Flame retardant type thermoplastic polyurethane elastomer and preparation method thereof

A thermoplastic polyurethane and elastomer technology, used in the field of polyurethane elastomers, can solve the problems of limited application and poor flame retardancy, and achieve the effects of low tensile permanent deformation, excellent flame retardancy, and uniform distribution of micropores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Synthesis of flame retardant TPU:

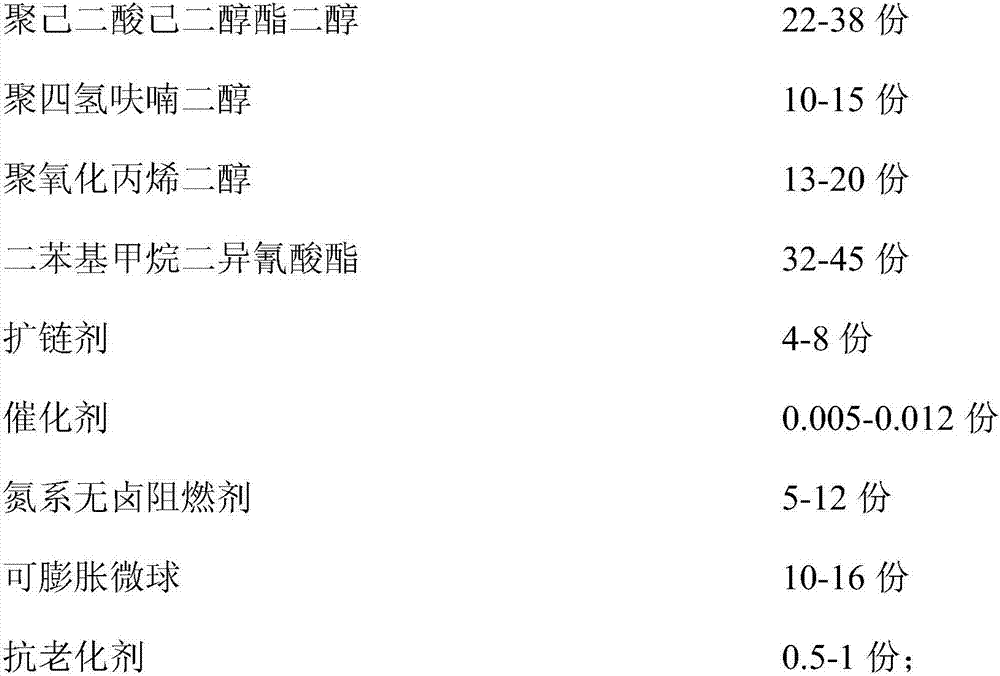

[0033] In terms of weight percentage,

[0034]

[0035]

[0036] The catalyst is organic tin and organic bismuth with a mass ratio of 3:1.

[0037] The anti-aging agent is 1076 and UV-531 with a mass ratio of 7:1.

[0038] The weight-average molecular weights of the polytetrahydrofuran diol and polyoxypropylene diol are independently 1200-1300.

[0039] The nitrogen-based halogen-free flame retardant is melamine.

[0040] The chain extender is ethylene glycol.

[0041] Mix the formulated amount of polyhexamethylene adipate diol, polyether polyol, nitrogen-based halogen-free flame retardant, expandable microspheres, catalyst, anti-aging agent and chain extender, and dehydrate at 110°C for 2 hours , then lower the temperature to 80°C, add metered MDI-100, mix at 4000r / min for 2min, pour into a flat mold coated with a release agent, and mature in an oven at 90°C for 24h, and the obtained flakes are broken into Uniform particle...

Embodiment 2

[0043] Synthesis of flame retardant TPU:

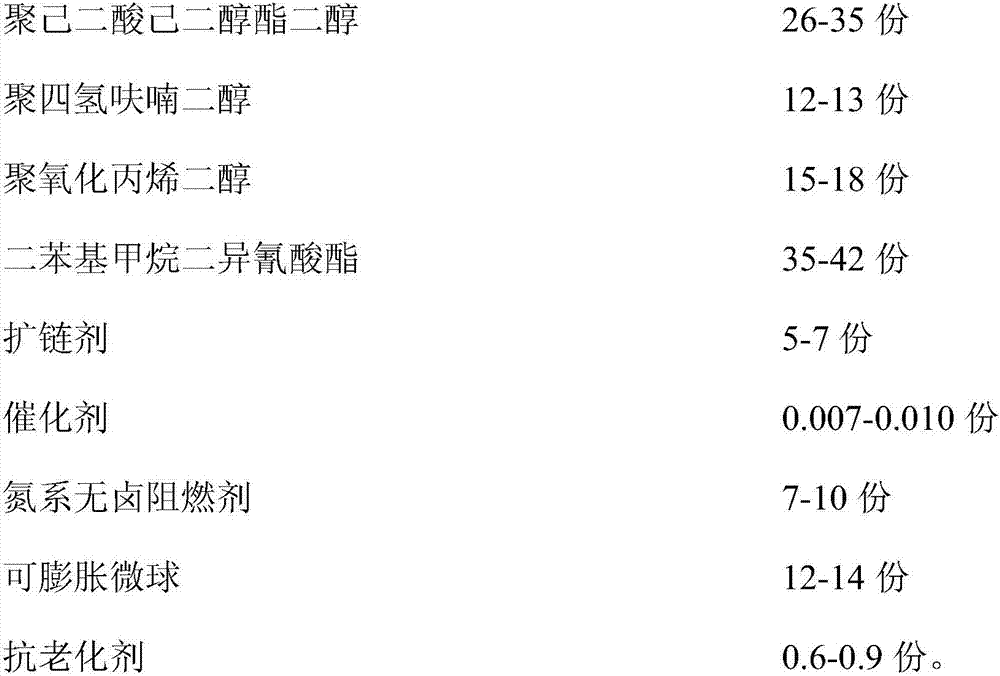

[0044] In terms of weight percentage,

[0045]

