Manufacturing method of vacuum phase-change radiator

A manufacturing method and radiator technology, applied in manufacturing tools, non-electric welding equipment, welding equipment, etc., can solve problems such as cost reduction, end cap micro-holes or slits, etc., and achieve long service life, reduced processing costs, and vacuum sealing. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

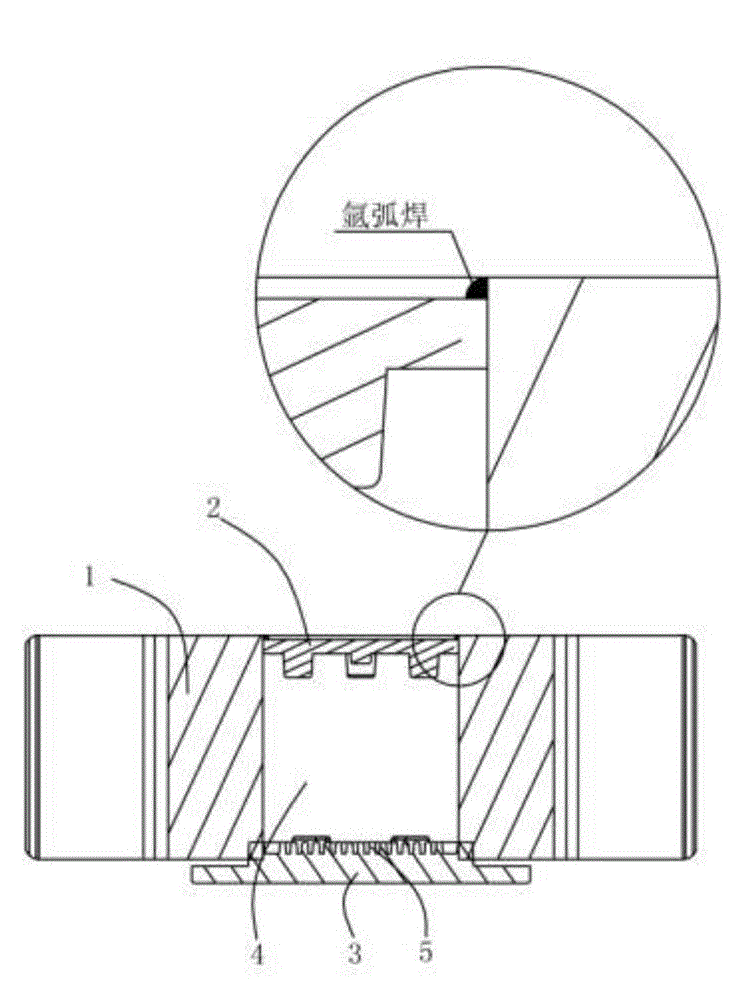

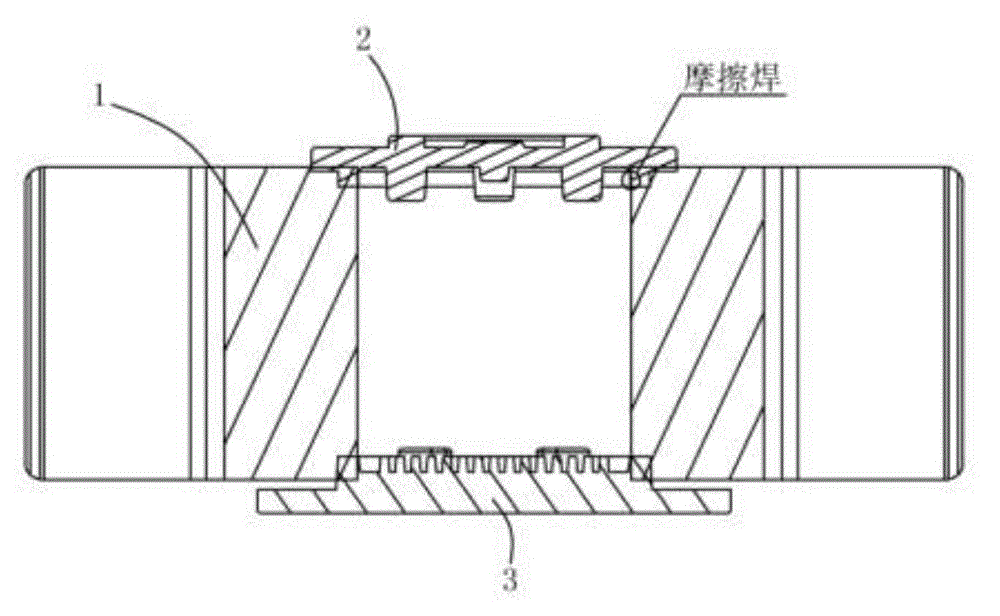

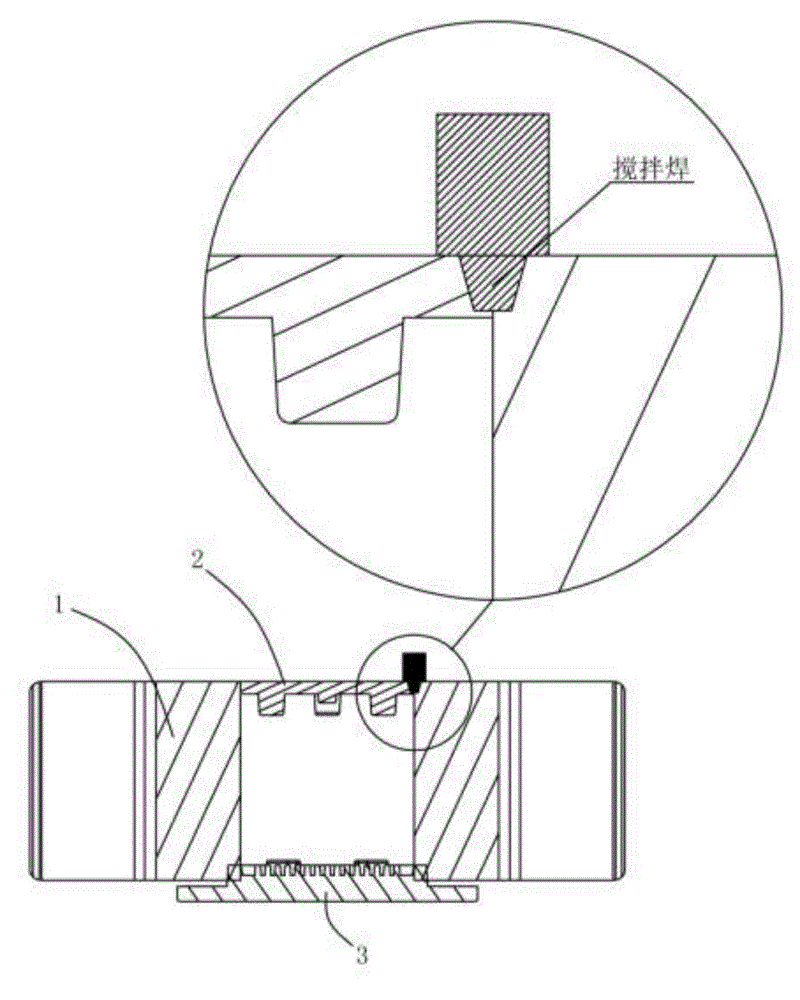

[0034] Examples, see Figure 2 to Figure 9 Shown:

[0035] A method for manufacturing a vacuum phase-change radiator. The vacuum phase-change radiator includes a radiator body 1, an upper end cover 2 and a lower end cover 3. The radiator body 1 has a hollow tube 4, and the hollow tube 4 is equipped with a phase-change radiator. The working medium, the upper end cover 2 and the lower end cover 3 are respectively welded to the two ends of the hollow tube 4, and the upper end cover 2 and the lower end cover 3 are processed and formed by a red punching process; the red punching process includes the following steps: A, material cutting, Cut the aluminum profile into a cylinder, cut the cylindrical aluminum into a cylinder, and calculate the cutting length according to the equal volume before and after forming; B, hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com