Method for preparing polyvinylidene fluoride (PVDF)-hexafluoropropylene (HFP) modification membrane of high energy density through hot pressing cross linking

A PVDF-HFP, high energy storage density technology, applied in the field of new energy storage materials, can solve the problems of poor stability and reproducibility of structure modulation, less dosage, unfavorable mass production, etc., and achieve light weight, simple method, and relatively powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

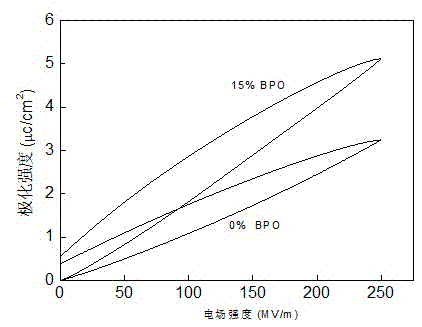

[0033]Weigh 1.00g of vinylidene fluoride-hexafluoropropylene copolymer PVDF-HFP with a molecular weight of 300,000 to 400,000, and the molar ratio of vinylidene fluoride to hexafluoropropylene in the copolymer is 97.5:2.5, and dissolve 0.050g of crosslinking agent BPO In a 50ml stoppered Erlenmeyer flask containing 25ml of N,N-dimethylformamide, stir with a magnetic stirrer at room temperature until a transparent and uniform solution is poured on a tetrafluoroethylene mold , first dry in an oven at room temperature, and then continue to dry in a vacuum oven to ensure that there is no residual solvent in it, and the binary composite material of crosslinking agent BPO / PVDF-HFP can be obtained. Weigh a binary composite material with a mass of about 0.035g and place it between two gaskets. Under the conditions of temperature 200°C and pressure 5Mpa, use a powder tablet press 769YP-15A for hot pressing and crosslinking for 2 hours to ensure The cross-linking reaction with the cross...

Embodiment 2

[0035] Weigh 1.00g of vinylidene fluoride-hexafluoropropylene copolymer PVDF-HFP with a molecular weight of 300,000 to 400,000, and the molar ratio of vinylidene fluoride to hexafluoropropylene in the copolymer is 97.5:2.5, and dissolve 0.100g of crosslinking agent BPO In a 50ml stoppered Erlenmeyer flask containing 25ml of N,N-dimethylformamide, stir with a magnetic stirrer at room temperature until a transparent and uniform solution is poured on a tetrafluoroethylene mold , first dry in an oven at room temperature, and then continue to dry in a vacuum oven to ensure that there is no residual solvent in it, and the binary composite material of crosslinking agent BPO / PVDF-HFP can be obtained. Weigh a binary composite material with a mass of about 0.035g and place it between two gaskets. Under the conditions of temperature 200°C and pressure 5Mpa, use a powder tablet press 769YP-15A for hot pressing and crosslinking for 2 hours to ensure The cross-linking reaction with the cros...

Embodiment 3

[0037] Weigh 1.00 g of vinylidene fluoride-hexafluoropropylene copolymer PVDF-HFP with a molecular weight of 300,000 to 400,000 and a molar ratio of vinylidene fluoride to hexafluoropropylene in the copolymer of 97.5:2.5, and 0.150 g of crosslinking agent peroxidized Benzoyl was dissolved in a 50ml stoppered conical flask filled with 25ml of N,N-dimethylformamide, stirred with a magnetic stirrer at room temperature until it became a transparent and uniform solution, and the above solution was poured into tetrafluoroethylene On the vinyl mold, first dry it in an oven at room temperature, and then continue to dry it in a vacuum oven to ensure that there is no residual solvent in it, and you can get a binary composite material of crosslinking agent BPO / PVDF-HFP. Weigh a binary composite material with a mass of about 0.035g and place it between two gaskets. Under the conditions of temperature 200°C and pressure 5Mpa, use a powder tablet press 769YP-15A for hot pressing and crosslin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com