Thick electrode structure and manufacturing method thereof

A technology of electrode structure and manufacturing method, which is applied to battery electrodes, structural parts, non-aqueous electrolyte battery electrodes, etc., can solve the problems of battery capacity and rate performance deterioration, and achieve the goal of increasing quantity, avoiding polarization, and improving cycle performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

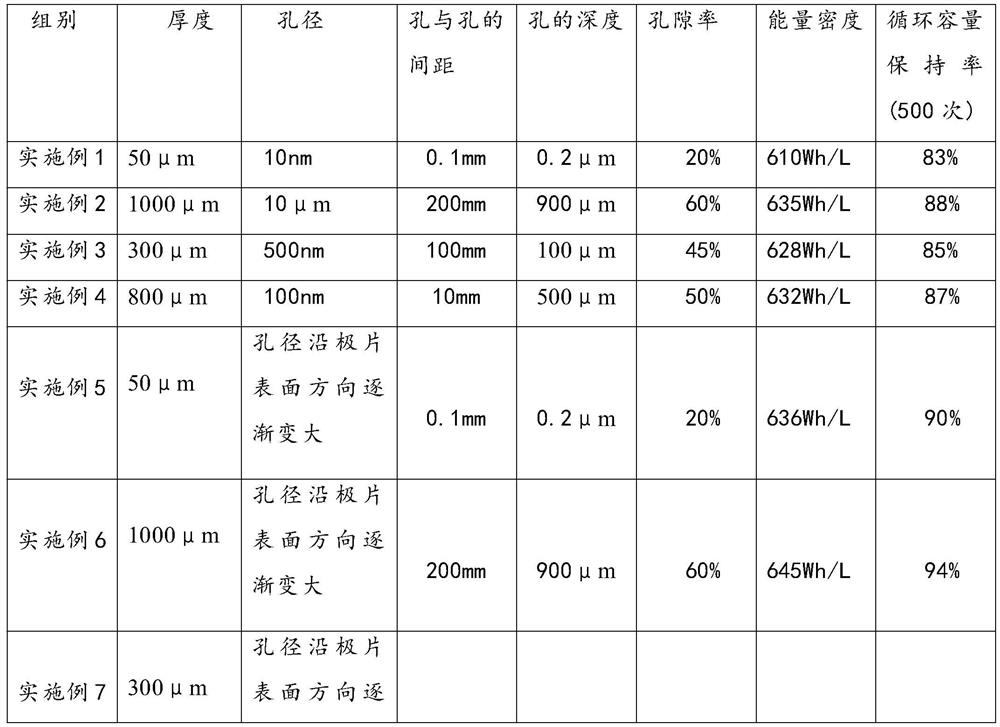

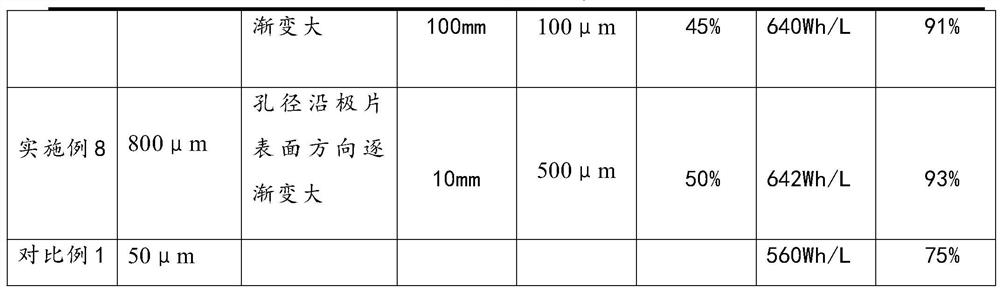

Embodiment 1

[0027] This embodiment provides a thick electrode structure, including a positive electrode and / or a negative electrode, and the positive electrode and / or negative electrode are manufactured by the following manufacturing method.

[0028] A method for fabricating a thick electrode structure, comprising the steps of:

[0029] Step 1), coating the electrode sheet with a predetermined thickness and rolling it, the predetermined thickness is 50 μm;

[0030] Step 2), after the roll pressing is completed, carry out micro-pore making to the surface of the electrode sheet; the method of carrying out micro-pore making on the surface of the electrode sheet includes laser hole making or mechanical hole making; the aperture of the hole is 10nm; the distance between the holes is 0.1mm; the depth of the hole is 0.2μm; the porosity of the electrode sheet is 20%;

[0031] Step 3), the particles on the surface of the electrode sheet are removed, and the method of removing particles on the sur...

Embodiment 2

[0034] Different from Embodiment 1, this embodiment is a method for fabricating a thick electrode structure, comprising the following steps:

[0035] Step 1), coating the electrode sheet with a predetermined thickness and rolling it, the predetermined thickness is 1000 μm;

[0036] Step 2), after the rolling is completed, micropores are made on the surface of the electrode sheet; the method of micropores on the surface of the electrode sheet includes laser hole making or mechanical hole making; the aperture of the hole is 10 μm; the distance between the holes It is 200mm; the depth of the hole is 900 μm; the porosity of the electrode sheet is 60%;

[0037] Step 3), the particles on the surface of the electrode sheet are removed, and the method of removing particles on the surface of the electrode sheet includes a vacuum cleaning method or a brush powder method.

[0038] Step 4), forming a thick electrode sheet with a porous structure;

[0039] Others are the same as in Embod...

Embodiment 3

[0041] Different from Embodiment 1, this embodiment is a method for fabricating a thick electrode structure, comprising the following steps:

[0042] Step 1), coating the electrode sheet with a predetermined thickness and rolling it, the predetermined thickness is 300 μm;

[0043] Step 2), after the roll pressing is completed, micropores are carried out on the surface of the electrode sheet; the method of carrying out micropores on the surface of the electrode sheet includes laser hole making or mechanical hole making; the aperture of the hole is 500nm; the distance between the holes is 100mm; the depth of the hole is 100 μm; the porosity of the electrode sheet is 45%;

[0044] Step 3), the particles on the surface of the electrode sheet are removed, and the method of removing particles on the surface of the electrode sheet includes a vacuum method or a brush powder method;

[0045] Step 4), forming a thick electrode sheet with a porous structure.

[0046] Others are the sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com