Aluminum oxide modified polymer electrolyte thin film and preparation method thereof

An electrolyte film and polymer technology, applied in circuits, electrical components, secondary batteries, etc., can solve the problems of long process flow, complicated operation, easy agglomeration, etc., and achieve the effect of simplifying process, simple synthesis process, and preventing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

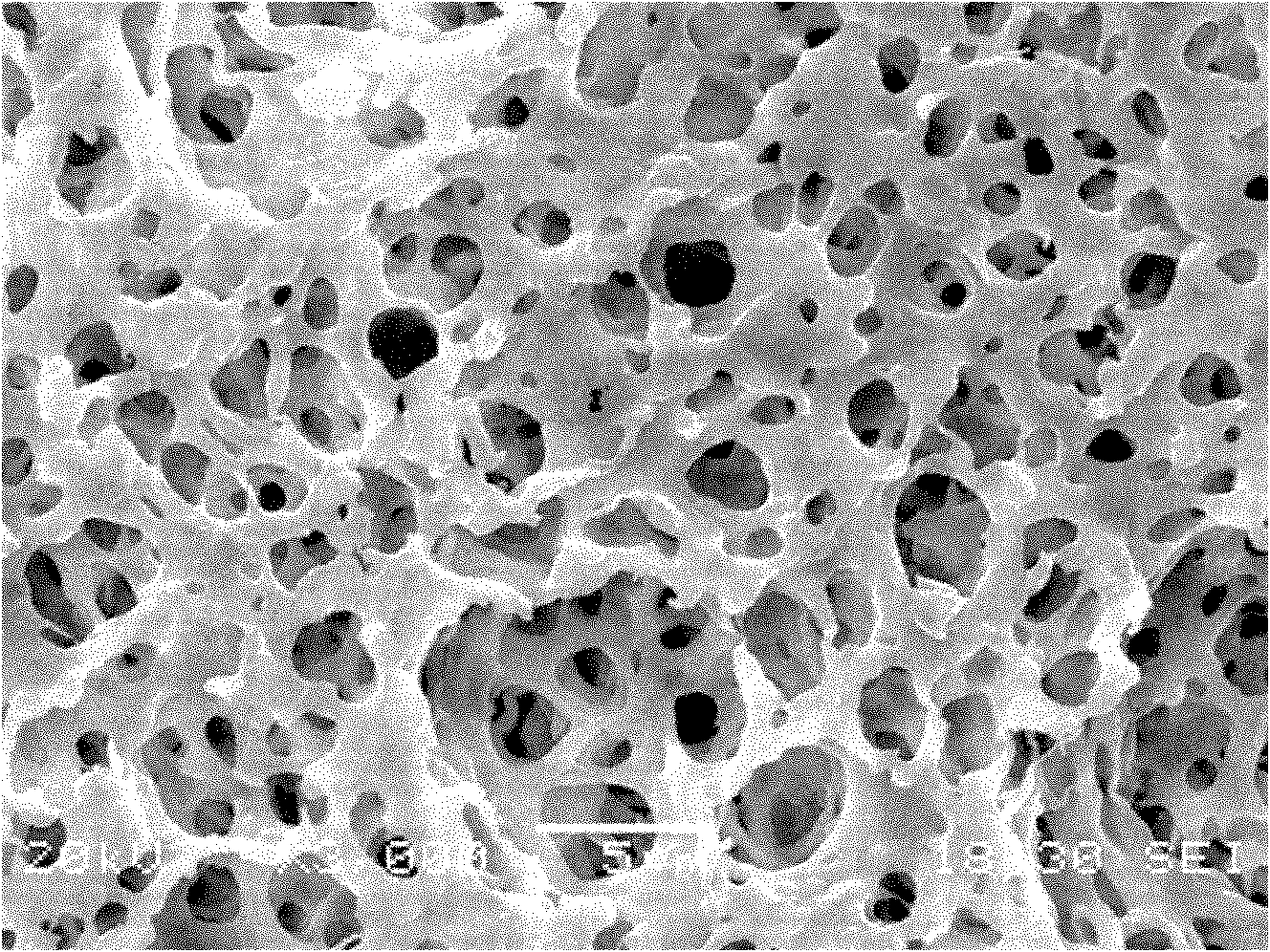

Image

Examples

Embodiment 1

[0021] Vinylidene fluoride and hexafluoropropylene copolymer PVDF-HFP (produced by Atochem, KYNAR2801, the same below) are mixed with aluminum isobutoxide by ball milling, and then the pore-forming agent polyvinylpyrrolidone (PVP) is added, wherein PVDF-HFP, The mass ratio of aluminum isobutoxide and PVP is 100:3:20; the solvent dimethylformamide (DMAC) is added and mixed, the mass ratio of PVDF-HFP and DMAC is 1:8, and DMAC is stirred at 10°C for 5h to obtain Uniform gel, let it stand, vacuumize to remove the air bubbles in the gel, apply the gel evenly on the aluminum foil, volatilize the solvent at 80°C to form a film, and obtain nano-alumina (containing part of aluminum oxyhydroxide) generated in situ ) Modified PVDF-HFP / PVP polymer electrolyte membrane.

[0022] The resulting PVDF-HFP / PVP / Al 2 o 3 The polymer electrolyte film was treated with 1mol / L LiPF 6 After the EC-DMC-EMC solution was soaked, activated and plasticized, its ion conductivity was tested by AC impedan...

Embodiment 2

[0024] Mix vinylidene fluoride and hexafluoropropylene copolymer PVDF-HFP with aluminum isobutoxide by ball milling, then add pore-forming agent polyvinylpyrrolidone (PVP), wherein the mass ratio of PVDF-HFP, aluminum isobutoxide, and PVP is 100 : 10:10; add solvent dimethylformamide (DMAC) and mix, the mass ratio of PVDF-HFP and DMAC