[0046]

[0047] The catalyst is organic tin and organic bismuth with a mass ratio of 5:1.

[0048] The anti-aging agent is 1076 and UV-531 with a mass ratio of 4:1.

[0049] The weight-average molecular weights of the polytetrahydrofuran diol and polyoxypropylene diol are independently 1700-1800.

[0050] The nitrogen-based halogen-free flame retardants are melamine and dicyandiamide.

[0051] The chain extenders are ethylene glycol and 1,2-propanediol.

[0052]Mix the formulated amount of polyhexamethylene adipate diol, polyether polyol, nitrogen-based halogen-free flame retardant, expandable microspheres, catalyst, anti-aging agent and chain extender, and dehydrate at 110°C for 2 hours , then lower the temperature to 80°C, add metered MDI-100, mix at 4000r / min for 2min, pour into a flat mold coated with a release agent, and mature in an oven at 90°C for 24h, and the obtained...

Embodiment 3

[0054] Synthesis of flame retardant TPU:

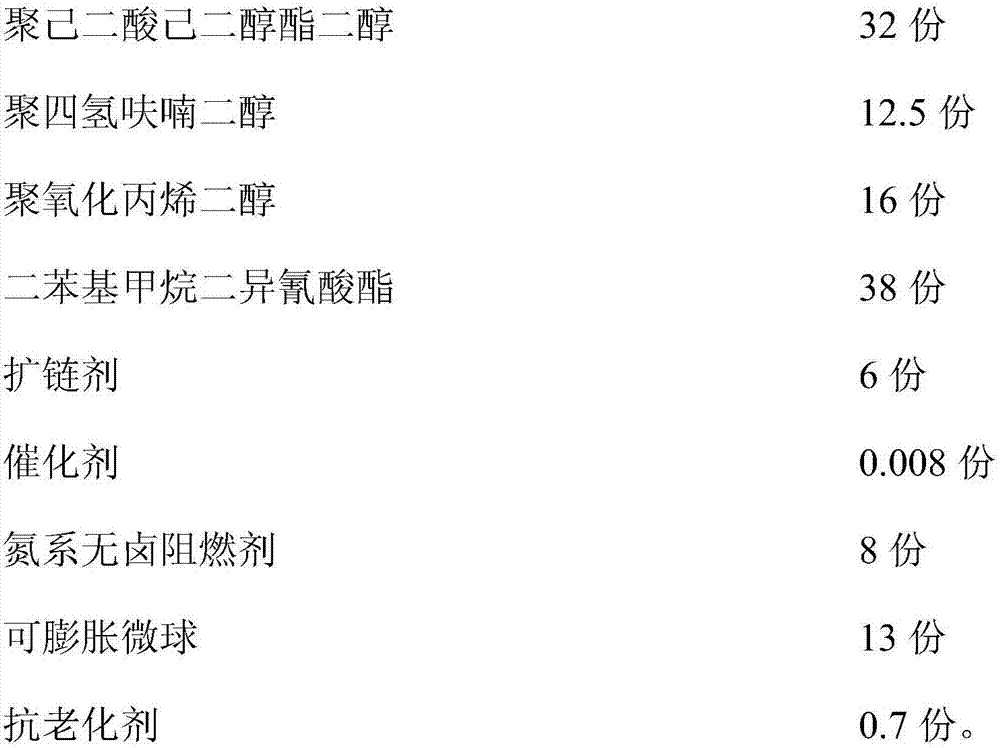

[0055] In terms of weight percentage,

[0056]

[0057] The catalyst is organic tin and organic bismuth with a mass ratio of 4:1.

[0058] The anti-aging agent is 1076 and UV-531 with a mass ratio of 10:1.

[0059] The weight-average molecular weights of the polytetrahydrofuran diol and polyoxypropylene diol are independently 1400-1500.

[0060] The nitrogen-based halogen-free flame retardants are melamine, dicyandiamide and melamine cyanurate.

[0061] The chain extenders are ethylene glycol, 1,2-propanediol and 1,4-butanediol.

[0062] Mix the formulated amount of polyhexamethylene adipate diol, polyether polyol, nitrogen-based halogen-free flame retardant, expandable microspheres, catalyst, anti-aging agent and chain extender, and dehydrate at 110°C for 2 hours , then lower the temperature to 80°C, add metered MDI-100, mix at 4000r / min for 2min, pour into a flat mold coated with a release agent, and mature in an oven at 90°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com