Low-noise traveling crane

A low-noise, trolley technology, applied in the direction of load hanging components, rail systems, transportation and packaging, etc., can solve problems such as increasing surface area, affecting workers' production operations, and high noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

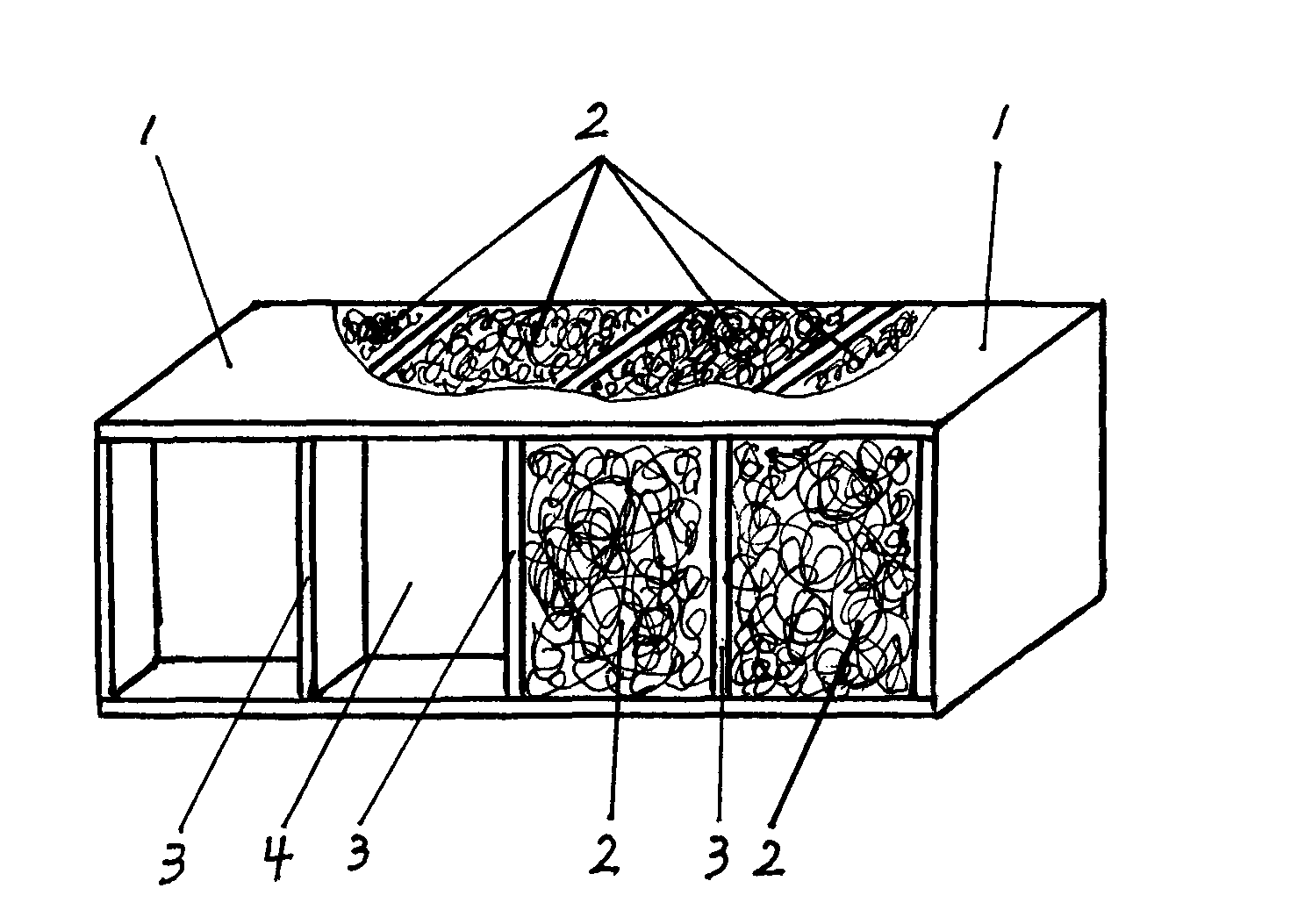

[0008] figure 1 The medium and low-noise trains include a box girder 1, wheels are installed at both ends of the box girder 1, ribs 3 and trolley tracks are installed on the outer surface of the box girder 1, and movable The trolley is equipped with an electric hoist, and the inner space of the box girder 1 and the recessed space 4 on both sides of the rib plate 3 are filled with polyurethane foam material 2 (the wheel set, trolley track, trolley, electric Gourds are not shown). The polyurethane foam material 2 in the inner space of the box girder 1 destroys the resonant cavity structure in the inner space of the box girder 1, and the polyurethane foam material 2 in the recessed spaces 4 on both sides of the rib plate 3 changes the noise from The propagation medium that the box girder spreads to the surrounding space, and the polyurethane foam material has the characteristics of flexibility and microporosity, and has a certain sound absorption effect, so it can be transmitted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com