Multi-nozzle ointment shell

An ointment and multi-mouth technology, which is applied in the field of toothpaste shells, can solve the problems that toothpaste materials are not easy to distribute evenly on the toothbrush surface, the handling operation is not so casual and calm, and the articulation is not easy to clean and save time. Easier and more uniform application or application and controllable output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

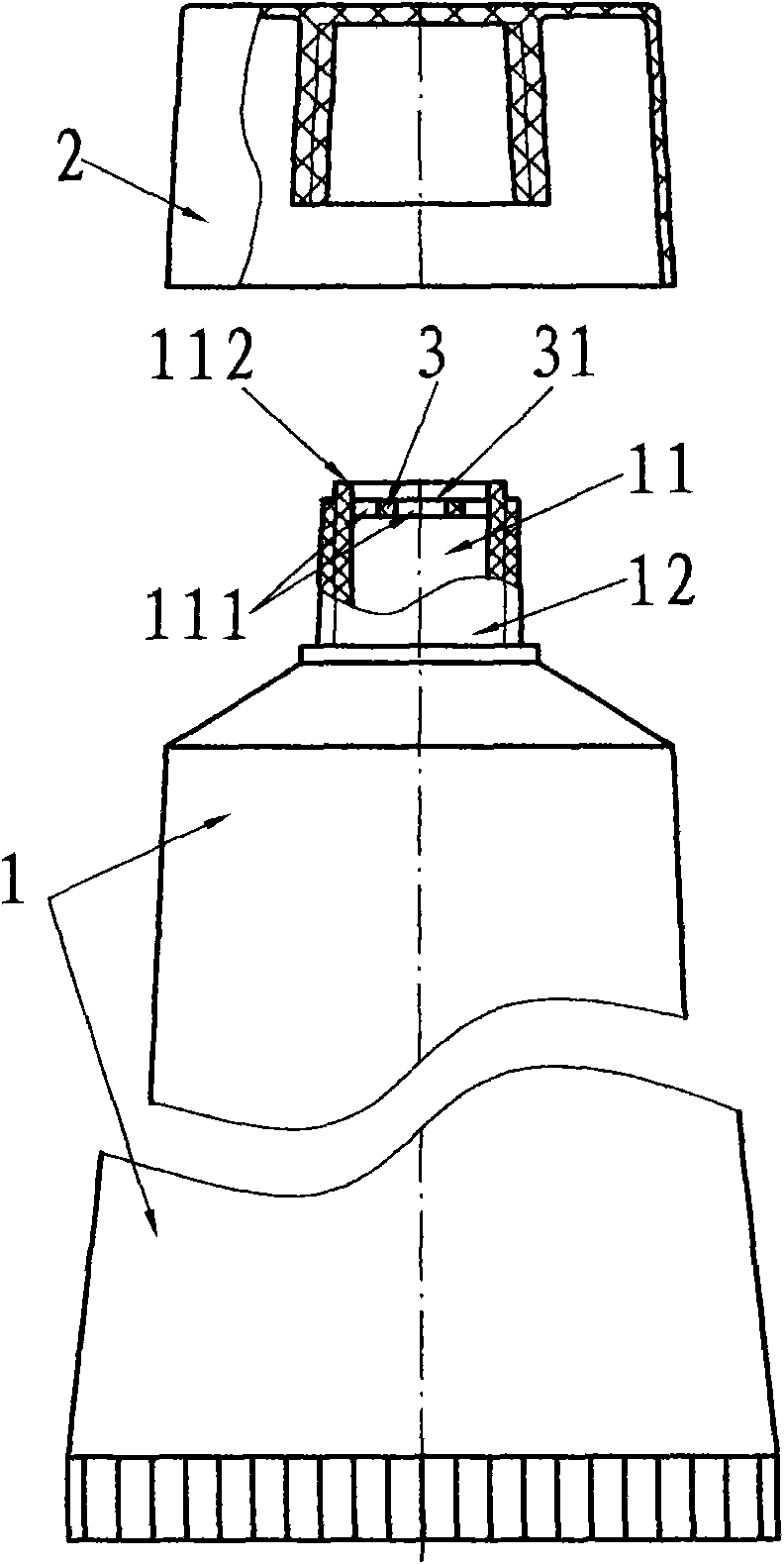

[0034] A kind of multi-mouthed ointment shell of the embodiment of the present invention (see structure Figure 1 to Figure 3 ), including a soft shell 1 with a cavity inside and an extruding head 12 integrally connected with the soft shell 1, the extruding head 12 is provided with a cavity corresponding to the soft shell 1 The through circular discharge hole 11 is provided with a barrier 3 in the port of the discharge hole 11 , and the barrier 3 divides the discharge hole 11 into four nozzle holes 111 .

