Method for preparing thermoplastic polymer foamed beads by clean waterless process

A thermoplastic polymer and foamed bead technology, which is applied in the chemical industry, climate sustainability, sustainable manufacturing/processing, etc., can solve the problems of easy shrinkage and deformation of foamed bead products, open cell structure, high open cell rate, etc. problems, to achieve the effect of good uniformity of cell diameter, clean process and high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

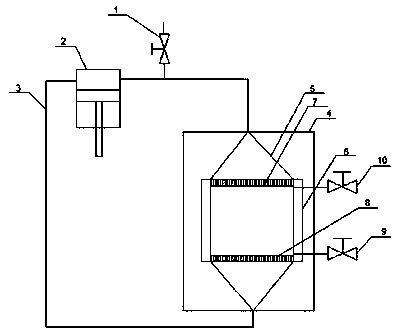

[0035] A method for preparing thermoplastic polymer foam beads by a clean and water-free process, comprising a reciprocating booster pump, an air supply valve, a fluidized bed, and a feed inlet valve and a discharge outlet valve connected to the fluidized bed. The reciprocating booster pump is connected to the fluidized bed through an insulation pipeline, and the air supply valve is connected to the insulation pipeline, and the fluidized bed includes a vulcanization kettle body, an air distribution plate, a ventilation net, and a heating interlayer;

[0036] Concrete preparation steps are as follows:

[0037] 1) Open the inlet valve of the fluidized bed, put an appropriate amount of polymer particles into the fluidized bed, and then close the valve without adding water medium and anti-sticking release agent;

[0038] 2) Open the gas supply valve of the reciprocating booster pump, feed foaming agent gas into the vulcanization kettle, adjust the foaming pressure to 30MPa, close ...

Embodiment 2

[0043] A method for preparing thermoplastic polymer foam beads by a clean and water-free process, comprising a reciprocating booster pump, an air supply valve, a fluidized bed, and a feed inlet valve and a discharge outlet valve connected to the fluidized bed. The reciprocating booster pump is connected to the fluidized bed through an insulation pipeline, and the air supply valve is connected to the insulation pipeline, and the fluidized bed includes a vulcanization kettle body, an air distribution plate, a ventilation net, and a heating interlayer;

[0044] Concrete preparation steps are as follows:

[0045] 1) Open the inlet valve of the fluidized bed, put an appropriate amount of polymer particles into the fluidized bed, and then close the valve without adding water medium and anti-sticking release agent;

[0046] 2) Open the gas supply valve of the reciprocating booster pump, feed foaming agent gas into the vulcanization kettle, adjust the foaming pressure to 30MPa, close ...

Embodiment 3

[0051] A method for preparing thermoplastic polymer foam beads by a clean and water-free process, comprising a reciprocating booster pump, an air supply valve, a fluidized bed, and a feed inlet valve and a discharge outlet valve connected to the fluidized bed. The reciprocating booster pump is connected to the fluidized bed through an insulation pipeline, and the air supply valve is connected to the insulation pipeline, and the fluidized bed includes a vulcanization kettle body, an air distribution plate, a ventilation net, and a heating interlayer;

[0052] Concrete preparation steps are as follows:

[0053] 1) Open the inlet valve of the fluidized bed, put an appropriate amount of polymer particles into the fluidized bed, and then close the valve without adding water medium and anti-sticking release agent;

[0054] 2) Open the gas supply valve of the reciprocating booster pump, feed foaming agent gas into the vulcanization kettle, adjust the foaming pressure to 20MPa, close ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com