Method for manufacturing ceramic diaphragm for high-safety lithium ion battery

A lithium-ion battery, ceramic diaphragm technology, used in secondary batteries, battery pack parts, separators/films/diaphragms/spacers, etc., can solve the problem that the diaphragm cannot be thinner than 16μm, and achieve dimensional stability. , to maintain stability, the effect of stable strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

[0015] The preparation method includes the following steps:

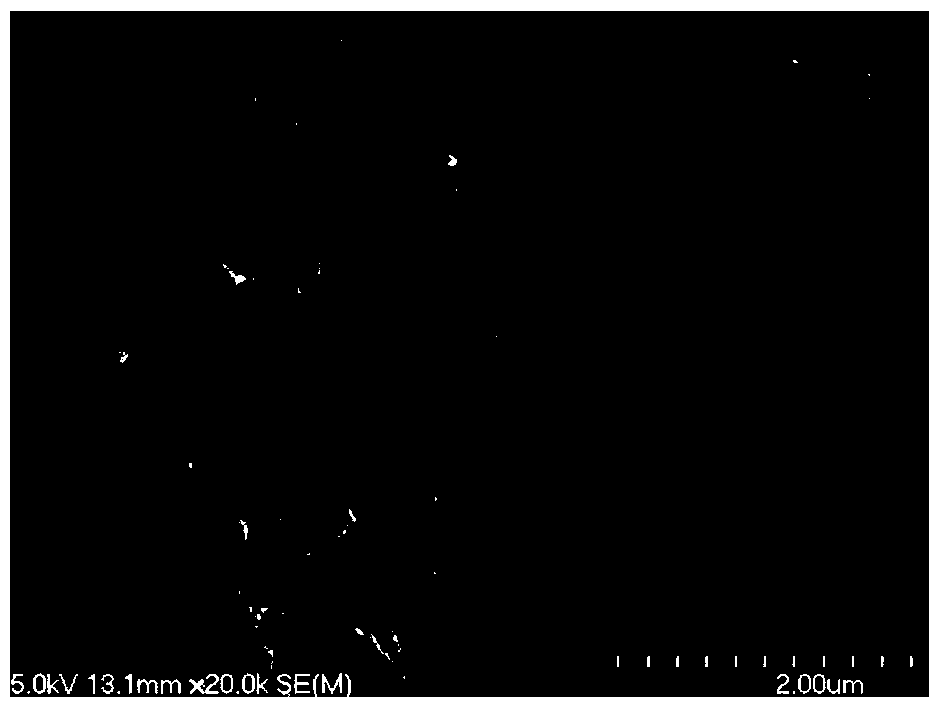

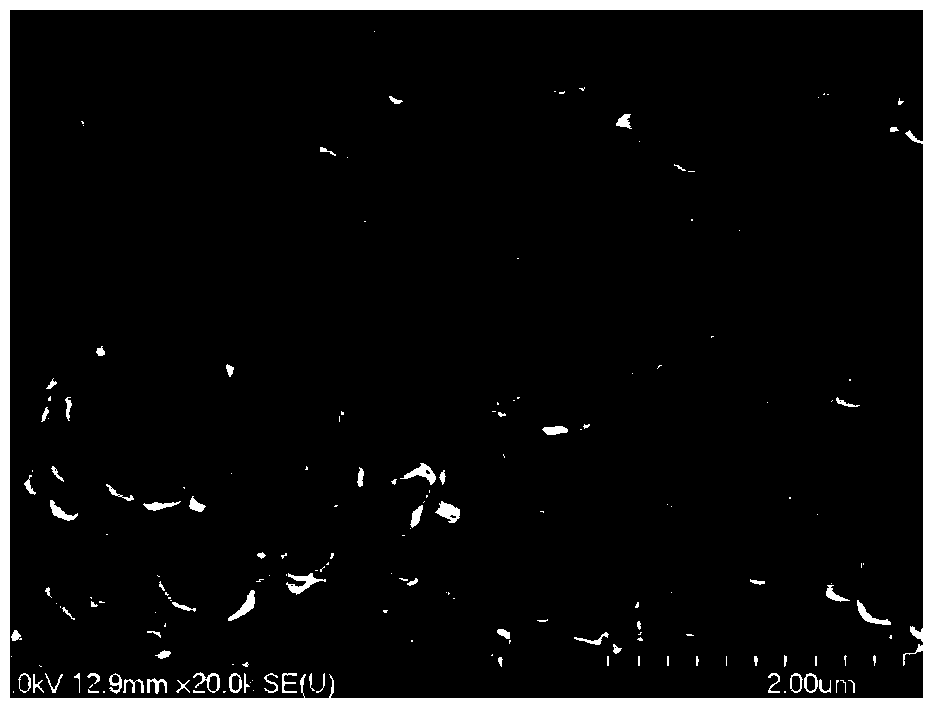

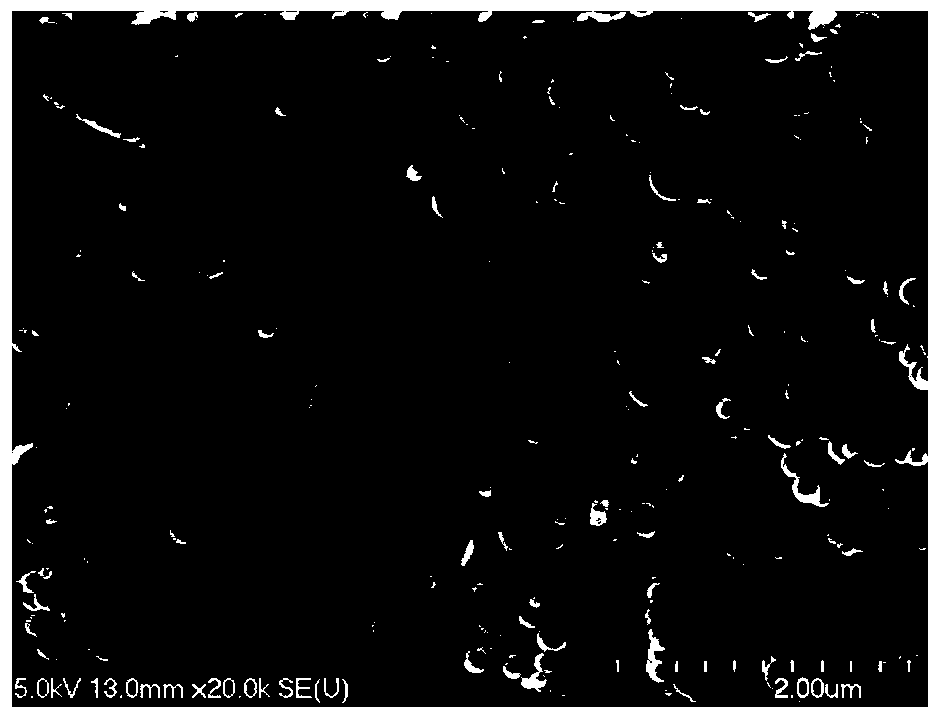

[0016] 1) Ingredients, first dissolve PVDF-HFP (polyvinylidene fluoride-hexafluoropropylene) as a binder in NMP (N-methylpyrrolidone) to form a glue with a solid content of 5-10%, and then add it to the glue Add ceramic powder accounting for 1-3% of the weight of the glue into the liquid, and stir to form a suspension, then add acetone while stirring, dilute to a total solid content of 1-3%, and finally pass through a sand mill to form a suspension Standby; the ceramic powder is selected from spherical or spherical ceramic particles with a particle size ranging from 300nm to 700nm. The solvent of the present invention adopts the mixed solution of NMP and acetone, which can keep the stability of the solvent system.

[0017] 2) Coating: Coat the suspension prepared in step 1) on the polyolefin film by dippin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com