A kind of degradable aliphatic polycarbonate film and preparation method thereof

A family of polycarbonate, fat degradation technology, applied in the field of degradable aliphatic polycarbonate film and its preparation, to achieve the effect of easy realization, low equipment dependence, and less material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1, the preparation of polypropylene carbonate film

[0027] Dissolve polypropylene carbonate (Wn=200,000) in chloroform to prepare a 10wt% casting solution; pour the casting solution into a flat glass mold and let it stand at 20°C for 8 hours to evaporate and remove Most of the solvent; then vacuum-dried to constant weight, the vacuum degree is 0.03MPa, the drying temperature is 50°C, and the drying time is 5 hours, and the porous degradable polypropylene carbonate film is obtained.

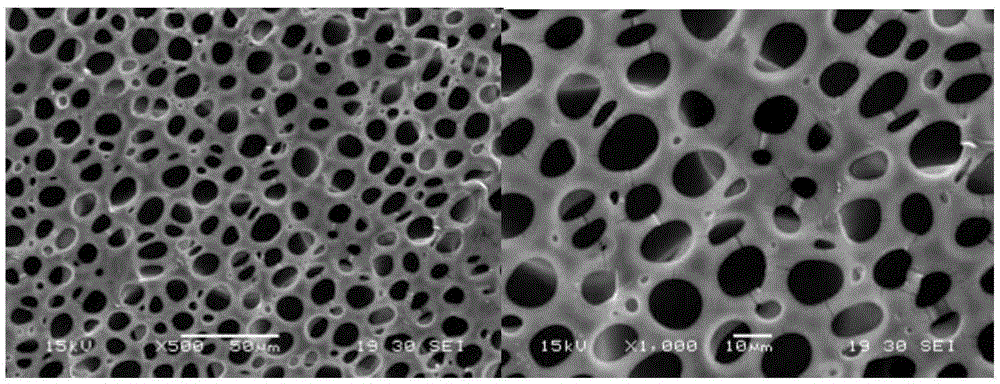

[0028] figure 1 The scanning electron microscope image of the polypropylene carbonate film prepared above shows that the pore diameter is 8-18 μm, the porosity is 50%, and the thickness is 20 μm.

Embodiment 2

[0029] Embodiment 2, the preparation of polypropylene carbonate film

[0030] Dissolve polypropylene carbonate (Wn=150,000) in tetrahydrofuran to make a 12wt% casting solution; pour the casting solution into a flat glass mold and let it stand at 25°C for 10 hours to remove most of it by volatilization The solvent and the chamber were then vacuum-dried to constant weight with a vacuum degree of 0.02 MPa, a drying temperature of 70° C., and a drying time of 6 hours to obtain a porous degradable polypropylene carbonate film.

[0031] The polypropylene carbonate film prepared in this example has a pore diameter of 3-8 μm, a porosity of 30%, and a thickness of 35 μm.

Embodiment 3

[0032] Embodiment 3, the preparation of polypropylene carbonate film

[0033] Dissolve polypropylene carbonate (Wn=250,000) in ethyl formate to prepare a 10wt% casting solution; pour the casting solution into a flat glass mold and let it stand at 25°C for 7 hours to evaporate and remove Most of the solvent; then vacuum-dried to constant weight, the vacuum degree is 0.03MPa, the drying temperature is 60°C, and the drying time is 5 hours, and the porous degradable polypropylene carbonate film is obtained.

[0034] The polypropylene carbonate film prepared in this example has a pore diameter of 3-8 μm, a porosity of 60%, and a thickness of 40 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com