Surface growth type photosynthetic microorganism culture plate having core-shell structure, culture unit, system and culture method

A technology for photosynthetic microorganisms and surface growth, applied in biochemical equipment and methods, enzymology/microbiology devices, bioreactors/fermenters for specific purposes, etc. Water and other problems, to achieve the effect of good water absorption/permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

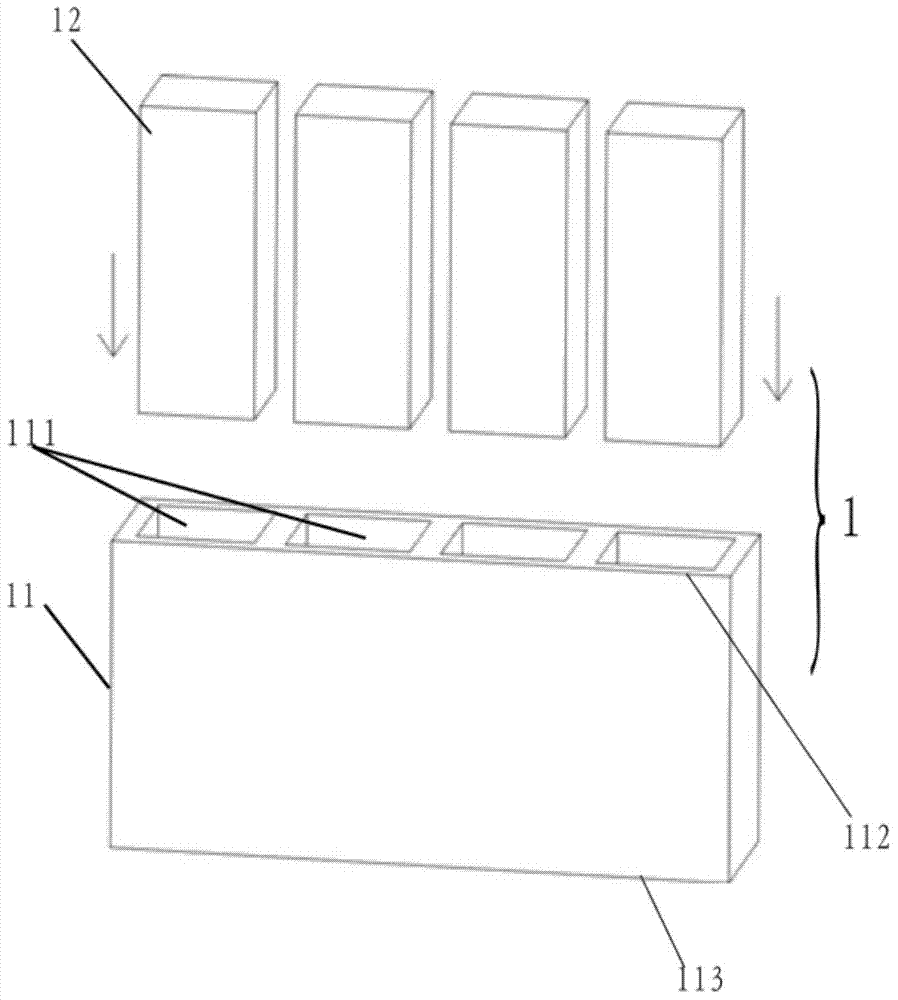

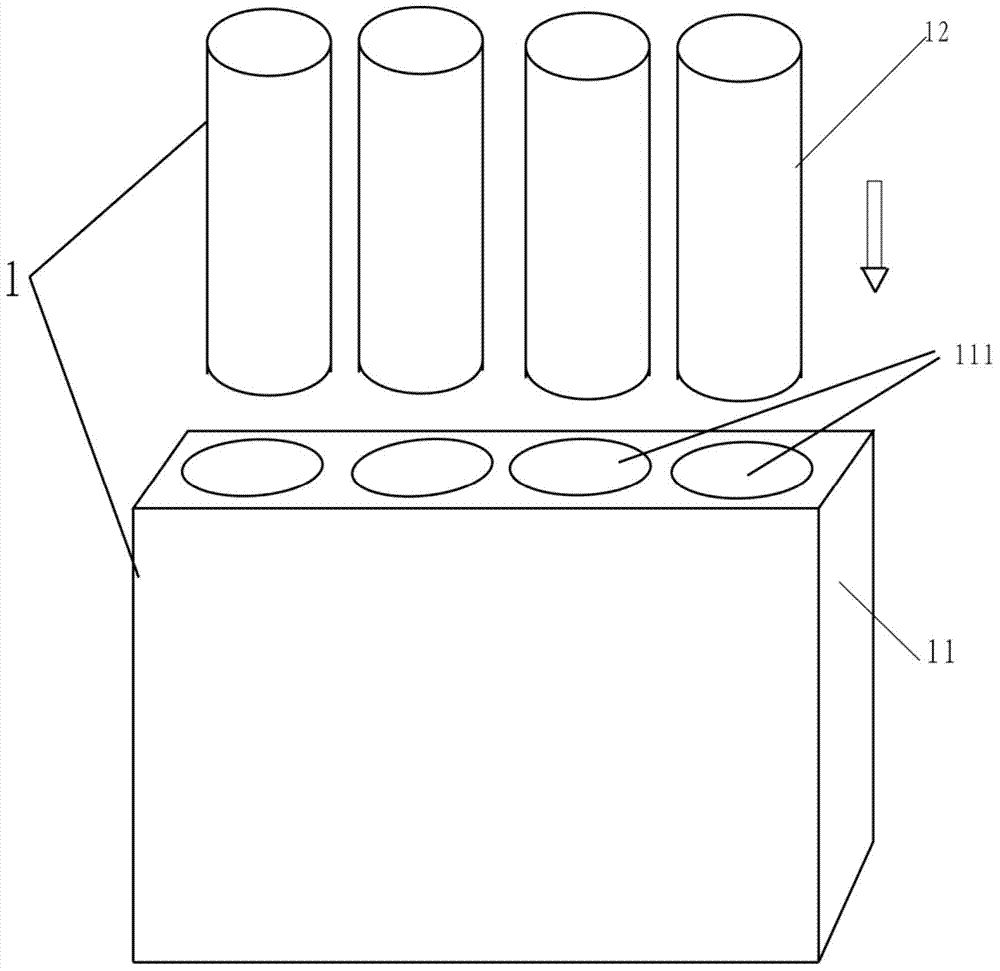

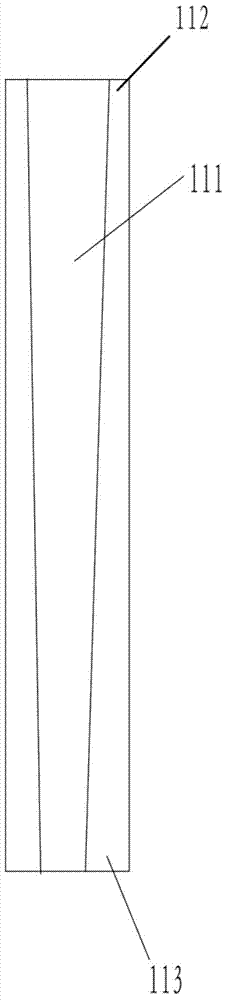

[0087] combine figure 2 with image 3 Be explained, image 3 Showing the surface growth type culture system 1000a of the present invention, the surface growth type culture system 1000a may comprise a plurality of such as figure 2 Shown are the culture units 101 , the light source device 8 disposed between the culture units 101 , and the culture solution supply device 9 for supplying the culture solution to the culture units 101 .

[0088] Such as figure 2 with 3 As shown, the fixing device 2 includes opposite fixing components 21 and 22, and a hole 23 for fixing the culture plate 1 is formed between the fixing components 21 and 22, and the culture plate 1 can also be taken out from the hole 23 upwards.

[0089] image 3 A plurality of culture units 101 in the set are arranged parallel to each other and separated by a distance. At least one light source device 8 is arranged between every two culture units 101 . The light source device can be a double-sided light source ...

Embodiment 2

