Lithium ion battery diaphragm, preparation method thereof and lithium ion battery

A technology for lithium ion batteries and separators, which is applied in the field of battery materials and their preparation, can solve the problems that affect the mechanical properties of battery safety performance, the pore size and porosity of separators are difficult to control, and the structure of polymer separators is difficult to control, etc., so as to achieve good ionic conductivity. , The effect of small electrochemical impedance value and good electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

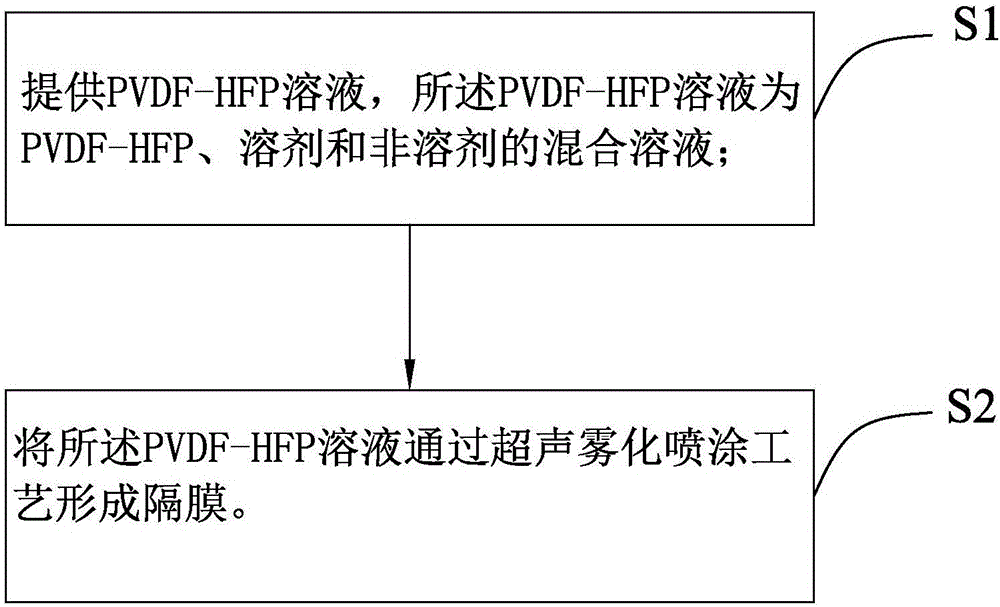

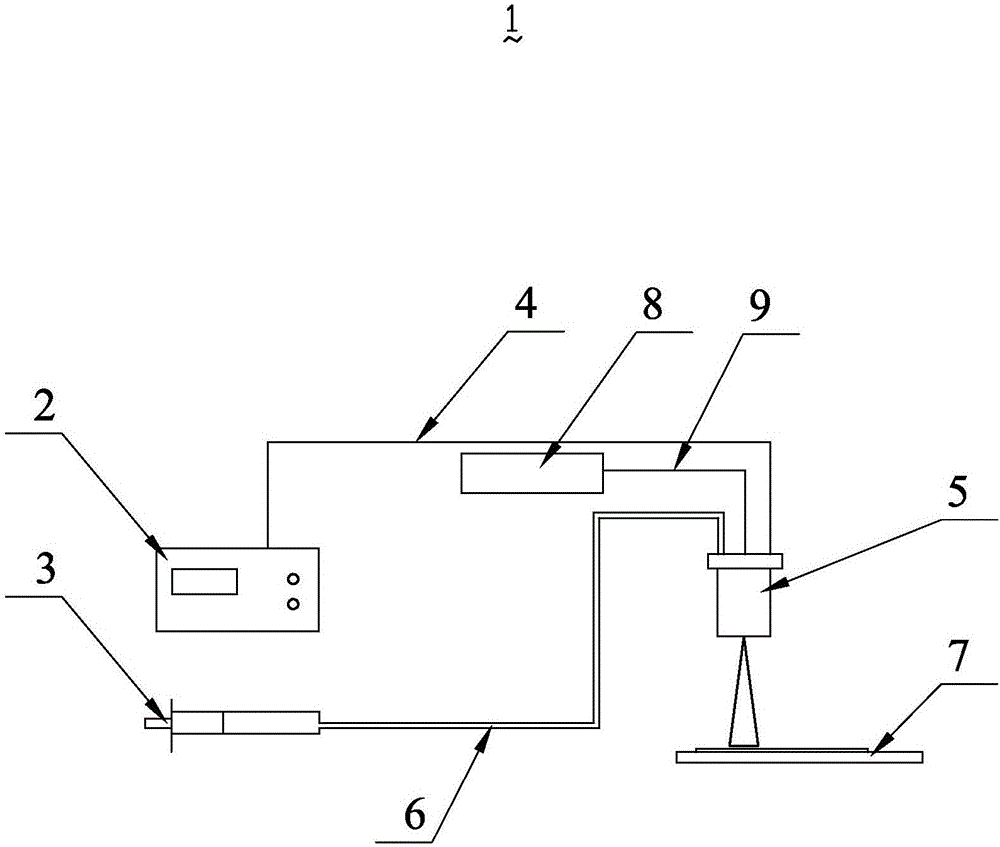

[0036] see figure 1 , the first embodiment of the present invention provides a method for preparing a lithium-ion battery separator, comprising the steps of:

[0037] S1: Provide PVDF-HFP solution, the PVDF-HFP solution is a mixed solution of PVDF-HFP, solvent and non-solvent;

[0038] S2: The PVDF-HFP solution is formed into a diaphragm through an ultrasonic atomization spraying process.