[0035] The above barrier 3 is a spoke-shaped structure with a ring hub and three spokes uniformly distributed along the circumference of the discharge hole 11 at the same center as the discharge hole 11, and the barrier 3 is integrally connected with the extrusion head 12 , and the discharge hole 11 is divided into four nozzle holes 111, three of which are identical and uniformly distributed along the circumference of the discharge hole 11, and the other is a small circular ...

Embodiment 2

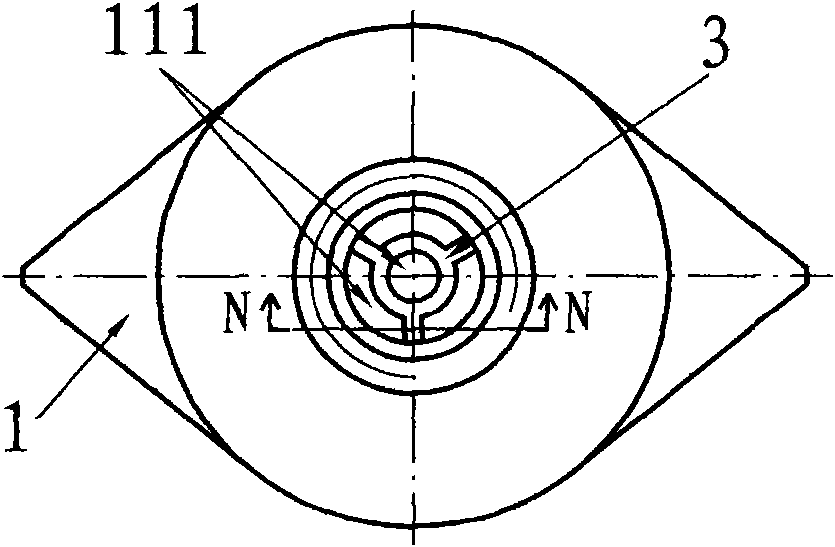

[0052] A kind of multi-mouthed ointment shell of the embodiment of the present invention two (for structure see Figure 4 , 5 ), including a soft shell 1 with a cavity inside and an extruding head 12 integrally connected with the soft shell 1, the extruding head 12 is provided with a cavity corresponding to the soft shell 1 The through circular discharge hole 11 is provided with a barrier 3 in the port of the discharge hole 11 , and the barrier 3 divides the discharge hole 11 into two nozzle holes 111 .

[0053] The barrier 3 in the second embodiment has an "S" shape structure, and is integrally connected with the extrusion head 12 through the central position of the discharge hole 11, and separates the discharge hole 11 into two identical flat curved shapes. The nozzle holes 111 , the two nozzle holes 111 are evenly distributed along the circumference of the discharge hole 11 .

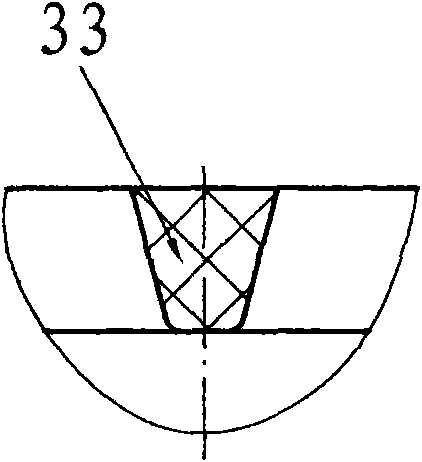

[0054] On the inner side of the barrier 3 and at the center of the discharge hole 11, a conical...

Embodiment 3

[0062] A kind of multi-mouthed ointment shell of the embodiment of the present invention three (for structure see Figure 6 , 7 ), including a soft shell 1 with a cavity inside and an extruding head 12 integrally connected with the soft shell 1, the extruding head 12 is provided with a cavity corresponding to the soft shell 1 The through circular discharge hole 11 is provided with a barrier 3 in the port of the discharge hole 11 , and the barrier 3 divides the discharge hole 11 into two nozzle holes 111 .

[0063] The above-mentioned barrier 3 is a "one"-shaped structure, and is integrally connected with the extrusion head 12 through the central position of the discharge hole 11. The barrier 3 separates the discharge hole 11 into two identical arc-shaped grooves. The nozzle holes 111 , the two nozzle holes 111 are evenly distributed along the circumference of the discharge hole 11 .

[0064] The middle part of the above-mentioned barrier 3 is provided with a bulge 34 protrud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com