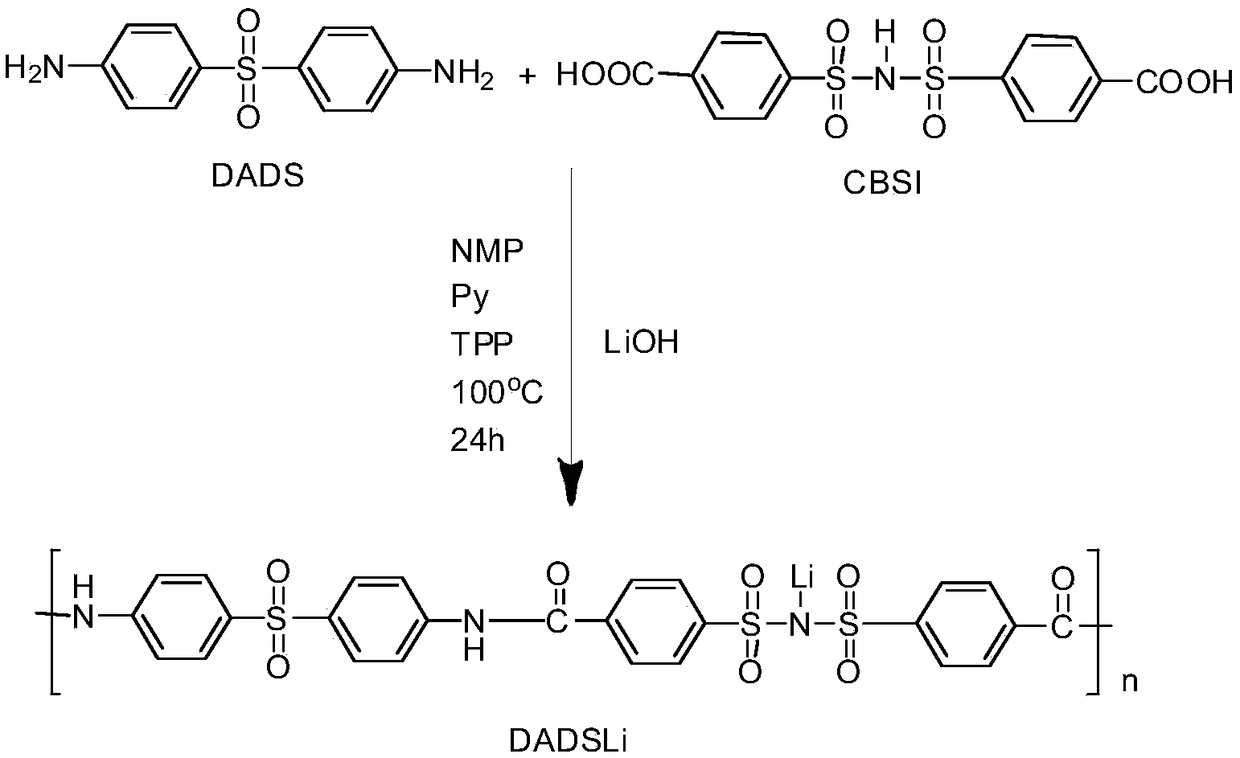

[0029] Please refer to figure 1 , 2 , 3, the embodiment of the present invention provides a kind of method that electrospinning is used to prepare single-ion conductive polymer electrolyte composite fiber membrane, comprises the following steps:

[0030] (1) Weigh p-toluenesulfonamide and sodium hydroxide in an appropriate amount of water by molar ratio, heat and dissolve to form a solution, and slowly add p-toluenesulfonyl chloride with half the molar content of p-toluenesulfonamide to the above solution Reaction, after the reaction is completed, the reaction solution is cooled to room temperature, the pH value of the reaction solution is adjusted to be neutral, and the solid is completely precipitated;

[0031] (2) Filter the precipitated solid, adjust the pH value of the filtrate to be strongly acidic to form a white precipitate, perform suction filtration to obtain the crude product, wash the crude product, dry and recrystallize to obtain 4,4'-dimethylbisbenzenesulfonyl ...

Embodiment 2

[0038] According to the method of Embodiment 1 of the present invention, a single-ion conductive polymer electrolyte composite fiber membrane is prepared, comprising the following steps:

[0039](1) Take a 1L round bottom flask, add 0.6L deionized water and slowly add 0.25mol of sodium hydroxide under stirring conditions, after completely dissolving, add 0.2mol of 4-methylbenzenesulfonamide to the above Sodium hydroxide solution until completely dissolved; slowly add 0.1mol of 4-methylbenzenesulfonyl chloride, react at 95°C for 12h; After complete precipitation, filter to obtain a clear solution;

[0040] (2) Add an appropriate amount of concentrated hydrochloric acid to the filtrate to obtain a large amount of white solid. After suction filtration, the white product is obtained, and then placed in a blast drying oven for drying. Finally, the product 4,4'- is obtained after recrystallization in deionized water. Dimethylbisbenzenesulfonylimide is also vacuum-dried for subseque...

Embodiment 3

[0047] Refer to attached Figure 4 According to the method of Example 2 of the present invention, a single-ion conductive polymer electrolyte composite fiber membrane is prepared, the concentration of the PVDF-HFP / polybissulfonimide lithium solution is 15wt%, the spinning voltage is 25kv, and the solution flow rate is 5ul / min, The receiving distance is 15cm. All the other are with embodiment two.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com