[0094] combine figure 2 with Figure 4 Another cultivation system 1000b of the present invention is illustrated. Figure 4 A surface-grown culture system 1000b of the present invention is shown. and image 3 Similar to the illustrated embodiment, the culture system 1000b may also include one or more figure 2 The culture unit 101. Specifically, the culture system 1000b may include a core-shell structure culture plate 1, a fixing device 2, a culture solution recovery device 3, a liquid supply device 4, a culture solution pool 6, a pressure tank 11, a compressed air source 12, a liquid level gauge 13, Stop valve 14, stop valve 15, pressure reducing valve 16, exhaust valve 17, and pressure gauge 18.

[0095] Figure 4 The surface growth culture system 1000b includes a culture solution circulation device 9b, and the air compression method can be optionally used in the culture solution circulation device 9b. The device used in this air compression method is other optional p...

preparation example

[0115] Obtain the core-shell structure culture plate ① of the present invention according to the aforementioned preparation method 1;

[0116] According to the preparation method 2, the core-shell structure culture plate of the present invention was prepared with molecular sieve ZSM-5 ②.

[0117] The dimensions of the core-shell structure culture plates ① and ② are both 1 meter*2 meters*3 centimeters.

[0118] Set up 3 groups of controls:

[0119] Group 1: control canvas (32 pieces), the size is equivalent to the core-shell structure culture plate 1, and the sandwich layer has a sponge water-absorbing material.

[0120] Group 2: According to the aforementioned preparation method 1, a porous plate was made with molecular sieves and alumina stone, but no channel 111 was formed, and the control plate ① was obtained;

[0121] Group 3: A block made of molecular sieve ZSM-5 was clamped between two water-permeable ceramic plates to obtain a control plate ②.

[0122] The size of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com