[0039] In the embodiment of the present invention, in the method of PVDF-HFP solution provided, PVDF-HFP, solvent, and non-solvent can be mixed in any order or at the same time. Specifically, the method of PVDF-HFP solution provided can be : Weigh the dried PVDF-HFP and add it into the mixed solution of solvent and non-solvent to stir at a low speed for 1.5-4h to obtain the PVDF-HFP solution.

[0040] The method of the provided PVDF-HFP solution can also be: weigh the dried PVDF-HFP and add it to the solvent, after the PVDF-HFP is dissolved in the solvent, then add a non-solvent and stir ...

no. 1 Embodiment

[0058] PVDF-HFP was added to a mixed solvent of acetone and tetrahydrofuran, and deionized water was added as a non-solvent, and the above solution was stirred at 60° C. for 2 h to completely dissolve PVDF-HFP. Wherein, the mass ratio of PVDF-HFP:(acetone+tetrahydrofuran):deionized water is 2:90:8; and in the solvent, the mass ratio of acetone:tetrahydrofuran is 1:1. The prepared PVDF-HFP solution was prepared by the above-mentioned ultrasonic atomization spraying method to obtain a diaphragm.

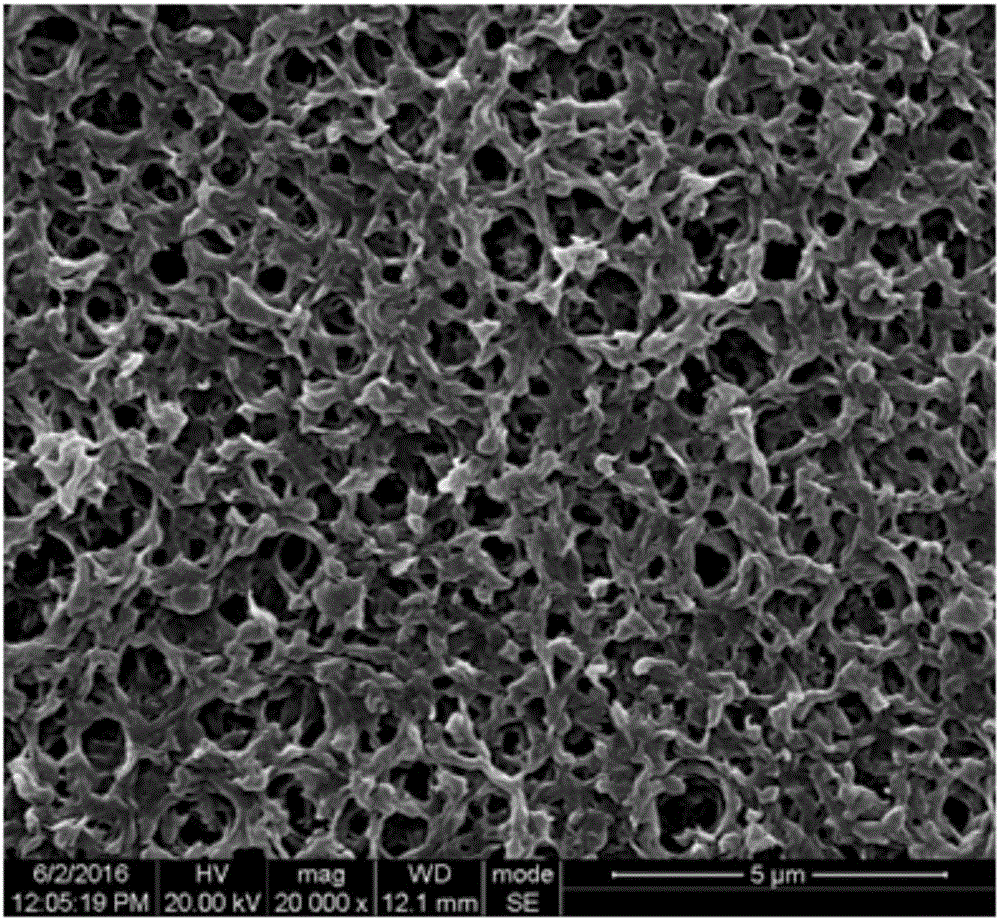

[0059] Detection method 1: Cut the above-prepared separator into 2cm×2cm, and use scanning electron microscope to characterize it.

[0060] Test result: if image 3 As shown, it can be seen that the distribution of micropores on the surface of the separator is uniform, and the pore size of the surface micropores is uniform, which is between 0.3um-1.5um.

[0061] Detection method 2: Cut the above diaphragm into 12mm×12mm, use 1mol / L LiPF6 (lithium hexafluorophosphate)-EC (Ethylene car...

no. 2 Embodiment

[0066] The difference between the second specific embodiment and the first specific embodiment is that the mass ratio of PVDF-HFP:(acetone+tetrahydrofuran):deionized water is 4:88:8.

[0067] Detection method 1: Cut the above-prepared separator into 2cm×2cm, and use scanning electron microscope to characterize it.

[0068] Test result: if Figure 7 As shown, it can be seen that the separator includes uniformly distributed micropores, and the pore size of the surface micropores is relatively uniform, ranging from 0.3um to 2.5um.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com