is 1:9, DMAC and DMAC are stirred at 30°C for 3h to obtain a uniform gel, stand still, and vacuumize to remove the gel The air bubbles in the glue, the gel is evenly coated on the aluminum foil, and the solvent is volatilized at 50°C to form a film, and the PVDF-HFP / PVP polymer modified by nano-alumina (containing part of aluminum oxyhydroxide) generated in situ is obtained. Electrolyte film.

[0025] The resulting PVDF-HFP / PVP / Al 2 o 3 The polymer electrolyte film was treated with 1mol / L LiPF 6 After the EC-DMC-EMC solution was soaked, activated and plasticized, the ionic conductivity was tested by AC impedance method to be 2.6mS / cm. Cyclic ...

Embodiment 3

[0027] Mix vinylidene fluoride and hexafluoropropylene copolymer PVDF-HFP with aluminum isobutoxide by ball milling, then add pore-forming agent polyvinylpyrrolidone (PVP), wherein the mass ratio of PVDF-HFP, aluminum isobutoxide, and PVP is 100 : 20:5; add solvent dimethylformamide (DMAC) and mix, the mass ratio of PVDF-HFP and DMAC is 1:7, DMAC and DMAC are stirred at 40°C for 1 hour to obtain a uniform gel, let it stand, and vacuumize to remove the gel. The air bubbles in the glue, the gel is evenly coated on the aluminum foil, and the solvent is volatilized at 30°C to form a film, and the PVDF-HFP / PVP polymer modified by nano-alumina (containing part of aluminum oxyhydroxide) generated in situ is obtained. Electrolyte film.

[0028] The resulting PVDF-HFP / PVP / Al 2 o 3 The polymer electrolyte film was treated with 1mol / L LiPF 6 After the EC-DMC-EMC solution was soaked, activated and plasticized, its ion conductivity was tested by AC impedance method to be 3.1mS / cm. Cycl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ionic conductivity | aaaaa | aaaaa |

| Electrochemical stability window | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com