Compound lithium-ion battery diaphragm and preparation method thereof

A technology for ion batteries and lithium composites, which is applied to battery components, separators/films/diaphragms/spacers, circuits, etc., and can solve the problems of inability to meet the requirements of high-rate charge and discharge, increased curvature of the internal aperture of the diaphragm, and Increase the ion transfer path and other issues to achieve the effects of avoiding interface defects, improving electrochemical performance, and increasing liquid absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1. Preparation of PVDF-HFP composite diaphragm supported by PP non-woven fabric (slurry solid content 10%):

[0038] (1) Treatment of PP non-woven fabrics: arrange PP non-woven fabrics in ethanol, ultrasonically clean them for 30 minutes, dry them and place them in an oven at 70 °C for flattening treatment;

[0039] (2) Preparation of PVDF-HFP composite diaphragm supported by PP non-woven fabric: Weigh 5 g polyvinylidene fluoride hexafluoropropylene (PVDF-HFP), dissolve it in 45 g acetone and 5 g DMF, stir and dissolve for 2 hours, It was then coated on a flat polypropylene non-woven fabric, dried naturally for 30 minutes, and then vacuum-dried at 60°C for 8 hours to obtain a PVDF-HFP composite separator supported by PP non-woven fabric.

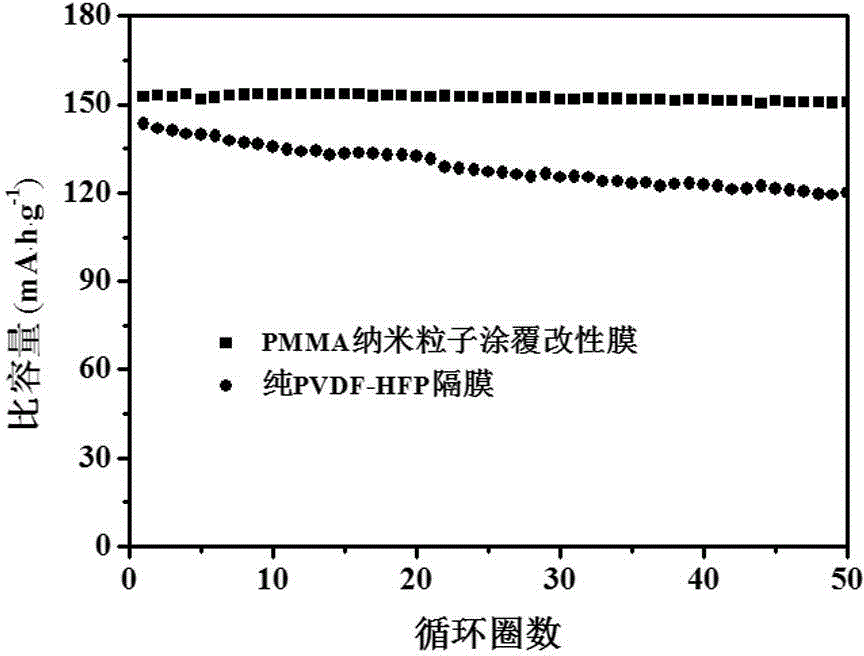

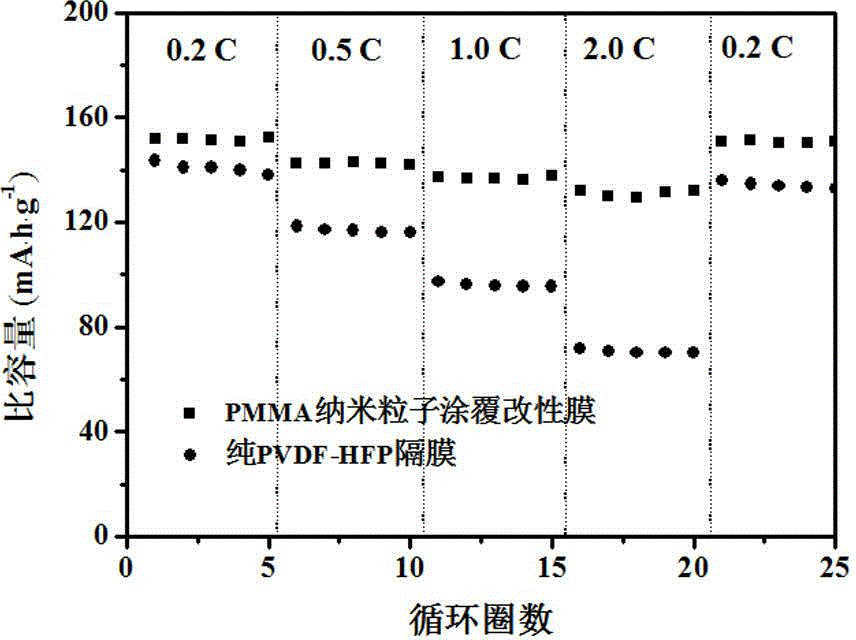

[0040] 2. Half-battery test results: The theoretical specific capacity of the lithium-ion half-battery is 170 mA·h·g -1 , the actual discharge specific capacity at 0.2 C / 0.2 C is 143 mA·h·g -1 , the coulombic efficiency of the batte...

