A preparing method of a lithium ion battery composite separating membrane

A technology of lithium-ion batteries and composite diaphragms, which is applied to battery components, separators/films/diaphragms/spacers, circuits, etc., can solve the problems of large gaps between diaphragms and pole pieces, poor safety performance of diaphragms, etc., and achieve Effects of improving mechanical properties and heat resistance, and improving battery safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

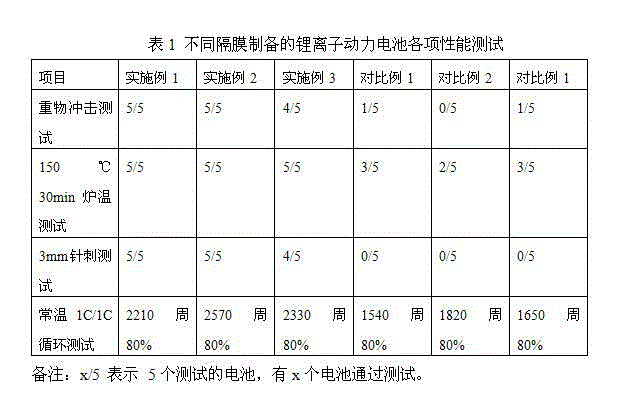

Examples

Embodiment 1

[0020] Dissolve 1 part of polyvinylidene fluoride in 54 parts of N-methylpyrrolidone, then add 30 parts of aluminum oxide and mix evenly to form a slurry. The slurry is uniformly sprayed on both sides of the support body of the composite diaphragm to form an oxide coating, and then dried. The support body is a 25 micron PE film. The oxide coating thickness is 1 micron. Dissolve 1 part of polyvinylidene fluoride in 70 parts of dimethyl sulfoxide, then add 5 parts of aramid 1414, and mix evenly to form an aramid resin coating solution. The dried oxide-coated diaphragm is dipped into an aramid resin coating solution to form an aramid resin coating, and then dried. The thickness of the aramid resin coating is 10 microns. Dissolve 5 parts of PVDF-HFP copolymer in 99 parts of acetone and mix evenly, and then spray evenly on the outside of the aramid resin coating to form a PVDF-HFP copolymer coating. During the coating process, pore-forming treatment is performed and then dried. ...

Embodiment 2

[0023] Dissolve 1.5 parts of polyvinylidene fluoride in 60 parts of N-methylpyrrolidone, then add 38 parts of magnesium oxide and mix uniformly to form a slurry. The slurry is evenly sprayed on both sides of the support of the composite diaphragm to form an oxide coating, and then dried. The support is a 25 micron PP-PE composite film. The oxide coating thickness is 5 microns. Dissolve 2 parts of polyvinylidene fluoride in 75 parts of dimethyl sulfoxide, then add 6 parts of aramid 1414, and mix evenly to form an aramid resin coating solution. The dried oxide-coated diaphragm is dipped into an aramid resin coating solution to form an aramid resin coating, and then dried. The thickness of the aramid resin coating is 5 microns. Dissolve 3 parts of PVDF-HFP copolymer in 97 parts of acetone and mix evenly, and then spray evenly on the outside of the aramid resin coating to form a PVDF-HFP copolymer coating. During the coating process, pore-forming treatment is performed and then ...

Embodiment 3

[0026] Dissolve 2 parts of polyvinylidene fluoride in 68 parts of N-methylpyrrolidone, then add 45 parts of aluminum oxide and mix evenly to form a slurry. The slurry is evenly sprayed on both sides of the support body of the composite diaphragm to form an oxide coating, and then dried. The support body is a 25 micron PP film. The oxide coating thickness is 10 microns. Dissolve 3 parts of polyvinylidene fluoride in 80 parts of dimethyl sulfoxide, then add 7 parts of aramid 1414, and mix evenly to form an aramid resin coating solution. The dried oxide-coated diaphragm is dipped into an aramid resin coating solution to form an aramid resin coating, and then dried. The thickness of the aramid resin coating is 1 micron. Dissolve 1 part of PVDF-HFP copolymer in 95 parts of acetone and mix evenly, and then spray evenly on the outside of the aramid resin coating to form a PVDF-HFP copolymer coating. During the coating process, pore-forming treatment is performed and then dried. Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com