Paste tube with serrated nozzle

A technology of tooth shape and ointment, which is applied in the field of toothpaste shells, can solve the problems of uneasy handling, shedding of toothpaste materials, and difficulty in grasping accurately, so as to achieve easier and more uniform application, reduce the cross-sectional area of the material, and squeeze out The output is also easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

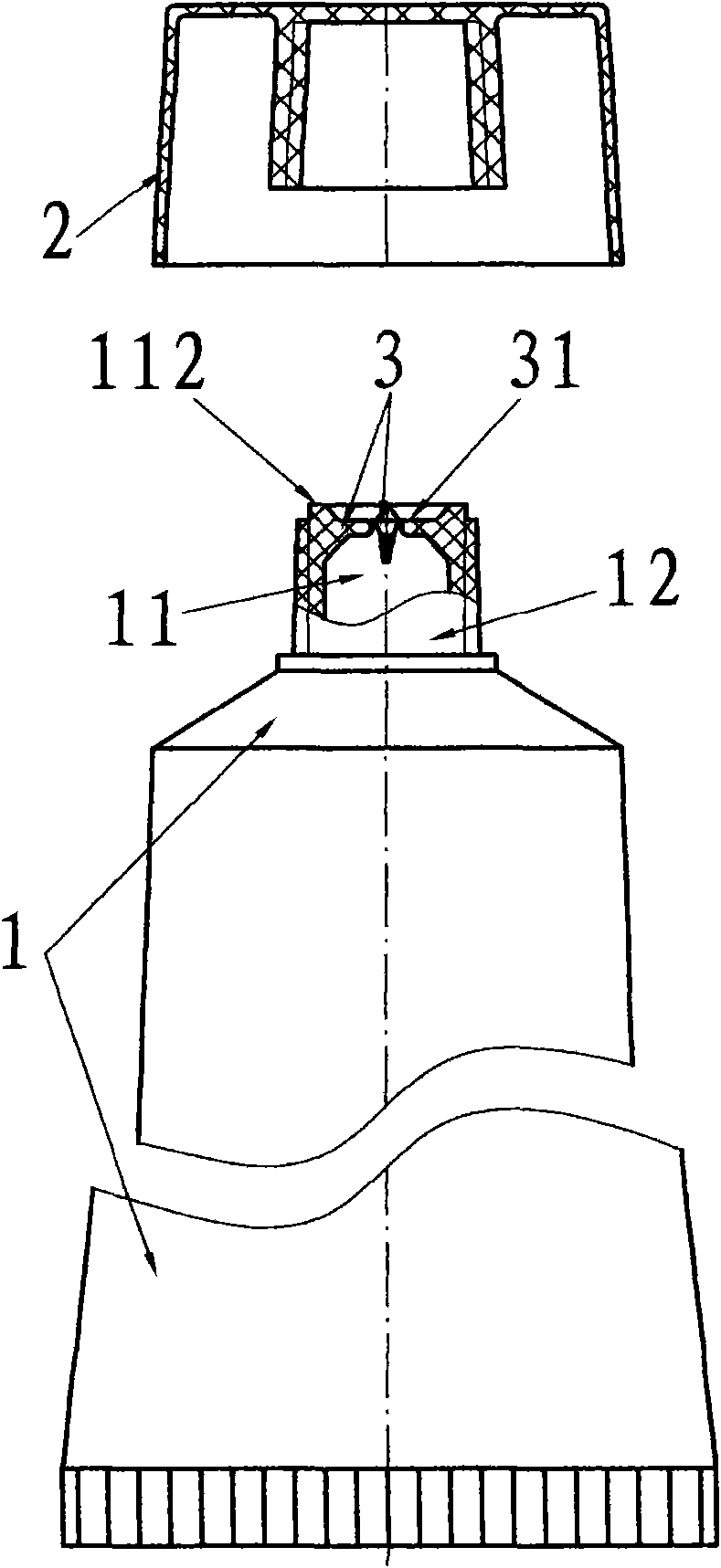

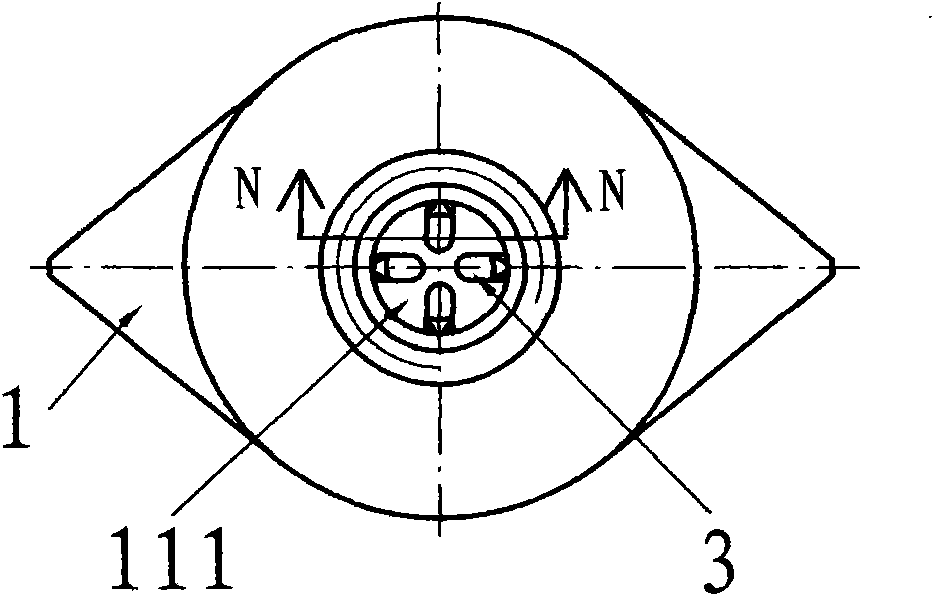

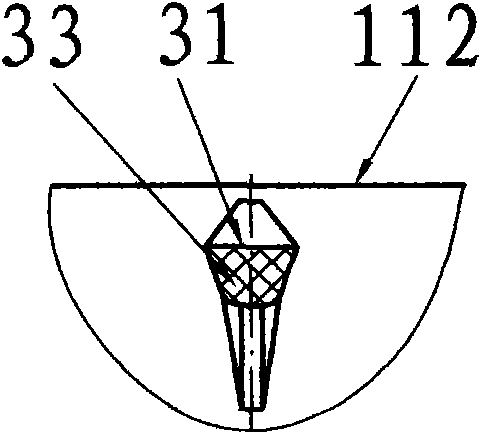

[0024] A kind of tooth-shaped mouth ointment shell of the embodiment of the present invention (see structure Figure 1 to Figure 3 ), including a soft shell 1 with a cavity inside and an extruding head 12 integrally connected with it, the extruding head 12 is provided with a circular discharge hole 11, and in the discharge hole 11 There are four tooth protrusions 3 inside the port, and the tooth protrusions 3 are integrally connected with the extrusion head 12 through the inner wall of the discharge hole 11 , and block the discharge hole 11 to form a toothed nozzle hole 111 .

[0025] In the first embodiment, there are four identical tooth protrusions 3, and the four tooth protrusions 3 are arranged in a straight state and evenly distributed along the circumference of the discharge hole 11, so that the discharge hole 11 is blocked to have four corresponding grooves. The toothed mouth hole 111. When the cavity of the soft shell 1 is filled with ointment, the ointment is extrud...

Embodiment 2

[0042] A kind of toothed mouth ointment shell of the embodiment of the present invention two (for structure see Figure 4 , 5 ), including a soft shell 1 with a cavity inside and an extruding head 12 integrally connected with the soft shell 1, the extruding head 12 is screwed with a screw sleeve 211, and the Both the extruding head 12 and the screwing sleeve 211 are provided with a circular discharge hole 11 connected with the cavity of the soft shell 1, and six holes are arranged in the port of the discharge hole 11 of the screwing sleeve 211. A tooth protrusion 3, said tooth protrusion 3 is integrally connected with the screw sleeve 211 through the inner side wall of the discharge hole 11, and blocks the discharge hole 11 into a toothed mouth hole 111 with six grooves.

[0043] The port of the discharge hole 11 of the second embodiment is provided with six tooth protrusions 3, and according to the different states of the protrusions, the above-mentioned tooth protrusions 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com