Embodiment 2

[0042] 1. Preparation of three-layer composite separator for lithium ion battery:

[0043] (1) PMMA nanoparticles were obtained by soap-free emulsion polymerization, with an average particle size of 200 nm; the emulsion obtained by polymerization was concentrated to a solid content of 10% by a rotary evaporator;

[0044] (2) Treatment of PP non-woven fabric: arrange PP non-woven fabric in ethanol, ultrasonically clean it for 30 minutes, dry it and place it in an oven at 70 °C for flattening treatment;

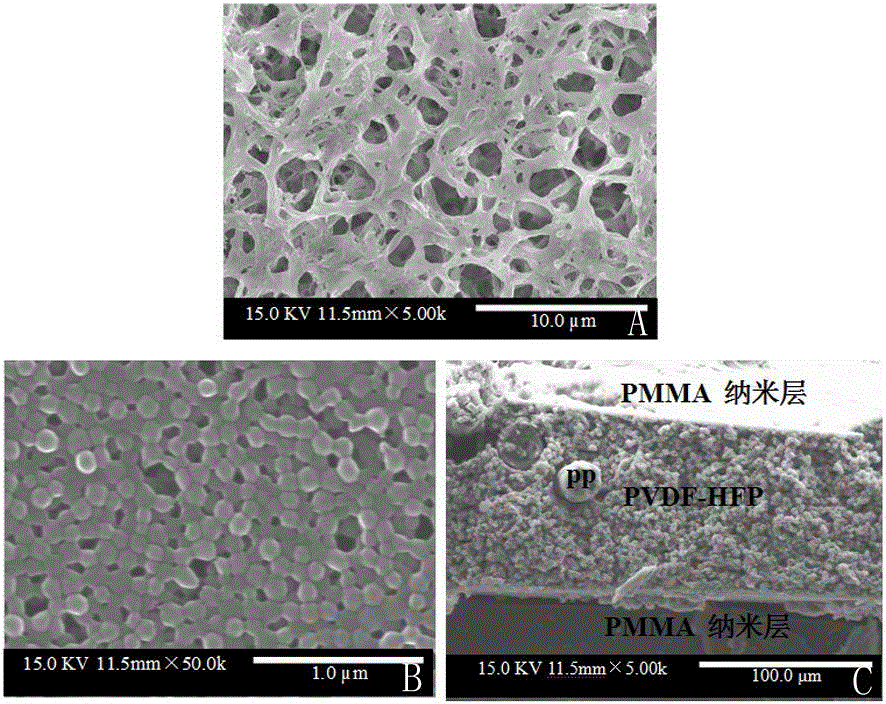

[0045] (3) The intermediate matrix layer is obtained by solution coating, and the large-pore diameter PP non-woven fabric is used as the support material. The preparation process is as follows: weigh 5 g of PVDF-HFP, dissolve in 45 g of acetone and 5 g of DMF, and stir to dissolve 2 hours, then coated on a flat polypropylene non-woven fabric, dried naturally for 30 minutes, and then vacuum-dried at 60°C for 8 hours to obtain a PVDF-HFP matrix film supported by a PP non-woven fa...

Embodiment 3

[0057] A three-layer composite separator for lithium-ion batteries was prepared as follows:

[0058] (1) PMMA nanoparticles were obtained by soap-free emulsion polymerization, 100 nm; the emulsion obtained by polymerization was concentrated to a solid content of 20% by a rotary evaporator;

[0059] (2) Treatment of PP non-woven fabrics: arrange PP non-woven fabrics in ethanol, ultrasonically clean them for 30 min, dry them and place them in an oven at 70 °C for flattening treatment;

[0060](3) The intermediate matrix layer was obtained by solution coating, and the above-mentioned PP non-woven fabric was used as the supporting material. The preparation process is as follows: weigh 5 g PVDF-HFP, dissolve in 45 g acetone and 5 g DMF, stir and dissolve for 2 hours, and then apply it on a flat PP non-woven fabric, let it dry naturally for 30 minutes, and then dry it at 60 Vacuum drying at ℃ for 8 hours to obtain a PVDF-HFP matrix layer supported by PP non-woven fabric;

[0061] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com