Lithium ion battery diaphragm and preparation method thereof

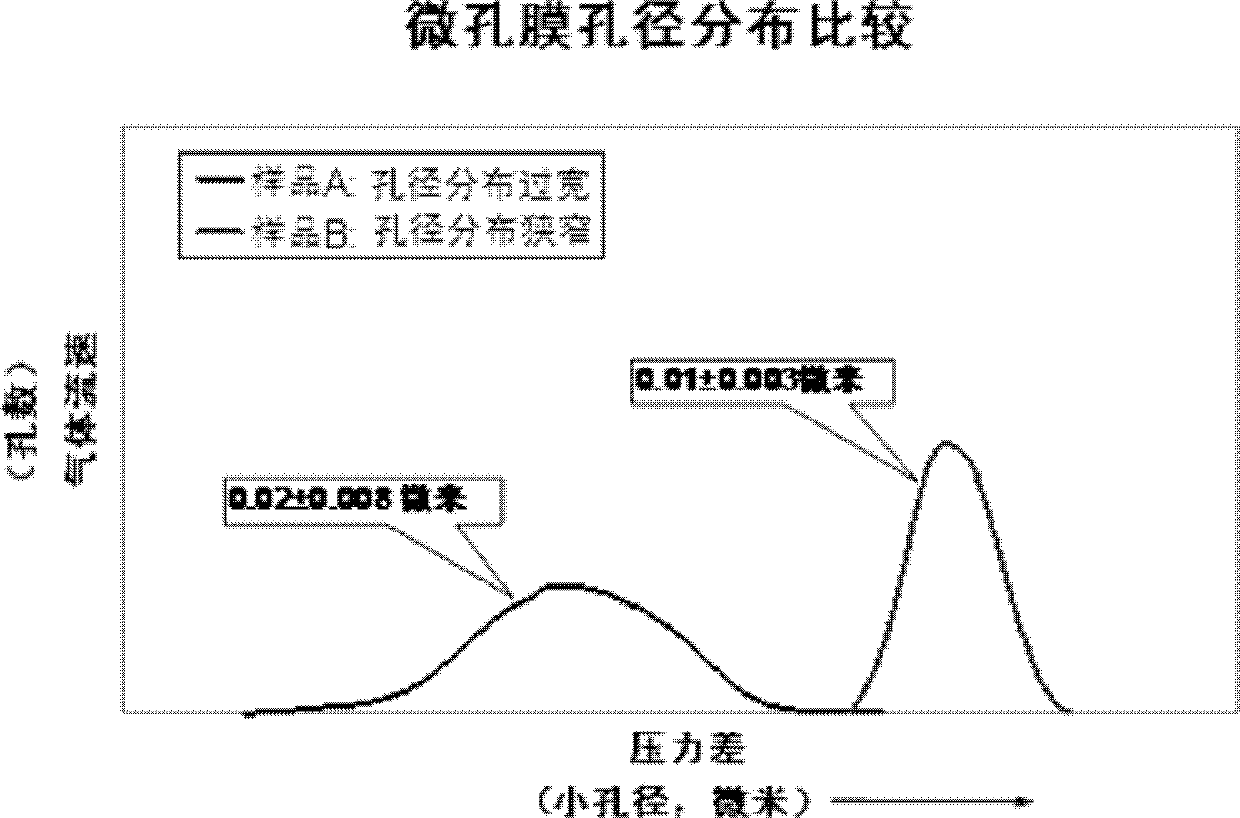

A lithium-ion battery and separator technology, applied in battery pack parts, circuits, electrical components, etc., can solve problems such as affecting the performance of the separator, excessive thickness of the film, and uneven film thickness, and achieve uniform distribution of micropores and shrinkage. The effect of small rate and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Add ultra-high molecular weight polyethylene with a molecular weight of 1 million, mineral oil with an available viscosity grade of 55, and a pore-forming agent, dioctyl phthalate, into the mixer to fully stir the raw materials at a speed of 60 RPM. The mass ratio of high molecular polyethylene is 8-9:1; the mass ratio of dioctyl phthalate and ultra-high molecular polyethylene is 9-10:1; ℃ heating and continuous extrusion to form a flat film; the flat film is cooled and formed by a cooling molding machine with a temperature of 50 °C; Stretch the flat film into a film, and the thickness of the stretched film reaches 20 μm; add n-hexane to extract the mineral oil and dioctyl phthalate in the film; heat-treat the film at a temperature of 100 ° C for 5 minutes; curl Lithium battery separators are cut and packaged.

[0030] The thickness, porosity, average pore diameter and thermal shrinkage of the diaphragm are tested using the following methods.

[0031] (1) Determinatio...

Embodiment 2

[0049] Add ultra-high molecular weight polyethylene with a molecular weight of 10 million, mineral oil with an available viscosity grade of 55, and a pore-forming agent, dioctyl phthalate, into the mixer to fully stir the raw materials at a speed of 60 RPM. The mass ratio of high molecular polyethylene is 8-9:1; the mass ratio of dioctyl phthalate and ultra-high molecular polyethylene is 9-10:1; ℃ heating and continuous extrusion to form a flat film; the flat film is cooled and formed by a cooling molding machine with a temperature of 50 °C; Stretch the flat film into a film, and the thickness of the stretched film reaches 20 μm; add n-hexane to extract the mineral oil and dioctyl phthalate in the film; heat-treat the film at a temperature of 100 ° C for 5 minutes; curl Lithium battery separators are cut and packaged.

[0050] The thickness of the lithium-ion battery separator of this embodiment measured by the above method is 20 microns, the porosity is 73%, the average pore...

Embodiment 3

[0052] Add ultra-high molecular weight polyethylene with a molecular weight of 5 million, mineral oil with an available viscosity grade of 55, and a pore-forming agent, dioctyl phthalate, into the mixer to fully stir the raw materials at a speed of 60 RPM. The mass ratio of high molecular polyethylene is 8-9:1; the mass ratio of dioctyl phthalate and ultra-high molecular polyethylene is 9-10:1; ℃ heating and continuous extrusion to form a flat film; the flat film is cooled and formed by a cooling molding machine with a temperature of 50 °C; Stretch the flat film into a film, and the thickness of the stretched film reaches 20 μm; add n-hexane to extract the mineral oil and dioctyl phthalate in the film; heat-treat the film at a temperature of 100 ° C for 5 minutes; curl Lithium battery separators are cut and packaged.

[0053] The thickness of the lithium-ion battery separator of this embodiment measured by the above method is 20 microns, the porosity is 73%, the average pore ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com