Method for preparing synthetic paper based on ultrahigh-molecular weight polyethylene

A technology of ultra-high molecular weight and polyethylene, applied in the field of synthetic paper based on ultra-high molecular weight polyethylene, can solve the problems of low heat distortion temperature and surface hardness, difficult molding and processing, and large expansion coefficient, and achieve controllable performance and mechanical The effect of good performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

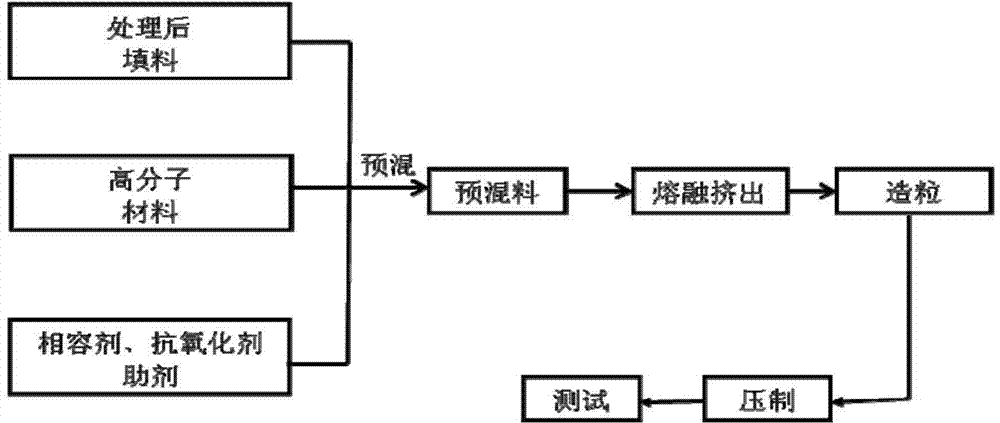

Method used

Image

Examples

Embodiment 1

[0035] (1) Filler treatment: 20g nano-SiO 2 Add 350ml of absolute ethanol / water mixed solution (V 无水乙醇 :V 蒸馏水 =3:1), after shearing and stirring at a speed of 3000r / min for 20min under a high-shear emulsifier, the nano-SiO 2 The suspension was placed in a three-necked flask. Add 34ml of silane coupling agent KH550 with a mass fraction of 12% (absolute ethanol as diluent) into the three-necked bottle. Heat to 85°C in a water bath, stir (300r / min) and react for 90min. After the reaction, the suspension system in the three-neck flask was suction-filtered, and the filter cake was washed with absolute ethanol, dried and ground to obtain the modified nano-SiO 2 .

[0036] (2) Preparation of masterbatch: 4g modified nano-SiO 2 , 16g UHMWPE, 60g white oil, 0.1g antioxidant 1010, after being stirred and ultrasonically premixed, extruded through a twin-screw extruder (the temperatures in the four temperature setting zones are respectively set to 160°C, 200°C, 240°C, and 270°C) , ...

Embodiment 2

[0045] (1) Filler treatment: 20g nano-SiO 2 Add 350ml of absolute ethanol / water mixed solution (V 无水乙醇 :V 蒸馏水 =3:1), after shearing and stirring at a speed of 3000r / min for 20min under a high-shear emulsifier, the nano-SiO 2 The suspension was placed in a three-necked bottle. Add 34ml of 12wt% (absolute ethanol as diluent) silane coupling agent KH560 into the three-necked bottle. Heat to 85°C in a water bath, stir (300r / min) and react for 90min. After the reaction, the suspension system in the three-neck flask was suction-filtered, and the filter cake was washed with absolute ethanol, dried and ground to obtain the modified nano-SiO 2 .

[0046] (2) Preparation of masterbatch: 6g of the above-mentioned modified nano-SiO 2 , 14g UHMWPE, 60g white oil, 0.1g antioxidant 1010, after being stirred and ultrasonically premixed, extruded through a twin-screw extruder (the temperatures in the four temperature setting zones are respectively set to 160°C, 200°C, 240°C, and 270°C) ...

Embodiment 3

[0054] (1) Filler treatment: 20g nano-SiO 2 Add 350ml of absolute ethanol / water mixed solution (V 无水乙醇 :V 蒸馏水 =3:1), after shearing and stirring at a speed of 3000r / min for 20min under a high-shear emulsifier, the nano-SiO 2 The suspension was placed in a three-necked bottle. Add 34ml of 12wt% (absolute ethanol as diluent) silane coupling agent KH570 into the three-necked bottle, and adjust pH=4 with dilute hydrochloric acid (absolute ethanol as diluent). Heat to 85°C in a water bath, stir (300r / min) and react for 90min. After the reaction, the suspension system in the three-neck flask was suction-filtered, and the filter cake was washed with absolute ethanol, dried and ground to obtain the modified nano-SiO 2 .

[0055] (2) Preparation of masterbatch: 8g of the above-mentioned modified nano-SiO 2 , 12g UHMWPE, 60g white oil, 0.1g antioxidant 1010, after being stirred and ultrasonically premixed, extruded through a twin-screw extruder (the temperatures in the four temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com